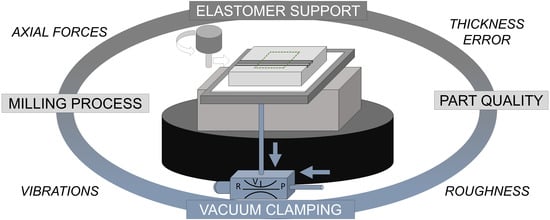

Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Compression Tests

2.2. Milling Tests

2.3. Force Mechanistic Model in the Tool Axis Direction with a Bull-Nose Mill

3. Results

3.1. Rubbers Compressive Behaviour

3.2. Thickness Error

3.3. Roughness

3.4. Force Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Herranz, S.; Campa, F.J.; De Lacalle, L.L.; Rivero, A.; Lamikiz, A.; Ukar, E.; Sánchez, J.A.; Bravo, U. The milling of airframe components with low rigidity: A general approach to avoid static and dynamic problems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 219, 789–801. [Google Scholar] [CrossRef]

- Del Sol, I.; Rivero, A.; López de Lacalle, L.N.; Gamez, A.J. Thin-Wall Machining of Light Alloys: A Review of Models and Industrial Approaches. Materials 2019, 12, 2012. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Xue, J.; Tang, D.; Chen, H.; Qu, S. Deformation prediction and error compensation in multilayer milling processes for thin-walled parts. Int. J. Mach. Tools Manuf. 2009, 49, 859–864. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Eynian, M. Vibration frequencies in stable and unstable milling. Int. J. Mach. Tools Manuf. 2015, 90, 44–49. [Google Scholar] [CrossRef]

- Gurdal, O.; Ozturk, E.; Sims, N.D. Analysis of Process Damping in Milling. Procedia CIRP 2016, 55, 152–157. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.-Y.; Wang, J.-J.J. A pole/zero cancellation approach to reducing forced vibration in end milling. Int. J. Mach. Tools Manuf. 2010, 50, 601–610. [Google Scholar] [CrossRef]

- Perez, I.; Madariaga, A.; Cuesta, M.; Garay, A.; Arrazola, P.J.; Ruiz, J.J.; Rubio, F.J.; Sanchez, R. Effect of cutting speed on the surface integrity of face milled 7050-T7451 aluminium workpieces. Procedia CIRP 2018, 71, 460–465. [Google Scholar] [CrossRef]

- Campa, F.J.; Lopez de Lacalle, L.N.; Celaya, A. Chatter avoidance in the milling of thin floors with bull-nose end mills: Model and stability diagrams. Int. J. Mach. Tools Manuf. 2011, 51, 43–53. [Google Scholar] [CrossRef] [Green Version]

- Altintaş, Y.; Budak, E. Analytical Prediction of Stability Lobes in Milling. CIRP Ann. 1995, 44, 357–362. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wang, J.-J.J. Effects of cutting conditions on dynamic cutting factor and process damping in milling. Int. J. Mach. Tools Manuf. 2011, 51, 320–330. [Google Scholar] [CrossRef]

- Gameros, A.; Lowth, S.; Axinte, D.; Nagy-Sochacki, A.; Craig, O.; Siller, H.R. State-of-the-art in fixture systems for the manufacture and assembly of rigid components: A review. Int. J. Mach. Tools Manuf. 2017, 123, 1–21. [Google Scholar] [CrossRef]

- Butt, M.A.; Yang, Y.; Pei, X.; Liu, Q. Five-axis milling vibration attenuation of freeform thin-walled part by eddy current damping. Precis. Eng. 2018, 51, 682–690. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, D.; Liu, Q. Milling vibration attenuation by eddy current damping. Int. J. Adv. Manuf. Technol. 2015, 81, 445–454. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Yan, S.; Ding, M.; Xiao, J.; Zhang, J.; Zhang, X.; Ji, C.; Sui, T. Chatter mitigation using moving damper. J. Sound Vib. 2017, 410, 49–63. [Google Scholar] [CrossRef]

- Matsubara, A.; Taniyama, Y.; Wang, J.; Kono, D. Design of a support system with a pivot mechanism for suppressing vibrations in thin-wall milling. CIRP Ann. 2017, 66, 381–384. [Google Scholar] [CrossRef]

- Zhang, Y.; Sims, N.D. Milling workpiece chatter avoidance using piezoelectric active damping: A feasibility study. Smart Mater. Struct. 2005, 14, N65. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. Chatter suppression based on nonlinear vibration characteristic of electrorheological fluids. Int. J. Mach. Tools Manuf. 1999, 39, 1925–1934. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, D.; Wu, B.; Luo, M.; Chen, B. Vibration suppression of thin-walled workpiece machining considering external damping properties based on magnetorheological fluids flexible fixture. Chin. J. Aeronaut. 2016, 29, 1074–1083. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Xie, R.; Liu, Q. Design of a passive damper with tunable stiffness and its application in thin-walled part milling. Int. J. Adv. Manuf. Technol. 2017, 89, 2713–2720. [Google Scholar] [CrossRef]

- Shoyama, T.; Fujimoto, K. Direct measurement of high-frequency viscoelastic properties of pre-deformed rubber. Polym. Test. 2018, 67, 399–408. [Google Scholar] [CrossRef]

- Chung, D.D.L. Review: Materials for vibration damping. J. Mater. Sci. 2001, 36, 5733–5737. [Google Scholar] [CrossRef]

- Ge, C.; Rice, B. Impact damping ratio of a nonlinear viscoelastic foam. Polym. Test. 2018, 72, 187–195. [Google Scholar] [CrossRef]

- Albooyeh, A.R. The effect of addition of Multiwall Carbon Nanotubes on the vibration properties of Short Glass Fiber reinforced polypropylene and polypropylene foam composites. Polym. Test. 2019, 74, 86–98. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, J.; Zhao, D.; Lu, Y.; Wang, W.; Zhang, L.; Nishi, T. Natural rubber/nitrile butadiene rubber/hindered phenol composites with high-damping properties. Int. J. Smart Nano Mater. 2015, 6, 239–250. [Google Scholar] [CrossRef] [Green Version]

- Shit, S.C.; Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Kolluru, K.; Axinte, D. Novel ancillary device for minimising machining vibrations in thin wall assemblies. Int. J. Mach. Tools Manuf. 2014, 85, 79–86. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Song, Q.; Wang, B. Analysis and implementation of chatter frequency dependent constrained layer damping tool holder for stability improvement in turning process. J. Mater. Process. Technol. 2019, 266, 687–695. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Review of elastomer seal assemblies in oil & gas wells: Performance evaluation, failure mechanisms, and gaps in industry standards. J. Pet. Sci. Eng. 2019, 179, 1046–1062. [Google Scholar] [CrossRef]

- Mitra, S.; Ghanbari-Siahkali, A.; Almdal, K. A novel method for monitoring chemical degradation of crosslinked rubber by stress relaxation under tension. Polym. Degrad. Stab. 2006, 91, 2520–2526. [Google Scholar] [CrossRef]

- Da Rocha, E.B.D.; Linhares, F.N.; Gabriel, C.F.S.; De Sousa, A.M.F.; Furtado, C.R.G. Stress relaxation of nitrile rubber composites filled with a hybrid metakaolin/carbon black filler under tensile and compressive forces. Appl. Clay Sci. 2018, 151, 181–188. [Google Scholar] [CrossRef]

- Mallipudi, P.K.; Ramanaiah, N. Effect of Carbon Black on the Performance of Nitrile Rubber For Analyzing Free Layered Surface Damping Treatment. Mater. Today Proc. 2019, 18, 3371–3379. [Google Scholar] [CrossRef]

- Olsson, A.K. Finite Element Procedures in Modelling the Dynamic Properties of Rubber; Department of Construction Sciences, Structural Mechanics, Lund University: Lund, Sweden, 2007. [Google Scholar]

- Mullins, L. Softening of Rubber by Deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Balasubramanian, P.; Ferrari, G.; Amabili, M. Identification of the viscoelastic response and nonlinear damping of a rubber plate in nonlinear vibration regime. Mech. Syst. Signal Process. 2018, 111, 376–398. [Google Scholar] [CrossRef]

- Austrell, P.-E.; Olsson, A.K. Modelling procedures and properties of rubber in rolling contact. Polym. Test. 2013, 32, 306–312. [Google Scholar] [CrossRef]

- ASTM D 395. Standard test method for rubber. In Philadelphia: Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 1955. [Google Scholar]

- Del Sol, I.; Rivero, A.; Salguero, J.; Fernández-Vidal, S.R.; Marcos, M. Tool-path effect on the geometric deviations in the machining of UNS A92024 aeronautic skins. Procedia Manuf. 2017, 13, 639–646. [Google Scholar] [CrossRef] [Green Version]

- Del Sol, I.; Rivero, A.; Gamez, A.J. Effects of Machining Parameters on the Quality in Machining of Aluminium Alloys Thin Plates. Metals 2019, 9, 927. [Google Scholar] [CrossRef] [Green Version]

- Engin, S.; Altintas, Y. Mechanics and dynamics of general milling cutters.: Part I: Helical end mills. Int. J. Mach. Tools Manuf. 2001, 41, 2195–2212. [Google Scholar] [CrossRef]

- Altintas, Y. Analytical Prediction of Three Dimensional Chatter Stability in Milling. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2001, 44, 717–723. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.-S.; Hsu, W.-Y. Characterizations and models for the thermal growth of a motorized high speed spindle. Int. J. Mach. Tools Manuf. 2003, 43, 1163–1170. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Huang, W.; Becker, A.A. Milling error prediction and compensation in machining of low-rigidity parts. Int. J. Mach. Tools Manuf. 2004, 44, 1629–1641. [Google Scholar] [CrossRef]

- Rubio-Mateos, A.; Rivero, A.; del Sol, I.; Ukar, E.; Lamikiz, A. Capacitation of flexibles fixtures for its use in high quality machining processes: An application case of the industry 4.0. paradigm. DYNA 2018, 93, 608–612. [Google Scholar] [CrossRef] [Green Version]

- Bi, Q.; Huang, N.; Zhang, S.; Shuai, C.; Wang, Y. Adaptive machining for curved contour on deformed large skin based on on-machine measurement and isometric mapping. Int. J. Mach. Tools Manuf. 2019, 136, 34–44. [Google Scholar] [CrossRef]

- De Lacalle, L.N.L.; Lamikiz, A.; Sánchez, J.A.; de Bustos, I.F. Recording of real cutting forces along the milling of complex parts. Mechatronics 2006, 16, 21–32. [Google Scholar] [CrossRef]

| Properties | Rubber A | Rubber B |

|---|---|---|

| Hardness (Sh·A) | 65 | 90 |

| Density (g/cm3) | 1.45 | 1.43 |

| Polymer (wt.%) | 37.3 | 54.6 |

| Carbon black (wt.%) | 3.5 | 14.4 |

| Other inorganic charges (wt.%) | 59.2 | 31.0 |

| Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Clamping material | Rubber A | Rubber B | No rubber |

| (mm) | 0.2 | 0.8 | - |

| (mm/tooth) | 0.06 | 0.1 | - |

| (rpm) | 2000 | 4000 | 6000 |

| (m/min) | 63 | 126 | 189 |

| (mm/min) | 240; 400 | 480; 800 | 720; 1200 |

| Analysis | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| Normal distribution | AD | 0.276 | 0.322 | 0.447 |

| p-value | 0.628 | 0.510 | 0.257 | |

| Homogeneity of variance | Bartlett’s | 4.480 | 5.160 | 2.310 |

| p-value | 0.723 | 0.640 | 0.941 |

| Factor | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| F-value | 7.040 | 3.200 | 1.990 | |

| p-value | 0.017 | 0.093 | 0.178 | |

| F-value | 0.680 | 0.430 | 0.350 | |

| p-value | 0.420 | 0.520 | 0.562 | |

| F-value | 1.540 | 1.940 | 0.050 | |

| p-value | 0.233 | 0.182 | 0.830 | |

| F-value | 0.000 | 0.080 | 0.090 | |

| p-value | 0.990 | 0.787 | 0.770 | |

| F-value | 0.300 | 0.090 | 0.140 | |

| p-value | 0.593 | 0.774 | 0.716 | |

| F-value | 0.540 | 0.280 | 0.060 | |

| p-value | 0.475 | 0.606 | 0.804 | |

| F-value | 1.200 | 0.010 | 0.350 | |

| p-value | 0.289 | 0.936 | 0.563 |

| Analysis | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| Normal distribution | AD | 0.251 | 0.497 | 0.305 |

| p-value | 0.694 | 0.181 | 0.528 | |

| Homogeneity of variance | Bartlett’s | 3.400 | 12.750 | 5.510 |

| p-value | 0.846 | 0.078 | 0.599 |

| Factor | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| F-value | 54.100 | 2.880 | 17.360 | |

| p-value | 0.000 | 0.128 | 0.003 | |

| F-value | 42.240 | 13.910 | 4.850 | |

| p-value | 0.000 | 0.006 | 0.059 | |

| F-value | 0.820 | 2.690 | 0.790 | |

| p-value | 0.391 | 0.140 | 0.399 | |

| F-value | 16.740 | 2.280 | 2.990 | |

| p-value | 0.003 | 0.170 | 0.122 | |

| F-value | 1.070 | 0.110 | 0.590 | |

| p-value | 0.331 | 0.746 | 0.464 | |

| F-value | 8.320 | 0.460 | 0.040 | |

| p-value | 0.020 | 0.519 | 0.844 | |

| F-value | 0.450 | 0.000 | 0.100 | |

| p-value | 0.521 | 0.994 | 0.755 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio-Mateos, A.; Rivero, A.; Ukar, E.; Lamikiz, A. Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals 2020, 10, 289. https://doi.org/10.3390/met10020289

Rubio-Mateos A, Rivero A, Ukar E, Lamikiz A. Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals. 2020; 10(2):289. https://doi.org/10.3390/met10020289

Chicago/Turabian StyleRubio-Mateos, Antonio, Asuncion Rivero, Eneko Ukar, and Aitzol Lamikiz. 2020. "Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations" Metals 10, no. 2: 289. https://doi.org/10.3390/met10020289

APA StyleRubio-Mateos, A., Rivero, A., Ukar, E., & Lamikiz, A. (2020). Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals, 10(2), 289. https://doi.org/10.3390/met10020289