Nanoindentation Creep, Elastic Properties, and Shear Strength Correlated with the Structure of Sn-9Zn-0.5nano-Ag Alloy for Advanced Green Electronics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Microstructure Observation

2.2. Mechanical Properties Measurements

3. Results and Discussions

3.1. Microstructure of Bulk Sn-Zn-Based Material

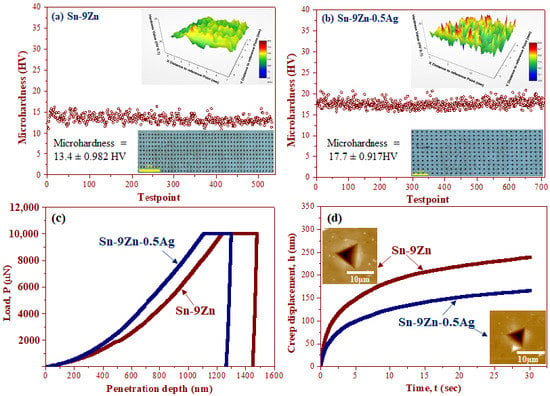

3.2. Microhadness and Creep of Sn-Zn-Based Material

3.3. Temperature Dependence of the Elastic Properties of Sn-Zn-Based Material

3.4. Interfacial Microstructure of Sn-Zn-Based Material on OSP-Cu and Au/Ni BGA Pads

3.5. Temperature and Humidity Effect on Sn-Zn-Based Material

3.6. Shear Strength of Sn-Zn-Based Material on Au/Ni-Plated BGA Pad

4. Conclusions

- The structural-property analysis revealed that nanosized-Ag particles refined the microstructure in the presence of fine spherical-shaped AgZn3 IMC particles in the β-Sn matrix. These fine microstructures increased the microhardness, creep, and damping resistance as well as the storage modulus as compared to the reference Sn-9Zn material due to the second phase dispersion-strengthening mechanism.

- In an interfacial microstructure analysis of the OSP-Cu pad/Sn-Zn-0.5Ag system, an additional AgZn3 IMC layer was found to be adhered to the top surface of the Cu5Zn8 IMC layer. On the other hand, in the Au/Ni-plated-Cu pad BGA pad/Sn-Zn-0.5Ag system, sandwich-type AgZn3 and AuZn3 IMC layers had grown at the substrate surface. Furthermore, the addition of Ag nanoparticles also enhanced the oxidation resistance of the Sn-Zn material due to the formation of fine AgZn3 IMC particles.

- The addition of Ag nanoparticles increased the shear strength value of the Sn-Zn material in the presence of a fine Zn-rich phase and AgZn3 IMC particles by about 12% with changing the fracture mode to a typical ductile failure with rough dimpled surfaces.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ma, Y.; Li, X.; Zhou, W.; Yang, L.; Wu, P. Reinforcement of graphene nanosheets on the microstructure and properties of Sn58Bi lead-free solder. Mater. Des. 2017, 113, 264–272. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Effect of thin gold/nickel coating on the microstructure, wettability and hardness of lead-free tin-bismuth-silver solder. J. Mater. Sci. Mater. Electron. 2017, 28, 4885–4896. [Google Scholar] [CrossRef]

- Zeng, G.; McDonald, S.D.; Gu, Q.; Terada, Y.; Uesugi, K.; Yasuda, H.; Nogita, K. The influence of Ni and Zn additions on microstructure and phase transformations in Sn-0.7Cu/Cu solder joints. Acta. Mater. 2015, 83, 357–371. [Google Scholar] [CrossRef]

- Chen, G.; Wu, F.; Liu, C.; Xia, W.; Liu, H. Effects of fullerenes reinforcement on the performance of 96.5Sn-3Ag-0.5Cu lead-free solder. Mater. Sci. Eng. A 2015, 636, 484–492. [Google Scholar] [CrossRef]

- Gain, A.K.; Chan, Y.C.; Sharif, A.; Yung, W.K.C. Effect of small Sn–3.5 Ag–0.5 Cu additions on the structure and properties of Sn–9Zn solder in ball grid array packages. Microelectron. Eng. 2009, 86, 2347–2353. [Google Scholar] [CrossRef]

- Liu, X.D.; Han, Y.D.; Jing, H.Y.; Wei, J.; Xu, L.Y. Effect of graphene nanosheets reinforcement on the performance of Sn-Ag-Cu lead-free solder. Mater. Sci. Eng. A 2013, 562, 25–32. [Google Scholar] [CrossRef]

- Laurila, T.; Vuorinen, V.; Kivilahti, J.K. Interfacial reactions between lead-free solders and common base materials. Mater. Sci. Eng. R 2005, 49, 1–60. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L.; Chan, Y.C. Microstructure, elastic modulus and shear strength of alumina (Al2O3) nanoparticles-doped tin-silver-copper (Sn-Ag-Cu) solders on copper (Cu) and gold/nickel (Au/Ni)-plated Cu substrates. J. Mater. Sci. Mater. Electron. 2015, 26, 7039–7048. [Google Scholar] [CrossRef]

- Novakovic, R.; Lanata, T.; Delsante, S.; Borzone, G. Interfacial reactions in the Sb-Sn/(Cu, Ni) systems: Wetting experiments. Mater. Chem. Phys. 2012, 137, 458–465. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Microstructure, mechanical and electrical performances of zirconia nanoparticles-doped tin-silver-copper solder alloys. J. Mater. Sci. Mater. Electron. 2016, 27, 7524–7533. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Howes, P.D.; Mannan, S.H. A review: On the development of low melting temperature Pb-free solders. Microelectron. Reliab. 2014, 54, 1253–1273. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Harsh service environment effects on the microstructure and mechanical properties of Sn-Ag-Cu-1 wt% nano-Al solder alloy. J. Mater. Sci. Mater. Electron. 2016, 27, 11273–11283. [Google Scholar] [CrossRef]

- Cheng, S.; Huang, C.M.; Michael, P.M. A review of lead-free solders for electronics applications. Microelectron. Reliab. 2017, 75, 77–95. [Google Scholar] [CrossRef]

- Gain, A.K.; Fouzder, T.; Chan, Y.C.; Sharif, A.; Yung, W.K.C. Investigation of small Sn-3.5 Ag-0.5 Cu additions on the microstructure and properties of Sn-8Zn-3Bi solder on Au/Ni/Cu pads. J. Alloys Compd. 2010, 489, 678–684. [Google Scholar] [CrossRef]

- Knott, S.; Mikula, A. Thermodynamic properties of liquid Al-Sn-Zn alloys: A possible new lead-free solder materials. Mater. Trans. 2002, 43, 1868–1872. [Google Scholar] [CrossRef] [Green Version]

- Tu, K.N. Reliability challenges in 3D packaging technology. Microelectron. Reliab. 2011, 51, 517–523. [Google Scholar] [CrossRef]

- Lee, B.T.; Kang, I.C.; Gain, A.K.; Kim, K.H.; Song, H.Y. Fabrication of pore-gradient Al2O3-ZrO2 sintered bodies by fibrous monolithic process. J. Eur. Ceram. Soc. 2006, 26, 3525–3530. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Effect of Ag nanoparticles on microstructure, damping property and hardness of low melting point eutectic tin-bismuth solder. J. Mater. Sci. Mater. Electron. 2017, 28, 15718–15730. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, K.N. Structure and properties of lead-free solders bearing micro and nanoparticles. Mater. Sci. Eng. R 2014, 82, 1–32. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Effects of Ni nanoparticles addition on the microstructure, electrical and mechanical properties of Sn-Ag-Cu alloy. Materialia 2019, 5, 100234. [Google Scholar] [CrossRef]

- Lee, B.T.; Han, J.K.; Gain, A.K.; Lee, K.H.; Saito, F. TEM microstructure characterization of nano TiO2 coated on nano ZrO2 powders and their photocatalytic activity. Mater. Lett. 2006, 60, 2101–2104. [Google Scholar] [CrossRef]

- Chen, W.; Xue, S.; Wang, H. Wetting properties and interfacial microstructures of Sn-Zn-xGa solders on Cu substrate. Mater. Des. 2010, 31, 2196–2200. [Google Scholar] [CrossRef]

- Chang, T.C.; Wang, J.W.; Wang, M.C.; Hon, M.H. Solderability of Sn-9Zn-0.5Ag-1In lead-free solder on Cu substrate: Part 1. Thermal properties, microstructure, corrosion and oxidation resistance. J. Alloys Compd. 2006, 422, 239–243. [Google Scholar] [CrossRef]

- Chang, S.H.; Wu, S.K. Damping characteristics of Sn-3Ag-0.5Cu and Sn-37Pb solders studied by dynamic mechanical analysis. Scr. Mater. 2010, 63, 957–960. [Google Scholar] [CrossRef]

- Ahmed, S.; Hasnine, M.; Suhling, J.C.; Lall, P. Mechanical characterization of SAC solder joints at high temperature using nanoindentation. In Proceedings of the 67th IEEE Electronic Components and Technology Conference (ECTC 2017), Orlando, FL, USA, 30 May–2 June 2017; pp. 1128–1135. [Google Scholar]

- Sutou, Y.; Omori, T.; Koeda, N.; Kainuma, R.; Ishida, K. Effects of grain size and texture on damping properties of Cu-Al-Mn-based shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 743–746. [Google Scholar] [CrossRef]

- Kripesh, V.; Teo, P.S.; Tai, C.T.; Vishwanadam, G.; Mui, Y.C. Development of a lead-free chip scale package for wireless applications. In Proceedings of the 51st Electronic Components & Technology Conference, Orlando, FL, USA, 29 May–1 June 2001; pp. 665–670. [Google Scholar]

- Song, J.M.; Liu, P.C.; Shih, C.L.; Lin, K.L. Role of Ag in the formation of interfacial intermetallic phases in Sn-Zn soldering. J. Electron. Mater. 2005, 34, 1249–1254. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, K.S.; Inoue, M.; Jiang, J.; Suganuma, K. Effects of Ag and Cu addition on microstructural properties and oxidation resistance of Sn-Zn eutectic alloy. J. Alloys Compd. 2008, 454, 310–320. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gain, A.K.; Zhang, L. Nanoindentation Creep, Elastic Properties, and Shear Strength Correlated with the Structure of Sn-9Zn-0.5nano-Ag Alloy for Advanced Green Electronics. Metals 2020, 10, 1137. https://doi.org/10.3390/met10091137

Gain AK, Zhang L. Nanoindentation Creep, Elastic Properties, and Shear Strength Correlated with the Structure of Sn-9Zn-0.5nano-Ag Alloy for Advanced Green Electronics. Metals. 2020; 10(9):1137. https://doi.org/10.3390/met10091137

Chicago/Turabian StyleGain, Asit Kumar, and Liangchi Zhang. 2020. "Nanoindentation Creep, Elastic Properties, and Shear Strength Correlated with the Structure of Sn-9Zn-0.5nano-Ag Alloy for Advanced Green Electronics" Metals 10, no. 9: 1137. https://doi.org/10.3390/met10091137

APA StyleGain, A. K., & Zhang, L. (2020). Nanoindentation Creep, Elastic Properties, and Shear Strength Correlated with the Structure of Sn-9Zn-0.5nano-Ag Alloy for Advanced Green Electronics. Metals, 10(9), 1137. https://doi.org/10.3390/met10091137