Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel

Abstract

:1. Introduction

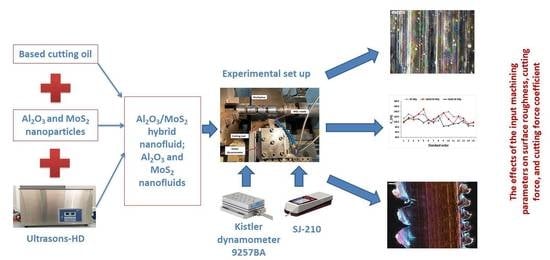

2. Material and Method

2.1. Experimental Set Up

2.2. Experiment Design

3. Results and Discussion

3.1. Surface Roughness Ra

3.2. Surface Microstructure

3.3. Effects on the Cutting Force Components Fp, Fc

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 0.046012 | 0.005112 | 2.71 | 0.142 |

| Linear | 3 | 0.020964 | 0.006988 | 3.70 | 0.096 |

| NC | 1 | 0.012013 | 0.012013 | 6.36 | 0.053 |

| p | 1 | 0.003281 | 0.003281 | 1.74 | 0.245 |

| Q | 1 | 0.005671 | 0.005671 | 3.00 | 0.144 |

| Square | 3 | 0.023296 | 0.007765 | 4.11 | 0.081 |

| NC*NC | 1 | 0.022910 | 0.022910 | 12.14 | 0.018 |

| p*p | 1 | 0.000675 | 0.000675 | 0.36 | 0.576 |

| Q*Q | 1 | 0.000675 | 0.000675 | 0.36 | 0.576 |

| 2-Way Interaction | 3 | 0.001752 | 0.000584 | 0.31 | 0.818 |

| NC*p | 1 | 0.001463 | 0.001463 | 0.78 | 0.419 |

| NC*Q | 1 | 0.000086 | 0.000086 | 0.05 | 0.840 |

| p*Q | 1 | 0.000203 | 0.000203 | 0.11 | 0.756 |

| Error | 5 | 0.009437 | 0.001887 | ||

| Lack-of-Fit | 3 | 0.009371 | 0.003124 | 94.42 | 0.010 |

| Pure Error | 2 | 0.000066 | 0.000033 | ||

| Total | 14 | 0.055449 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 0.010922 | 0.001214 | 3.35 | 0.098 |

| Linear | 3 | 0.005832 | 0.001944 | 5.37 | 0.051 |

| NC | 1 | 0.003570 | 0.003570 | 9.85 | 0.026 |

| p | 1 | 0.002261 | 0.002261 | 6.24 | 0.055 |

| Q | 1 | 0.000001 | 0.000001 | 0.00 | 0.965 |

| Square | 3 | 0.003191 | 0.001064 | 2.94 | 0.138 |

| NC*NC | 1 | 0.001539 | 0.001539 | 4.25 | 0.094 |

| p*p | 1 | 0.001876 | 0.001876 | 5.18 | 0.072 |

| Q*Q | 1 | 0.000103 | 0.000103 | 0.29 | 0.616 |

| 2-Way Interaction | 3 | 0.001899 | 0.000633 | 1.75 | 0.273 |

| NC*p | 1 | 0.000298 | 0.000298 | 0.82 | 0.406 |

| NC*Q | 1 | 0.000977 | 0.000977 | 2.70 | 0.162 |

| p*Q | 1 | 0.000625 | 0.000625 | 1.72 | 0.246 |

| Error | 5 | 0.001812 | 0.000362 | ||

| Lack-of-Fit | 3 | 0.001777 | 0.000592 | 34.17 | 0.029 |

| Pure Error | 2 | 0.000035 | 0.000017 | ||

| Total | 14 | 0.012734 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 0.010447 | 0.001161 | 4.88 | 0.048 |

| Linear | 3 | 0.000522 | 0.000174 | 0.73 | 0.576 |

| NC | 1 | 0.000003 | 0.000003 | 0.01 | 0.913 |

| p | 1 | 0.000288 | 0.000288 | 1.21 | 0.321 |

| Q | 1 | 0.000231 | 0.000231 | 0.97 | 0.370 |

| Square | 3 | 0.008661 | 0.002887 | 12.13 | 0.010 |

| NC*NC | 1 | 0.007148 | 0.007148 | 30.04 | 0.003 |

| p*p | 1 | 0.001099 | 0.001099 | 4.62 | 0.084 |

| Q*Q | 1 | 0.001333 | 0.001333 | 5.60 | 0.064 |

| 2-Way Interaction | 3 | 0.001263 | 0.000421 | 1.77 | 0.269 |

| NC*p | 1 | 0.000182 | 0.000182 | 0.77 | 0.422 |

| NC*Q | 1 | 0.000025 | 0.000025 | 0.11 | 0.759 |

| p*Q | 1 | 0.001056 | 0.001056 | 4.44 | 0.089 |

| Error | 5 | 0.001190 | 0.000238 | ||

| Lack-of-Fit | 3 | 0.001172 | 0.000391 | 43.40 | 0.023 |

| Pure Error | 2 | 0.000018 | 0.000009 | ||

| Total | 14 | 0.011636 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 1766.40 | 196.27 | 2.92 | 0.125 |

| Linear | 3 | 543.68 | 181.23 | 2.70 | 0.156 |

| NC | 1 | 379.09 | 379.09 | 5.65 | 0.063 |

| p | 1 | 19.07 | 19.07 | 0.28 | 0.617 |

| Q | 1 | 145.52 | 145.52 | 2.17 | 0.201 |

| Square | 3 | 1128.19 | 376.06 | 5.60 | 0.047 |

| NC*NC | 1 | 1072.68 | 1072.68 | 15.98 | 0.010 |

| p*p | 1 | 2.49 | 2.49 | 0.04 | 0.855 |

| Q*Q | 1 | 15.64 | 15.64 | 0.23 | 0.650 |

| 2-Way Interaction | 3 | 94.54 | 31.51 | 0.47 | 0.717 |

| NC*p | 1 | 33.24 | 33.24 | 0.50 | 0.513 |

| NC*Q | 1 | 61.15 | 61.15 | 0.91 | 0.384 |

| p*Q | 1 | 0.15 | 0.15 | 0.00 | 0.964 |

| Error | 5 | 335.69 | 67.14 | ||

| Lack-of-Fit | 3 | 62.02 | 20.67 | 0.15 | 0.921 |

| Pure Error | 2 | 273.67 | 136.84 | ||

| Total | 14 | 2102.09 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 2796.93 | 310.77 | 1.55 | 0.329 |

| Linear | 3 | 416.50 | 138.83 | 0.69 | 0.596 |

| NC | 1 | 22.55 | 22.55 | 0.11 | 0.751 |

| p | 1 | 167.54 | 167.54 | 0.83 | 0.403 |

| Q | 1 | 226.42 | 226.42 | 1.13 | 0.337 |

| Square | 3 | 600.85 | 200.28 | 1.00 | 0.466 |

| NC*NC | 1 | 316.81 | 316.81 | 1.58 | 0.265 |

| p*p | 1 | 105.21 | 105.21 | 0.52 | 0.502 |

| Q*Q | 1 | 263.35 | 263.35 | 1.31 | 0.304 |

| 2-Way Interaction | 3 | 1779.58 | 593.19 | 2.95 | 0.137 |

| NC*p | 1 | 0.53 | 0.53 | 0.00 | 0.961 |

| NC*Q | 1 | 1072.56 | 1072.56 | 5.34 | 0.069 |

| p*Q | 1 | 706.50 | 706.50 | 3.51 | 0.120 |

| Error | 5 | 1005.15 | 201.03 | ||

| Lack-of-Fit | 3 | 773.97 | 257.99 | 2.23 | 0.324 |

| Pure Error | 2 | 231.18 | 115.59 | ||

| Total | 14 | 3802.08 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 3085.15 | 342.79 | 7.31 | 0.021 |

| Linear | 3 | 615.22 | 205.07 | 4.37 | 0.073 |

| NC | 1 | 14.66 | 14.66 | 0.31 | 0.600 |

| p | 1 | 8.36 | 8.36 | 0.18 | 0.690 |

| Q | 1 | 592.20 | 592.20 | 12.62 | 0.016 |

| Square | 3 | 2294.11 | 764.70 | 16.30 | 0.005 |

| NC*NC | 1 | 96.30 | 96.30 | 2.05 | 0.211 |

| p*p | 1 | 1979.57 | 1979.57 | 42.19 | 0.001 |

| Q*Q | 1 | 413.08 | 413.08 | 8.80 | 0.031 |

| 2-Way Interaction | 3 | 175.82 | 58.61 | 1.25 | 0.385 |

| NC*p | 1 | 14.36 | 14.36 | 0.31 | 0.604 |

| NC*Q | 1 | 153.39 | 153.39 | 3.27 | 0.130 |

| p*Q | 1 | 8.07 | 8.07 | 0.17 | 0.696 |

| Error | 5 | 234.62 | 46.92 | ||

| Lack-of-Fit | 3 | 220.80 | 73.60 | 10.65 | 0.087 |

| Pure Error | 2 | 13.83 | 6.91 | ||

| Total | 14 | 3319.78 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 344,220 | 38,247 | 60.37 | 0.000 |

| Linear | 3 | 99,040 | 33,013 | 52.11 | 0.000 |

| NC | 1 | 96,332 | 96,332 | 152.05 | 0.000 |

| p | 1 | 2427 | 2427 | 3.83 | 0.108 |

| Q | 1 | 282 | 282 | 0.44 | 0.535 |

| Square | 3 | 240,212 | 80,071 | 126.38 | 0.000 |

| NC*NC | 1 | 236,944 | 236,944 | 373.99 | 0.000 |

| p*p | 1 | 3724 | 3724 | 5.88 | 0.060 |

| Q*Q | 1 | 160 | 160 | 0.25 | 0.637 |

| 2-Way Interaction | 3 | 4968 | 1656 | 2.61 | 0.163 |

| NC*p | 1 | 3758 | 3758 | 5.93 | 0.059 |

| NC*Q | 1 | 400 | 400 | 0.63 | 0.463 |

| p*Q | 1 | 810 | 810 | 1.28 | 0.310 |

| Error | 5 | 3168 | 634 | ||

| Lack-of-Fit | 3 | 2896 | 965 | 7.11 | 0.126 |

| Pure Error | 2 | 271 | 136 | ||

| Total | 14 | 347,388 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 46,527.0 | 5169.7 | 4.72 | 0.051 |

| Linear | 3 | 18,106.6 | 6035.5 | 5.51 | 0.048 |

| NC | 1 | 645.8 | 645.8 | 0.59 | 0.477 |

| p | 1 | 16,327.1 | 16,327.1 | 14.90 | 0.012 |

| Q | 1 | 1133.6 | 1133.6 | 1.03 | 0.356 |

| Square | 3 | 10,407.9 | 3469.3 | 3.17 | 0.123 |

| NC*NC | 1 | 4342.9 | 4342.9 | 3.96 | 0.103 |

| p*p | 1 | 3013.5 | 3013.5 | 2.75 | 0.158 |

| Q*Q | 1 | 4627.9 | 4627.9 | 4.22 | 0.095 |

| 2-Way Interaction | 3 | 18,012.5 | 6004.2 | 5.48 | 0.049 |

| NC*p | 1 | 408.2 | 408.2 | 0.37 | 0.568 |

| NC*Q | 1 | 10,063.1 | 10,063.1 | 9.19 | 0.029 |

| p*Q | 1 | 7541.2 | 7541.2 | 6.88 | 0.047 |

| Error | 5 | 5477.8 | 1095.6 | ||

| Lack-of-Fit | 3 | 1829.1 | 609.7 | 0.33 | 0.807 |

| Pure Error | 2 | 3648.7 | 1824.3 | ||

| Total | 14 | 52,004.8 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 2959.31 | 328.81 | 4.92 | 0.047 |

| Linear | 3 | 458.10 | 152.70 | 2.28 | 0.197 |

| NC | 1 | 6.25 | 6.25 | 0.09 | 0.772 |

| p | 1 | 6.64 | 6.64 | 0.10 | 0.765 |

| Q | 1 | 445.21 | 445.21 | 6.66 | 0.049 |

| Square | 3 | 2081.26 | 693.75 | 10.37 | 0.014 |

| NC*NC | 1 | 33.47 | 33.47 | 0.50 | 0.511 |

| p*p | 1 | 1653.34 | 1653.34 | 24.72 | 0.004 |

| Q*Q | 1 | 562.55 | 562.55 | 8.41 | 0.034 |

| 2-Way Interaction | 3 | 419.95 | 139.98 | 2.09 | 0.220 |

| NC*p | 1 | 1.80 | 1.80 | 0.03 | 0.876 |

| NC*Q | 1 | 418.00 | 418.00 | 6.25 | 0.054 |

| p*Q | 1 | 0.16 | 0.16 | 0.00 | 0.963 |

| Error | 5 | 334.36 | 66.87 | ||

| Lack-of-Fit | 3 | 330.62 | 110.21 | 58.86 | 0.017 |

| Pure Error | 2 | 3.74 | 1.87 | ||

| Total | 14 | 3293.67 |

References

- Lee, P.-H.; Nam, J.S.; Li, C.; Lee, S.W. An Experimental Study on Micro-Grinding Process with Nanofluid Minimum Quantity Lubrication (MQL). Int. J. Precis. Eng. Manuf. 2012, 13, 331–338. [Google Scholar] [CrossRef]

- Garg, A.; Sarma, S.; Panda, B.; Zhang, J.; Gao, L. Study of effect of nanofluid concentration on response characteristics of machining process for cleaner production. J. Clean. Prod. 2016, 135, 476–489. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Zhang, K.; Deng, J.; Meng, R.; Gao, P.; Yue, H. Effect of nano-scale textures on cutting performance of WC/Co-based Ti55Al45N coated tools in dry cutting. Int. J. Refract. Met. Hard Mater. 2015, 51, 35–49. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, J.; Wang, W.; Duan, R.; Meng, R.; Ge, D.; Li, X. Effect of texture parameters on cutting performance of flank-faced textured carbide tools in dry cutting of green Al2O3 ceramics. Ceram. Int. 2018, 44, 13205–13217. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M.; Sun, K. Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J. Clean. Prod. 2017, 154, 1–11. [Google Scholar] [CrossRef]

- Minh, D.T.; The, L.T.; Bao, N.T. Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60Si2Mn steel using cemented carbide tools. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Pryazhnikov, M.I.; Minakov, A.V.; Rudyak, V.Y.; Guzei, D.V. Thermal conductivity measurements of nanofluids. Int. J. Heat Mass Transf. 2017, 104, 1275–1282. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nanolubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Gadallah, M.H.; Umer, U.; Deiab, I. On machining of Ti-6Al-4V using multi-walled carbon nanotubes-based nano-fluid under minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2018, 97, 1593–1603. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H. Towards Sustainable Machining of Inconel 718 Using Nano-Fluid Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2018, 2, 50. [Google Scholar] [CrossRef] [Green Version]

- Uysal, A.; Demiren, F.; Altan, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano MoS2 Reinforced Vegetable Cutting Fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef] [Green Version]

- Eltaggaz, A.; Zawada, P.; Hegab, H.A.; Deiab, I.; Kishawy, H.A. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2018, 94, 3875–3887. [Google Scholar] [CrossRef]

- Günan, F.; Kıvak, T.; Yıldırım, Ç.V.; Sarıkaya, M. Performance evaluation of MQL with Al2O3 mixed nanofluids prepared at different concentrations in milling of Hastelloy C276 alloy. J. Mater. Res. Technol. 2020, 9, 10386–10400. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Dong, P.Q. Effect of the alumina nanofluid concentration on minimum quantity lubrication hard machining for sustainable production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5977–5988. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Sayuti, M. Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J. Clean. Prod. 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Yücel, A.; Yıldırım, Ç.V.; Sarıkaya, M.; Şirin, Ş.; Kıvak, T.; Gupta, M.K.; Ítalo, V.T. Influence of MoS2 based nanofluid-MQL on tribological and machining characteristics in turning of AA 2024 T3 aluminum alloy. J. Mater. Res. Technol. 2021, 15, 1688–1704. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Tiwari, A.K.; Pramanik, A.; Mandal, A. Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J. Clean. Prod. 2017, 162, 830–845. [Google Scholar] [CrossRef] [Green Version]

- Şirin, Ş.; Kıvak, T. Effects of hybrid nanofluids on machining performance in MQL-milling of Inconel X-750 superalloy. J. Manuf. Process. 2021, 70, 163–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int. J. Mach. Tools Manuf. 2015, 99, 19–33. [Google Scholar] [CrossRef]

- Vineet, D.; Sharma, K.A.; Vats, P.; Pimenov, D.Y.; Giasin, K.; Chuchala, D. Study of a Multicriterion Decision-Making Approach to the MQL Turning of AISI 304 Steel Using Hybrid Nano cutting Fluid. Materials 2021, 14, 7207. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Sarıkaya, M. A comparative study on the tribological behavior of mono & proportional hybrid nanofluids for sustainable turning of AISI 420 hardened steel with cermet tools. J. Manuf. Process. 2022, 73, 695–714. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance Evaluation of MQL Parameters Using Al2O3 and MoS2 Nanofluids in Hard Turning 90CrSi Steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef] [Green Version]

- Duc, T.M.; Tuan, N.M.; Long, T.T.; Ngoc, T.B. Machining feasibility and Sustainability study associated with air pressure, air flow rate, and nanoparticle concentration in Nanofluid minimum quantity lubrication-assisted hard milling process of 60Si2Mn steel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 11256–11269. [Google Scholar] [CrossRef]

- Dong, P.Q.; Duc, T.M.; Long, T.T. Performance Evaluation of MQCL Hard Milling of SKD 11 Tool Steel Using MoS2 Nanofluid. Metals 2019, 9, 658. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Tuan, N.M. Novel Uses of Al2O3/MoS2 Hybrid Nanofluid in MQCL Hard Milling of Hardox 500 Steel. Lubricants 2021, 9, 45. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Li, B.; Yang, M.; Zhang, X.; Guo, S.; Liu, G. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in MQL grinding with different nanofluids. Tribol. Int. 2016, 99, 198–210. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhang, Y.; Ding, W.; Yang, M.; Gao, T.; Cao, H.; Xu, X.; Wang, D.; Said, Z.; et al. Vegetable oil-based nanofluid minimum quantity lubrication turning: Academic review and perspectives. J. Manuf. Process. 2020, 59, 76–97. [Google Scholar] [CrossRef]

- Oberg, E.; Jones, F.; Horton, H.; Ryffel, H.; McCauley, C. Machinery’s Handbook, 30th ed.; Toolbox Edition; Industrial Press: New York, NY, USA, 2016; ISBN 9780831130916. [Google Scholar]

- Yuan, Z.; He, Y.; Cheng, K.; Duan, Z.; Wang, L. Effect of self-developed graphene lubricant on tribological behaviour of silicon carbide/silicon nitride interface. Ceram. Int. 2019, 45, 10211–10222. [Google Scholar] [CrossRef]

- Gao, G.; Wu, B.; Zhang, D.; Luo, M. Mechanistic identification of cutting force coefficients in bull-nose milling process. Chin. J. Aeronaut. 2013, 26, 823–830. [Google Scholar] [CrossRef] [Green Version]

- Yao, Q.; Luo, M.; Zhang, D.; Wu, B. Identification of cutting force coefficients in machining process considering cutter vibration. Mech. Syst. Signal Process. 2018, 103, 39–59. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | S | P | Cr | Mo | W | V | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | 0.85–0.95 | 1.20–1.60 | 0.30–0.60 | Max 0.40 | Max 0.03 | Max 0.03 | 0.95–1.25 | Max 0.20 | Max 0.20 | Max 0.15 | Max 0.03 | Max 0.3 |

| Input Variables | Unit | Symbol | Level | |

|---|---|---|---|---|

| Low | High | |||

| Nanoparticle concentration of Al2O3 and Al2O3/MoS2 | wt.% | NC | 0.5 | 1.5 |

| Nanoparticle concentration of MoS2 | wt.% | NC | 0.2 | 0.8 |

| Air pressure | bar | p | 4 | 6 |

| Air flow rate | l/min | Q | 150 | 250 |

| Std Order | Run Order | Input Variables | Responses | ||||

|---|---|---|---|---|---|---|---|

| NC (wt.%) | p (bar) | Q (l/min) | Ra (µm) | Fp (N) | Fc (N) | ||

| 1 | 8 | 0.2 | 4 | 200 | 0.249 | 220.6 | 98.7 |

| 2 | 5 | 0.8 | 4 | 200 | 0.355 | 508.7 | 112.9 |

| 3 | 11 | 0.2 | 6 | 200 | 0.356 | 345.5 | 108.9 |

| 4 | 12 | 0.8 | 6 | 200 | 0.385 | 510.9 | 111.5 |

| 5 | 13 | 0.2 | 5 | 150 | 0.345 | 268.0 | 97.1 |

| 6 | 6 | 0.8 | 5 | 150 | 0.442 | 460.2 | 108.4 |

| 7 | 10 | 0.2 | 5 | 250 | 0.240 | 236.0 | 97.3 |

| 8 | 4 | 0.8 | 5 | 250 | 0.318 | 468.2 | 124.3 |

| 9 | 2 | 0.5 | 4 | 150 | 0.254 | 101.4 | 83.7 |

| 10 | 7 | 0.5 | 6 | 150 | 0.280 | 135.9 | 85.1 |

| 11 | 14 | 0.5 | 4 | 250 | 0.276 | 165.6 | 92.3 |

| 12 | 9 | 0.5 | 6 | 250 | 0.274 | 143.2 | 94.4 |

| 13 | 15 | 0.5 | 5 | 200 | 0.244 | 124.8 | 105.3 |

| 14 | 3 | 0.5 | 5 | 200 | 0.238 | 104.8 | 84.6 |

| 15 | 1 | 0.5 | 5 | 200 | 0.250 | 104.4 | 85.5 |

| Std Order | Run Order | Input Variables | Responses | ||||

|---|---|---|---|---|---|---|---|

| NC (wt.%) | p (bar) | Q (l/min) | Ra (µm) | Fp (N) | Fc (N) | ||

| 1 | 1 | 0.5 | 4 | 200 | 0.313 | 157.0 | 100.5 |

| 2 | 9 | 1.5 | 4 | 200 | 0.353 | 135.4 | 115.8 |

| 3 | 7 | 0.5 | 6 | 200 | 0.315 | 248.0 | 116.6 |

| 4 | 11 | 1.5 | 6 | 200 | 0.390 | 266.8 | 130.5 |

| 5 | 14 | 0.5 | 5 | 150 | 0.317 | 280.8 | 148.9 |

| 6 | 4 | 1.5 | 5 | 150 | 0.313 | 145.9 | 94.8 |

| 7 | 3 | 0.5 | 5 | 250 | 0.307 | 171.0 | 110.4 |

| 8 | 10 | 1.5 | 5 | 250 | 0.365 | 236.8 | 121.8 |

| 9 | 13 | 1 | 4 | 150 | 0.302 | 230.6 | 134.7 |

| 10 | 12 | 1 | 6 | 150 | 0.375 | 213.3 | 111.0 |

| 11 | 2 | 1 | 4 | 250 | 0.305 | 105.6 | 92.5 |

| 12 | 8 | 1 | 6 | 250 | 0.328 | 262.0 | 122.0 |

| 13 | 15 | 1 | 5 | 200 | 0.301 | 188.0 | 113.1 |

| 14 | 5 | 1 | 5 | 200 | 0.303 | 109.9 | 92.2 |

| 15 | 6 | 1 | 5 | 200 | 0.295 | 118.9 | 98.5 |

| Std Order | Run Order | Input Variables | Responses | ||||

|---|---|---|---|---|---|---|---|

| NC (wt.%) | p (bar) | Q (l/min) | Ra (µm) | Fp (N) | Fc (N) | ||

| 1 | 1 | 0.5 | 4 | 200 | 0.313 | 137.6 | 113.3 |

| 2 | 9 | 1.5 | 4 | 200 | 0.353 | 141.7 | 130.3 |

| 3 | 7 | 0.5 | 6 | 200 | 0.315 | 139.2 | 119.3 |

| 4 | 11 | 1.5 | 6 | 200 | 0.390 | 145.9 | 128.7 |

| 5 | 14 | 0.5 | 5 | 150 | 0.317 | 159.7 | 128.8 |

| 6 | 4 | 1.5 | 5 | 150 | 0.313 | 130.3 | 108.7 |

| 7 | 3 | 0.5 | 5 | 250 | 0.307 | 113.8 | 99.5 |

| 8 | 10 | 1.5 | 5 | 250 | 0.365 | 125.2 | 104.1 |

| 9 | 13 | 1 | 4 | 150 | 0.302 | 152.0 | 134.7 |

| 10 | 12 | 1 | 6 | 150 | 0.375 | 153.1 | 139.4 |

| 11 | 2 | 1 | 4 | 250 | 0.305 | 148.1 | 120.1 |

| 12 | 8 | 1 | 6 | 250 | 0.328 | 148.4 | 119.1 |

| 13 | 15 | 1 | 5 | 200 | 0.301 | 115.4 | 96.8 |

| 14 | 5 | 1 | 5 | 200 | 0.303 | 117.3 | 91.7 |

| 15 | 6 | 1 | 5 | 200 | 0.295 | 118.0 | 95.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngoc, T.B.; Duc, T.M.; Tuan, N.M.; Hoang, V.L.; Long, T.T. Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants 2023, 11, 54. https://doi.org/10.3390/lubricants11020054

Ngoc TB, Duc TM, Tuan NM, Hoang VL, Long TT. Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants. 2023; 11(2):54. https://doi.org/10.3390/lubricants11020054

Chicago/Turabian StyleNgoc, Tran Bao, Tran Minh Duc, Ngo Minh Tuan, Vu Lai Hoang, and Tran The Long. 2023. "Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel" Lubricants 11, no. 2: 54. https://doi.org/10.3390/lubricants11020054

APA StyleNgoc, T. B., Duc, T. M., Tuan, N. M., Hoang, V. L., & Long, T. T. (2023). Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants, 11(2), 54. https://doi.org/10.3390/lubricants11020054