Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment

Abstract

:1. Introduction

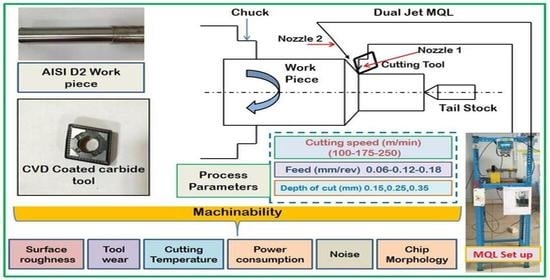

2. Materials and Methods

3. Results and Discussions

3.1. Assessment of Finished Surface Quality

3.2. Assessment of Tool Flank Wear

3.3. Assessment of Cutting Temperature

3.4. Assessment of Power Consumption

3.5. Assessment of Noise Emission

3.6. Assessment of Chip Morphology

4. Conclusions

- The dual nozzle MQL discharged an adequate amount of cutting fluid in the cutting region, thus significantly reducing the friction between the pairs of tool–workpiece and tool–chip interfaces, resulting in reduced cutting temperature, tool wear, and surface roughness.

- The obtained surface roughness in the entire 27 runs ranged from 0.448 to 1.265 µm and was heavily influenced by tool feed (66.70%), followed by the depth of cut (14.30%) and cutting speed (14.18%).

- The lowest and highest flank wear values were 0.041 mm and 0.112 mm, respectively, which were extremely beneficial for hard turning concerns. Abrasion, adhesion, and chipping were the main wear mechanisms found. The tool edge was broken when machining was executed at the highest depth of cut (0.35 mm) with the largest cutting speed (250 m/min) and feed (0.35 mm/rev), due to a severe load on the tool edge. The greatest influence on tool flank wear was exerted by cutting speed (74.58%), followed by the depth of cut (12.40%) and feed (6.95%).

- In the MQL cooling process, mist coolant impinged with higher frequency, resulting in an improvement in Nusselt number, and, thus, a significant reduction in cutting temperature (40.6 to 117 °C). The cutting temperature was largely impacted by cutting speed (75.84%), followed by the depth of cut (17.18%), tool feed (3.12%), and the interaction of depth of cut––feed (2.44%).

- The power consumption was found to be lower in a range of 0.424 to 1.214 kW, due to the easy shearing of metal by delivering the mist lubricant into the shearing zone through a double nozzle. The depth of cut had the largest influence (46.69%) on power consumption, followed by cutting speed (40.76%) and feed (9.70%).

- The noise emission in machining was found to be in the range of 68.54–82.7 dB, which was lower than the human hearing limit (85 dB). All of the input terms in the L27 design were acceptable for providing controlled noise emission during the hard turning process. The depth of cut had the greatest influence on noise emission (57.57%), followed by cutting speed (34.52%), feed (3.66%), and interaction depth of cut–feed (2.12%).

- The chip’s shapes were discovered to be either helical (long and short), curly ribbon, flat ribbon, or broken spiral (c type), and their colors to be metallic, light blue, deep blue, or lightly golden.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Musavi, S.H.; Davoodi, B.; Niknam, S.A. Environmental-friendly turning of A286 superalloy. J. Manuf. Process. 2018, 32, 734–743. [Google Scholar] [CrossRef]

- Felho, C.; Varga, G. Theoretical Roughness Modeling of Hard Turned Surfaces Considering Tool Wear. Machines 2022, 10, 188. [Google Scholar] [CrossRef]

- Das, A.; Kamal, M.; Das, S.R.; Patel, S.K.; Panda, A.; Rafighi, M.; Biswal, B.B. Comparative Assessment Between Al-TiN and AlTiSiN Coated Carbide Tools Towards Machinability Improvement of AISI D6 Steel in Dry Hard Turning. Proc. Inst. Mech. Eng. Part C 2022, 236, 3174–3197. [Google Scholar] [CrossRef]

- Parsi, P.K.; Kotha, R.S.; Routhu, T.; Pandey, S.; Dwivedy, M. Machinability Evaluation of Coated Carbide In-serts in Turning of Super-Duplex Stainless Steel. S. N. Appl. Sci. 2020, 2, 1933. [Google Scholar] [CrossRef]

- Ambhore, N.; Kamble, D.; Chinchanikar, S. Machining Performances of TiN+AlCrN Coated WC and Al2O3+TiC Inserts for Turning of AISI 4140 steel Under Dry Condition. J. Manuf. Process. 2020, 50, 412–420. [Google Scholar]

- Asiltürk, I.; Akkuş, H. Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 2011, 44, 1697–1704. [Google Scholar] [CrossRef]

- Zheng, G.; Li, L.; Li, Z.; Gao, J.; Niu, Z. Wear mechanisms of coated tools in high-speed hard turning of high strength steel. Int. J. Adv. Manuf. Technol. 2017, 94, 4553–4563. [Google Scholar] [CrossRef]

- Sharma, N.; Gupta, K. Influence of coated and uncoated carbide tools on tool wear and surface quality during dry machining of stainless steel 304. Mater. Res. Express 2019, 6, 086585. [Google Scholar] [CrossRef]

- Ullas, H.B. Experimental Determination of Cutting Forces and Surface Roughness when Turning 50CrV4 Steel (SAE 6150) and Modelling with the Artificial Neural Network Approach. Transact. Ind. Inst. Met. 2014, 67, 869–879. [Google Scholar] [CrossRef]

- Kaladhar, M. Parametric optimization and modeling for flank wear of TiSiN-TiAlNnanolaminate cutting insert. J. Mech. Eng. 2020, 17, 69–84. [Google Scholar] [CrossRef]

- Nitin, A.; Dinesh, K.; Satish, C. Evaluation of cutting tool vibration and surface roughness in hard turning of AISI 52100 steel: An experimental and ANN approach. J. Vibration Eng. Technol. 2020, 8, 455–462. [Google Scholar]

- Dash, L.; Padhan, S.; Das, A.; Das, S.R. Machinability investigation and sustainability assessment in hard turning of AISI D3 steel with coated carbide tool under nanofluid minimum quantity lubrication-cooling condition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6496–6528. [Google Scholar] [CrossRef]

- Abidin, S.; Mohammad, R. Optimization of cutting parameters with respect to roughness for machining of hardened AISI 1040 steel. Mater. Test. 2020, 62, 85–95. [Google Scholar]

- Suresh, R.; Basavarajappa, S.; Samuel, G. Some studies on hard turning of AISI 4340 steel using multilayer coated carbide tool. Measurement 2012, 45, 1872–1884. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Suresh, R.; Gaitonde, V.; Samuel, G. Analysis of cutting forces and surface roughness in hard turning of AISI 4340 using multilayer coated carbide tool. Int. J. Mach. Mach. Mater. 2014, 16, 169. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V.; Samuel, G. Machinability investigations on hardened AISI 4340 steel using coated carbide insert. Int. J. Refract. Met. Hard Mater. 2012, 33, 75–86. [Google Scholar] [CrossRef]

- Ginting, A.; Skein, R.; Cuaca, D.; Masyithah, Z. The characteristics of CVD- and PVD-coated carbide tools in hard turning of AISI 4340. Measurement 2018, 129, 548–557. [Google Scholar] [CrossRef]

- Szczotkarz, N.; Maruda, R.W.; Dębowski, D.; Leksycki, K.; Wojciechowski, S.; Khanna, N.; Królczyk, G.M. Formation of Surface Topography During Turning of AISI 1045 Steel Considering the Type of Cutting Edge Coat-ing. Adv. Sci. Technol. Res. J. 2021, 15, 253–266. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. Evaluation of micro-features of chips of Inconel 825 during dry turning with un-coated and chemical vapour deposition multilayer coated tools. Proceed. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 979–994. [Google Scholar] [CrossRef]

- Sahoo, A.K.; Sahoo, B. Performance studies of multilayer hard surface coatings (TiN/TiCN/Al2O3/TiN) of indexable carbide inserts in hard machining: Part-II (RSM, grey relational and techno economical approach). Measurement 2013, 46, 2868–2884. [Google Scholar] [CrossRef]

- Tuan, N.M.; Duc, T.M.; Long, T.T.; Hoang, V.L.; Ngoc, T.B. Investigation of Machining Performance of MQL and MQCL Hard Turning Using Nano Cutting Fluids. Fluids 2022, 7, 143. [Google Scholar] [CrossRef]

- Craig, M.; Raval, J.; Tai, B.; Patterson, A.; Hung, W. Effect of Channel Roughness on Micro-Droplet Distribution in Internal Minimum Quantity Lubrication. Dynamics 2022, 2, 19. [Google Scholar] [CrossRef]

- Paul, I.D.; Bhole, G.P.; Chaudhari, J.R. A Review on Green Manufacturing: It’s Important, Methodology and Its Application. Procedia Mater. Sci. 2014, 6, 1644–1649. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.; Yi, Q. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Leppert, T. Surface layer properties of AISI 316L steel when turning under dry and with minimum quantity lubri-cation conditions. Proc. Inst. Mech. Eng. B. J. Eng. Manuf. 2012, 226, 617–631. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.F.; Wang, Y.W. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean. Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Bhowmick, S.; Alpas, A.T. The role of diamond-like carbon coated drills on minimum quantity lubrication drilling of magnesium alloys. Surf. Coat. Technol. 2011, 205, 5302–5311. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Pombo, I.; Alberdi, R.; Izquierdo, B.; Ortega, N.; Plaza, S.; Martinez-Toledano, J. Machining evalua-tion of a hybrid MQL-CO2 grinding technology. J. Clean. Prod. 2010, 18, 1840–1849. [Google Scholar] [CrossRef]

- Boswell, B.; Islam, M.; Davies, I.; Ginting, Y.R.; Ong, A.K. A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int. J. Adv. Manuf. Technol. 2017, 92, 321–340. [Google Scholar] [CrossRef] [Green Version]

- Arsene, B.; Gheorghe, C.; Sarbu, F.A.; Barbu, M.; Cioca, L.-I.; Calefariu, G. MQL-Assisted Hard Turning of AISI D2 Steel with Corn Oil: Analysis of Surface Roughness, Tool Wear, and Manufacturing Costs. Metals 2021, 11, 2058. [Google Scholar] [CrossRef]

- Chavan, A.A.; Sargade, V.G. Statistical and Multi-attribute Analysis in Hardened Steel Turning Under Vegetable Oil-Based MQL. In Techno-Societal 2020; Springer: New York, NY, USA, 2021; pp. 777–789. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.; Biswal, B.; Sahoo, N.; Pradhan, A. Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Mawandiya, B.K.; Patel, H.V.; Makhesana, M.A.; Patel, K.M. Machinability investigation of AISI 4340 steel with biodegradable oil-based MQL system. Mater. Today Proc. 2021, 59, 1–6. [Google Scholar] [CrossRef]

- Sani, A.S.A.; Abd Rahim, E.; Sharif, S.; Sasahara, H. Machining performance of vegetable oil with phosphoni-um-and ammonium-based ionic liquids via MQL technique. J. Clean. Prod. 2019, 209, 947–964. [Google Scholar] [CrossRef]

- Gupta, M.K.; Boy, M.; Korkmaz, M.E.; Yaşar, N.; Günay, M.; Krolczyk, G.M. Measurement and analysis of ma-chining induced tribological characteristics in dual jet minimum quantity lubrication assisted turning of duplex stainless steel. Measurement 2022, 187, 110353. [Google Scholar] [CrossRef]

- Singh, G.; Pruncu, C.I.; Gupta, M.K.; Mia, M.; Khan, A.M.; Jamil, M.; Pimenov, D.Y.; Sen, B.; Sharma, V.S. Investi-gations of machining characteristics in the upgraded MQL-assisted turning of pure titanium alloys using evolu-tionary algorithms. Materials 2019, 12, 999. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mia, M.; Dhar, N.R. Effects of duplex jets high-pressure coolant on machining temperature and machinability of Ti-6Al-4V superalloy. J. Mater. Process. Technol. 2018, 252, 688–696. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Influence of single and dual cryogenic jets on machinability characteristics in turning of Ti-6Al-4V. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 711–726. [Google Scholar] [CrossRef]

- Sohrabpoor, H.; Khanghah, S.P.; Teimouri, R. Investigation of lubricant condition and machining parameters while turning of AISI 4340. Int. J. Adv. Manuf. Technol. 2015, 76, 2099–2116. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, H.E.; Noebe, R.D.; Jawahir, I.S. Tool-wear analysis in cryogenic machining of NiTi shape memory alloys: A comparison of tool-wear performance with dry and MQL machining. Wear 2013, 306, 51–63. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of cryo-MQL environment for machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Zhu, Z.; He, B.; Chen, J. RETRACTED: Evaluation of tool temperature distribution in MQL drilling of aluminum 2024-T351. J. Manuf. Process. 2020, 56, 757–765. [Google Scholar] [CrossRef]

- Bonfá, M.M.; Costa, S.; Sales, W.F.; Amorim, F.L.; Maia, L.H.A.; Machado, A.R. Evaluation of tool life and workpiece surface roughness in turning of AISI D6 hardened steel using PCBN tools and minimum quantity of lubricant (MQL) applied at different directions. Int. J. Adv. Manuf. Technol. 2019, 103, 971–984. [Google Scholar] [CrossRef]

- Touggui, Y.; Uysal, A.; Emiroglu, U.; Belhadi, S.; Temmar, M. Evaluation of MQL performances using various nanofluids in turning of AISI 304 stainless steel. Int. J. Adv. Manuf. Technol. 2021, 115, 3983–3997. [Google Scholar] [CrossRef]

- Özbek, O.; Saruhan, H. The effect of vibration and cutting zone temperature on surface roughness and tool wear in eco-friendly MQL turning of AISI D2. J. Mater. Res. Technol. 2020, 9, 2762–2772. [Google Scholar] [CrossRef]

- Özbek, N.A.; Özbek, O.; Kara, F.; Saruhan, H. Effect of Eco-Friendly Minimum Quantity Lubrication in Hard Machining of Vanadis 10: A High Strength Steel. Steel Res. Int. 2022, 93, 2100587. [Google Scholar] [CrossRef]

- Gürbüz, H.; Gönülaçar, Y.E. Experimental and statistical investigation of the effects of MQL, dry and wet ma-chining on machinability and sustainability in turning of AISI 4140 steel. Proc. Inst. Mech. Eng. Part E J. Proc. Mech. Eng. 2022, 236, 09544089221076243. [Google Scholar]

- Shihab, S.K.; Khan, Z.A.; Mohammad, A.; Siddiquee, A.N. A review of turning of hard steels used in bearing and automotive applications. Prod. Manuf. Res. 2014, 2, 24–49. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Liu, J.; Cai, G.; Jiang, D.; Zhou, J. A Fuzzy Evaluation of Tool Materials in the Turning of Marine Steels. Metals 2021, 11, 1710. [Google Scholar] [CrossRef]

- Kumar, P.; Chauhan, S.R.; Pruncu, C.I.; Gupta, M.K.; Pimenov, D.Y.; Mia, M.; Gill, H.S. Influence of Different Grades of CBN Inserts on Cutting Force and Surface Roughness of AISI H13 Die Tool Steel during Hard Turning Operation. Materials 2019, 12, 177. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Yuan, S.; Liu, Q. Influence of minimum quantity lubrication parameters on tool wear and surface roughness in milling of forged steel. Chin. J. Mech. Eng. 2012, 25, 419–429. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, G.; Aggarwal, V. Analysis and optimization of nozzle distance during turning of EN 31 steel using minimum quantity lubrication. Mater. Today Proc. 2022, 49, 1360–1366. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Sap, E.; Gupta, M.K. Investigations on tool wear, surface roughness, cutting temperature, and chip formation in machining of Cu-B-CrC composites. Int. J. Adv. Manuf. Technol. 2021, 116, 3011–3025. [Google Scholar] [CrossRef]

- DAS, S.R.; Panda, A.; Dhupal, D. Experimental investigation of surface roughness, flank wear, chip morphology and cost estimation during machining of hardened AISI 4340 steel with coated carbide insert. Mech. Adv. Mater. Mod. Process. 2017, 3, 9. [Google Scholar] [CrossRef]

- Rajan, K.M.; Sahoo, A.K.; Routara, B.C.; Kumar, R. Investigation on surface roughness, tool wear and cutting power in MQL turning of bio-medical Ti-6Al-4V ELI alloy with sustainability. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 236, 1452–1466. [Google Scholar] [CrossRef]

- Kulshreshtha, M. Analysis of the Effect of Machining Parameters on Surface Roughness of EN 36 Nickel Steel. Int. J. Adv. Inf. Sci. Technol. 2013, 16, 1–7. [Google Scholar]

- Smith, G.T. Industrial Metrology; Springer: New York, NY, USA, 2002. [Google Scholar]

- Zhu, S.; Huang, P. Influence mechanism of morphological parameters on tribological behaviors based on bearing ratio curve. Tribol. Int. 2017, 109, 10–18. [Google Scholar] [CrossRef]

- Cîrstoiu, A.C. Surface roughness evaluation in turning based on abbott firestone curve. Roma Rev. Precis. Mech. Opt. Mech. 2010, 20, 163–169. [Google Scholar]

- Luo, X.; Cheng, K.; Holt, R.; Liu, X. Modeling flank wear of carbide tool insert in metal cutting. Wear 2005, 259, 1235–1240. [Google Scholar] [CrossRef] [Green Version]

- Pandey, K.; Datta, S. Performance of Si-doped TiAlxN supernitride coated carbide tool during dry machining of Inconel 718 superalloy. J. Manuf. Process. 2022, 84, 1258–1273. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Machining of hardened steel—Experimental investigations, performance modeling and cooling techniques: A review. Int. J. Mach. Tool. Manuf. 2015, 89, 95–109. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. J. Manuf. Process. 2019, 44, 179–196. [Google Scholar] [CrossRef]

- Mia, M.; Razi, M.H.; Ahmad, I.; Mostafa, R.; Rahman, S.M.; Ahmed, D.H.; Dhar, N.R. Effect of time-controlled MQL pulsing on surface roughness in hard turning by statistical analysis and artifificial neural network. Int. J. Adv. Manuf. Technol. 2017, 91, 3211–3223. [Google Scholar] [CrossRef]

- Yang, K.Z.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Shankar, S.; Vatin, N.I. Application of coolants during tool-based machining–A review. Ain Shams Eng. J. 2022, 1018, 30. [Google Scholar]

- Bilga, P.S.; Singh, S.; Kumar, R. Optimization of energy consumption response parameters for turning operation using Taguchi method. J. Clean. Prod. 2016, 137, 1406–1417. [Google Scholar] [CrossRef]

- Nur, R.; Noordin, M.Y.; Izman, S.; Kurniawan, D. The Effect of Cutting Parameters on Power Consumption during Turning Nickel Based Alloy. Adv. Mater. Res. 2013, 845, 799–802. [Google Scholar] [CrossRef]

- Abbas, A.T.; Gupta, M.K.; Soliman, M.S.; Mia, M.; Hegab, H.; Luqman, M.; Pimenov, D.Y. Sustainability assessment associated with surface roughness and power consumption characteristics in nanofluid MQL-assisted turning of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1311–1327. [Google Scholar] [CrossRef]

- Valeraa, H.Y.; Bhavsara, S.N. Experimental Investigation of Surface Roughness and Power Consumption in Turning Operation of EN 31 Alloy Steel. Proced. Technol. 2014, 14, 528–534. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Kant, G. Optimization of Machining Parameters for Improving Energy Efficiency using Integrated Response Surface Methodology and Genetic Algorithm Approach. Procedia CIRP 2017, 61, 517–522. [Google Scholar] [CrossRef]

- Şahinoğlu, A.; Rafighi, M. Investigation of Tool Wear, Surface Roughness, Sound Intensity and Power Consumption During Hard Turning of AISI 4140 using Multilayer-Coated Carbide Inserts. J. Eng. Res. 2021, 9, 377–395. [Google Scholar] [CrossRef]

- Rafighi, M. Effects of shallow cryogenic treatment on surface characteristics and machinability factors in hard turning of AISI 4140 steel. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 236, 2118–2130. [Google Scholar] [CrossRef]

- Karaaslan, F.; Şahinoğlu, A. Determination of Ideal Cutting Conditions for Maximum Surface Quality and Mini-mum Power Consumption During Hard Turning of AISI 4140 Steel Using TOPSIS Method Based on Fuzzy Distance. Arab. J. Sci. Eng. 2020, 45, 9145–9157. [Google Scholar] [CrossRef]

- Şahinoğlu, A.; Ulas, E. An investigation of cutting parameters effect on sound level, surface roughness, and power consumption during machining of hardened AISI 4140. Mech. Ind. 2020, 21, 523. [Google Scholar] [CrossRef]

- Su, Y.; Li, Z.; Li, L.; Wang, J.; Gao, H.; Wang, G. Cutting performance of micro-textured polycrystalline diamond tool in dry cutting. J. Manuf. Process. 2017, 27, 1–7. [Google Scholar] [CrossRef]

- Dogra, M.; Sharma, V.S.; Sachdeva, A.; Suri, N.M.; Dureja, J.S. Tool wear, chip formation and work piece surface issues in CBN hard turning: A review. Int. J. Precis. Eng. Manuf. 2010, 11, 341–358. [Google Scholar]

- Ducobu, F.; Rivière-Lorphèvre, E.; Filippi, E. Materiał constitutive model and chip separation criterion influence on the modeling of Ti6A14V machining with experimental validation, in strictly orthogonal cutting condition. Int. J. Mech. Sci. 2016, 107, 136–149. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Niesłony, P.; Krolczyk, J.B.; Legutko, S. Chip Formation Zone Analysis During the Turning of Austenitic Stainless Steel 316L under MQCL Cooling Condition. Proc. Eng. 2016, 149, 297–304. [Google Scholar] [CrossRef] [Green Version]

- Leadebal, W.V., Jr.; Melo, A.C.A.D.; De Oliveira, A.J.; Castro, N.A. Tool wear and chip analysis after the hard turning of AISI D6 steel assisted by LN2. Mach. Sci. Technol. 2019, 23, 886–905. [Google Scholar] [CrossRef]

| Items | Details |

|---|---|

| Machine tool | CNC lathe(DX 2004A) |

| Work sample | AISI D2 steel |

| Work specimen hardness | 57 ± 1 HRC |

| Work dimension | 45 mm diameter, length 200 mm |

| Machining length | 160 mm |

| Cutting tool | CVD coated carbide(TiCN-Al2O3), KENNAMETAL ISO geometry- CNMG120408FN, Grade- KCK05 |

| Tool holder | PCLNR2525M12 |

| Design of Experiment (DOE) | Taguchi L27 orthogonal array |

| Cutting speed (V), m/min | 100, 175, 250 |

| Depth of cut(a), mm | 0.15, 0.25, 0.35 |

| Feed(f), mm/rev | 0.06, 0.12, 0.18 |

| Cutting environment | Dual Nozzle MQL Air Pressure—6 bar (Fixed) Flow rate of each nozzle—50 mL/h (Fixed) |

| MQL lubricant | Spring Oil (LRM 30) |

| Run | Turning Parameters (Inputs) | Performance Indexes (Outputs) | ||||||

|---|---|---|---|---|---|---|---|---|

| a (mm) | f (mm/rev) | V (m/min) | Ra (µm) | VBc (mm) | T (°C) | Pc (kW) | Ne (dB) | |

| 1 | 0.15 | 0.06 | 100 | 0.533 | 0.041 | 62.4 | 0.424 | 68.54 |

| 2 | 0.15 | 0.06 | 175 | 0.503 | 0.049 | 79.5 | 0.643 | 71.28 |

| 3 | 0.15 | 0.06 | 250 | 0.448 | 0.068 | 100.6 | 0.956 | 74.33 |

| 4 | 0.15 | 0.12 | 100 | 0.584 | 0.045 | 52.4 | 0.683 | 70.12 |

| 5 | 0.15 | 0.12 | 175 | 0.586 | 0.053 | 71.0 | 0.868 | 72.56 |

| 6 | 0.15 | 0.12 | 250 | 0.501 | 0.075 | 97.0 | 0.985 | 75.82 |

| 7 | 0.15 | 0.18 | 100 | 1.024 | 0.047 | 56.8 | 0.628 | 69.24 |

| 8 | 0.15 | 0.18 | 175 | 0.974 | 0.055 | 70.4 | 0.745 | 71.30 |

| 9 | 0.15 | 0.18 | 250 | 0.855 | 0.078 | 95.5 | 0.899 | 75.42 |

| 10 | 0.25 | 0.06 | 100 | 0.614 | 0.043 | 48.8 | 0.464 | 72.32 |

| 11 | 0.25 | 0.06 | 175 | 0.566 | 0.054 | 67.4 | 0.667 | 76.61 |

| 12 | 0.25 | 0.06 | 250 | 0.513 | 0.073 | 93.6 | 0.712 | 79.3 |

| 13 | 0.25 | 0.12 | 100 | 0.783 | 0.047 | 40.6 | 0.524 | 73.84 |

| 14 | 0.25 | 0.12 | 175 | 0.684 | 0.059 | 58.4 | 0.712 | 76.52 |

| 15 | 0.25 | 0.12 | 250 | 0.561 | 0.078 | 83.7 | 0.832 | 79.97 |

| 16 | 0.25 | 0.18 | 100 | 1.048 | 0.051 | 50 | 0.567 | 75.4 |

| 17 | 0.25 | 0.18 | 175 | 0.926 | 0.062 | 61.1 | 0.768 | 77.37 |

| 18 | 0.25 | 0.18 | 250 | 0.805 | 0.081 | 79.1 | 0.896 | 79.51 |

| 19 | 0.35 | 0.06 | 100 | 0.845 | 0.046 | 65.8 | 0.755 | 74.6 |

| 20 | 0.35 | 0.06 | 175 | 0.743 | 0.061 | 79.5 | 0.936 | 77.6 |

| 21 | 0.35 | 0.06 | 250 | 0.612 | 0.083 | 107.1 | 1.069 | 80.2 |

| 22 | 0.35 | 0.12 | 100 | 0.874 | 0.051 | 58.5 | 0.932 | 75.5 |

| 23 | 0.35 | 0.12 | 175 | 0.742 | 0.066 | 73.4 | 1.037 | 79.64 |

| 24 | 0.35 | 0.12 | 250 | 0.634 | 0.089 | 98.2 | 1.214 | 81.2 |

| 25 | 0.35 | 0.18 | 100 | 1.265 | 0.057 | 73.4 | 0.901 | 79.52 |

| 26 | 0.35 | 0.18 | 175 | 1.076 | 0.071 | 83.5 | 1.052 | 80.14 |

| 27 | 0.35 | 0.18 | 250 | 0.910 | 0.112 | 117 | 1.196 | 82.7 |

| Terms | DF | Adj-SS | AdJ-MS | F | P | % Contribution | Significant |

|---|---|---|---|---|---|---|---|

| a | 2 | 0.16854 | 0.084272 | 205.54 | 0.000 | 14.30 | Yes |

| f | 2 | 0.78621 | 0.393103 | 958.77 | 0.000 | 66.71 | Yes |

| V | 2 | 0.16714 | 0.083570 | 203.82 | 0.000 | 14.18 | Yes |

| a × f | 4 | 0.02168 | 0.005420 | 13.22 | 0.001 | 1.84 | Yes |

| a × V | 4 | 0.02133 | 0.005332 | 13.00 | 0.001 | 1.81 | Yes |

| f × V | 4 | 0.01040 | 0.002600 | 6.34 | 0.013 | 0.88 | Yes |

| Inaccuracy | 8 | 0.00328 | 0.000410 | ||||

| Aggregate | 26 | 1.17858 | |||||

| Summary: R2 = 99.72%; R2 (adjacent) = 99.10%; R2 (prediction) = 96.83%. | |||||||

| Terms | DF | Adj-SS | AdJ-MS | F | P | % Contribution | Significant |

|---|---|---|---|---|---|---|---|

| a | 2 | 0.000916 | 0.000458 | 41.86 | 0.000 | 12.40 | Yes |

| f | 2 | 0.000513 | 0.000256 | 23.42 | 0.000 | 6.95 | Yes |

| V | 2 | 0.005509 | 0.002754 | 251.66 | 0.000 | 74.58 | Yes |

| a × f | 4 | 0.000103 | 0.000026 | 2.36 | 0.141 | 1.39 | No |

| a × V | 4 | 0.000195 | 0.000049 | 4.46 | 0.035 | 2.64 | Yes |

| f × V | 4 | 0.000063 | 0.000016 | 1.45 | 0.304 | 0.85 | No |

| Inaccuracy | 8 | 0.000088 | 0.000011 | ||||

| Aggregate | 26 | 0.007387 | |||||

| Summary: R2 = 98.81%; R2 (adjacent) = 96.15%; R2 (prediction) = 86.50%. | |||||||

| Terms | DF | Adj-SS | AdJ-MS | F | P | % Contribution | Significant |

|---|---|---|---|---|---|---|---|

| a | 2 | 1695.29 | 847.64 | 87.80 | 0.000 | 17.18 | Yes |

| f | 2 | 307.62 | 153.81 | 15.93 | 0.002 | 3.12 | Yes |

| V | 2 | 7481.62 | 3740.81 | 387.46 | 0.000 | 75.84 | Yes |

| a × f | 4 | 241.11 | 60.28 | 6.24 | 0.014 | 2.44 | Yes |

| a × V | 4 | 27.58 | 6.89 | 0.71 | 0.605 | 0.28 | No |

| f × V | 4 | 34.28 | 8.57 | 0.89 | 0.513 | 0.35 | No |

| Inaccuracy | 8 | 77.24 | 9.65 | ||||

| Aggregate | 26 | 9864.73 | |||||

| Summary: R2 = 99.22%; R2 (adjacent) = 97.46%; R2 (prediction) = 91.08%. | |||||||

| Terms | DF | Adj-SS | AdJ-MS | F | P | % Contribution | Significant |

|---|---|---|---|---|---|---|---|

| a | 2 | 0.52923 | 0.264617 | 95.82 | 0.000 | 47.53 | Yes |

| f | 2 | 0.08959 | 0.044793 | 16.22 | 0.002 | 8.04 | Yes |

| V | 2 | 0.46201 | 0.231004 | 83.64 | 0.000 | 41.5 | Yes |

| a × f | 4 | 0.01642 | 0.004104 | 1.49 | 0.293 | 1.47 | No |

| a × V | 4 | 0.00955 | 0.002388 | 0.86 | 0.525 | 0.86 | No |

| f × V | 4 | 0.00461 | 0.001152 | 0.42 | 0.792 | 0.41 | No |

| Inaccuracy | 8 | 0.00209 | 0.002762 | ||||

| Aggregate | 26 | 1.11350 | |||||

| Summary: R2 = 98.05%; R2 (adjacent) = 93.67%; R2 (prediction) = 77.80% | |||||||

| Terms | DF | Adj-SS | AdJ-MS | F | P | % Contribution | Significant |

|---|---|---|---|---|---|---|---|

| a | 2 | 225.883 | 112.941 | 271.58 | 0.000 | 57.57 | Yes |

| f | 2 | 14.360 | 7.180 | 17.26 | 0.001 | 3.66 | Yes |

| V | 2 | 135.452 | 67.726 | 162.85 | 0.000 | 34.52 | Yes |

| a × f | 4 | 8.333 | 2.083 | 5.01 | 0.026 | 2.12 | Yes |

| a × V | 4 | 1.602 | 0.401 | 0.96 | 0.477 | 0.41 | No |

| f × V | 4 | 3.425 | 0.857 | 2.06 | 0.178 | 0.87 | No |

| Inaccuracy | 8 | 3.327 | 0.416 | ||||

| Aggregate | 26 | 392.383 | |||||

| Summary: R2 = 99.15%; R2 (prediction) = 97.24%; R2 (adjacent) = 90.34%. | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment. Lubricants 2023, 11, 16. https://doi.org/10.3390/lubricants11010016

Mallick R, Kumar R, Panda A, Sahoo AK. Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment. Lubricants. 2023; 11(1):16. https://doi.org/10.3390/lubricants11010016

Chicago/Turabian StyleMallick, Rajashree, Ramanuj Kumar, Amlana Panda, and Ashok Kumar Sahoo. 2023. "Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment" Lubricants 11, no. 1: 16. https://doi.org/10.3390/lubricants11010016

APA StyleMallick, R., Kumar, R., Panda, A., & Sahoo, A. K. (2023). Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment. Lubricants, 11(1), 16. https://doi.org/10.3390/lubricants11010016