Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester

Abstract

:1. Introduction

2. Methodology

2.1. Materials

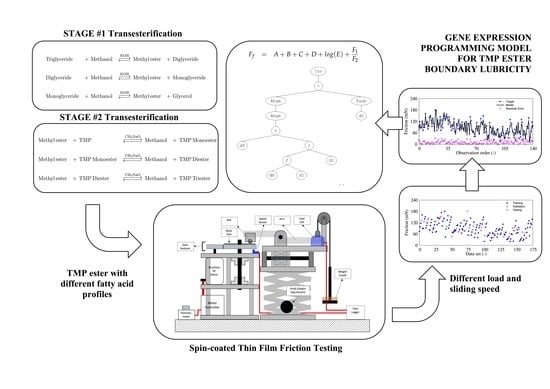

2.2. Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester

2.3. Physicochemical Properties of Trimethylolpropane (TMP) Esters

2.4. Spin Coating of Lubricant Film

2.5. Friction Measurement

- G + ;

- U = ;

- ;

- R = curvature radius of ball;

- = reduced modulus of elasticity;

- E = modulus of elasticity for wear disc and ball;

- = Poisson’s ratio for wear disc and ball;

- w = load;

- u = sliding speed;

- = dynamic viscosity.

2.6. Gene Expression Programming (GEP)

3. Results and Discussion

GEP Model for TMP Ester Boundary Lubricity

- ;

- ;

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Input Parameters for GEP Algorithm

| Parameters | Settings |

| General parameters | |

| Number of chromosomes | 75, 150, 225 |

| Head size | 6, 8, 10 |

| Number of genes | 3, 6, 9 |

| Linking function | Addition |

| Fitness function | Enhanced RSE |

| Function set | +, -, ×, ÷, exp, natural logarithm, power of 2, cube root, |

| arctangent, hyperbolic tangent | |

| Genetic operators | |

| Strategy | Optimal evolution |

| Mutation rate | 0.00138 |

| Inversion rate | 0.00546 |

| IS transportation rate | 0.00546 |

| RIS transportation rate | 0.00546 |

| One-point recombination rate | 0.00277 |

| Two-point recombination rate | 0.00277 |

| Gene recombination rate | 0.00277 |

| Gene transposition rate | 0.00277 |

| Numerical constants | |

| Constants per gene | 10 |

| Data type | Floating point |

| Upper-bound value | −10 |

| Lower-bound value | 10 |

Appendix B. Statistical Parameters

References

- Research and Markets. Biolubricants—Global Market Trajectory & Analytics. 2022. Available online: https://www.researchandmarkets.com/reports/1824122/biolubricants_global_market_trajectory_and (accessed on 2 November 2022).

- Singh, A.K.; Gupta, A.K. Metalworking fluids from vegetable oils. J. Synth. Lub. 2006, 23, 167–176. [Google Scholar] [CrossRef]

- Fox, N.J.; Tyrer, B.; Stachowiak, G.W. Boundary lubrication performance of free fatty acids in sunflower oil. Tribol. Lett. 2004, 16, 275–281. [Google Scholar] [CrossRef]

- Edla, S.; Thampi, A.D.; Prasannakumar, P.; Rani, S. Evaluation of physicochemical, tribological and oxidative stability properties of chemically modified rice bran and karanja oils as viable lubricant base stocks for industrial applications. Tribol. Int. 2022, 2022, 107631. [Google Scholar] [CrossRef]

- Owuna, F.J.; Dabai, M.U.; Sokoto, M.A.; Dangoggo, S.M.; Bagudo, B.U.; Birnin-Yauri, U.A.; Hassan, L.G.; Sada, I.; Abubakar, A.L.; Jibrin, M.S. Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: A review. Egypt. J. Petrol. 2020, 29, 75–82. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Azman, S.S.N.; Kalam, M.A.; Masjuki, H.H.; Yunus, R.; Gulzar, M. Lubricity of bio-based lubricant derived from different chemically modified fatty acid methyl ester. Tribol. Int. 2016, 93, 555–562. [Google Scholar] [CrossRef]

- Narayanasarma, S.; Kuzhiveli, B.T. Evaluation of lubricant properties of polyolester oil blended with sesame oil-An experimental investigation. J. Clean. Prod. 2021, 281, 125347. [Google Scholar] [CrossRef]

- Aziz, N.A.M.; Yunus, R.; Hamid, H.A.; Ghassan, A.A.K.; Omar, R.; Rashid, U.; Abbas, Z. An acceleration of microwave-assisted transesterification of palm oil-based methyl ester into trimethylolpropane ester. Sci. Rep. 2020, 10, 1–17. [Google Scholar]

- Attia, N.K.; El-Mekkawi, S.A.; Elardy, O.A.; Abdelkader, E.A. Chemical and rheological assessment of produced biolubricants from different vegetable oils. Fuel 2020, 271, 117578. [Google Scholar] [CrossRef]

- Carvalho, W.C.A.; Luiz, J.H.H.; Fernandez-Lafuente, R.; Hirata, D.B.; Mendes, A.A. Eco-friendly production of trimethylolpropane triesters from refined and used soybean cooking oils using an immobilized low-cost lipase (Eversa>® Transform 2.0) as heterogeneous catalyst. Biomass Bioener 2021, 155, 106302. [Google Scholar] [CrossRef]

- Gul, M.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam, M.A.; Mujtaba, M.A.; Harith, M.H.; Syahir, A.Z.; Ahmed, W.; Farooq, A.B. Effect of TMP-based-cottonseed oil-biolubricant blends on tribological behavior of cylinder liner-piston ring combinations. Fuel 2020, 278, 118242. [Google Scholar] [CrossRef]

- Guimarey, M.J.G.; Goncalves, D.E.P.; del Río, J.M.L.; Comuñas, M.J.P.; Fernández, J.; Seabra, J.H.O. Lubricant properties of trimethylolpropane trioleate biodegradable oil: High pressure density and viscosity, film thickness, Stribeck curves and influence of nanoadditives. J. Mol. Liq. 2021, 335, 116410. [Google Scholar] [CrossRef]

- Elmelawy, M.S.; El-Meligy, A.; Mawgoud, H.A.; Morshedy, A.S.; Hanafy, S.A.; El-sayed, I.E. Synthesis and kinetics study of trimethylolpropane fatty acid triester from oleic acid methyl ester as potential biolubricant. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Lee, C.T.; Lee, M.B.; Mong, G.R.; Chong, W.W.F. A bibliometric analysis on the tribological and physicochemical properties of vegetable oil–based bio-lubricants (2010–2021). Environ. Sci. Pollut. Environ. 2022, 29, 56215–56248. [Google Scholar] [CrossRef]

- Rahim, E.A.; Amiril, S.A.S.; Mohid, Z.; Syahrullail, S. Tribological evaluation on vegetable oils based trimethylolpropane (TMP) ester as sustainable metalworking fluids in machining applications. In Proceedings of the 7th International Conference Mechanical, Manufacturing Engineering, Yogyakarta, Indonesia, 1–3 August 2016; pp. 1–8. [Google Scholar]

- Verma, P.; Sharma, M.P. Review of process parameters for biodiesel production from different feedstocks. Renew. Sustain. Energy Rev. 2016, 62, 1063–1071. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Biresaw, G.; Bantchev, G.B. Pressure viscosity coefficient of vegetable oils. Tribol. Lett. 2013, 49, 501–512. [Google Scholar] [CrossRef]

- Fasina, O.O.; Hallman, H.; Craig-Schmidt, M.; Clements, C. Predicting temperature-dependence viscosity of vegetable oils from fatty acid composition. J. Am. Oil Chem. Soc. 2006, 83, 899–903. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.N.; Lee, S.H.; Yoo, S.; Lee, S. Correlation of fatty acid composition of vegetable oils with rheological behaviour and oil uptake. Food Chem. 2010, 118, 398–402. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Evaluation and enhancement of cold flow properties of palm oil and its biodiesel. Energy Rep. 2016, 2, 8–13. [Google Scholar] [CrossRef] [Green Version]

- Siniawski, M.T.; Saniei, N.; Adhikari, B.; Doezema, L.A. Influence of fatty acid composition on the tribological performance of two vegetable-based lubricants. J. Synth. Lub. 2007, 24, 101–110. [Google Scholar] [CrossRef]

- Rajasozhaperumal, G.; Kannan, C. Influence of Fatty Acid Composition on the Tribological Performance of Methyl Esters Under Boundary Lubrication Regime. Arab. J. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Hamdan, S.H.; Chong, W.W.F.; Ng, J.H.; Ghazali, M.J.G.; Wood, R.J.K. Influence of fatty acid methyl ester composition on tribological properties of vegetable oils and duck fat derived biodiesel. Tribol. Int. 2017, 113, 76–82. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M.; Profito, F.J.; Aragon, N.; Shah, R. The use of artificial intelligence in tribology—A perspective. Lubricants 2020, 9, 2. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S. Current trends and applications of machine learning in tribology? A review. Lubricants 2021, 9, 86. [Google Scholar] [CrossRef]

- Durak, E.; Salman, Ö.; Kurbanoğlu, C. Analysis of effects of oil additive into friction coefficient variations on journal bearing using artificial neural network. Ind. Lub. Tribol. 2008, 60, 309–316. [Google Scholar] [CrossRef]

- Bhaumik, S.; Mathew, B.R.; Datta, S. Computational intelligence-based design of lubricant with vegetable oil blend and various nano friction modifiers. Fuel 2019, 241, 733–743. [Google Scholar] [CrossRef]

- Sattari Baboukani, B.; Ye, Z.; G Reyes, K.; Nalam, P.C. Prediction of nanoscale friction for two-dimensional materials using a machine learning approach. Tribol. Lett. 2020, 68, 1–14. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Liu, Q.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef]

- Sebaaly, H.; Varma, S.; Maina, J.W. Optimizing asphalt mix design process using artificial neural network and genetic algorithm. Construct. Build. Mater. 2018, 168, 660–670. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, C. Gene expression programming: A new adaptive algorithm for solving problems. arXiv 2001, arXiv:cs/0102027. [Google Scholar]

- Faradonbeh, R.S.; Armaghani, D.J.; Monjezi, M.; Mohamad, E.T. Genetic programming and gene expression programming for flyrock assessment due to mine blasting. Int. J. Rock. Mech. Mining Sci. 2016, 88, 254–264. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of artificial neural network and genetic programming as predictive tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Aslam, F.; Farooq, F.; Amin, M.N.; Khan, K.; Waheed, A.; Akbar, A.; Javed, M.F.; Alyousef, R.; Alabdulijabbar, H. Applications of gene expression programming for estimating compressive strength of high-strength concrete. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Ren, L.; Wang, N.; Pang, W.; Li, Y.; Zhang, G. Modeling and monitoring the material removal rate of abrasive belt grinding based on vision measurement and the gene expression programming (GEP) algorithm. Int. J. Adv. Manufact. Tech. 2022, 120, 385–401. [Google Scholar] [CrossRef]

- Mahdinia, S.; Eskandari-Naddaf, H.; Shadnia, R. Effect of cement strength class on the prediction of compressive strength of cement mortar using GEP method. Construct. Build. Mater. 2019, 198, 27–41. [Google Scholar] [CrossRef]

- Tariq, M.; Ali, S.; Ahmad, F.; Ahmad, M.; Zafar, M.; Khalid, N.; Khan, M.A. Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process. Technol. 2011, 92, 336–341. [Google Scholar] [CrossRef]

- Yunus, R.; Lye, O.T.; Fakhru’l-Razi, A.; Basri, S. A simple capillary column GC method for analysis of palm oil-based polyol esters. J. Am. Oil Chem. Soc. 2002, 79, 1075–1080. [Google Scholar] [CrossRef]

- Meng, F.; Han, H.; Ma, Z.; Tang, B. Effects of Aviation Lubrication on Tribological Performances of Graphene/MoS2 Composite Coating. J. Tribol. 2021, 143, 031401. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part IV–starvation results. J. Lubrication Tech. 1977, 99, 15–23. [Google Scholar] [CrossRef]

- Dunlop, P.; Smith, S. Estimating key characteristics of the concrete delivery and placement process using linear regression analysis. Civ. Eng. Environ. Syst. 2003, 20, 273–290. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Aminian, P.; Gandomi, A.H.; Alavi, A.H.; Bolandi, H. A new predictive model for compressive strength of HPC using gene expression programming. Adv. Eng. Softw. 2012, 45, 105–114. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Babanajad, S.K.; Alavi, A.H.; Farnam, Y. Novel approach to strength modeling of concrete under triaxial compression. J. Mater. Civ. Eng. 2012, 24, 1132–1143. [Google Scholar] [CrossRef]

- Lee, C.T.; Lee, M.B.; Hamdan, S.H.; Chong, W.W.F.; Chong, C.T.; Zhang, H.; Chen, A.W.L. Trimethylolpropane trioleate as eco-friendly lubricant additive. Eng. Sci. Tech. Int. J. 2022, 35, 101068. [Google Scholar] [CrossRef]

- Yuan, W.; Hansen, A.C.; Zhang, Q. Vapor pressure and normal boiling point predictions for pure methyl esters and biodiesel fuels. Fuel 2005, 84, 943–950. [Google Scholar] [CrossRef]

- Folayan, A.J.; Anawe, P.A.L.; Aladejare, A.E.; Ayeni, A.O. Experimental investigation of the effect of fatty acids configuration, chain length, branching and degree of unsaturation on biodiesel fuel properties obtained from lauric oils, high-oleic and high-linoleic vegetable oil biomass. Energy Rep. 2019, 5, 793–806. [Google Scholar] [CrossRef]

- He, Y.; Fujikawa, Y.; Zhang, H.; Fukuzawa, K.; Mitsuya, Y. Evaluations of tribological characteristics of PFPE lubricants on DLC surfaces of magnetic disks. Tribol. Lett. 2007, 27, 1–11. [Google Scholar] [CrossRef]

| Parameter | Palm | Olive | Coconut | Grapeseed–Coconut | Canola | Canola–Sunflower | Canola–Palm–Soybean |

|---|---|---|---|---|---|---|---|

| C8:0 | 0.02 | 0.07 | 3.89 | 3.79 | - | 0.13 | 0.09 |

| C10:0 | 0.01 | 0.10 | 5.16 | 4.82 | 0.01 | 0.19 | 0.09 |

| C12:0 | 0.13 | 1.03 | 19.30 | 14.99 | 0.03 | 1.81 | 0.98 |

| C14:0 | 1.51 | 0.55 | 12.89 | 9.93 | 0.02 | 1.08 | 2.05 |

| C16:0 | 34.47 | 16.83 | 10.16 | 10.40 | 0.04 | 11.05 | 25.22 |

| C18:0 | 6.51 | 4.99 | 4.37 | 2.58 | 0.12 | 5.73 | 6.79 |

| C20:0 | - | 1.92 | 0.36 | 1.43 | 0.09 | 1.70 | 1.57 |

| C21:0 | - | 0.36 | - | 0.40 | 2.28 | - | 0.06 |

| C16:1 | 0.51 | 4.53 | 0.09 | 1.31 | 0.69 | 0.83 | 0.75 |

| C18:1 | 48.05 | 47.83 | 13.21 | 2.07 | 11.31 | 15.21 | 13.42 |

| C20:1 | 0.81 | 1.49 | 0.70 | 3.01 | 2.27 | 2.98 | 1.08 |

| C18:2 | 0.38 | - | - | - | 73.83 | 2.56 | 1.42 |

| C18:3 | 0.33 | 4.27 | 3.56 | 26.75 | 5.21 | 44.93 | 39.21 |

| Other | 7.27 | 16.04 | 26.30 | 18.52 | 4.10 | 11.78 | 7.27 |

| Saturation, SA (%) | 46.00 | 30.79 | 76.17 | 59.32 | 2.70 | 24.60 | 39.74 |

| Monounsaturation, MU (%) | 53.24 | 64.13 | 19.00 | 7.85 | 14.88 | 21.57 | 16.44 |

| Polyunsaturation, PU (%) | 0.76 | 5.08 | 4.83 | 32.83 | 82.42 | 53.83 | 43.82 |

| Parameters | SA (%) | MU (%) | PU (%) | Load (mN) | Speed (m/s) |

|---|---|---|---|---|---|

| SA (%) | 1 | ||||

| MU (%) | −0.103 | 1 | |||

| PU (%) | −0.715 | −0.621 | 1 | ||

| Load (mN) | −0.027 | −0.047 | 0.054 | 1 | |

| Speed (m/s) | 0.058 | 0.033 | −0.069 | −0.043 | 1 |

| Parameter | Palm | Olive | Coconut | Grapeseed–Coconut | Canola | Canola–Sunflower | Canola–Palm–Soybean |

|---|---|---|---|---|---|---|---|

| Density (g/mL) | |||||||

| @25 °C | 0.902 | 0.921 | 0.898 | 0.954 | 0.935 | 0.937 | 0.922 |

| Kin. viscosity (mm/s2 | |||||||

| @40 °C | 22.95 | 72.29 | 12.87 | 20.82 | 154.50 | 142.16 | 65.34 |

| @100 °C | 5.45 | 13.85 | 4.12 | 4.79 | 18.03 | 17.23 | 12.04 |

| ISO viscosity grade | VG 22 | VG 68 | - | VG 22 | VG 150 | VG 150 | VG 68 |

| Viscosity index (VI) | 188 | 199 | 259 | 160 | 121 | 132 | 184 |

| Flash point (°C) | 152 | 116 | 140 | 148 | 98 | 102 | 118 |

| Pour point (°C) | 11 | −8 | 7 | −6 | −9 | −4 | 6 |

| Decomposition | |||||||

| onset temperature (°C) | 362 | 384 | 345 | 326 | 401 | 392 | 367 |

| Spin-coated film | |||||||

| thickness (μm) | 4.85 | 8.6 | 3.84 | 4.21 | 11.4 | 10.27 | 7.42 |

| Viscosity–pressure | |||||||

| coefficient, @25 °C | |||||||

| (×10−8 Pa−1) | 1.63 | 1.69 | 1.29 | 1.7 | 2.24 | 2.2 | 1.77 |

| Parameters | Training | Validation | Testing |

|---|---|---|---|

| 13.567 | 11.173 | 12.049 | |

| 10.920 | 9.047 | 10.161 | |

| 0.143 | 0.201 | 0.093 | |

| 0.154 | 0.135 | 0.119 | |

| R | 0.926 | 0.908 | 0.957 |

| 0.858 | 0.824 | 0.916 | |

| 0.080 | 0.071 | 0.061 | |

| - | 0.078 | 0.076 |

| Parameters | Criteria | Training | Validation | Testing |

|---|---|---|---|---|

| k | 0.976 | 0.998 | 0.957 | |

| 1.003 | 0.986 | 1.033 | ||

| 0.973 | 0.999 | 0.894 | ||

| 0.999 | 0.988 | 0.933 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.T.; Lee, M.B.; Chong, W.W.F.; Ng, J.-H.; Wong, K.J.; Chong, C.T. Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester. Lubricants 2022, 10, 346. https://doi.org/10.3390/lubricants10120346

Lee CT, Lee MB, Chong WWF, Ng J-H, Wong KJ, Chong CT. Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester. Lubricants. 2022; 10(12):346. https://doi.org/10.3390/lubricants10120346

Chicago/Turabian StyleLee, Chiew Tin, Mei Bao Lee, William Woei Fong Chong, Jo-Han Ng, King Jye Wong, and Cheng Tung Chong. 2022. "Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester" Lubricants 10, no. 12: 346. https://doi.org/10.3390/lubricants10120346

APA StyleLee, C. T., Lee, M. B., Chong, W. W. F., Ng, J. -H., Wong, K. J., & Chong, C. T. (2022). Boundary Lubricity of Vegetable-Oil-Derived Trimethylolpropane (TMP) Ester. Lubricants, 10(12), 346. https://doi.org/10.3390/lubricants10120346