Contact Mechanics for Solids with Randomly Rough Surfaces and Plasticity

Abstract

:1. Introduction

2. Experiments

2.1. UHMWPE

2.2. UHMWPE Repeat

2.3. Nylon 66

2.4. Polypropylene (PP)

2.5. Polypropylene Repeat

2.6. Polytetrafluorethylene (PTFE)

2.7. Polycarbonate (PC)

3. Theory

3.1. Asperity Deformations and Contact Area

3.2. Macroscopic Deformations and Surface Curvature

3.3. Finite-Element Analysis of Macroscopic Deformations

4. Summary and Conclusions

- (1)

- For all the polymer balls, which are semi-crystalline, the short scale (micrometer wavelength) surface roughness was nearly the same before and after the ball was squeezed against the flat surface. We attributed this to inhomogeneous plastic flow at short (micrometer) length scales.

- (2)

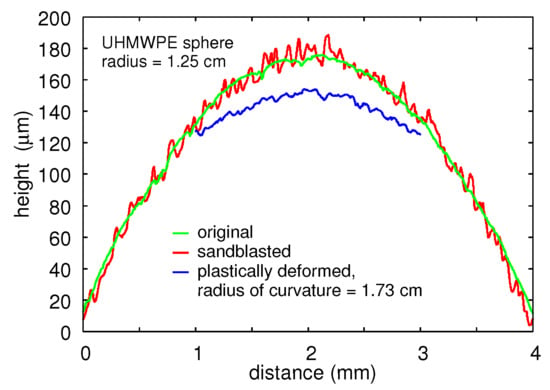

- For UHMWPE, we observed an elastic rebound of the plastically deformed surface region, resulting in a locally spherical surface, but with an increased curvature radius as compared to the undeformed ball radius; this result was reproduced by the FEM calculations.

- (3)

- The height probability distributions for many of the polymer balls show that the plastic flow reduces both the peak heights and valley depth in a similar way. This could be related to strain hardening, which may result in an upward (volume conserving) plastic flow relatively far away (here at the bottom of the valleys) from the asperity contact regions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Persson, B.N.J. Sliding Friction: Physical Principles and Applications; Springer: Heidelberg, Germany, 2000. [Google Scholar]

- Gnecco, E.; Meyer, E. Elements of Friction Theory and Nanotribology; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Israelachvili, J.N. Intermolecular and Surface Forces, 3rd ed.; Academic: London, UK, 2011. [Google Scholar]

- Barber, J.R. Contact Mechanics (Solid Mechanics and Its Applications); Springer: Heidelberg, Germany, 2018. [Google Scholar]

- Persson, B.N.J. Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 2006, 61, 201–207. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Albohr, O.; Tartaglino, U.; Volokitin, A.I.; Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 2005, 17, R1. [Google Scholar] [CrossRef] [PubMed]

- Creton, C.; Ciccotti, M. Fracture and adhesion of soft materials: A review. Rep. Prog. Phys. 2016, 79, 046601. [Google Scholar] [CrossRef] [PubMed]

- Spolenak, R.; Gorb, S.; Gao, H.; Arzt, E. Effects of contact shape on the scaling of biological attachments. Proc. R. Soc. A Math. Phys. Eng. Sci. 2005, 461, 305–319. [Google Scholar] [CrossRef]

- Pastewka, L.; Robbins, M.O. Contact between rough surfaces and a criterion for macroscopic adhesion. Proc. Natl. Acad. Sci. USA 2014, 111, 3298–3303. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Müser, M.H.; Dapp, W.B.; Bugnicourt, R.; Sainsot, P.; Lesaffre, N.; Lubrecht, T.A.; Persson, B.N.J.; Harris, K.; Bennett, A.; Schulze, K.; et al. Meeting the contact-mechanics challenge. Tribol. Lett. 2017, 65, 118. [Google Scholar] [CrossRef]

- Vakis, A.I.; Yastrebov, V.A.; Scheibert, J.; Minfray, C.; Nicola, L.; Dini, D.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Tiwari, A. Adhesion, Friction and Leakage in Contacts with Elastomers. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Persson, B.N.J. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef] [Green Version]

- Persson, B.N.J. Leakage of Metallic Seals: Role of Plastic Deformations. Tribol. Lett. 2016, 63, 42. [Google Scholar] [CrossRef]

- Ráfols, F.P.; Larsson, R.; Riet, E.J.V.; Almqvist, A. On the loading and unloading of metal-to-metal seals: A two-scale stochastic approach. Proc. Inst. Mech. Eng. Part J Eng. Tribol. 2018, 232, 1525–1537. [Google Scholar] [CrossRef] [Green Version]

- Persson, B.N.J. On the elastic energy and stress correlation in the contact between elastic solids with randomly rough surfaces. J. Phys. Condens. Matter 2008, 20, 312001. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Clarendon Press: Oxford, UK, 1951. [Google Scholar]

- Medel, F.J.; Martinez, M.J.; Alonso, P.J.; Rubin, J.; Pascual, F.J.; Puertola, J.A. Microstructure, thermooxidation and mechanical behavior of a novel highly linear, vitamin E stabilized, UHMWPE. Mater. Sci. Eng. C 2013, 33, 182–188. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Venugopalan, S.P.; Irani, N.; Nicola, L. Plastic contact of self-affine surfaces: Persson’s theory versus discrete dislocation plasticity. J. Mech. Phys. Solids 2019, 132, 103676. [Google Scholar] [CrossRef]

- Bowden, F.; Tabor, D. The Friction and Lubrication of Solids; Number v. 1 in Oxford Classic Texts in the Ph; Clarendon Press: Oxford, UK, 2001. [Google Scholar]

- Greenwood, J.A. Contact of rough surfaces. In Fundamentals of Friction: Macroscopic and Microscopic Processes; Kluwer: Dordrecht, The Netherlands, 1992; pp. 37–56. [Google Scholar]

- Falk, M.L.; Langer, J.S. Dynamics of viscoplastic deformation in amorphous solids. Phys. Rev. E 1998, 57, 7192. [Google Scholar] [CrossRef]

- Physical Testing of Plastics; Crompton, T.R. (Ed.) Smithers Rapra Technology: Shropshire, UK, 2012; ISBN1 978-1-84735-486-0. ISBN2 1-84735-486-6. Available online: https://www.smithersrapra.com/SmithersRapra/media/Sample-Chapters/Physical-Testing-of-Plastics.pdf (accessed on 9 September 2019).

- Vu-Quoc, L.; Zhang, X.; Lesburg, L. A Normal Force-Displacement Model for Contacting Spheres Accounting for Plastic Deformation: Force-Driven Formulation. J. Appl. Mech. 2000, 67, 363–371. [Google Scholar] [CrossRef]

- Fanconi, B.; Tesk, J.A.; Guthrie, W. Reference Material 8457, Ultra High Molecular Weight Polyethylene 0.5 cm Cubes. Available online: https://ws680.nist.gov/publication/get_pdf.cfm?pub_id=852105 (accessed on 9 September 2019).

- Kogut, L.; Etsion, I. Elastic-Plastic Contact Analysis of a Sphere and a Rigid Flat. ASME J. Appl. Mech. 2002, 69, 657–662. [Google Scholar] [CrossRef] [Green Version]

- Ghaednia, H.; Wang, X.; Saha, S.; Xu, Y.; Sharma, A.; Jackson, R.L. A Review of Elastic-Plastic Contact Mechanics. Appl. Mech. Rev. 2017, 69, 060804. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Pruitt, L.; Jewett, C.W.; Crawford, R.P.; Crane, D.J.; Edidin, A.A. The yielding, plastic flow, and fracture behavior of ultra-high molecular weight polyethylene used in total joint replacements. Biomaterials 1998, 19, 1989–2003. [Google Scholar] [CrossRef]

| Polymer | (mm) | (MPa) | rms (m) | |

|---|---|---|---|---|

| PTFE | 5.8 (3.0) | 17 1(64) | 29 (45) | 3.0 [2.3] |

| UHMWPE | 4.5 (2.7) | 28 1(82) | 47 (50) | 4.1 [1.6] |

| PP | 3.2 (2.2) | 56 (117) | 25 (50) | 7.8 [4.1] |

| Nylon 66 | 3.2 (1.3) | 56 (324) | 19 (30) | 2.0 [2.0] |

| PC | 2.7 (1.5) | 77 (258) | 12 (43) | 2.5 [1.6] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwari, A.; Wang, A.; Müser, M.H.; Persson, B.N.J. Contact Mechanics for Solids with Randomly Rough Surfaces and Plasticity. Lubricants 2019, 7, 90. https://doi.org/10.3390/lubricants7100090

Tiwari A, Wang A, Müser MH, Persson BNJ. Contact Mechanics for Solids with Randomly Rough Surfaces and Plasticity. Lubricants. 2019; 7(10):90. https://doi.org/10.3390/lubricants7100090

Chicago/Turabian StyleTiwari, Avinash, Anle Wang, Martin H. Müser, and B. N. J. Persson. 2019. "Contact Mechanics for Solids with Randomly Rough Surfaces and Plasticity" Lubricants 7, no. 10: 90. https://doi.org/10.3390/lubricants7100090

APA StyleTiwari, A., Wang, A., Müser, M. H., & Persson, B. N. J. (2019). Contact Mechanics for Solids with Randomly Rough Surfaces and Plasticity. Lubricants, 7(10), 90. https://doi.org/10.3390/lubricants7100090