Mechanical Behaviour of an Al2O3 Dispersion Strengthened γTiAl Alloy Produced by Centrifugal Casting

Abstract

:1. Introduction

2. Experimental

- Heating up to 250 °C and residence at this temperature for 30 min.

- Heating up to 900 °C and residence at this temperature for 30 min.

- Oven cooling up to 450 °C.

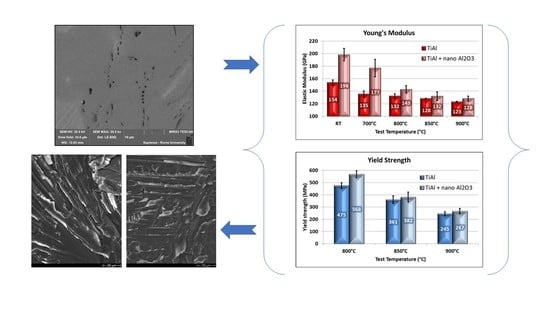

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Clemens, H.; Smarsly, W. Light-weight intermetallic titanium aluminides—Status of research and development. Adv. Mater. Res. 2011, 278, 551–556. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.W. Gamma titanium aluminides: Their status and future. JOM 1995, 47, 39–42. [Google Scholar] [CrossRef]

- Appel, F.; Brossmann, U.; Christoph, U.; Eggert, S.; Janschek, P.; Lorenz, U.; Müllauer, J.; Oehring, M.; Paul, J.D.H. Recent progress in the development of gamma titanium aluminide alloys. Adv. Eng. Mater. 2000, 2, 699–720. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications—Processing, microstructure and properties. Mater. High Temp. 2016, 33, 560–570. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Tetsui, T. Development of a second generation TiAl turbocharger. Mater. Sci. Forum 2007, 561–565, 379–382. [Google Scholar] [CrossRef]

- Noda, T. Application of cast gamma TiAl for automobiles. Intermetallics 1998, 6, 709–713. [Google Scholar] [CrossRef]

- Keller, M.M.; Jones, P.E.; Porter, W.J.; Eylon, D. The development of low-cost TiAl automotive valves. JOM 1997, 49, 42–44. [Google Scholar] [CrossRef]

- Liu, K.; Ma, Y.C.; Gao, M.; Rao, G.B.; Li, Y.Y.; Wei, K.; Wu, X.; Loretto, M.H. Single step centrifugal casting TiAl automotive valves. Intermetallics 2005, 13, 925–928. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Sauthoff, G. Intermetallics; VCH (Ed.): Weinheim, Germany, 1995. [Google Scholar]

- Brotzu, A.; Felli, F.; Pilone, D. Fracture toughness of TiAl-Cr-Nb-Mo alloys produced via centrifugal casting. Frat. Integrita Strutt. 2012, 22, 20–25. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Marra, F.; Pilone, D.; Pulci, G. Mechanical properties of a TiAl-based alloy at room and high temperatures. Mater. Sci. Technol. 2018, 34, 1847–1853. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Pilone, D. Effect of alloying elements on the behaviour of TiAl-based alloys. Intermetallics 2014, 54, 176–180. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Pilone, D. Effects of the manufacturing process on fracture behaviour of cast TiAl intermetallic alloys. Frat. Integrita Strutt. 2014, 8, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Kubena, I.; Fournier, B.; Kruml, T. Effect of microstructure on low cycle fatigue properties of ODS steels. J. Nucl. Mater. 2012, 424, 101–108. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, W.; Mishra, R.S.; Charit, I. Microstructure and mechanical properties of friction stir welded oxide dispersion strengthened alloy. J. Nucl. Mater. 2013, 432, 274–280. [Google Scholar] [CrossRef]

- Koch, C.C.; Whittenberger, J.D. Mechanical milling/alloying of intermetallics. Intermetallics 1996, 4, 339–355. [Google Scholar] [CrossRef]

- Benjamin, J.S. Dispersion strengthened superalloys by mechanical alloying. Metall. Trans. 1970, 1, 2943–2951. [Google Scholar] [CrossRef]

- Rittinghaus, S.-K.; Wilms, M.B. Oxide dispersion strengthening of gamma TiAl by laser additive manufacturing. J. Alloys Compd. 2019, 804, 4. [Google Scholar] [CrossRef]

- Ai, T. Microstructure and mechanical properties of in-situ synthesized Al 2O3/TiAl composites. Chin. J. Aeronaut. 2008. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Li, J.; Chen, X.; Qiu, J.; Wang, Y.; Liu, B.; Liu, Y.; Rashad, M.; Pan, F. Mechanical, tribological and electrochemical corrosion properties of in-situ synthesized Al2O3/TiAl composites. Intermetallics 2020, 120, 106758. [Google Scholar] [CrossRef]

- Kenel, C.; Lis, A.; Dawson, K.; Stiefel, M.; Pecnik, C.; Barras, J.; Colella, A.; Hauser, C.; Tatlock, G.J.; Leinenbach, C.; et al. Mechanical performance and oxidation resistance of an ODS γ-TiAl alloy processed by spark plasma sintering and laser additive manufacturing. Intermetallics 2017, 91, 169–180. [Google Scholar] [CrossRef]

- ASTM C1161-13. Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperatures; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C1211-13. Standard Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Pulci, G.; Tului, M.; Tirillò, J.; Marra, F.; Lionetti, S.; Valente, T. High temperature mechanical behavior of UHTC coatings for thermal protection of re-entry vehicles. J. Therm. Spray Technol. 2011, 20, 139–144. [Google Scholar] [CrossRef]

- Baiamonte, L.; Marra, F.; Pulci, G.; Tirillò, J.; Sarasini, F.; Bartuli, C.; Valente, T. High temperature mechanical characterization of plasma-sprayed zirconia-yttria from conventional and nanostructured powders. Surf. Coat. Technol. 2015, 277, 289–298. [Google Scholar] [CrossRef]

- Di Girolamo, G.; Marra, F.; Blasi, C.; Schioppa, M.; Pulci, G.; Serra, E.; Valente, T. High-temperature mechanical behavior of plasma sprayed lanthanum zirconate coatings. Ceram. Int. 2014. [Google Scholar] [CrossRef]

| Elements | Aluminium | Titanium | Chromium | Niobium |

|---|---|---|---|---|

| Atomic % | 46 | 48.3 | 3.2 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilone, D.; Pulci, G.; Paglia, L.; Mondal, A.; Marra, F.; Felli, F.; Brotzu, A. Mechanical Behaviour of an Al2O3 Dispersion Strengthened γTiAl Alloy Produced by Centrifugal Casting. Metals 2020, 10, 1457. https://doi.org/10.3390/met10111457

Pilone D, Pulci G, Paglia L, Mondal A, Marra F, Felli F, Brotzu A. Mechanical Behaviour of an Al2O3 Dispersion Strengthened γTiAl Alloy Produced by Centrifugal Casting. Metals. 2020; 10(11):1457. https://doi.org/10.3390/met10111457

Chicago/Turabian StylePilone, Daniela, Giovanni Pulci, Laura Paglia, Avishek Mondal, Francesco Marra, Ferdinando Felli, and Andrea Brotzu. 2020. "Mechanical Behaviour of an Al2O3 Dispersion Strengthened γTiAl Alloy Produced by Centrifugal Casting" Metals 10, no. 11: 1457. https://doi.org/10.3390/met10111457

APA StylePilone, D., Pulci, G., Paglia, L., Mondal, A., Marra, F., Felli, F., & Brotzu, A. (2020). Mechanical Behaviour of an Al2O3 Dispersion Strengthened γTiAl Alloy Produced by Centrifugal Casting. Metals, 10(11), 1457. https://doi.org/10.3390/met10111457