Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings

Abstract

:1. Introduction

2. Experiments

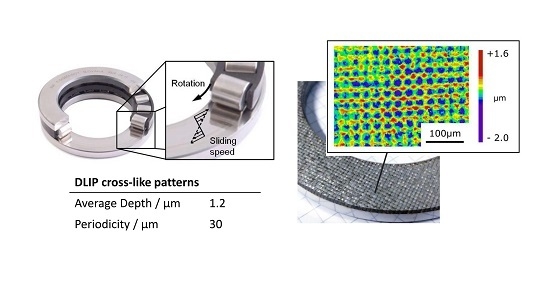

2.1. FE8 Test Rig

2.2. Direct Laser Interference Patterning (DLIP)

2.3. Characterization

3. Results and Discussions

3.1. Surface topography

3.2. Tribological Performance

3.3. Raman Spectroscopy

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hsu, S.M.; Gates, R.S. Boundary lubricating films: Formation and lubrication mechanism. Tribol. Int. 2005, 38, 305–312. [Google Scholar] [CrossRef]

- Spikes, H.A. Boundary Lubrication and Boundary Films. Tribol. Ser. 1993, 25, 331–346. [Google Scholar]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Hsu, S.M. Boundary Lubrication of Materials. MRS Bull. 1991, 16, 54–58. [Google Scholar] [CrossRef]

- Martin, J.M. Antiwear mechanisms of zinc dithiophosphate: A chemical hardness approach. Tribol. Lett. 1999, 6, 1–8. [Google Scholar] [CrossRef]

- Fuller, M.; Bancroft, G.M.; Tan, K.H.; Yamaguchi, E.S.; Ryason, P.R.; Wiliermet, P.A. Chemical characterization of chemical and thermal films generated from neutral and basic ZDDPs using X-ray absorption spectroscopy. Tribol. Int. 1997, 30, 305–315. [Google Scholar] [CrossRef]

- Fujita, H.; Spikes, H.A. The formation of zinc dithiophosphate antiwear films. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2004, 218, 265–278. [Google Scholar] [CrossRef]

- Bancroft, G.M.; Kasrai, M.; Fuller, M.; Yin, Z.; Fyfe, K.; Tan, K.H. Mechanisms of tribochemical film formation: Stability of tribo- and thermally-generated ZDDP films. Tribol. Lett. 1997, 3, 47–51. [Google Scholar] [CrossRef]

- Gosvami, N.N.; Bares, J.A.; Mangolini, F.; Konicek, A.R.; Yablon, D.G.; Carpick, R.W. Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 2015, 348, 102–106. [Google Scholar] [CrossRef] [PubMed]

- Gachot, C.; Hsu, C.; Suárez, S.; Grützmacher, P.; Rosenkranz, A.; Stratmann, A.; Jacobs, G. Microstructural and Chemical Characterization of the Tribolayer Formation in Highly Loaded Cylindrical Roller Thrust Bearings. Lubricants 2016, 4, 19. [Google Scholar] [CrossRef]

- Spikes, H. The history and mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Lasagni, A.; Holzapfel, C.; Weirich, T.; Mücklich, F. Laser interference metallurgy: A new method for periodic surface microstructure design on multilayered metallic thin films. Appl. Surf. Sci. 2007, 253, 8070–8074. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G.; Brizmer, V.; Kligerman, Y. Experimental investigation of laser surface textured parallel thrust bearings. Tribol. Lett. 2004, 17, 295–300. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. Micromechanical and tribological characterization of hard amorphous carbon coatings as thin as 5 nm for magnetic recording heads. Wear 1998, 220, 51–58. [Google Scholar] [CrossRef]

- Mücklich, F.; Lasagni, A.; Daniel, C. Laser interference metallurgy—Periodic surface patterning and formation of intermetallics. Intermetallics 2005, 13, 437–442. [Google Scholar] [CrossRef]

- Duarte, M.; Lasagni, A.; Giovanelli, R.; Narciso, J.; Louis, E.; Mücklich, F. Increasing lubricant film lifetime by grooving periodical patterns using laser interference metallurgy. Adv. Eng. Mater. 2008, 10, 554–558. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Jaeger, S.; Gachot, C.; Vogel, S.; Mücklich, F. Wear Behavior of Laser-Patterned Piston Rings in Squeeze Film Dampers. Adv. Eng. Mater. 2015, 17, 1208–1214. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Reinert, L.; Ramos-Moore, E.; Souza, N.; Müser, M.H.; Mücklich, F. Dry friction between laser-patterned surfaces: Role of alignment, structural wavelength and surface chemistry. Tribol. Lett. 2013, 49, 193–202. [Google Scholar] [CrossRef]

- Trinh, K.E.; Tsipenyuk, A.; Varenberg, M.; Rosenkranz, A.; Souza, N.; Mücklich, F. Wear debris and electrical resistance in textured Sn-coated Cu contacts subjected to fretting. Wear 2015, 344–345, 86–98. [Google Scholar] [CrossRef]

- Hans, M.; Müller, F.; Grandthyll, S.; Hüfner, S.; Mücklich, F. Anisotropic wetting of copper alloys induced by one-step laser micro-patterning. Appl. Surf. Sci. 2012, 263, 416–422. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Gachot, C. How to guide lubricants—Tailored laser surface patterns on stainless steel. Appl. Surf. Sci. 2016, 370, 59–66. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Stratmann, A.; Gachot, C.; Burghardt, G.; Jacobs, G.; Mücklich, F. Improved wear behavior of cylindrical roller thrust bearings by three-beam laser interference. Adv. Eng. Mater. 2016, 18, 854–862. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R.; Whitaker, A.V. Elasto-hydrodynamic Lubrication: A Survey of Isothermal Solutions. J. Mech. Eng. Sci. 1962, 4, 121–126. [Google Scholar] [CrossRef]

- Stratmann, A.; Jacobs, G.; Hsu, C.J.; Gachot, C.; Burghardt, G. Antiwear tribofilm growth in rolling bearings under boundary lubrication conditions. Tribol. Int. 2017, 113, 43–49. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- De Barros, M.I.; Bouchet, J.; Raoult, I.; Le Mogne, T.; Martin, J.M.; Kasrai, M.; Yamada, Y. Friction reduction by metal sulfides in boundary lubrication studied by XPS and XANES analyses. Wear 2003, 254, 863–870. [Google Scholar] [CrossRef]

- Brafman, O.; Mitra, S.S. Raman effect in wurtzite- and zinc-blende-type ZnS single crystals. Phys. Rev. 1968, 171, 931–934. [Google Scholar] [CrossRef]

- Ushioda, S. Raman scattering from phonons in iron pyrite (FeS2). Solid State Commun. 1972, 10, 307–310. [Google Scholar] [CrossRef]

- Berkani, S.; Dassenoy, F.; Minfray, C.; Martin, J.M.; Cardon, H.; Montagnac, G.; Reynard, B. Structural changes in tribo-stressed zinc polyphosphates. Tribol. Lett. 2013, 51, 489–498. [Google Scholar] [CrossRef]

- De Faria, D.L.A.; Silva, S.V.; de Oliveira, M.T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J. Raman Spectrosc. 1997, 28, 873–878. [Google Scholar] [CrossRef]

| Prior to Rubbing | After Rubbing | |||||

|---|---|---|---|---|---|---|

| Rrms/µm | Rtm/µm | Rsk | Rrms/µm | Rtm/µm | Rsk | |

| Reference | 0.07 ± 0.01 | 0.28 ± 0.05 | −0.60 ± 0.05 | 0.08 ± 0.01 | 0.03 ± 0.01 | −0.88 ± 0.27 |

| Cross-patterned | 0.30 ± 0.02 | 1.39 ± 0.07 | 0.15 ± 0.13 | 0.20 ± 0.01 | 0.81 ± 0.07 | −0.23 ± 0.04 |

| Washer Mass Loss ∆m/mg | Roller Set Mass Loss ∆m/mg | |

|---|---|---|

| Reference | 62.5 | 80.5 |

| Cross-patterned | 0.1 | 0.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, C.-J.; Stratmann, A.; Rosenkranz, A.; Gachot, C. Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings. Lubricants 2017, 5, 39. https://doi.org/10.3390/lubricants5040039

Hsu C-J, Stratmann A, Rosenkranz A, Gachot C. Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings. Lubricants. 2017; 5(4):39. https://doi.org/10.3390/lubricants5040039

Chicago/Turabian StyleHsu, Chia-Jui, Andreas Stratmann, Andreas Rosenkranz, and Carsten Gachot. 2017. "Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings" Lubricants 5, no. 4: 39. https://doi.org/10.3390/lubricants5040039

APA StyleHsu, C. -J., Stratmann, A., Rosenkranz, A., & Gachot, C. (2017). Enhanced Growth of ZDDP-Based Tribofilms on Laser-Interference Patterned Cylinder Roller Bearings. Lubricants, 5(4), 39. https://doi.org/10.3390/lubricants5040039