Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions †

Abstract

:1. Introduction

2. Methods and Lubricants

3. Results

3.1. Measurement Results at Constant Rolling Speed

3.2. Measurement Results at Increasing Rolling Speed

4. Discussion

5. Conclusions

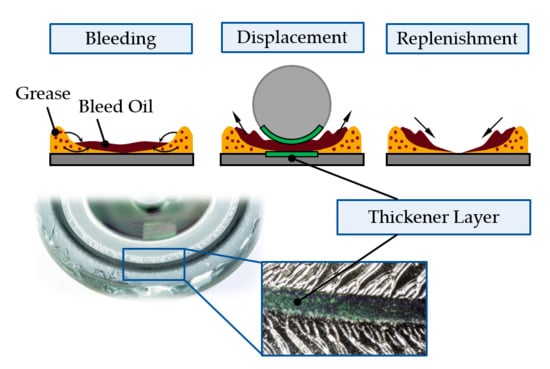

- The film thickness at a constant rolling speed of 100 mm/s could be stepwise-reduced by a closer position of the second ball to the measuring ball. Thus, the presented model in Figure 2 could be confirmed. It can be pointed out that the film formation in grease lubricated EHD contacts under starved conditions depends on the lubricant supply, which is reduced by a higher over rolling frequency.

- Since the film thickness was not reduced towards a zero-level using a setup with the second ball, even at high over rolling frequencies >3.0 Hz, it is concluded that the residual film thickness of approximately 40–60 nm is formed by a deposited thickener layer on the surfaces. The presence of a semi-solid thickener layer at the rolling track could be verified by measurement results at zero speed, which is in accordance to published studies [6,8,13,15,21,23,32].

- Moreover, the film thickness does not drop below approximately 60 nm, even when increasing the rolling speed and thereby the over rolling frequency up to 10 Hz using the setup with two ball specimens. From these results, it can be concluded that even in the range of starvation, the thickener layer is present and separates the contacting surfaces.

- Using the test setup with the second ball, the effect of replenishment on the film formation with dependence on the over rolling frequency, i.e., replenishment time, could be emphasized. It has been shown that the lubricating film formation as well as the onset of starvation depends on the over rolling frequency, i.e., replenishment time. Additionally, it can be emphasized that the minimum time for a reflow ensuring a sufficient lubricant supply can be determined to be approximately >2.0 s for the investigated grease, which is in accordance with results for oil lubricated contacts under starved conditions in [29].

- Moreover, with these measurement results it could be shown, that an increase in film thickness at speeds >1000 mm/s does not refer to a recovery phase due to shear degradation. It can be pointed out that centrifugal forces become dominant at high rotational speeds and push the grease on the disc into the contact area, which leads to an increase in film thickness.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wedeven, L.D.; Evans, D.; Cameron, A. Optical analysis of ball bearing starvation. J. Lubr. Technol. 1971, 93, 349–361. [Google Scholar] [CrossRef]

- Kauzlarich, J.J.; Greenwood, J.A. Elastohydrodynamic lubrication with herschel-bulkley model greases. ASLE Trans. 1972, 15, 269–277. [Google Scholar] [CrossRef]

- Lugt, P.M. A review on grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Cann, P.M.; Spikes, H.A. Film thickness measurements of lubrication greases under normally starved conditions. NLGI Spokesm. 1992, 56, 21–27. [Google Scholar]

- Scarlett, N.A. Use of Grease in Rolling Bearings. Proc. Inst. Mech. Eng. 1967, 182, 585–624. [Google Scholar] [CrossRef]

- Cann, P.M.E. Understanding grease lubrication. Tribol. Ser. 1996, 31, 573–581. [Google Scholar] [CrossRef]

- Cann, P.M. Starved grease lubrication of rolling contacts. Tribol. Trans. 1999, 42, 867–873. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Kuhn, M.; Rankl, M.; Spallek, R. Film forming behavior of greases under starved and fully flooded EHL conditions. Tribol. Trans. 2016, 59, 62–71. [Google Scholar] [CrossRef]

- Couronné, I.; Vergne, P.; Mazuyer, D.; Truong-Dinh, N.; Girodin, D. Effects of grease composition and structure on film thickness in rolling contact. Tribol. Trans. 2003, 46, 31–36. [Google Scholar] [CrossRef]

- Kaneta, M.; Ogata, T.; Takubo, Y.; Naka, M. Effects of a thickener structure on grease elastohydrodynamic lubrication films. Proc. Inst. Mech. Eng. 2000, 214, 327–336. [Google Scholar] [CrossRef]

- Kimura, Y.; Endo, T.; Dong, D. EHL with Grease at Low Speeds. In Advanced Tribology; Luo, J., Meng, Y., Shao, T., Zhao, Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 15–19. [Google Scholar]

- Cyriac, F.; Lugt, P.M.; Bosman, R.; Padberg, C.J.; Venner, C.H. Effect of thickener particle geometry and concentration on the grease EHL film thickness at medium speeds. Tribol. Lett. 2016, 61, 1–13. [Google Scholar] [CrossRef]

- Cann, P.M. Grease lubrication of rolling element bearings—Role of the grease thickener. Lubr. Sci. 2007, 19, 183–196. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Lugt, P.M.; Pasaribu, H.R.; Cen, H. Film thickness in grease lubricated slow rotating rolling bearings. Tribol. Int. 2014, 74, 7–19. [Google Scholar] [CrossRef]

- Chen, J.; Tanaka, H.; Sugimura, J. Experimental study of starvation and flow behavior in grease-lubricated EHD contact. Tribol. Online 2015, 10, 48–55. [Google Scholar] [CrossRef]

- Cann, P.M.E. Thin-film grease lubrication. Proc. Inst. Mech. Eng. Conf. 1999, 213, 405–416. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M.; Morales-Espejel, G. On the film thickness of grease-lubricated contacts at low speeds. Tribol. Trans. 2014, 57, 668–678. [Google Scholar] [CrossRef]

- Fischer, D.; Jacobs, G.; Stratmann, A.; Burghardt, G. Effect of base oil type in grease composition on the lubricating film formation in EHD contacts. Lubricants 2018, 6, 32. [Google Scholar] [CrossRef]

- Wilson, A.R. The Relative Thickness of Grease and Oil Films in Rolling Bearings. Proc. Inst. Mech. Eng. 1979, 193, 185–192. [Google Scholar] [CrossRef]

- International Organization for Standardization. Rolling Bearings—Dynamic Load Ratings and Rating Life (ISO 281:2007); DIN ISO 281:2010-10; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Cann, P.M. Starvation and reflow in a grease-lubricated elastohydrodynamic contact. Tribol. Trans. 1996, 39, 698–704. [Google Scholar] [CrossRef]

- Baker, A. Grease bleeding—A factor in ball bearing performance. NLGI Spokesm. 1958, 22, 271–277. [Google Scholar]

- Hurley, S.; Cann, P.M. IR spectroscopic analysis of grease lubricant films in rolling contacts. Tribol. Ser. 1999, 36, 589–600. [Google Scholar] [CrossRef]

- Cann, P.M.; Chevalier, F.; Lubrecht, A.A. Track depletion and replenishment in a grease lubricated point contact: A quantitative analysis. Tribol. Ser. 1997, 32, 405–413. [Google Scholar] [CrossRef]

- Chiu, Y.P. An analysis and prediction of lubricant film starvation in rolling contact systems. ASLE Trans. 1974, 17, 22–35. [Google Scholar] [CrossRef]

- Jacod, B.; Pubilier, F.; Cann, P.M.; Lubrecht, A.A. An analysis of track replenishment mechanisms in the starved regime. Tribol. Ser. 1999, 36, 483–492. [Google Scholar] [CrossRef]

- Pemberton, J.; Cameron, A. A mechanism of fluid replenishment in elastohydrodynamic contacts. Wear 1976, 37, 184–190. [Google Scholar] [CrossRef]

- Kostal, D.; Sperka, P.; Svoboda, P.; Krupka, I.; Hartl, M. Experimental observation of elastohydrodynamically lubricated contacts replenishment. MM Sci. J. 2015, 3, 640–644. [Google Scholar] [CrossRef]

- Kostal, D.; Sperka, P.; Svoboda, P.; Krupka, I.; Hartl, M. Influence of lubricant inlet film thickness on elastohydrodynamically lubricated contact starvation. J. Tribol. 2017, 139, 1–6. [Google Scholar] [CrossRef]

- Huang, L.; Guo, D.; Shizhu, W. Film thickness decay and replenishment in point contact lubricated with different greases. Tribol. Int. 2016, 93, 620–627. [Google Scholar] [CrossRef]

- Mérieux, J.-S.; Hurley, S.; Lubrecht, A.A.; Cann, P.M. Shear-degradation of grease and base oil availability in starved EHL lubrication. Tribol. Ser. 2000, 38, 581–588. [Google Scholar] [CrossRef]

- Lubrecht, T.; Mazuyer, D.; Cann, P. Starved elastohydrodynamic lubrication theory: Application to emulsions and greases. C. R. Acad. Sci. Ser. IV Phys. 2001, 2, 717–728. [Google Scholar] [CrossRef]

- Huang, L.; Guo, D.; Liu, X.; Xie, G.; Wan, G.T.Y.; Wen, S. Effects of nano thickener deposited film on the behaviour of starvation and replenishment of lubricating greases. Friction 2016, 4, 313–323. [Google Scholar] [CrossRef]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; John Wiley & Sons, Ltd.: Chichester, UK, 2013; ISBN 978-1-118-35391-2. [Google Scholar]

- Johnston, G.J.; Wayte, R.; Spikes, H.A. The measurement and study of very thin lubricant films in concentrated contacts. Tribol. Trans. 1991, 34, 187–194. [Google Scholar] [CrossRef]

- Cousseau, T.; Björling, M.; Graça, B.; Campos, A.; Seabra, J.; Larsson, R. Film thickness in a ball-on-disc contact lubricated with greases, bleed oils and base oils. Tribol. Int. 2012, 53, 53–60. [Google Scholar] [CrossRef]

- Åström, H.; Isaksson, O.; Höglund, E. Video recordings of an EHD point contact lubricated with grease. Tribol. Int. 1991, 24, 179–184. [Google Scholar] [CrossRef]

- Åström, H.; Östensen, J.O.; Höglund, E. Lubricating grease replenishment in an elastohydrodynamic point contact. J. Tribol. 1993, 115, 501–506. [Google Scholar] [CrossRef]

- Gonçalves, D.; Campos, A.; Seabra, J. An Experimental Study on Starved Grease Lubricated Contacts. Lubricants 2018, 6, 82. [Google Scholar] [CrossRef]

- Svoboda, P.; Kostal, D.; Kunak, J.; Krupka, I. Study of grease behaviour in starved elastohydrodynamically lubricated contact. MM Sci. J. 2014, 2, 465–469. [Google Scholar] [CrossRef]

- Cann, P.M.; Damiens, B.; Lubrecht, A.A. The transition between fully flooded and starved regimes in EHL. Tribol. Int. 2004, 37, 859–864. [Google Scholar] [CrossRef]

- Li, X.M.; Guo, F.; Wong, P.L.; Zhao, Y. Regulation of lubricant supply by wettability gradient in rolling EHL contacts. Tribol. Inte. 2018, 120, 565–574. [Google Scholar] [CrossRef]

| Parameter | Glass Disc | Steel Ball |

|---|---|---|

| Modulus of Elasticity | 75 MPa | 207 MPa |

| Poisson Ratio | 0.22 | 0.29 |

| Surface Roughness (Ra) | 0.02 µm | 0.02 µm |

| Lubricant | Thickener Type | Thickener Content | Base Oil Type | Viscosity at 40 °C |

|---|---|---|---|---|

| Base Oil | – | – | PAO | 98 mm2/s |

| Grease | Lithium Complex | 22 wt.% | PAO | 98 mm2/s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, D.; Mues, H.; Jacobs, G.; Stratmann, A. Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions. Lubricants 2019, 7, 19. https://doi.org/10.3390/lubricants7020019

Fischer D, Mues H, Jacobs G, Stratmann A. Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions. Lubricants. 2019; 7(2):19. https://doi.org/10.3390/lubricants7020019

Chicago/Turabian StyleFischer, Dennis, Helko Mues, Georg Jacobs, and Andreas Stratmann. 2019. "Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions" Lubricants 7, no. 2: 19. https://doi.org/10.3390/lubricants7020019

APA StyleFischer, D., Mues, H., Jacobs, G., & Stratmann, A. (2019). Effect of Over Rolling Frequency on the Film Formation in Grease Lubricated EHD Contacts under Starved Conditions. Lubricants, 7(2), 19. https://doi.org/10.3390/lubricants7020019