Influence of Finite Mobilities of Triple Junctions on the Grain Morphology and Kinetics of Grain Growth

Abstract

:1. Introduction

2. Problem Description and Methods

2.1. Geometrical Arrangement

2.2. Description of the Numerical Procedure

3. Results

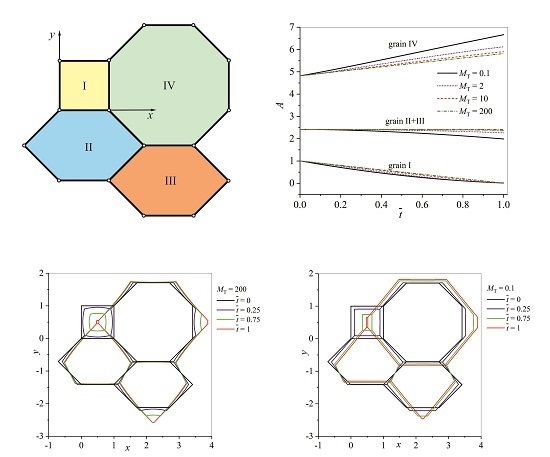

3.1. From Curvature Controlled to Triple Junction Controlled Grain Growth

3.2. Structural Elements with Reduced Mobilities

3.2.1. Triple Points with Reduced Mobilities

3.2.2. Grain Boundaries with Reduced Mobilities

3.2.3. Pinning of Microstructural Entities

4. Discussion

5. Conclusions

- It is demonstrated that differences in the mobilities of triple junctions and grain boundaries of a grain have the potential to significantly change the shape of this grain. Small differences will always occur e.g., due to spatial fluctuations of dissolved components in the migrating grain boundary or a different retarding forces due to dragging of the triple junctions.

- Even if all triple junctions have the same mobility, the grain arrangement evolves differently depending on the value of this mobility. Grain structures with smaller mobilities of the triple junctions will result in a structure with strongly deformed grains compared to structures, where a smaller influence of triple junction drag on the kinetics prevails. Small mobilities of triple junctions and grain boundaries may enhance the increase of the area of those n-sided grains with the highest amount of sides. A broader size distribution can be expected for microstructures with small mobilities of triple junctions rather than in microstructures where curvature-driven grain growth prevails.

- It is demonstrated by simulations that reduced mobilities of microstructural grain boundary elements can give rise to a deviation from a unimodal area distribution and to strongly elongated grains. Supporting these simulation results, titanium and niobium microalloyed steels [31] develop such a microstructure when held at 1100°C due to the retarding force of the (Ti,Nb)C precipitates. The precipitates dissolve at higher temperatures (1200°C) and normal grain growth is obtained eventually.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lücke, K.; Detert, K. A quantitative theory of grain-boundary motion and recrystallization in metals in the presence of impurities. Acta Metall. 1957, 5, 628–637. [Google Scholar] [CrossRef]

- Cahn, J.W. The impurity-drag effect in grain boundary motion. Acta Metall. 1962, 10, 768–798. [Google Scholar] [CrossRef]

- Hillert, M. On the theory of normal and abnormal grain growth. Acta Metall. 1965, 13, 227–238. [Google Scholar] [CrossRef]

- Lücke, K.; Stüwe, H.P. On the theory of impurity controlled grain boundary motion. Acta Metall. 1971, 19, 1087–1099. [Google Scholar] [CrossRef]

- Aziz, M.J.; Kaplan, T. Continuous growth model for interface motion during alloy solidification. Acta Metall. 1988, 36, 2335–2347. [Google Scholar] [CrossRef]

- Hillert, M. Nature of local equilibrium at the interface in the growth of ferrite from alloyed austenite. Scr. Mater. 2002, 46, 447–453. [Google Scholar] [CrossRef]

- Loginova, I.; Odqvist, J.; Amberg, G.; Ågren, J. The phase-field approach and solute drag modeling of the transition to massive γ → α transformation in binary Fe-C alloys. Acta Mater. 2003, 51, 1327–1339. [Google Scholar] [CrossRef]

- Grönhagen, K.; Ågren, J. Grain-boundary segregation and dynamic solute drag theory—A phase field approach. Acta Mater. 2007, 55, 955–960. [Google Scholar] [CrossRef]

- Strandlund, H.; Odqvist, J.; Ågren, J. An effective mobility approach to solute drag in computer simulations of migrating grain boundaries. Comput. Mater. Sci. 2008, 44, 265–273. [Google Scholar] [CrossRef]

- Dillon, S.J.; Behera, S.K.; Harmer, M.P. An experimentally quantifiable solute drag factor. Acta Mater. 2008, 56, 1374–1379. [Google Scholar] [CrossRef]

- Zurob, H.S.; Hutchinson, C.R.; Béché, A.; Purdy, G.R.; Bréchet, Y.J.M. A transition from local equilibrium to paraequilibrium kinetics for ferrite growth in Fe–C–Mn: A possible role of interfacial segregation. Acta Mater. 2008, 56, 2203–2211. [Google Scholar] [CrossRef]

- Kim, S.G.; Park, Y.B. Grain boundary segregation, solute drag and abnormal grain growth. Acta Mater. 2008, 56, 3739–3753. [Google Scholar] [CrossRef]

- Svoboda, J.; Fischer, F.D.; Leindl, M. Transient solute drag in migrating grain boundaries. Acta Mater. 2011, 59, 6556–6562. [Google Scholar] [CrossRef]

- Svoboda, J.; Gamsjäger, E.; Liu, Y.; Fischer, F.D.; Kozeschnik, E. Diffusion processes in a migrating interface—the thick interface model. Acta Mater. 2011, 59, 4775–4786. [Google Scholar] [CrossRef]

- Greenwood, M.; Sinclair, C.; Militzer, M. Phase field crystal model of solute drag. Acta Mater. 2012, 60, 5752–5761. [Google Scholar] [CrossRef]

- Gamsjäger, E.; Rettenmayr, M. The kinetics of diffusive phase transformations in the light of trans-interface diffusion. Philos. Mag. 2015, 95, 2851–2865. [Google Scholar] [CrossRef]

- Gong, P.; Palmiere, E.J.; Rainforth, W.M. Dissolution and precipitation behaviour in steels microalloyed with niobium during thermomechanical processing. Acta Mater. 2015, 97, 392–403. [Google Scholar] [CrossRef]

- Rheinheimer, W.; Schoof, E.; Selzer, M.; Nestler, B.; Hoffmann, M.J. Non-Arrhenius grain growth in strontium titanate: Quantification of bimodal grain growth. Acta Mater. 2019, 174, 105–115. [Google Scholar] [CrossRef]

- Dennis, J.; Bate, P.S.; Humphreys, F.J. Abnormal grain growth in metals. Mater. Sci. Forum 2007, 558–559, 717–722. [Google Scholar] [CrossRef]

- Kang, S.-J.L. Abnormal grain growth. In Sintering: Densification, Grain Growth and Microstructure; Elsevier Butterworth-Heinemann: Offord, UK; pp. 117–135.

- Rios, P.R.; Zöllner, D. Critical assessment 3 0: Grain growth – Unresolved issues. Mater. Sci. Technol. 2018, 34, 629–638. [Google Scholar] [CrossRef]

- Rios, P.R. Some theoretical considerations on abnormal grain growth. Mater. Sci. Forum 1996, 204–206, 247–256. [Google Scholar] [CrossRef]

- Rios, P.R.; Glicksman, M.E. Topological theory of abnormal grain growth. Acta Mater. 2006, 54, 5313–5321. [Google Scholar] [CrossRef]

- Thompson, C.V.; Frost, H.J.; Spaepen, F. The relative rates of secondary and normal grain growth. Acta metall. 1987, 35, 887–890. [Google Scholar] [CrossRef]

- Rios, P.R. Abnormal grain growth development from uniform grain size distributions in the presence of stable particles. Scr. Mater. 1998, 39, 1725–1730. [Google Scholar] [CrossRef]

- Tweed, C.J.; Hansen, N.; Ralph, B. Grain growth in samples of aluminum containing alumina particles. Metall. Trans. A 1983, 14, 2235–2243. [Google Scholar] [CrossRef]

- Oliveira, V.B.; Sandim, H.R.Z.; Raabe, D. Abnormal grain growth in Eurofer-97 steel in the ferrite phase field. J. Nucl. Mater. 2017, 485, 23–38. [Google Scholar] [CrossRef]

- Zöllner, D.; Rios, P.R. On the topology and size advantage of potentially abnormal grains. Comput. Mat. Sci. 2018, 153, 382–391. [Google Scholar]

- Bruno, J.C.; Rios, P.R. The grain size distribution and the detection of abnormal grain growth of austenite in an eutectoid steel containing niobium. Scr. Metall. Mater. 1995, 32, 601–606. [Google Scholar] [CrossRef]

- Zhuo, T.H.; Zurob, H.S. Abnormal and post-abnormal austenite grain growth kinetics in Nb–Ti microalloyed steels. Can. Metall. Q. 2011, 50, 389–395. [Google Scholar] [CrossRef]

- Graux, A.; Cazottes, S.; De Castro, D.; San Martín, D.; Capdevila, C.; Cabrera, J.M.; Molas, S.; Schreiber, S.; Mirković, D.; Danoix, F.; et al. Precipitation and grain growth modelling in Ti-Nb microalloyed steels. Materialia 2019, 5, 3267–3275. [Google Scholar] [CrossRef] [Green Version]

- Rheinheimer, W.; Hoffmann, M.J. Non-Arrhenius behavior of grain growth in strontium titanate: New evidence for a structural transition of grain boundaries. Scr. Mater. 2015, 101, 68–71. [Google Scholar] [CrossRef]

- Olmsted, D.L.; Molm, E.A.; Foiles, S.M. Survey of computed grain boundary properties in face-centered cubic metals—II: Grain boundary mobility. Acta Mater. 2009, 57, 3704–3713. [Google Scholar] [CrossRef]

- Streitenberger, P.; Zöllner, D. Evolution equations and size distributions in nanocrystalline grain growth. Acta Mater. 2011, 59, 4235–4243. [Google Scholar] [CrossRef]

- Gottstein, G.; Shvindlerman, L.S. Theory of grain boundary motion in the presence of mobile particles. Acta Metall. Mater. 1993, 41, 3267–3275. [Google Scholar] [CrossRef]

- Apel, M.; Böttger, B.; Rudnizky, J.; Schaffnit, P.; Steinbach, I. Grain growth simulations including particle pinning using the multiphase-field concept. ISIJ Int. 2009, 49, 1024–1029. [Google Scholar] [CrossRef] [Green Version]

- Rios, P.R. Abnormal grain growth development from uniform grain size distributions due to a mobility advantage. Scr. Mater. 1998, 38, 1359–1364. [Google Scholar] [CrossRef]

- Weygand, D.; Bréchet, Y.; Lépinoux, J. Mechanisms and Kinetics of Recrystallisation: A Two Dimensional Vertex Dynamics Simulation. Interface Sci. 2001, 9, 311–317. [Google Scholar] [CrossRef]

- Barrales-Mora, L.A.; Mohles, V.; Shvindlerman, L.S. Effect of a finite quadruple junction mobility on grain microstructure evolution: Theory and simulation. Acta Mater. 2008, 56, 1151–1164. [Google Scholar] [CrossRef]

- Gottstein, G.; Ma, Y.; Shvindlerman, L.S. Triple junction motion and grain microstructure evolution. Acta Mater. 2005, 53, 1535–1544. [Google Scholar] [CrossRef]

- Barrales-Mora, L.A. 2D vertex modeling for the simulation of grain growth and related phenomena Math. Comput. Simul. 2010, 80, 1411–1427. [Google Scholar] [CrossRef]

- Streitenberger, P.; Zöllner, D. Triple junction controlled grain growth in two-dimensional polycrystals and thin films: Self-similar growth laws and grain size distributions. Acta Mater. 2014, 78, 114–124. [Google Scholar] [CrossRef]

- Gamsjäger, E.; Ogris, D.M.; Svoboda, J. Kinetics of grain boundary networks controlled by triple junction and grain boundary mobility. Metals 2018, 8, 977. [Google Scholar]

- Maalekian, M.; Radis, R.; Militzer, M.; Moreau, A.; Poole, W.J. In situ measurement and modelling of austenite grain growth in a Ti/Nb microalloyed steel. Acta Mater. 2012, 60, 1015–1026. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, M.; Langelier, B.; Zurob, H.S. Effect of Solute Nb on Grain Growth in Fe-30 Pct Mn Steel. Metall. Mater. Trans. A 2019, 50, 3674–3682. [Google Scholar] [CrossRef]

- Chang, K.; Feng, W.; Chen, L.-Q. Effect of second-phase particle morphology on grain growth kinetics. Acta Mater. 2009, 57, 5229–5236. [Google Scholar] [CrossRef]

- Novikov, V.Y. Grain growth in nanocrystalline materials. Mater. Lett. 2015, 159, 510–513. [Google Scholar] [CrossRef]

- Fiji. Available online: https://imagej.net/Fiji (accessed on 25 September 2019).

- Zöllner, D.; Rios, P.R. Investigating the von Neumann-Mullins relation under triple junction dragging. Acta Mater. 2014, 70, 290–297. [Google Scholar]

- Seikh, A.H.; Soliman, M.S.; AlMajid, A.; Alhajeri, K.; Alshalfan, W. Austenite Grain Growth Kinetics in API X65 and X70 Line-Pipe Steels during Isothermal Heating. Adv. Mater. Sci. Eng. 2014, 246143, 1–8. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamsjäger, E.; Gschöpf, B.; Svoboda, J. Influence of Finite Mobilities of Triple Junctions on the Grain Morphology and Kinetics of Grain Growth. Metals 2020, 10, 185. https://doi.org/10.3390/met10020185

Gamsjäger E, Gschöpf B, Svoboda J. Influence of Finite Mobilities of Triple Junctions on the Grain Morphology and Kinetics of Grain Growth. Metals. 2020; 10(2):185. https://doi.org/10.3390/met10020185

Chicago/Turabian StyleGamsjäger, Ernst, Boris Gschöpf, and Jiří Svoboda. 2020. "Influence of Finite Mobilities of Triple Junctions on the Grain Morphology and Kinetics of Grain Growth" Metals 10, no. 2: 185. https://doi.org/10.3390/met10020185

APA StyleGamsjäger, E., Gschöpf, B., & Svoboda, J. (2020). Influence of Finite Mobilities of Triple Junctions on the Grain Morphology and Kinetics of Grain Growth. Metals, 10(2), 185. https://doi.org/10.3390/met10020185