Microstructure and Wear Resistance of Ni–WC–TiC Alloy Coating Fabricated by Laser

Abstract

:1. Introduction

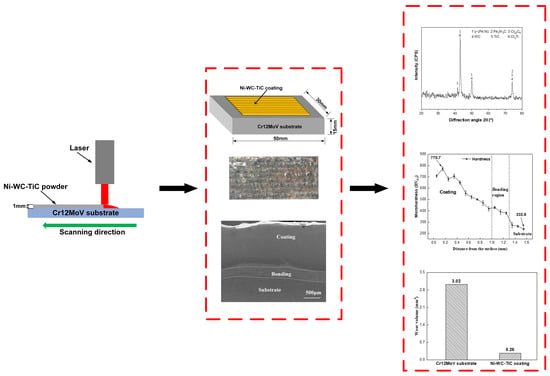

2. Experiment and Methods

2.1. Materials

2.2. Experimental Details

2.3. Surface Morphology

3. Results and Discussion

3.1. Phase Composition

3.2. Microstructure Analysis

3.3. Hardness

- —yield limit of the materials;

- —lattice frictional resistance when moving individual dislocations;

- —related constants;

- —average grain diameter.

3.4. Wear Properties and Mechanisms

4. Conclusions

- (1)

- The Ni–WC–TiC coating was fabricated on the substrate of Cr12MoV die steel by laser. There is a good metallurgical bond between the coating and substrate. The surface morphology of the coating is smooth and uniform;

- (2)

- The coating’s microstructures, from top to bottom, are mainly equiaxed crystal, columnar, and cellular dendrite. The phases of the coating are mainly composed of γ~(Fe, Ni), Cr23C6, WC, TiC, Cr2Ti, and Fe3W3C. The grain boundaries are enriched in Cr and C elements, which include some Cr carbides. There are some W and Ti carbides in grains;

- (3)

- The coating’s maximum hardness is 770.7 HV0.5, which is about 3.3 times the hardness of the substrate. The hardness of the coating surface is higher and gradually decreases down to the substrate. The presence of reinforced phases, such as WC, Fe3W3C, and Cr23C6, can significantly enhance the hardness of the Ni–WC–TiC coating;

- (4)

- The coating wear volume is 0.26 mm3, which is only 8.6% of the substrate. The friction coefficients of the Cr12MoV substrate and Ni–WC–TiC coating are stable at 0.5 and 0.2, respectively. The friction coefficient of the Ni–WC–TiC coating was lower than that of the Cr12MoV substrate at all stages. This demonstrates that the coating has an important role in improving the wear properties of the substrate. The reinforced phases, such as WC, TiC, and Cr23C6, improve the strength of the coating and bring it closer together. The wear mechanisms of both the coating and the substrate are abrasive wear and adhesive wear, but there is no significant brittle spalling of the coating.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.G.; Xu, H.B.; Shi, H.S.; Wu, J.S.; Sun, D.S. Microstructure and properties of spray formed Cr12MoV steel for rolls. J. Mater. Process. Technol. 2001, 111, 79–84. [Google Scholar] [CrossRef]

- Wu, B.; Liu, P.; Duan, J.; Deng, L.; Zeng, X.; Wang, X. Study on picosecond pulse laser ablation of Cr12MoV cold work mold steel. Mater. Des. 2016, 110, 549–557. [Google Scholar] [CrossRef]

- Kong, D.J.; Xie, C.Y. Effect of laser quenching on fatigue properties and fracture morphologies of boronized layer on Cr12MoV steel. Int. J. Fatigue 2015, 80, 391–396. [Google Scholar] [CrossRef]

- Gong, L.; Pan, Y.; Peng, C.; Fu, X.; Jiang, Z.; Jiang, S. Effect of ultrasonic surface rolling processing on wear properties of Cr12MoV steel. Mater. Today Commun. 2022, 33, 104762. [Google Scholar] [CrossRef]

- Feng, A.; Zhao, J.; Lin, J.; Pan, X.; Feng, H.; Wang, C.; Lu, Z. Effect of Laser Quenching-Shock Peening Strengthening on the Microstructure and Mechanical Properties of Cr12MoV Steel. Materials 2022, 15, 6693. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.; Wang, B.; Lin, J. Improvement in Tribological Properties of Cr12MoV Cold Work Die Steel by HVOF Sprayed WC-CoCr Cermet Coatings. Coatings 2019, 9, 825. [Google Scholar] [CrossRef]

- Pang, G.; Li, Z.; Chen, Z. Research on Ion Nitriding Temperature Effect on Wear Resistance of Cr12MoV Steel. Phys. Proc. 2013, 50, 120–123. [Google Scholar] [CrossRef]

- Duraiselvam, M.; Galun, R.; Wesling, V.; Mordike, B.L. Laser clad WC reinforced Ni-based intermetallic-matrix composites to improve cavitation erosion resistance. J. Laser Appl. 2006, 18, 297–304. [Google Scholar] [CrossRef]

- Kim, C.K.; Choi, S.G.; Kim, J.H.; Jo, H.J.; Jo, Y.-C.; Choi, S.-P.; Cho, Y.T. Characterization of surface modification by laser cladding using low melting point metal. J. Ind. Eng. Chem. 2020, 87, 54–59. [Google Scholar] [CrossRef]

- Ma, N.-N.; Chen, J.; Huang, Z.-R.; Li, Y.-J.; Liu, M.; Zhu, M.; Liu, X.-J.; Chen, Z.-M.; Zhu, Y.-Z. Joining of sintered SiC ceramics at a lower temperature using borosilicate glass with laser cladding Si modification layer. J. Eur. Ceram. Soc. 2020, 41, 2974–2978. [Google Scholar] [CrossRef]

- Yin, L.; Ma, X.; Tang, G.; Fu, Z.; Yang, S.; Wang, T.; Wang, L.; Li, L. Characterization of carburized 14Cr14Co13Mo4 stainless steel by low pressure carburizing. Surf. Coat. Technol. 2019, 358, 654–660. [Google Scholar] [CrossRef]

- Lin, Z.; Li, S.-J.; Sun, F.; Ba, D.-C.; Li, X.-C. Surface characteristics of a dental implant modified by low energy oxygen ion implantation. Surf. Coat. Technol. 2019, 365, 208–213. [Google Scholar] [CrossRef]

- Wang, L.; Chen, C.; Yeh, J.; Ke, S. The microstructure and strengthening mechanism of thermal spray coating NixCo0.6Fe0.2CrySizAlTi0.2 high-entropy alloys. Mater. Chem. Phys. 2011, 126, 880–885. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Hu, Z.; Tan, N.; Zhang, G.; Li, Q. Microstructure and properties of laser cladding turning machining scrap. Opt. Laser Technol. 2022, 147, 107614. [Google Scholar] [CrossRef]

- Gao, W.; Chang, C.; Li, G.; Xue, Y.; Wang, J.; Zhang, Z.; Lin, X. Study on the laser cladding of FeCrNi coating. Optik 2019, 178, 950–957. [Google Scholar] [CrossRef]

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Hadavi, E.; Rolfe, B. Laser subtractive and laser powder bed fusion of metals: Review of process and production features. Rapid Prototyp. J. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Yan, X.-L.; Dong, S.-Y.; Xu, B.-S.; Cao, Y. Progress and Challenges of Ultrasonic Testing for Stress in Remanufacturing Laser Cladding Coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Hagino, H. Effects of the ambient oxygen concentration on WC-12Co cermet coatings fabricated by laser cladding. Opt. Laser Technol. 2021, 139, 106922. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, C.; Zhao, Z.; Dong, C.; Zhang, Y. New Ni-based superalloys designed for laser additive manufacturing. J. Alloys Compd. 2021, 861, 157979. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, G.; Wang, Y.; Li, H.; Qin, Z.; Lu, X. Crack-free Fe-based amorphous coating synthesized by laser cladding. Mater. Lett. 2018, 210, 46–50. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J. Fabrication of Co-Based Coatings on Titanium Alloy by Laser Cladding with CeO2 Addition. Mater. Manuf. Process. 2016, 31, 1461–1467. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Xuan, F.Z. Fabrication of TiC reinforced Ni based coating by laser cladding. Surf. Eng. 2012, 28, 560–563. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, Y.; Lu, B.; Xu, M.; Xu, J. Microstructure and Properties of the Interface Area in the Laser Cladded Ni Based Coatings on the 1Cr10Mo1NiWVNbN Steel. Metals 2017, 7, 175. [Google Scholar] [CrossRef]

- Yue, T.; Li, T. Laser cladding of Ni/Cu/Al functionally graded coating on magnesium substrate. Surf. Coat. Technol. 2008, 202, 3043–3049. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, S.; Huang, Y.; Yang, L. Laser hot-wire cladding of Ni/WC composite coatings with a tubular cored wire. J. Mater. Process. Technol. 2021, 298, 117273. [Google Scholar] [CrossRef]

- Farzaneh, A.; Khorasani, M.; Farabi, E.; Gibson, I.; Leary, M.; Ghasemi, A.; Rolfe, B. Sandwich structure printing of Ti-Ni-Ti by directed energy deposition. Virtual Phys. Prototyp. 2022, 17, 1006–1030. [Google Scholar] [CrossRef]

- Shengbin, Z.; Chenpeng, J.; Yuxue, Y.; Lixin, W.; Yiming, H.; Lijun, Y. Effects of laser remelting on microstructural characteristics of Ni-WC composite coatings produced by laser hot wire cladding. J. Alloys Compd. 2022, 908, 164612. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and wear behavior of laser cladded WC-Co and Ni/WC-Co deposits at high temperature. Int. J. Refract. Met. Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Li, G.; Tang, L. Friction and wear behavior of Ni-based alloy coatings with different amount of WC–TiC ceramic particles. J. Mater. Sci. 2023, 58, 1116–1126. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Z.; Pang, M. Effect of WC content on laser cladding Ni-based coating on the surface of stainless steel. Mater. Today Commun. 2022, 31, 103357. [Google Scholar] [CrossRef]

- Hu, Z.; Li, Y.; Lu, B.; Tan, N.; Cai, L.; Yong, Q. Effect of WC content on microstructure and properties of high-speed laser cladding Ni-based coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- Jiang, J.; Pang, X.; Zhou, J.; Li, B.; Zhou, F. Optical performance and corrosion resistance of TiN/Ni multiphase cermet by laser cladding. Opt. Laser Technol. 2021, 143, 107308. [Google Scholar] [CrossRef]

- Cai, Y.; Luo, Z.; Chen, Y.; Ao, S. Influence of CeO2 on tribological behaviour of TiC/Fe-based composite coating. Surf. Eng. 2017, 33, 936–943. [Google Scholar] [CrossRef]

- Liu, D.; Li, L.; Li, F.; Chen, Y. WCp/Fe metal matrix composites produced by laser melt injection. Surf. Coat. Technol. 2008, 202, 1771–1777. [Google Scholar] [CrossRef]

- Thawari, N.; Gullipalli, C.; Katiyar, J.K.; Gupta, T. Influence of buffer layer on surface and tribomechanical properties of laser cladded Stellite 6. Mater. Sci. Eng. B 2021, 263, 114799. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.-T.; Li, R.-D.; Niu, P.-D.; Wang, M.-B.; Yuan, T.-C.; Li, K. Hall-Petch relationship in selective laser melting additively manufactured metals: Using grain or cell size? J. Cent. South Univ. 2021, 28, 1043–1057. [Google Scholar] [CrossRef]

- Long, S.-L.; Liang, Y.-L.; Jiang, Y.; Liang, Y.; Yang, M.; Yi, Y.-L. Effect of quenching temperature on martensite multi-level microstructures and properties of strength and toughness in 20CrNi2Mo steel. Mater. Sci. Eng. A 2016, 676, 38–47. [Google Scholar] [CrossRef]

- Jie, M.; Gao, Y.L. Study on Hardness and Wear Resistance of Laser Cladding Al-Si Coating. Appl. Laser 2016, 35, 629–633. [Google Scholar] [CrossRef]

| Cr | C | V | Mo | Si | Mn | Ni | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 11.5~13 | 1.4~1.6 | ≤1.0 | 0.7~1.2 | ≤0.6 | ≤0.6 | ≤0.25 | ≤0.03 | ≤0.03 | Bal. |

| Cr | Fe | Si | C | B | Ni |

|---|---|---|---|---|---|

| 16.5 | 7.0 | 4.0 | 0.8 | 4.0 | Bal. |

| Parameters | Laser Power (kW) | Scan Speed (mm/min) | Spot Diameter (mm) | Overlapping Ratio |

|---|---|---|---|---|

| Value | 1.65 | 100 | 3 | 30% |

| Parameters | Wear Time (min) | Frequency (Hz) | Load (N) |

|---|---|---|---|

| Value | 30 | 2 | 3 |

| Point | Fe | Ni | W | C | Ti | Cr | Si |

|---|---|---|---|---|---|---|---|

| D | 47.14 | 20.32 | 8.86 | 11.46 | 1.19 | 9.49 | 1.54 |

| E | 20.97 | 12.19 | 21.12 | 14.81 | 23.75 | 6.54 | 0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, Z.; Li, G.; Du, F.; Yu, M. Microstructure and Wear Resistance of Ni–WC–TiC Alloy Coating Fabricated by Laser. Lubricants 2023, 11, 170. https://doi.org/10.3390/lubricants11040170

Liu Y, Li Z, Li G, Du F, Yu M. Microstructure and Wear Resistance of Ni–WC–TiC Alloy Coating Fabricated by Laser. Lubricants. 2023; 11(4):170. https://doi.org/10.3390/lubricants11040170

Chicago/Turabian StyleLiu, Yu, Zeyu Li, Guohui Li, Fengming Du, and Miao Yu. 2023. "Microstructure and Wear Resistance of Ni–WC–TiC Alloy Coating Fabricated by Laser" Lubricants 11, no. 4: 170. https://doi.org/10.3390/lubricants11040170

APA StyleLiu, Y., Li, Z., Li, G., Du, F., & Yu, M. (2023). Microstructure and Wear Resistance of Ni–WC–TiC Alloy Coating Fabricated by Laser. Lubricants, 11(4), 170. https://doi.org/10.3390/lubricants11040170