Running-In Effects of Lubricated Polyether Ether Ketone on Steel for Different Spreading and Sorption Tendencies

Abstract

:1. Introduction

- One hypothesis to be tested is whether the tendency to form a transfer layer can be affected by a specific loading strategy.

- Furthermore, it will be tested whether or not the time development of the build-up of a transfer layer depends on the local interaction between asperites and polymer and the already present transfer layer.

- The third hypothesis which will be tested is whether an altered wear behavior in the glass transition temperature region can be detected for lubricants that are strongly absorbed in PEEK.

2. Materials and Methods

2.1. Tribological Experiments

2.2. Indenter Measurements

2.3. Contact Angle Measurements

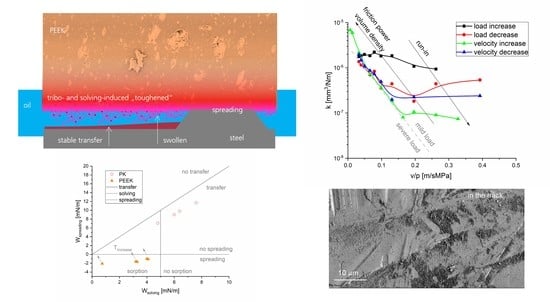

3. Results and Discussion

Contact Angle Measurements and Interaction Energies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, S.W. State-of-the-art of polymer tribology. Tribiology Int. 1998, 31, 49–60. [Google Scholar] [CrossRef]

- Scherge, M.; Kramlich, J.; Böttcher, R.; Hoppe, T. Running-in due to material transfer of lubricated steel/PA46 (aliphatic polyamide) contacts. Wear 2013, 301, 758–762. [Google Scholar] [CrossRef]

- Samyn, P.; Schoukens, G. Calculation and significance of the maximum polymer surface temperature T * in reciprocating cylinder-on-plate sliding. Polym. Eng. Sci. 2008, 48, 774–785. [Google Scholar] [CrossRef]

- Samyn, P.; Schoukens, G.; van Driessche, I.; van Craenenbroeck, J.; Verpoort, F. Softening and melting mechanisms of polyamides interfering with sliding stability under adhesive conditions. Polymer 2006, 47, 5050–5065. [Google Scholar] [CrossRef]

- Koplin, C.; Abdel-Wahed, S.A.; Jaeger, R.; Scherge, M. The Transition from Static to Dynamic Boundary Friction of a Lubricated Spreading and a Non-Spreading Adhesive Contact by Macroscopic Oscillatory Tribometry. Lubricants 2019, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Koplin, C.; Oehler, H.; Praß, O.; Schlüter, B.; Alig, I.; Jaeger, R. Wear and the Transition from Static to Mixed Lubricated Friction of Sorption or Spreading Dominated Metal-Thermoplastic Contacts. Lubricants 2022, 10, 93. [Google Scholar] [CrossRef]

- Samyn, P.; Baets, P.; de Schoukens, G.; Quintelier, J. Wear transitions and stability of polyoxymethylene homopolymer in highly loaded applications compared to small-scale testing. Tribol. Int. 2007, 40, 819–833. [Google Scholar] [CrossRef]

- Clerico, M. Tribological behaviour of polyacetals. Wear 1980, 64, 259–272. [Google Scholar] [CrossRef]

- Harris, L. A Study of the Crystallisation Kinetics in PEEK and PEEK Composites. Master’s Thesis, The University of Birmingham, Birmingham, UK, September 2011. [Google Scholar]

- Briscoe, B.J.; Stuart, B.H.; Rostami, S. A Fourier transform Raman spectroscopy study of the crystallization behaviour of poly (ether ether ketone)/poly (ether imide) blends. Spectrochim. Acta Part A Mol. Spectrosc. 1993, 49, 753–758. [Google Scholar] [CrossRef]

- Zhang, G.; Liao, H.; Li, H.; Mateus, C.; Bordes, J.-M.; Coddet, C. On dry sliding friction and wear behaviour of PEEK and PEEK/SiC-composite coatings. Wear 2006, 260, 594–600. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, H.; Zhang, C.; Liao, H.; Coddet, C. Temperature dependence of the tribological mechanisms of amorphous PEEK (polyetheretherketone) under dry sliding conditions. Acta Mater. 2008, 56, 2182–2190. [Google Scholar] [CrossRef]

- Mir, A.H.; Charoo, M.S. Friction and wear characteristics of polyetheretherketone (PEEK): A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 561, 12051. [Google Scholar] [CrossRef]

- Lu, Z.P.; Friedrich, K. On sliding friction and wear of PEEK and its composites. Wear 1995, 181–183, 624–631. [Google Scholar] [CrossRef]

- Knör, N.; Gebhard, A.; Haupert, F.; Schlarb, A.K. Polyetheretherketone (PEEK) nanocomposites for extreme mechanical and tribological loads. Mech. Compos. Mater. 2009, 45, 199–206. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef] [Green Version]

- Savan, A.; Pflüger, E.; Voumard, P.; Schröer, A.; Simmonds, M. Modern solid lubrication: Recent developments and applications of MoS2. Lubr. Sci. 2000, 12, 185–203. [Google Scholar] [CrossRef]

- Pedroso, J.M.; Enger, M.; Bandeira, P.; Magalhães, F.D. Comparative Study of Friction and Wear Performance of PEK, PEEK and PEKK Binders in Tribological Coatings. Polymers 2022, 14, 4008. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Váradi, K.; Néder, Z.; Friedrich, K.; Flöck, J. Contact and thermal analysis of transfer film covered real composite-steel surfaces in sliding contact. Tribol. Int. 2000, 33, 789–802. [Google Scholar] [CrossRef]

- Laux, K.A.; Schwartz, C.J. Effects of contact pressure, molecular weight, and supplier on the wear behavior and transfer film of polyetheretherketone (PEEK). Wear 2013, 297, 919–925. [Google Scholar] [CrossRef] [Green Version]

- Burris, D.L.; Sawyer, W.G. Improved wear resistance in alumina-PTFE nanocomposites with irregular shaped nanoparticles. Wear 2006, 260, 915–918. [Google Scholar] [CrossRef]

- Abdel-Wahed, S.A.; Koplin, C.; Jaeger, R.; Scherge, M. On the Transition from Static to Dynamic Boundary Friction of Lubricated PEEK for a Spreading Adhesive Contact by Macroscopic Oscillatory Tribometry. Lubricants 2017, 5, 21. [Google Scholar] [CrossRef] [Green Version]

- Hamrock, B.J.; Dowson, D. Starved Conjunction; NASA Technical Paper NASA-TP-1273; NASA: Washington, DC, USA, 1978.

- Grellmann, W.; Seidler, S. (Eds.) Polymer Testing; Hanser Publications: Cincinnati, OH, USA, 2022; ISBN 9781569908068. [Google Scholar]

- Gebhardt, K.F. Grundlagen der Physikalischen Chemie von Grenzflächen und Methoden zur Bestimmung Grenzflächenenergetischer Probleme; IGB: Stuttgart, Germany, 1982. [Google Scholar]

- Busscher, H.J.; van Pelt, A.W.J.; de Boer, P.; de Jong, H.P.; Arends, J. The effect of surface roughening of polymers on measured contact angles of liquids. Colloids Surf. 1984, 9, 319–331. [Google Scholar] [CrossRef]

- Rice, J.R.; Lapusta, N.; Ranjith, K. Rate and state dependent friction and the stability of sliding between elastically deformable solids. J. Mech. Phys. Solids 2001, 49, 1865–1898. [Google Scholar] [CrossRef] [Green Version]

- Fedorov, S.V.; Assenova, E. Synergy and Self-organization in Tribosystem’s evolution. Energy Model of Friction. IOP Conf. Ser. Mater. Sci. Eng. 2018, 295, 12028. [Google Scholar] [CrossRef]

| Property | Equation | |

|---|---|---|

| Interfacial energy | (1) | |

| Spreading energy of system | (2) | |

| Solving energy of lubricated thermoplastic | (3) | |

| Transfer energy of system | (4) | |

| Minimal isothermal 3-factor model for mixed lubricated friction | (5) | |

| Minimal isothermal 3-factor model for mixed lubricated wear | (6) |

| Lubricant or Body | Viscosity | Cohesive or Surface Energy | PEEK | PK | |||

|---|---|---|---|---|---|---|---|

| at 40 °C (mm2/s) | γ Polar (mN/m) | γ Dispersive (mN/m) | Wsolving (mN/m) | Wspreading (mN/m) | Wsolving (mN/m) | Wspreading (mN/m) | |

| PAO | 30 | 0.6 | 31.5 | - | - | 6.4 | 9.8 |

| PEE | 23.5 | 0.7 | 31.6 | - | - | 6.0 | 9.0 |

| nPG | 30 | 0.27 | 30.1 | - | - | 7.6 | 11.7 |

| pPG | 30 | 1.4 | 34.7 | - | - | 4.8 | 7.1 |

| hvPAO | 66.1 | 6.5 | 30.9 | 4.1 | −1.1 | - | - |

| hvTSE | 70.8 | 5.7 | 33.2 | 3.2 | −1.6 | - | - |

| hvPEE | 52.7 | 5.7 | 32.3 | 3.3 | −1.7 | - | - |

| hvnPG | 120.6 | 6.8 | 33.1 | 4.0 | −1.0 | - | - |

| hvpPG | 97.8 | 2.4 | 38.9 | 0.74 | −2.1 | - | - |

| PEEK | - | 0.5 | 40.5 | - | - | - | - |

| PK | - | 4.2 | 29.3 | - | - | - | - |

| Steel | - | 6.8 | 25.2 | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koplin, C.; Schlüter, B.; Jaeger, R. Running-In Effects of Lubricated Polyether Ether Ketone on Steel for Different Spreading and Sorption Tendencies. Lubricants 2023, 11, 135. https://doi.org/10.3390/lubricants11030135

Koplin C, Schlüter B, Jaeger R. Running-In Effects of Lubricated Polyether Ether Ketone on Steel for Different Spreading and Sorption Tendencies. Lubricants. 2023; 11(3):135. https://doi.org/10.3390/lubricants11030135

Chicago/Turabian StyleKoplin, Christof, Bernadette Schlüter, and Raimund Jaeger. 2023. "Running-In Effects of Lubricated Polyether Ether Ketone on Steel for Different Spreading and Sorption Tendencies" Lubricants 11, no. 3: 135. https://doi.org/10.3390/lubricants11030135

APA StyleKoplin, C., Schlüter, B., & Jaeger, R. (2023). Running-In Effects of Lubricated Polyether Ether Ketone on Steel for Different Spreading and Sorption Tendencies. Lubricants, 11(3), 135. https://doi.org/10.3390/lubricants11030135