Carbon Particle In-Situ Alloying of the Case-Hardening Steel 16MnCr5 in Laser Powder Bed Fusion

Abstract

:1. Introduction and Literature Review

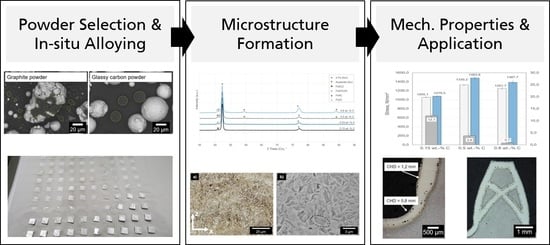

2. Materials and Methods

3. Results

3.1. Microstructure and Carbon Depletion of 16MnCr5

3.2. Carbon Particle Selection and Particle Size Distribution of Pre-Mixed Powders

3.3. Processing by Powder Bed Fusion Using a Laser Beam

3.4. Mechanical Properties

4. Discussion

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Kranz, J.; Herzog, D.; Emmelmann, C. Design guidelines for laser additive manufacturing of lightweight structures in TiAl6V4. J. Laser Appl. 2015, 27, S14001. [Google Scholar] [CrossRef]

- VDI-Fachbereich Produktionstechnik und Fertigungsverfahren. 2014. VDI-Richtlinie 3405. Available online: https://www.vdi.de/richtlinien/details/vdi-3405-additive-fertigungsverfahren (accessed on 23 March 2021).

- Lutter-Guenther, M.; Seidel, S.; Kamps, T.; Reinhart GLutter-Guenther, M.; Seidel, S.; Kamps, T.; Reinhart, G. Imple-mentation of Additive Manufacturing Business Models. Appl. Mech. Mater. 2015, 794, 547–554. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Schmitt, M.; Schlick, G.; Seidel, C.; Reinhart, G. Examination of the processability of 16MnCr5 by means of laser powder bed fusion. Procedia CIRP 2018, 74, 76–81. [Google Scholar] [CrossRef]

- Niemann, G.; Winter, H. Maschinenelemente: Band 2: Getriebe Allgemein, Zahnradgetriebe—Grundlagen, Stirnradgetriebe, Zweite, Völlig Neubearbeitete Auflage Ed; Springer: Berlin/Heidelberg, Germany, 2003; 376p. [Google Scholar]

- Conrado, E.; Gorla, C.; Davoli, P.; Boniardi, M. A comparison of bending fatigue strength of carburized and nitrided gears for industrial applications. Eng. Fail. Anal. 2017, 78, 41–54. [Google Scholar] [CrossRef]

- Kamps, T.; Reinhart, G. Increasing Transmission Efficiency by Implementation of a Conformal Cooling System Using Additive Manufacturing; Fraunhofer: Berlin, Germany, 2014. [Google Scholar]

- Ziebura, D.; Meiners, W. Verarbeitung von Einsatz- und Vergütungsstählen Mittels SLM; Fraunhofer ILT: Aachen, Germany, 2016; 1p. [Google Scholar]

- Kluge, M.; Kotthoff, G.; Cavallini, C.; Höges, S. Design and Production of Innovative Transmission Com-Ponents with Additive Manufacturing. In Proceedings of the 16th International CTI Symposium Automotive Transmissions, HEV and EV Drives, Berlin, Germany, 4–7 December 2017. [Google Scholar]

- Kamps, T. Leichtbau von Stirnzahnrädern aus Einsatzstahl Mittels Laserstrahlschmelzen; Technical University Munich: Munich, Germany, 2018; 199p. [Google Scholar]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Beer, O.; Merklein, C.; Gerhard, D.; Hentschel, O.; Rasch, M.; Schmidt, M. Processing of the Heat Resistant Bearing Steel M50NiL by Selective Laser Melting. HTM J. Heat Treat. Mater. 2018, 73, 187–201. [Google Scholar] [CrossRef]

- Siglmueller, F.; Kupfer, S.; Kamps, T.; Schmitt, M.; Lohner, T.; Reinhart, G.; Stahl, K. Efficiency of Additive Manufactured Gears with Conformal Cooling. In Proceedings of the 21st TAE International Colloquium Tribology, Stuttgart, Germany, 9–11 January 2018. [Google Scholar]

- Schmitt, M.; Jansen, D.; Bihlmeir, A.; Winkler, J.; Anstaett, C.; Schlick, G.; Tobie, T.; Stahl, K.; Reinhart, G. Framework and strategies for the lightweight construction of AM gears for the au-tomotive industry. Proc. RapidTech 2019. [Google Scholar] [CrossRef]

- Rehme, O. Cellular Design for Laser Freeform Fabrication. Ph.D. Dissertation, Technical University Hamburg-Harburg, Hamburg, Germany, 2009; 150p. [Google Scholar]

- Nakamoto, T.; Shirakawa, N.; Miyata, Y.; Inui, H. Selective laser sintering of high carbon steel powders studied as a function of carbon content. J. Mater. Process. Technol. 2009, 209, 5653–5660. [Google Scholar] [CrossRef] [Green Version]

- Taha, M.A.; Yousef, A.F.; Gany, K.A.; Sabour, H.A. On selective laser melting of ultra high carbon steel: Effect of scan speed and post heat treatment. Mater. und Werkst. 2012, 43, 913–923. [Google Scholar] [CrossRef]

- Jelis, E.; Clemente, M.; Kerwien, S.; Ravindra, N.M.; Hespos, M.R. Metallurgical and Mechanical Evaluation of 4340 Steel Produced by Direct Metal Laser Sintering. JOM 2015, 67, 582–589. [Google Scholar] [CrossRef]

- Zhao, X.; Song, B.; Zhang, Y.; Zhu, X.; Wei, Q.; Shi, Y. Decarburization of stainless steel during selective laser melting and its influence on Young’s modulus, hardness and tensile strength. Mater. Sci. Eng. A 2015, 647, 58–61. [Google Scholar] [CrossRef]

- Liedtke, D. Über den Zusammenhang zwischen dem Kohlenstoffgehalt in Stählen und der Härte des Martensits. Mater. Und Werkst. 2003, 34. [Google Scholar] [CrossRef]

- Prinz, C.; Clausen, B.; Hoffmann, F.; Kohlmann, R.; Zoch, H.-W. Metallurgical influence on distortion of the case-hardening steel 20MnCr5. Mater. Und Werkst. 2006, 37, 29–33. [Google Scholar] [CrossRef]

- Tobie, T. Zur Grübchen- und Zahnfußtragfähigkeit Einsatzgehärteter Zahnräder. Ph.D. Dissertation, Technical University Munich, Munich, Germany, 2001; 215p. [Google Scholar]

- Mosallanejad, M.H.; Niroumand, B.; Aversa, A.; Saboori, A. In-situ alloying in laser-based additive manufacturing processes: A critical review. J. Alloy. Compd. 2021, 872, 159567. [Google Scholar] [CrossRef]

- Anstaett, C.; Seidel, C.; Reinhart, G. Fabrication of 3D-Multi-Material Parts by Laser Beam Based Powder Bed Fusion. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Sing, S.; Huang, S.; Goh, G.; Tey, C.; Tan, J.H.K.; Yeong, W. Emerging metallic systems for additive manufacturing: In-situ alloying and multi-metal processing in laser powder bed fusion. Prog. Mater. Sci. 2021, 119, 100795. [Google Scholar] [CrossRef]

- Murali, K.; Chatterjee, A.; Saha, P.; Palai, R.; Kumar, S.; Roy, S.; Mishra, P.; Choudhury, A. Direct selective laser sintering of iron–graphite powder mixture. J. Mater. Process. Technol. 2003, 136, 179–185. [Google Scholar] [CrossRef]

- Simchi, A.; Pohl, H. Direct laser sintering of iron–graphite powder mixture. Mater. Sci. Eng. A 2004, 383, 191–200. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Zhang, B.; Fenineche, N.-E.; Liao, H.; Coddet, C. Magnetic properties of in-situ synthesized FeNi3 by selective laser melting Fe-80%Ni powders. J. Magn. Magn. Mater. 2013, 336, 49–54. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Mertens, R.; Hao, L.; van Humbeeck, J.; Kruth, J.-P. Selective Laser Melting to Manufacture “In Situ” Metal Matrix Composites: A Review. Adv. Eng. Mater. 2019, 21, 1801244. [Google Scholar] [CrossRef] [Green Version]

- Mair, P.; Goettgens, V.S.; Rainer, T.; Weinberger, N.; Letofsky-Papst, I.; Mitsche, S.; Leichtfried, G. Laser powder bed fusion of nano-CaB6 decorated 2024 aluminum alloy. J. Alloy. Compd. 2021, 863, 158714. [Google Scholar] [CrossRef]

- Vilardell, A.; Takezawa, A.; du Plessis, A.; Takata, N.; Krakhmalev, P.; Kobashi, M.; Albu, M.; Kothleitner, G.; Yadroitsava, I.; Yadroitsev, I. Mechanical behavior of in-situ alloyed Ti6Al4V(ELI)-3 at.% Cu lattice structures manufactured by laser powder bed fusion and designed for implant applications. J. Mech. Behav. Biomed. Mater. 2021, 113, 104130. [Google Scholar] [CrossRef] [PubMed]

- Mosallanejad, M.; Niroumand, B.; Aversa, A.; Manfredi, D.; Saboori, A. Laser Powder Bed Fusion in-situ alloying of Ti-5%Cu alloy: Process-structure relationships. J. Alloy. Compd. 2021, 857, 157558. [Google Scholar] [CrossRef]

- Hentschel, O.; Siegel, L.; Scheitler, C.; Huber, F.; Junker, D.; Gorunow, A.; Schmidt, M. Processing of AISI H11 Tool Steel Powder Modified with Carbon Black Nanoparticles for the Additive Manufacturing of Forging Tools with Tailored Mechanical Properties by Means of Laser Metal Deposition (LMD). Metals 2018, 8, 659. [Google Scholar] [CrossRef] [Green Version]

- Koptyug, A.; Popov, V.V.; Botero Vega, C.A.; Jiménez-Piqué, E.; Katz-Demyanetz, A.; Rännar, L.-E.; Bäckström, M. Compositionally-tailored steel-based materials manufactured by electron beam melting using blended pre-alloyed pow-ders. Mater. Sci. Eng. A 2020, 771, 138587. [Google Scholar] [CrossRef]

- Köhnen, P.; Ewald, S.; Schleifenbaum, J.H.; Belyakov, A.; Haase, C. Controlling microstructure and mechanical prop-erties of additively manufactured high-strength steels by tailored solidification. Addit. Manuf. 2020, 35, 101389. [Google Scholar]

- Katz-Demyanetz, A.; Koptyug, A.; Popov, V.V. In-situ Alloying as a Novel Methodology in Additive Manufac-Turing. In Proceedings of the 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP), Sumy, Ukraine, 9–13 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Chen, P.; Yang, C.; Li, S.; Attallah, M.M.; Yan, M. In-situ alloyed, oxide-dispersion-strengthened CoCrFeMnNi high entropy alloy fabricated via laser powder bed fusion. Mater. Des. 2020, 194, 108966. [Google Scholar] [CrossRef]

- Spira, C. Erweiterung der Prozessgrenzen Von Laserbasierten Härteverfahren im Automotive-Bereich; Technical University Dresden: Dresden, Germany, 2016; 178p. [Google Scholar]

- Schulze, G. Die Metallurgie des Schweissens: Eisenwerkstoffe—Nichteisenmetallische Werkstoffe, 4., Neu Bearbeitete Aufl. Ed; Springer: Heidelberg, Germany; New York, NY, USA, 2010; 614p. [Google Scholar]

- Burkart, K.; Bomas, H.; Zoch, H.-W. Fatigue of notched case-hardened specimens of steel SAE 5120 in the VHCF re-gime and application of the weakest-link concept. Int. J. Fatigue 2011, 33, 59–68. [Google Scholar] [CrossRef]

- Dahmen, M.; Lindner, S.; Monfort, D.; Petring, D. Weld Metallurgy and Mechanical Properties of High Manganese Ultra-high Strength Steel Dissimilar Welds. Phys. Procedia 2016, 83, 344–351. [Google Scholar] [CrossRef]

- Le, T.-N.; Lo, Y.-L. Effects of sulfur concentration and Marangoni convection on melt-pool formation in transition mode of selective laser melting process. Mater. Des. 2019, 179, 107866. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Hammons, J.A.; Khairallah, S.A.; Nielsen, M.H.; Shuttlesworth, R.M.; Sinclair, N.; Matthews, M.J.; Jeffries, J.R.; Willey, T.M.; et al. Ultrafast dynamics of laser-metal interactions in additive manufacturing alloys captured by in situ X-ray imaging. Mater. Today Adv. 2019, 1, 100002. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Tröster, T.; Hoyer, K.-P.; Schaper, M. Duplex stainless steel fabricated by selective laser melting—Microstructural and mechanical properties. Mater. Des. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Calleja-Ochoa, A.; Gonzalez-Barrio, H.; de Lacalle, N.L.; Martínez, S.; Albizuri, J.; Lamikiz, A. A New Approach in the Design of Microstructured Ultralight Components to Achieve Maximum Functional Performance. Materials 2021, 14, 1588. [Google Scholar] [CrossRef]

| Elements | C | Mn | Cr | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|

| (1) | 0.14–0.19 | 1.0–1.3 | 0.8–1.1 | ≤0.4 | ≤0.025 | ≤0.035 | residual |

| (2) | 0.15 | 1.05 | 0.9 | 0.19 | - | - | residual |

| Elements | C | Mn | Cr | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|

| (1) | 0.15 | 1.05 | 0.9 | 0.19 | - | - | residual |

| (2) | 0.13 | 0.86 | 0.97 | 0.15 | 0.01 | 0.008 | residual |

| (3) | −13% | −19% | +7% | −21% | - | - | - |

| Powder | D10 | D50 | D90 |

|---|---|---|---|

| 16MnCr5 | 28 µm | 47 µm | 72 µm |

| Graphite 1 | 5 µm | 14 µm | 130 µm |

| Graphite 2 | 15 µm | 42 µm | 116 µm |

| Glassy Carbon | 18 µm | 30 µm | 114 µm |

| Carbon Content, wt.% | 0.15 | 0.3 | 0.4 | 0.5 | 0.8 |

|---|---|---|---|---|---|

| Relative density, % | 99.93 | 99.89 | 99.91 | 99.91 | 99.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmitt, M.; Gottwalt, A.; Winkler, J.; Tobie, T.; Schlick, G.; Stahl, K.; Tetzlaff, U.; Schilp, J.; Reinhart, G. Carbon Particle In-Situ Alloying of the Case-Hardening Steel 16MnCr5 in Laser Powder Bed Fusion. Metals 2021, 11, 896. https://doi.org/10.3390/met11060896

Schmitt M, Gottwalt A, Winkler J, Tobie T, Schlick G, Stahl K, Tetzlaff U, Schilp J, Reinhart G. Carbon Particle In-Situ Alloying of the Case-Hardening Steel 16MnCr5 in Laser Powder Bed Fusion. Metals. 2021; 11(6):896. https://doi.org/10.3390/met11060896

Chicago/Turabian StyleSchmitt, Matthias, Albin Gottwalt, Jakob Winkler, Thomas Tobie, Georg Schlick, Karsten Stahl, Ulrich Tetzlaff, Johannes Schilp, and Gunther Reinhart. 2021. "Carbon Particle In-Situ Alloying of the Case-Hardening Steel 16MnCr5 in Laser Powder Bed Fusion" Metals 11, no. 6: 896. https://doi.org/10.3390/met11060896

APA StyleSchmitt, M., Gottwalt, A., Winkler, J., Tobie, T., Schlick, G., Stahl, K., Tetzlaff, U., Schilp, J., & Reinhart, G. (2021). Carbon Particle In-Situ Alloying of the Case-Hardening Steel 16MnCr5 in Laser Powder Bed Fusion. Metals, 11(6), 896. https://doi.org/10.3390/met11060896