Effects of Erucamide and N-phenyl-α-naphthylamine on the Friction and Torque Behaviors of Grease on Roller Bearings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of Base Oil

2.2. Preparation of Grease

2.2.1. Preparation of Polyurea Grease

- MDI and cyclohexylamine were individually dissolved in the base oil and continuously stirred to obtain two mixed solutions.

- The temperature of the reactor was set to 100 °C, and the two mixed solutions were introduced into the reactor for 30 min. During this process, a suitable amount of distilled water was added to remove excess MDI.

- The reactor temperature was set to 150 °C and maintained for 30 min.

- The temperature of the reactor was reduced to room temperature.

- The mixture was poured into a three-roller grinder for grinding to obtain PG.

2.2.2. Preparation of Lithium Complex Grease

- Half of the base oil was introduced into the reactor and heated to 80 °C.

- 12-Hydroxystearic acid and sebacic acid were added to the reactor and continuously stirred until fully dissolved.

- A solution of lithium hydroxide was poured into the reactor, with continuous stirring. The temperature of the reactor was set to 130 °C and maintained for 60 min.

- The temperature of the reactor was raised to 210 °C and held for 10 min.

- The remaining half of the base oil was added to the reactor, and the reactor’s temperature was lowered to room temperature.

- The mixture was poured into a three-roller grinder for grinding to obtain LCG.

2.2.3. Preparation of Grease with Erucamide and N-phenyl-α-naphthylamine

2.2.4. Structure Characterization of Thickener

- A small quantity of grease was poured into petroleum ether, thoroughly dissolved, and then the mixture was poured into a centrifuge tube.

- The centrifuge tube was placed in a centrifuge machine (JOANLAB MC-7K), centrifuged at a rotational speed of 7000 rpm for 30 min at room temperature, followed by 30 min of static settling.

- Step 2 was repeated three times.

- The upper clear liquid in the centrifuge tube was poured out, leaving behind the precipitate.

- Petroleum ether was added again to the centrifuge tube and allowed to settle for 30 min, ensuring thorough dissolution of the precipitate in petroleum ether.

- Steps 2–5 were repeated twice, and then Steps 2–4 were repeated once.

- The final precipitate was placed on a silicon wafer for drying.

- In a vacuum environment, an ion sputtering instrument (HITACHI E-1045) was used for gold sputtering treatment of the silicon wafer, with a sputtering time of 100 s and three sputtering cycles.

2.3. Tribological Test

2.4. Friction Torque Test

2.5. Surface Analysis and Characterization

3. Results and Discussion

3.1. Physicochemical Properties of Greases

3.2. Friction and Wear Effects of Greases

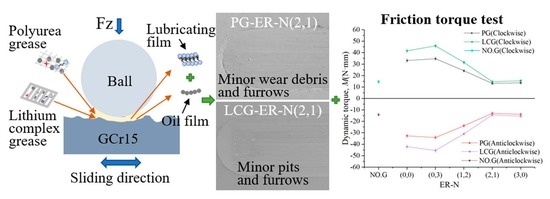

3.3. Lubrication Mechanism Analysis

3.4. Verifying Friction Torque Test Results

4. Conclusions

- (1)

- The addition of erucamide to polyurea grease/lithium complex grease demonstrated a notable friction reduction effect, while the inclusion of N-phenyl-α-naphthylamine yielded a modest and indirect reduction in friction. When a combination of 2 wt. % erucamide and 1 wt. % N-phenyl-α-naphthylamine was employed, the combined effect of erucamide and N-phenyl-α-naphthylamine resulted in the optimal friction reduction. This combination performed exceptionally well in conjunction with polyurea grease, exhibiting superior tribological properties.

- (2)

- The polyurea thickener comprised a lamellar thickener composed of short rod-shaped fibers, with the base oil, erucamide, and N-phenyl-α-naphthylamine molecules dispersed within the thickener. In contrast, the lithium complex thickener was structured as a network of intertwined fibers, with the base oil adsorbed within, while erucamide and N-phenyl-α-naphthylamine molecules were distributed on the surface of the thickener.

- (3)

- In the friction torque tests, it was observed that when 3 wt. % erucamide was utilized, the starting torque was minimized. However, when a combination of 2 wt. % erucamide and 1 wt. % N-phenyl-α-naphthylamine was employed, the dynamic torque was minimized.

- (4)

- Considering the tribological properties and bearing friction torque performance, the polyurea grease containing erucamide and N-phenyl-α-naphthylamine showed promising lubrication properties, warranting further research and optimization. By using the test method in this paper, the ratios of erucamide and N-phenyl-α-naphthylamine were further optimized, testing concentrations such as 1.6%, 1.8%, 2.2%, 2.4%, etc., so as to obtain the optimal ratios of erucamide and N-phenyl-α-naphthylamine in polyurea grease.

- (5)

- The results of this study support that erucamide and N-phenyl-α-naphthylamine added to grease act on roller bearings with excellent tribological properties. In addition, there are limitations in the friction reduction effect of ER and N. The friction reduction effect of erucamide and N-phenyl-α-naphthylamine is limited to that seen for the greases prepared in this paper.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, C.; Liu, Z.; Zhao, H.J.; Yang, H.N.; Li, X.L. Effect of the grease thickener on tribological properties of Si3N4/GCr15 contact interface and the performance in hybrid ceramic ball bearing. Ceram. Int. 2023, 49, 16857–16867. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Z.D. An optimization design method of a cylindrical roller bearing with the low friction torque. J. Tribol. Trans. ASME 2022, 144, 111201. [Google Scholar] [CrossRef]

- Liu, Y.W.; Fan, X.Y.; Wang, J.; Liu, X.Y. An Investigation for the Friction Torque of a Tapered Roller Bearing Considering the Geometric Homogeneity of Rollers. Lubricants 2022, 10, 154. [Google Scholar] [CrossRef]

- Gimeno, S.; Mescheder, H.; Quintana, I.; Gasión, A.; Arias-Egido, E.; Carbonell, A.; Mallo, C.; Miguel, I.; Paredes, J.; Zalakain, I. Effect of different laser texturing patterns on rolling contact surface and its tribological & fatigue life behavior on 100Cr6 bearing steel. Wear 2023, 522, 204717. [Google Scholar] [CrossRef]

- Wingertszahn, P.; Koch, O.; Maccioni, L.; Concli, F.; Sauer, B. Predicting Friction of Tapered Roller Bearings with Detailed Multi-Body Simulation Models. Lubricants 2023, 11, 369. [Google Scholar] [CrossRef]

- Farré-Lladós, J.; Westerberg, L.G.; Casals-Terré, J.; Leckner, J.; Westbroek, R. On the Flow Dynamics of Polymer Greases. Lubricants 2022, 10, 66. [Google Scholar] [CrossRef]

- Lugt, P.M.; Berens, F. The Grease Life Factor concept for ball bearings. Tribol. Int. 2022, 169, 107460. [Google Scholar] [CrossRef]

- Zhang, E.H.; Li, W.M.; Zhao, G.Q.; Wang, Z.; Wang, X.B. A study on microstructure, friction and rheology of four lithium greases formulated with four different base oils. Tribol. Lett. 2021, 69, 98. [Google Scholar] [CrossRef]

- Biazon, L.; Ferrer, B.P.; Toro, A.; Cousseau, T. Correlations between rail grease formulation and friction, wear and RCF of a wheel/rail tribological pair. Tribol. Int. 2021, 153, 106566. [Google Scholar] [CrossRef]

- Wang, Y.S.; Zhang, P.; Gao, X.D.; Cheng, Y.J. Rheological and tribological properties of polyurea greases containing additives of MoDDP and PB. Tribol. Int. 2023, 180, 108291. [Google Scholar] [CrossRef]

- Xia, Y.Q.; Yang, K.; Feng, X.; Wang, Y.H. Tribological properties of modified kaolin doped polymer as polytetrafluoroethylene grease additive. Tribol. Int. 2022, 173, 107612. [Google Scholar] [CrossRef]

- Kunishima, T.; Nagai, S.; Kurokawa, T.; Galipaud, J.; Guillonneau, G.; Bouvard, G.; Abry, J.C.; Minfray, C.; Fridrici, V.; Kapsa, P. Effects of temperature and addition of zinc carboxylate to grease on the tribological properties of PA66 in contact with carbon steel. Tribol. Int. 2021, 153, 106578. [Google Scholar] [CrossRef]

- Bas, H.; Özen, O.; Besirbeyoglu, M.A. Tribological properties of MoS2 and CaF2 particles as grease additives on the performance of block-on-ring surface contact. Tribol. Int. 2022, 168, 107433. [Google Scholar] [CrossRef]

- Padgurskas, J.; Johns, E.I.; Radulescu, I.; Radulescu, A.V.; Alexandru, V.; Rukuiz, R.; Snitka, V.; Kreivaitis, R.; Kupc, A.; Volskis, D. Tribological study of beeswax-thickened biogrease and its modification with carbon nanoparticles. Tribol. Int. 2023, 184, 108465. [Google Scholar] [CrossRef]

- Xie, M.X.; Pan, B.L.; Liu, H.Y.; Li, N.; Chen, Z.; Yan, J.J.; Fu, Z.H.; Guo, S.H.; Wang, H.G. One-step synthesis of carbon sphere@ 1 T-MoS2 towards superior antiwear and lubricity. Tribol. Int. 2022, 176, 107927. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.P.; Zhao, H.; Ren, S.Z.; Wang, C.C.; Huang, X.F.; Zheng, L.; Ren, T.H. Synergistic effects between sulfur- and phosphorus-free organic molybdenums and ZDDP as lubricating additives in PAO6. Tribol. Int. 2021, 165, 107324. [Google Scholar] [CrossRef]

- Wang, H.; Sun, A.N.; Qi, X.W.; Dong, Y.; Fan, B.L. Wear properties of textured lubricant films filled with graphite and polytetrafluoroethylene (PTFE) via laser surface texturing (LST). Tribol. Int. 2022, 176, 107414. [Google Scholar] [CrossRef]

- Huang, Y.J.; Xiong, Y.C.; Liu, C.J.; Li, L.L.; Xu, D.Y.; Lin, Y.H.; Nan, C.W. Single-crystalline 2D erucamide with low friction and enhanced thermal conductivity. Colloids Surf. A Physicochem. Eng. Asp. 2018, 540, 29–35. [Google Scholar] [CrossRef]

- Mansha, M.; Gauthier, C.; Gerard, P.; Schirrer, R. The effect of plasticization by fatty acid amides on the scratch resistance of PMMA. Wear 2011, 271, 671–679. [Google Scholar] [CrossRef]

- Silvano, J.D.; Santa, R.A.A.B.; Martins, M.A.P.M.; Riella, H.G.; Soares, C.; Fiori, M.A. Nanocomposite of erucamide-clay applied for the control of friction coefficient in surfaces of LLDPE. Polym. Test. 2018, 67, 1–6. [Google Scholar] [CrossRef]

- Jia, T.Y.; Tian, H.C.; Liu, S.T.; Zhang, S.J.; Ning, N.Y.; Yu, B.; Tian, M. Erucamide/thermoplastic polyurethane blend with low coefficient of friction, high elasticity and good mechanical properties for intelligent wearable devices. Polym. Int. 2023, 72, 813–821. [Google Scholar] [CrossRef]

- Velázquez, J.D.H.; Barroso-Flores, J.; Goicochea, A.G. Ab initio modeling of friction reducing agents shows quantum mechanical interactions can have macroscopic manifestation. J. Phys. Chem. A 2016, 120, 9244–9248. [Google Scholar] [CrossRef] [PubMed]

- Di, Y.Y.; Zhang, S.; Feng, X.Q.; Li, Q.Y. Tuning frictional properties of molecularly thin erucamide films through controlled self-assembling. Acta Mech. Sin. 2021, 37, 1041–1049. [Google Scholar] [CrossRef]

- Gubala, D.; Taylor, N.; Harniman, R.; Rawle, J.; Hussain, H.; Robles, E.; Chen, M.; Briscoe, W.H. Structure, nanomechanical properties, and wettability of organized erucamide layers on a polypropylene surface. Langmuir 2021, 37, 6521–6532. [Google Scholar] [CrossRef] [PubMed]

- Gubala, D.; Fox, L.J.; Harniman, R.; Hussain, H.; Robles, E.; Chen, M. Heads or tails: Nanostructure and molecular orientations in organised erucamide surface layers. J. Colloid Interface Sci. 2021, 590, 506–517. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.C.; Mo, Y.M. Effect of erucamide as polyurea grease additive on tribological properties of GCr15 steel. Tribol. Trans. 2023, 66, 507–518. [Google Scholar] [CrossRef]

- He, Z.Y.; Xiong, L.P.; Liu, J.; Han, S.; Hu, J.Q.; Xu, X.; Shen, M.X. Tribological property study of mercaptobenzothiazole-containing borate derivatives and its synergistic antioxidative effects with N-phenyl-α-naphthylamine. Lubr. Sci. 2019, 31, 239–251. [Google Scholar] [CrossRef]

- Xiong, L.P.; He, Z.Y.; Liu, J.; Hu, J.Q.; Han, S.; Wu, Y.L.; Yang, S.M. Tribological study of N-containing borate derivatives and their synergistic antioxidation effects with T531. Friction 2019, 7, 417–431. [Google Scholar] [CrossRef]

- Hu, J.Q.; Wei, X.Y.; Yao, J.B.; Han, L.; Zong, Z.M. Evaluation of molybdate ester as a synergist for arylamine antioxidant in lubricants. Tribol. Int. 2006, 39, 1469–1473. [Google Scholar] [CrossRef]

- Wang, S.P.; Yu, S.S.; Huang, B.; Feng, J.X.; Liu, S.G. Unique synergism between zinc dialkyldithiophosphates and Schiff base bridged phenolic diphenylamine antioxidants. Tribol. Int. 2019, 145, 106134. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, Y.N.; Su, H.G.; Li, W.M.; Lou, W.J.; Wang, X.B. Synthesis and evaluation of a protic ionic liquid as a multifunctional lubricant additive. Friction 2020, 8, 568–576. [Google Scholar] [CrossRef]

- Duangkaewmanee, S.; Petsom, A. Synergistic and antagonistic effects on oxidation stability of antioxidants in a synthetic esterbased oil. Tribol. Int. 2011, 44, 266–271. [Google Scholar] [CrossRef]

- Joly, J.F.; Miller, R.E. Density functional theory rate calculation of hydrogen abstraction reactions of N-Phenyl-α-naphthylamine antioxidants. Ind. Eng. Chem. Res. 2018, 57, 876–880. [Google Scholar] [CrossRef]

- Ma, R.; Li, W.M.; Zhao, Q.; Zheng, D.D.; Wang, X.B. In situ synthesized phosphate-based ionic liquids as high-performance lubricant additives. Tribol. Lett. 2019, 67, 60. [Google Scholar] [CrossRef]

- He, Z.Y.; Xiong, L.P.; Han, S.; Chen, A.X.; Qiu, J.W.; Fu, X.S. Tribological and antioxidation synergistic effect study of sulfonate-modified nano calcium carbonate. PLoS ONE 2013, 8, e62050. [Google Scholar] [CrossRef]

- GB/T 32562-2016; Rolling Bearings-Measuring Methods for Friction Torque. China Machinery Industry Federation: Beijing, China, 2016.

- Xue, Y.W.; Wu, C.H.; Shi, X.L.; Zhang, K.P.; Huang, Q.P. High temperature tribological behavior of textured CSS-42L bearing steel filled with Sn-Ag-Cu-Ti3C2. Tribol. Int. 2021, 164, 107205. [Google Scholar] [CrossRef]

- Dulal, N.; Shanks, R.; Chalmers, D.; Adhikari, B.; Gill, H. Migration and performance of erucamide slip additive in high-density polyethylene bottle caps. J. Appl. Polym. Sci. 2018, 153, 46822. [Google Scholar] [CrossRef]

| Project | PAO4 | Test Method |

|---|---|---|

| Kinematic viscosity (40 °C)/(mm2·s−1) | 19.063 | GB/T 265 |

| Kinematic viscosity (100 °C)/(mm2·s−1) | 6.342 | GB/T 265 |

| Number | Grease Samples | Base Oil, wt. % | Thickener, wt. % | ER, wt. % | N, wt. % |

|---|---|---|---|---|---|

| 1 | PG-ER-N (0,0) | PAO4, 80 | polyurea, 20 | 0 | 0 |

| 2 | PG-ER-N (0,3) | PAO4, 77 | 0 | 3 | |

| 3 | PG-ER-N (1,2) | PAO4, 77 | 1 | 2 | |

| 4 | PG-ER-N (2,1) | PAO4, 77 | 2 | 1 | |

| 5 | PG-ER-N (3,0) | PAO4, 77 | 3 | 0 | |

| 6 | LCG-ER-N (0,0) | PAO4, 80 | lithium, 20 | 0 | 0 |

| 7 | LCG-ER-N (0,3) | PAO4, 77 | 0 | 3 | |

| 8 | LCG-ER-N (1,2) | PAO4, 77 | 1 | 2 | |

| 9 | LCG-ER-N (2,1) | PAO4, 77 | 2 | 1 | |

| 10 | LCG-ER-N (3,0) | PAO4, 77 | 3 | 0 |

| Element | C | Cr | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|

| Wt. % | 0.95–1.05 | 1.4–1.65 | 0.2–0.4 | 0.15–0.35 | ≤0.027 | ≤0.02 | 2.747–3.497 |

| Reciprocating Distance/mm | Reciprocating Frequency/Hz | Test Load (Fz)/N | Test Time/min |

|---|---|---|---|

| 8 | 1 | 20 | 30 |

| Test Projects | PG-ER-N (0,0) | LCG-ER-N (0,0) | Test Method |

|---|---|---|---|

| Worked cone penetration (0.1 mm) | 289 | 272 | GB/T 269 |

| Extended worked cone penetration (10,000 times, 0.1 mm) | 303 | 296 | GB/T 269 |

| The difference between the extended work cone penetration and work cone penetration | 24 | 26 | / |

| Oil separation (100 °C, 24 h) % (m/m) | 2.31 | 1.79 | NB/SH/T 0324 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Mo, Y.; Lv, J.; Zhang, H. Effects of Erucamide and N-phenyl-α-naphthylamine on the Friction and Torque Behaviors of Grease on Roller Bearings. Lubricants 2023, 11, 531. https://doi.org/10.3390/lubricants11120531

Liu Q, Mo Y, Lv J, Zhang H. Effects of Erucamide and N-phenyl-α-naphthylamine on the Friction and Torque Behaviors of Grease on Roller Bearings. Lubricants. 2023; 11(12):531. https://doi.org/10.3390/lubricants11120531

Chicago/Turabian StyleLiu, Qingchun, Yimin Mo, Juncheng Lv, and Hong Zhang. 2023. "Effects of Erucamide and N-phenyl-α-naphthylamine on the Friction and Torque Behaviors of Grease on Roller Bearings" Lubricants 11, no. 12: 531. https://doi.org/10.3390/lubricants11120531

APA StyleLiu, Q., Mo, Y., Lv, J., & Zhang, H. (2023). Effects of Erucamide and N-phenyl-α-naphthylamine on the Friction and Torque Behaviors of Grease on Roller Bearings. Lubricants, 11(12), 531. https://doi.org/10.3390/lubricants11120531