Investigation on the Durability of Ti-6Al-4V Alloy Designed in a Harmonic Structure via Powder Metallurgy: Fatigue Behavior and Specimen Size Parameter Issue

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Processing

2.2. Mechanical Testing Procedure

- The miniature size (hereafter denoted MS) specimen with length, width and thickness dimensions of 18, 3 and 1 mm, respectively (see Figure 1b). To this end, an electro-dynamic fatigue testing machine using a 9514-AN/SD actuator (EMIC Corp., Tokyo, Japan), operating at a loading frequency of 10 Hz, is considered. The frame geometry of the four-point bending loading adopts an inner span of 5 mm and an outer span of 15 mm. Such a configuration is identical to the one accepted in our previous work [20].

- The standard size (SS) specimen, presenting the length, width and thickness values of 40, 4 and 3mm, respectively (see Figure 1c). The dedicated frame possesses inner and outer spans of 10 and 30 mm, respectively, in accordance with the ISO 22214 Standard. To this end, a servo-hydraulic fatigue testing machine (SMH201, SAGINOMIYA, Tokyo, Japan), accepting a loading frequency of 20 Hz, has been used.

2.3. Analysis Tools

3. Experimental Results

3.1. Characterization of the Materials’ Microstructure

3.2. Tensile Tests Results

3.3. Fatigue Tests Results

3.3.1. Fundamental Fatigue Strength from the MS Configuration

3.3.2. S-N Characteristics from SS Specimens

3.3.3. Fatigue Crack Initiation Features

3.3.4. Fatigue Crack Propagation Aspects in the MM Material

3.3.5. Characterization of the Fatigue Behavior of MM Material by Local Misorientation Analysis

4. Discussion

4.1. Why the Inclusion Induced Initiation Mechanism Occurs Exclusively in the 106~107 Cycles Region?

4.2. Why the MS Configuration did not Show Any Inclusion-Induced Fatigue Rupture?

4.3. Why the Fatigue Nucleation Site Tends to Move from a Surface-Induced to an Interior-Induced Pattern When Transitioning from the MS to SS Configuration?

4.4. Putting Aside the Inclusion-Induced Ruptures, Why MM Material did not Show Equivalent Fatigue Strength in MS and SS Configurations?

- MM material consists of an “assembly” of u = 150 μm edge length cubic pattern, where the core takes place in a rc = 50 μm-radius spherical region at its center (i.e., the region outside the sphere corresponds to the shell region). It leads to a harmonic structured material having a core areal fraction of 35%, close to the actual value in the MM material investigated here, as written in Table 2.

- The active interface takes place only inside the critical volume region, i.e., for a depth lower than hMS and hSS for the MS and SS configurations, respectively. Since the bending stress is maximum in this region, core grains inside the critical volume are very likely to yield there, generating the GNDs accumulation at the core interface.

- A core region generates an active interface only if its center is inside the critical volume region. Indeed, it is reasonable to consider that a sufficient volume of the core region is needed to cause dislocation pile-ups and tangles at the interface between the core and shell regions. For the sake of simplicity, the authors propose that this sufficient core volume threshold is half of the total core region, resulting in this third assumption.

5. Conclusions

- Analysis of the microstructure of 50 mm diameter sintered compact made from powder prone to mechanical milling revealed a harmonic microstructure, without significant discrepancies throughout the entire compact.

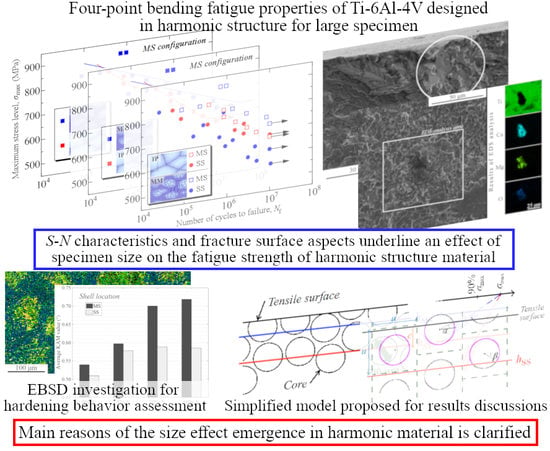

- Fatigue test results obtained from the MS configuration underlined fatigue endurance at 107 cycles of 738 ± 15 MPa, distinctly higher than the IP one of 683 ± 14 MPa. This trend is similar to results found in our previous work. An opposite situation is reported for fatigue tests accepting the SS configuration, where fatigue endurances at 107 cycles are 570 ± 10 and 680 ± 20 MPa, for the MM and IP materials, respectively.

- Excepting the case of the MM material in the SS configuration, fatigue crack nucleation of both IP and MM materials revealed facets, presumably induced by the basal slip of α-Ti grains. More particularly, the crack nucleates at the core region of the MM material in the MS configuration. However, the MM material highlighted other initiation features in the SS configuration, since inclusion-induced nucleation from the shell is found exclusively in the Nf > 106 region. According to the chemical compositions of the involved inclusions, they are likely caused by powder contamination during the mechanical milling process.

- A simplified model has been proposed to assess the activity between the core and shell regions, which outlined a significantly larger active interface fraction in the MS configuration than the SS one. Such a trend is in line with the more distinct increase of GNDs accumulation in the shell in the MS configuration, according to KAM analysis. GNDs accumulation mechanism mitigated, heterogeneous structure materials cannot keep their cohesion, leading to the generation of a local zone prone to considerable strain concentration, usually referred to as strain localization phenomenon.

- The fatigue strength loss observed in the MM material for the SS configuration, in comparison with the MS one, should be induced by two main reasons: mitigated GNDs accumulation resulting in strain localization in core regions; coupled to a larger critical volume increasing notably the number of cores vulnerable to generate early fatigue crack nucleation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. B 1951, 64, 747–752. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Tsuji, N.; Ito, Y.; Saito, Y.; Minamino, Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 2002, 47, 893. [Google Scholar] [CrossRef]

- Ma, E. Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scr. Mater. 2003, 49, 663–668. [Google Scholar] [CrossRef]

- Morita, T.; Hatsuoka, K.; Iizuka, T.; Kawasaki, K. Straightening of Ti-6Al-4V by short-time duplex heat treatment. Mater. Trans. 2005, 46, 1681–1686. [Google Scholar] [CrossRef] [Green Version]

- Szabo, P.J.; Field, D.P.; Joni, B.; Horky, J.; Ungar, T. Bimodal grain size distribution enhances strength and ductility simultaneously in a low-carbon low alloy steel. Metall. Mater. Trans. A 2015, 46, 1948–1957. [Google Scholar] [CrossRef]

- Terada, D.; Inoue, M.; Kitahara, H.; Tsuji, N. Change in mechanical and microstructure of ARB processed Ti during annealing. Mater. Trans. 2008, 49, 41–46. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef]

- Ma, E.; Zhu, T. Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 2017, 20, 323–331. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bagherifiard, S.; Astaraee, A.H.; Locati, M.; Nawaz, A.; Monti, S.; Kodas, J.; Singh, R.; Guagliano, M. Design and analysis of additive manufactures bimodal structures obtained by cold spray deposition. Addit. Manuf. 2020, 33, 101131. [Google Scholar]

- Sekiguchi, T.; Ono, K.; Fujiwara, H.; Ameyama, K. New microstructure design for commercially pure titanium with outstanding mechanical properties by mechanical milling and hot roll sintering. Mater. Trans. 2010, 51, 39–45. [Google Scholar] [CrossRef] [Green Version]

- Fujiwara, H.; Sekiguchi, T.; Ameyama, K. Mechanical properties of pure titanium and Ti-6Al-4V alloys with a new tailored nano/meso hybrid microstructure. Int. J. Mater. Res. 2009, 100, 796. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nakamura, Y.; Ueno, A.; Ameyama, K. Low temperature nitring of commercially pure titanium with harmonic structure. Mater. Trans. 2015, 56, 1807–1813. [Google Scholar] [CrossRef] [Green Version]

- Vajpai, S.K.; Ota, M.; Watanabe, T.; Maeda, R.; Sekiguchi, T.; Kusaka, T.; Ameyama, K. The development of high performance Ti-6Al-4V alloy via a unique microstructural design with bimodal grain size distribution. Mater. Metall. Mater. Trans. A 2015, 46, 903–914. [Google Scholar] [CrossRef]

- Ota, M.; Vajpai, S.K.; Imao, R.; Kurokawa, K.; Ameyama, K. Application of high pressure gas jet mill process to fabricate high performance harmonic structure designed pure titanium. Mater. Trans. 2015, 56, 154–159. [Google Scholar] [CrossRef] [Green Version]

- Vajpai, S.K.; Ota, M.; Zhang, Z.; Ameyama, K. Three-dimensionally gradient harmonic structure design: An integrated approach for high performance structural materials. Mater. Res. Lett. 2016, 4, 191–197. [Google Scholar] [CrossRef]

- Kikuchi, S.; Hayami, Y.; Ishiguri, T.; Guennec, B.; Ueno, A.; Ota, M.; Ameyama, K. Effect of bimodal grain size distribution on fatigue properties of Ti-6Al-4V alloy with harmonic structure under four-point bending. Mater. Sci. Eng. A 2017, 687, 269–275. [Google Scholar] [CrossRef] [Green Version]

- Kikuchi, S.; Imai, T.; Kubozono, H.; Nakai, Y.; Ota, M.; Ueno, A.; Ameyama, K. Effect of harmonic structure design with bimodal grain size distribution on near-threshold fatigue crack propagation in Ti-6Al-4V alloy. Int. J. Fatigue 2016, 92, 616–622. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, H.; Zheng, R.; Hu, Q.; Nakatani, M.; Ota, M.; Chen, G.; Chen, X.; Ma, C.; Ameyama, K. Fatigue behavior of a harmonic structure designed austenitic stainless steel under uniaxial stress loading. Mater. Sci. Eng. A 2017, 707, 287–294. [Google Scholar] [CrossRef]

- Kikuchi, S.; Mori, T.; Kubozono, H.; Nakai, Y.; Kawabata, M.; Ameyama, K. Evaluation of near-threshold fatigue crack propagation in harmonic-structured CP Titanium with a bimodal grain size distribution. Eng. Fract. Mech. 2017, 181, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Kikuchi, S.; Imai, T.; Kubozono, H.; Nakai, Y.; Ueno, A.; Ameyama, K. Evaluation of near-threshold fatigue crack propagation in Ti-6Al-4V alloy with harmonic structure created by mechanical milling and spark plasma sintering. Frat. Ed Integr. Strutt. 2015, 34, 261–270. [Google Scholar] [CrossRef] [Green Version]

- Kikuchi, S.; Nakatsuka, Y.; Nakai, Y.; Nakatani, M.; Kawabata, M.; Ameyama, K. Evaluation of fatigue properties under four-point bending and fatigue crack propagation in austenitic stainless steel with a bimodal harmonic structure. Frat. Ed Integr. Strutt. 2019, 48, 545–553. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nukui, Y.; Nakatsuka, Y.; Nakai, Y.; Nakatani, M.; Kawabata, M.; Ameyama, K. Effect of bimodal harmonic structure on fatigue properties of austenitic stainless steel under axial loading. Int. J. Fatigue 2019, 127, 222–228. [Google Scholar] [CrossRef]

- Osaki, K.; Kikuchi, S.; Nakai, Y.; Kawabata, M.; Ameyama, K. The effects of thermo-mechanical processing on fatigue crack propagation in commercially pure titanium with a harmonic structure. Mater. Sci. Eng. A 2020, 773, 13892. [Google Scholar] [CrossRef]

- JSMS Committee on Fatigue of Materials; JSMS Committee on Reliability Engineering. Standard Evaluation Method of Fatigue Reliability for Metallic Materials—Standard Regression Method of S-N Curves. JSMS-SD-11-08. J. Soc. Mater. Sci. Jpn. 2005. [Google Scholar] [CrossRef]

- Adachi, S.; Wagner, L.; Lutjering, G. Influence of microstructure and mean stress on fatigue strength of Ti-6Al4V. In Proceedings of the Fifth International Conference on Titanium, Munich, Germany, 10–14 September 1984; pp. 2139–2146. [Google Scholar]

- Zuo, J.H.; Wang, Z.G.; Han, E.H. Effect of microstructure on ultra-high cycle fatigue behavior of Ti-6Al-4V. Mater. Sci. Eng. A 2008, 473, 147–152. [Google Scholar] [CrossRef]

- Golden, P.J.; John, R.; Porter, W.J., III. Variability in room temperature fatigue life of alpha + beta processed Ti-6Al-4V. Int. J. Fatigue 2009, 31, 1764–1770. [Google Scholar] [CrossRef]

- Liu, X.; Sun, C.; Hong, Y. Effects of stress ratio on high-cycle and very-high-cycle fatigue behavior of a Ti-6Al-4V. Mater. Sci. Eng. A 2015, 622, 228–235. [Google Scholar] [CrossRef]

- Tokaji, K.; Kariya, H. Mean stress dependence of fatigue strength and subsurface crack initiation in Ti-15Mo5Zr-3Al. Mater. Sci. Eng. A 2000, 281, 268–274. [Google Scholar] [CrossRef]

- Kikuchi, S.; Kubozono, H.; Nukui, Y.; Nakai, Y.; Ueno, A.; Kawabata, M.; Ameyama, K. Statistical fatigue properties and small fatigue crack propagation in bimodal harmonic structured Ti-6Al-4V alloy under four point bending. Mater. Sci. Eng. A 2018, 711, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Nukui, Y.; Kubozono, H.; Kikuchi, S.; Nakai, Y.; Ueno, A.; Kawabata, M.; Ameyama, K. Fractographic analysis of fatigue crack initiation and propagation in CP titanium with a bimodal harmonic structure. Mater. Sci. Eng. A 2018, 716, 228–234. [Google Scholar] [CrossRef]

- Dirras, G.; Ueda, D.; Hocini, A.; Tingaud, D.; Ameyama, K. Cyclic shear behavior of conventional and harmonic structure-designed Ti-25Nb-25Zr β-titanium alloy: Back-stress hardening and twinning inhibition. Scr. Mater. 2017, 138, 44–47. [Google Scholar] [CrossRef]

- Mompiou, F.; Tingaud, D.; Chang, Y.; Gault, B.; Dirras, G. Conventional vs Harmonic-structured β-Ti-25Nb-25Zr alloys: A comparative study of deformation mechanisms. Acta Mater. 2018, 161, 420–430. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Allain-Bonasso, N.; Wagner, F.; Berbenni, S.; Field, D.P. A study of the heterogeneity of plastic deformation in IF steel by EBSD. Mater. Sci. Eng. A 2010, 548, 56–63. [Google Scholar] [CrossRef]

- He, W.; Ma, W.; Pantleon, W. Microstructure of individual grains in cold-rolled aluminum from orientation inhomogeneities resolved by electron backscattering diffraction. Mater. Sci. Eng. A 2008, 494, 21–27. [Google Scholar] [CrossRef]

- Britton, T.B.; Birosca, S.; Preuss, M.; Wilkinson, A.J. Electron backscatter diffraction study of dislocation content of a macrozone in hot-rolled Ti-6Al-4V alloy. Scr. Mater. 2010, 62, 639. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of defects, inclusions and inhomogeneities on fatigue strength. Int. J. Fatigue 1994, 16, 163–182. [Google Scholar] [CrossRef]

- Chapetti, M.D.; Tagawa, T.; Miyata, T. Ultra-long cycle fatigue of high-strength carbon steels part I: Review and analysis of the mechanism of failure. Mater. Sci. Eng. A 2003, 356, 227–235. [Google Scholar] [CrossRef]

- Sakai, T.; Nakagawa, A.; Oguma, N.; Nakamura, Y.; Ueno, A.; Kikuchi, S.; Sakaida, A. A review on fatigue fracture modes of structural metallic materials in very high cycle regime. Int. J. Fatigue 2016, 93, 339–351. [Google Scholar] [CrossRef]

- Sakai, T.; Takeda, M.; Tanaka, N.; Kanemitsu, M.; Oguma, N.; Shiozawa, K. S-N property and fractography of high carbon chromium bearing steel over ultra wide life region under rotating bending. Trans. Jpn. Soc. Mech. Eng. Ser. A 2001, 67, 1805–1812. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Shiozawa, K.; Morii, Y.; Nishino, S.; Lu, L. Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime. Int. J. Fatigue 2006, 28, 1521–1532. [Google Scholar] [CrossRef]

- Shiozawa, K.; Kuroda, Y.; Nishino, S. Effect of the stress ratio on subsurface fatigue crack initiation behavior of beta-type titanium alloy. Trans. Jpn. Soc. Mech. Eng. A 1998, 64, 2528–2535. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Xiong, B.; Hui, S.; Ye, W.; Yu, Y. Comparison of the fatigue and fracture of Ti-6Al-2Zr-1Mo-1V with lamellar and bimodal microstructures. Mater. Sci. Eng. A 2007, 460, 140–145. [Google Scholar] [CrossRef]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. Ser. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Park, H.K.; Ameyama, K.; Yoo, J.; Hwang, H.; Kim, H.S. Additional hardening in harmonic structured materials by strain partitioning and back stress. Mater. Res. Lett. 2018, 6, 261–267. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Watanabe, I.; Ameyama, K. Deformation behavior analysis of harmonic structure materials by multi-scale finite element analysis. Adv. Mater. Res. 2015, 108, 853–857. [Google Scholar] [CrossRef]

- Wang, X.; Cazes, F.; Li, J.; Hocini, A.; Ameyama, K.; Dirras, G. A 3D crystal plasticity model of monotonic and cyclic simple shear deformation for commercial-purity Ti with a harmonic structure. Mech. Mater. 2019, 128, 117–128. [Google Scholar] [CrossRef]

- Joseph, S.; Bantounas, I.; Lindley, T.C.; Dye, D. Slip transfer and deformation structures resulting from the low cycle fatigue of near-alpha titanium alloy Ti-6242Si. Int. J. Plast. 2018, 100, 90–103. [Google Scholar] [CrossRef]

- Zhang, Y.; Topping, T.D.; Yang, H.; Lavernia, E.J.; Schoenung, J.M.; Nutt, S.R. Micro-strain evolution and toughening mechanisms in a trimodal Al-based metal matrix composite. Metall. Mater. Trans. A 2015, 46, 1196–1204. [Google Scholar] [CrossRef]

- Zan, Y.N.; Zhou, Y.T.; Liu, Z.Y.; Ma, G.N.; Wang, D.; Wang, Q.Z.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites. Mater. Des. 2019, 166, 10762–10769. [Google Scholar] [CrossRef]

| Al | V | Fe | H | N | O | C | Ti |

|---|---|---|---|---|---|---|---|

| 6.24~6.37 | 4.10~4.15 | 0.10~0.13 | 0.002 | 0.005~0.006 | 0.108~0.116 | 0.0024 | Bal. |

| Position in Compact | Inner Region | Outer Region |

|---|---|---|

| Areal fraction of coarse grains (%) | 31 | 32 |

| Average coarse grain size (μm) | 7.1 | 7.1 |

| Overall average grain size (μm) | 4.3 | 4.3 |

| Material | Tensile strength σUTS (MPa) | Yield Stress at 0.2% Offset σy (MPa) | Reduction of Area φ (%) | Elongation at Fracture (%) |

|---|---|---|---|---|

| IP | 1092 | 984 | 34.0 | 22.7 |

| MM | 1124 | 1089 | 33.3 | 23.3 |

| Number of Cycles to Failure Nf (Cycles) | Depth of Inclusion dinc (μm) | Stress Range at Inclusion Δσat (MPa) | Projected Size of Inclusion area1/2 (μm) |

|---|---|---|---|

| 9.18 × 105 | 100 | 553 | 22.6 |

| 1.38 × 106 | 141 | 553 | 17.4 |

| 4.99 × 106 | 84 | 492 | 18.3 |

| 3.12 × 106 | 149 | 485 | 18.3 |

| 4.58 × 106 | 72 | 547 | 12.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guennec, B.; Ishiguri, T.; Kawabata, M.O.; Kikuchi, S.; Ueno, A.; Ameyama, K. Investigation on the Durability of Ti-6Al-4V Alloy Designed in a Harmonic Structure via Powder Metallurgy: Fatigue Behavior and Specimen Size Parameter Issue. Metals 2020, 10, 636. https://doi.org/10.3390/met10050636

Guennec B, Ishiguri T, Kawabata MO, Kikuchi S, Ueno A, Ameyama K. Investigation on the Durability of Ti-6Al-4V Alloy Designed in a Harmonic Structure via Powder Metallurgy: Fatigue Behavior and Specimen Size Parameter Issue. Metals. 2020; 10(5):636. https://doi.org/10.3390/met10050636

Chicago/Turabian StyleGuennec, Benjamin, Takayuki Ishiguri, Mie Ota Kawabata, Shoichi Kikuchi, Akira Ueno, and Kei Ameyama. 2020. "Investigation on the Durability of Ti-6Al-4V Alloy Designed in a Harmonic Structure via Powder Metallurgy: Fatigue Behavior and Specimen Size Parameter Issue" Metals 10, no. 5: 636. https://doi.org/10.3390/met10050636

APA StyleGuennec, B., Ishiguri, T., Kawabata, M. O., Kikuchi, S., Ueno, A., & Ameyama, K. (2020). Investigation on the Durability of Ti-6Al-4V Alloy Designed in a Harmonic Structure via Powder Metallurgy: Fatigue Behavior and Specimen Size Parameter Issue. Metals, 10(5), 636. https://doi.org/10.3390/met10050636