Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052

Abstract

:1. Introduction

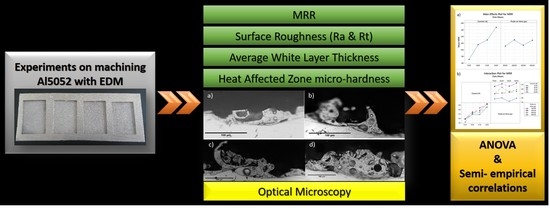

2. Experimental Procedure

3. Results and Discussion

3.1. Material Removal Rate

3.2. Surface Roughness

3.3. White Layer and Heat Affected Zone’s Micro-Hardness

4. Conclusions

- The main factor which affects the MRR is the pulse current IP.

- For optimization of the machining efficiency, the interactions between machining parameters must be considered. For the same mean machining power, different MRR were measured; however, the same MRR resulted with different mean machining powers. This is the result of interactions between pulse current and pulse-on time and the manner each parameter affects the material removal mechanism.

- The surface roughness mainly depends on the pulse-on time, with the measured values having statistically significant difference, when changing from 100 μs to 200, 300, and 500 μs.

- The morphology of the WL depends on the discharge energy, mostly by the pulse-on time. Increase of the pulse energy results to a thicker WL, more continuous, with bigger globule formations and more intense porosity. The AWLT can be expressed as a function of IP and Ton.

- The material of the HAZ has decreased micro-hardness.

Author Contributions

Funding

Conflicts of Interest

References

- Jahan, M.P. Electrical Discharge Machining (EDM) Types, Technologies and Applications; Nova Science Publishers: New York, NY, USA, 2015; p. 507. [Google Scholar]

- Abbas, N.M.; Solomon, D.G.; Bahari, M.F. A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- Khan, A.A. Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int. J. Adv. Manuf. Technol. 2008, 39, 482–487. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Iuliano, L. Performance Optimization in Machining of Aluminium Alloys for Moulds Production: HSM and EDM. In Aluminium Alloys, Theory and Applications; Kvackaj, T., Ed.; IntechOpen: Rijeka, Croatia, 2011; pp. 355–376. [Google Scholar]

- Radhika, N.; Sudhamshu, A.R.; Chandran, G.K. Optimization of Electrical Discharge Machining Parameters of Aluminium Hybrid Composites Using Taguchi Method. J. Eng. Sci. Technol. 2014, 9, 502–512. [Google Scholar]

- Imran, M.; Shah, M.; Mehmood, S.; Arshad, R. EDM of Aluminum Alloy 6061 Using Graphite Electrode Using Paraffin Oil and Distilled Water as Dielectric Medium. Adv. Sci. Technol. Res. J. 2017, 11, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Kandpal, B.C.; Kumar, J.; Singh, H. Machining of Aluminium Metal Matrix Composites with Electrical Discharge Machining - A Review. Mater. Today Proc. 2015, 2, 1665–1671. [Google Scholar] [CrossRef]

- Selvarajan, L.; Rajavel, J.; Prabakaran, V.; Sivakumar, B.; Jeeva, G. A Review Paper on EDM Parameter of Composite material and Industrial Demand Material Machining. Mater. Today Proc. 2018, 5, 5506–5513. [Google Scholar] [CrossRef]

- Dolatkhah, A.; Golbabaei, P.; Givi, M.K.B.; Molaiekiya, F. Investigating effects of process parameters on microstructural and mechanical properties of Al5052/SiC metal matrix composite fabricated via friction stir processing. Mater. Des. 2012, 37, 458–464. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Kovac, P.; Sekulic, M.; Skoric, B. Influence of discharge energy on machining characteristics in EDM. J. Mech. Sci. Technol. 2012, 26, 173–179. [Google Scholar] [CrossRef]

- Jameson, E.C. Electrical Discharge Machining; Society of Manufacturing Engineers: Dearborn, MI, USA, 2001; p. 342. [Google Scholar]

- Rebelo, J.C.; Dias, A.M.; Kremer, D.; Lebrun, J.L. Influence of EDM pulse energy on the surface integrity of martensitic steels. J. Mater. Process. Technol. 1998, 84, 90–96. [Google Scholar] [CrossRef]

| Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg | Cr | Zn (max) | Others (max) | Density (g/mm3) | Hardness (HV) |

|---|---|---|---|---|---|---|---|---|---|

| 0.25% | 0.40% | 0.10% | 0.10% | 2.2–2.8% | 0.15–0.35% | 0.1% | 0.15% | 0.00268 | 98 |

| # | IP (A) | Ton (μs) | Duty Factor | MRR (mm3/min) | Ra (μm) | Rt (μm) | AWLT (μm) |

|---|---|---|---|---|---|---|---|

| 1 | 15 | 100 | 0.6 | 173 | 10.8 | 77.2 | 18 |

| 2 | 18 | 100 | 0.61 | 207 | 10.7 | 76.6 | 17 |

| 3 | 21 | 100 | 0.52 | 207 | 11.2 | 76.2 | 20 |

| 4 | 24 | 100 | 0.54 | 257 | 11.8 | 86.4 | 21 |

| 5 | 15 | 200 | 0.67 | 180 | 15.1 | 95.6 | 23 |

| 6 | 18 | 200 | 0.66 | 213 | 14.5 | 98 | 26 |

| 7 | 21 | 200 | 0.58 | 252 | 14.4 | 96.8 | 27 |

| 8 | 24 | 200 | 0.54 | 274 | 14.5 | 101.6 | 28 |

| 9 | 15 | 300 | 0.65 | 155 | 14.1 | 93.8 | 36 |

| 10 | 18 | 300 | 0.64 | 217 | 16 | 113.2 | 37 |

| 11 | 21 | 300 | 0.57 | 224 | 15.2 | 104.2 | 35 |

| 12 | 24 | 300 | 0.58 | 259 | 14.4 | 104.4 | 37 |

| 13 | 15 | 500 | 0.73 | 177 | 14.2 | 94.4 | 39 |

| 14 | 18 | 500 | 0.72 | 224 | 17.1 | 114.8 | 42 |

| 15 | 21 | 500 | 0.62 | 234 | 16.7 | 105 | 42 |

| 16 | 24 | 500 | 0.63 | 280 | 19.4 | 140.6 | 49 |

| Ra | IP (A) | Ra | Ton (μs) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rt | Rt | ||||||||||||

| IP (A) | 15 | 18 | 21 | 24 | Ton (μs) | 100 | 200 | 300 | 500 | ||||

| 15 | 0.57 | 0.605 | 0.469 | 100 | 0.000 | 0.002 | 0.014 | ||||||

| 18 | 0.35 | 0.917 | 0.84 | 200 | 0.002 | 0.558 | 0.131 | ||||||

| 21 | 0.54 | 0.67 | 0.754 | 300 | 0.006 | 0.252 | 0.192 | ||||||

| 24 | 0.24 | 0.62 | 0.39 | 500 | 0.043 | 0.213 | 0.425 | ||||||

| No. of Experiment | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AWLT (μm) | 18 | 17 | 20 | 21 | 23 | 26 | 27 | 28 | 36 | 37 | 35 | 37 | 39 | 42 | 42 | 49 |

| Micro-hardness (HV) | 63 | 65 | 50 | 51 | 50 | 53 | 50 | 48 | 52 | 43 | 48 | 57 | 57 | 58 | 58 | 49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. https://doi.org/10.3390/machines8010012

Markopoulos AP, Papazoglou E-L, Karmiris-Obratański P. Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines. 2020; 8(1):12. https://doi.org/10.3390/machines8010012

Chicago/Turabian StyleMarkopoulos, Angelos P., Emmanouil-Lazaros Papazoglou, and Panagiotis Karmiris-Obratański. 2020. "Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052" Machines 8, no. 1: 12. https://doi.org/10.3390/machines8010012

APA StyleMarkopoulos, A. P., Papazoglou, E. -L., & Karmiris-Obratański, P. (2020). Experimental Study on the Influence of Machining Conditions on the Quality of Electrical Discharge Machined Surfaces of aluminum alloy Al5052. Machines, 8(1), 12. https://doi.org/10.3390/machines8010012