1. Introduction

Additive manufacturing (AM) technology builds parts layer by layer using powders as a medium in 3D printers. The powders are exposed to a heat source and are melted. Referring to the manufacturing method, the heat source could be a laser or electron beam. It can be regarded as a revolution in fabrication technologies due to its superior advantages. AM technology leads the part directly from design to production. It reduces the need for conventional methods like casting and punching and enables building complex parts directly. Fabrication with additive technology reduces the need for large assembly and allows manufacture of unique parts in assemblies [

1,

2]. One of the most favorable techniques of additive manufacturing technology is selective laser melting (SLM). In the SLM process, a layer of powder is spread on the build plate. The laser beam respecting the pattern which is designed and imported to the machine scans the powder layer, and the process repeats for every layer, and finally, the part will be ready for post-processes if needed [

3,

4,

5].

The properties of the final product, especially its metallurgical properties, are affected by various parameters, of which the most important one is the formed temperature during the printing [

6]. Subsequently, the forming temperature is affected by various factors such as laser power, scanning velocity, laser spot diameter, powder size, preheating, and laser beam properties. Keeping the temperature constant and preventing deviation of temperature from the specified value is also necessary for having a homogeneous and uniform structure [

7,

8]. Currently, the suitable process parameters which lead to a desired microstructure are often extracted by the experimental methods which are highly costly and time-consuming. A reliable model will able us to extract the process parameters at very low cost and in little time. The suitable process parameters will result in a final product with minimum defects. Zhang et al. [

9] investigated a thermal model to study the melt-pool of alumina ceramics. They showed that the laser power and the scanning velocity influence the maximum temperature, lifetime, dimensions, and temperature gradients of the melt-pool. Bruna-Rosso et al. [

10] developed a model to compute the thermal field in millimeter-scale together with the consequent melt-pool dimension and temperature, and the model was validated with high-speed imaging. A two-dimensional finite difference model was developed by Foteinopoulos et al. [

11] to calculate the temperature of a part in each time step, and employed an algorithm for node birth and distance adaptation over time to reduce the computational time.

However, it is not possible to obtain the true and error-free temperature of the weld pool without considering the driving forces in the weld pool. In other words, modeling the process only as a thermal model is not realistic, and it needs to contribute the convection in the flow to the model. Leitz et al. [

12] studied the effect of the laser power and laser energy density on the melt-pool width by developing a multiphysics model. They figured out that the melt-pool dimensions are wider in steel compared to the molybdenum because of the thermal conductivity difference in materials. Artinov et al. [

13] developed a multiphysics model to calculate a reliable equivalent heat source and to predict the thermal behavior during the laser welding using a moving mesh and weak constraints. Bayat et al. [

14] investigated a multiphysics model for laser-based powder bed fusion to study the keyhole phenomena in the melting of Ti6Al4V and confirmed their work by doing an X-CT analysis. Courtois et al. [

15] simulated the SLM and keyhole formation with a new approach. They took the reflection of the laser beam in the keyhole into account. Finally, they compared the melt-pool shapes resulting from modeling with experimental micrographs. T. Mukherjee et al. [

16] developed a three-dimensional (3D), transient, heat transfer, and fluid flow model to calculate temperature and velocity fields, build shape and size, cooling rates, and the solidification parameters during the PBF process. Shi, Xuezhi, et al. [

17] developed a single-track method for parameter optimization of Ti-47Al-2Cr-2Nb powder in SLM. Using the single-track scan results, they developed a parameter window and optimized the fabrication parameters for Ti-47Al-2Cr-2Nb powder. They also built regression models to predict the geometric characteristics of single tracks. The listed works do not suppose a certain process parameter window and do not comprise a sample part experimental task. Almost all of their experimental confirmation is done in single layer scanning, not sample part fabrication, which includes the previous and next layers’ effect. As such, these models are presented only as developed models, and there is a significant gap in the development of various process parameters and the relationships between them and their application for sustainable performance during printing. That is to say, what are still missing, are the various process parameter sets and the mutual relationships between them. These have been obtained via a reliable model that presents us the temperature values considering the melt process’s effective aspects.

The special properties of austenitic steels make them the most popular group of high-alloy stainless steels. The contribution of various alloy elements gives them a very important and notable feature in the laser powder bed fusion: their weldability and usefulness allocate a special space for them in additive manufacturing, and 316L stainless steel, as austenitic steel, stands out with its perfect resistance to oxidation at high temperatures while maintaining a low coefficient of thermal expansion, creep resistance, resistance to fatigue, and heat resistance [

18,

19,

20,

21].

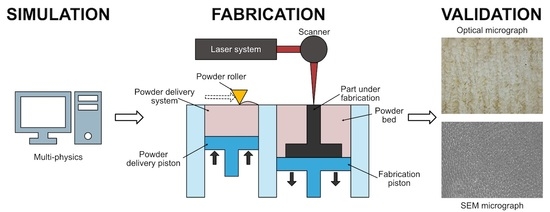

Based on these issues, the paper develops vast sets of the process parameters and the mathematical relationship between them for suitable and controllable fabrication using stainless steel 316L powder. A 3D multiphysics model is developed. The model solves three equations of heat transfer, conservation of mass, and time-dependent momentum by using temperature-dependent material properties. The volumetric moving heat source is included in heat transfer physics, and driving forces are considered in fluid flow physics. The model presents parameter sets and discusses the microstructure (defects) of samples fabricated by employing extracted parameters. In addition, the mathematical relationships between laser power, laser spot diameter, and temperature of the melt-pool are developed. These relationships allow one to predict the temperature and consequently to predict the part structure. The mathematical relationships are the basis of the controller design to form a sustainable melt-pool temperature during the printing process and to simultaneously achieve a final designed part with a minimum defect and homogeneous microstructure.

Although the process parameters applicable to 3D printing of 316L stainless steel to obtain dense structures are available in the literature, the method proposed in this study has the following advantages:

The proposed approach develops parameter sets by simulating multiphysics phenomena between the energy source and powder interaction. Therefore, comprehensive process parameter windows containing sensitive process parameters could be obtained for adding a promising numerical model to the literature.

The numerical model is developed using more than one type of physics. Rather than using heat transfer physics only, laminar flow physics is also included into the simulation which gives a more realistic approach to the SLM operation.

Direct mathematical relationships between process parameters are developed to instantly compute the melt-pool maximum temperature. These mathematical relationships could be used as the basic elements in the controller design of the 3D printer machine to control the melt-pool temperature during the process.

3. Equations Governing SLM Process

The mathematical model has been established to simulate laser and powder interaction in a 3D environment. Given the laser energy source,

, the temperature and temperature gradient field relationship is described by the energy Equation (1), which can be numerically solved to simulate the temperature change in the SLM process:

where

,

,

,

,

,

,

,

, and

are density

, modified specific heat capacity

, temperature

, time

, velocity

, thermal conductivity

, absorption coefficient (-), input laser energy source

, radiated energy source

, and evaporation heat loss

, respectively. Shadowing effect, multi-reflection, and beam angle effect on the absorption of the laser are neglected [

12].

Since the heat source determines the generated energy of laser power and leads to temperature build-up in the melt-pool, it is important to select an appropriate heat source model. The forming temperature would affect the microstructure and the mechanical structure of the final product, so the heat source model should be the nearest model to reality. The models may be introduced as two-dimensional or three-dimensional. The two-dimensional Gaussian model involves only the distribution of heat in x and y directions in time t. In reality, the laser beam acts in 3D and also penetrates the powders. The volumetric heat source [

23] is developed to contribute to the penetration of the laser beam into the powders. Then it should involve the penetration direction in addition to the surface directions of the powders. The model used in this paper belongs to the absorptivity profile group, which is a volumetric Gaussian distribution model and involves the penetration of the laser beam into the powders [

24,

25]:

where

,

,

,

,

, and

are the intensity of the laser beam at the beam axis

, penetration distance of the laser beam

, distance from the point to the center of the beam

, the radius of the laser beam

, the vertical position of the powder

, the position of the top of powder

, and

denotes the laser power

. The vertical position of the powder,

, shows the

and

positions of every irradiated point at time

(

) through the scanning path with a scanning velocity of

that is equal to

[

9].

On the other hand, radiative heat loss is illustrated using the Stefan–Boltzmann law, which is nonlinear and is denoted by:

where

,

, and

are the emissivity of the powder (-), Stefan–Boltzmann constant for radiation

, and ambient temperature (K), respectively. Evaporation heat loss is also introduced, which is determined through the following Equation [

26]:

where

,

, and

are latent heat of evaporation

, evaporation rate

, and mesh size (m), respectively. Referring to the Hertz–Knudsen equation, the evaporation rate is determined as [

27]:

where

,

,

, and

are vapor pressure

at the temperature of

, ambient pressure

, molar mass

, and ideal gas constant

, respectively. The vapor pressure at the temperature of

can be determined from the following Equation [

27]:

where

is the evaporation temperature

.

As powder absorbs heat energy from the laser beam, it melts, and phase transformation occurs from solid to liquid. Here, fluid flow physics solves the conservation of mass and momentum equations. The equations are:

where

,

,

,

, and

are pressure

, identity matrix, viscosity

, transposed matrix, gravity

, and volume force

, respectively [

13].

The volume force contains four terms involved in buoyancy force (first term), Carman–Kozeny equation (second term), surface tension force (third term), and Marangoni effect (fourth term) as [

16,

28,

29]:

where

,

,

,

,

, and

are coefficients of thermal expansion

, melting temperature

, curvature of interface, surface tension coefficient

, unit normal to the local surface, and surface gradient operator, respectively. The buoyancy force is the deviation of the density during changing temperature.

Carman–Kozeny equation defines the mushy zone. The transition from the solid phase to the liquid phase takes place during a temperature interval, which is named the melting interval (

). During this interval, the metal is a mixture of the solid and liquid phases. This mixed region is named the mushy zone [

29].

is a huge constant that is defined to fix the powders under melting temperature as a solid phase, and

is a small constant to satisfy the convergence during the simulation. Since the liquid fraction

is zero under the liquidus temperature

, the presence of

in this case does not allow the denominator to be zero. This damping force acts only in the mushy and solid-state of the material and vanishes in the liquid phase. The vanishing occurs linearly, along

, which changes linearly with respect to the solidus temperature (

) and liquidus temperature,

Conversely to melting, when the solidification of molten metal starts, respectively this force starts to grow and act on the solidified metal. As an alternative to the Carman–Kozeny force, powders can be assumed as a highly viscous fluid material in the solid phase in simulations. Parallel use of these two ways can be used as well, however, this may present convergence difficulties. Here, the simulations have been performed by applying the Carman–Kozeny force only.

The melt-pool surface indicates a free surface, which is defined as an open boundary. The Marangoni effect is a result of spatial variation of the surface tension coefficient due to temperature gradients. The surface tension acts as normal, and the Marangoni effect applies a tangential force on the surface. In simulations, the molten flow was assumed to be laminar and incompressible.

The present study uses the above-introduced multiphysical phenomena to simulate the powder–laser beam interaction. Although the use of these equations has been reported before, the main of objective of our study was to find out an allowable process parameter set for the SLM additive manufacturing of a given material.

6. Results and Discussion

The simulation model presents coupling of two types of physics, and the results are shown in

Figure 3. An SLM process was simulated and melting during moving laser heat source was presented. The simulations were done in symmetry mode to reduce the calculations and process time. Basically,

Figure 3 illustrates the temperature values of a powder layer for a given set of laser power, laser spot diameter, and scanning velocity. The symmetry view (

Figure 3a) shows the laser beam penetration in powder, and the complete view (

Figure 3b) shows a complete scanned row of powders. Isosurface temperature view (

Figure 3c) and the phase change is depicted (

Figure 3d).

Figure 3d is an illustration of the melted area. The area with the value of one is the liquid phase, while the zero value area belongs to the solid phase. Indeed, the area with the value of one is the melt-pool area. The thin border area, which has a value between one and zero, is the mushy region as illustrated earlier.

Selecting proper process parameters is undoubtedly crucial for various aspects of additively manufactured parts. Optimal process parameters can reduce the cracking effect and reach fully density [

35]. This also leads to optimum and adequate microstructure and mechanical properties [

36]. Improper parameters will result in pores and spatters, leading to undesired mechanical properties; also, low speed of manufacturing or high fabrication costs will be encountered if improper process parameters are used. The investigated model enables us to simulate the process with selected parameters. That is to say, the model is a tool that we can use to predict the process parameters in the SLM.

Low melt-pool temperature will result in pores in the manufactured parts. Lack of fusion causes elongated and inconsistent pores. These defects refer to insufficient temperature in the melt-pool [

37]. Through low temperature, there might be unmelted powders, which will lead to a part full of pore defects. On the other hand, extreme temperatures will result in defects such as spatter, overcooking, holes, and high heat tensions. Spatters come up due to evaporation force, which forces the melted metal to separate from the plane by overcoming surface tension. It leads to surface defects in layers. Accordingly, the temperature exceeding the evaporation temperature leads to undesirable products. Evaporation may lead to the formation of keyhole pores that are deeply embedded in the part [

38]. However, fabrication speed is an important issue in the process; high scanning speeds lead to fast fabrication.

Referring to all the mentioned notes above, the most important goal is to reach a complete melting without evaporation. Indeed, the favorable parameters are a set of parameters that melt the distributed powder layer completely and also melt a part of the prior layers to make a proper bond between layers. For this purpose, the selected parameters should satisfy the melting phenomena all over the powder layer. The most critical area is the depth of the powder layer. If the parameter set produces enough temperature at a depth of the powder layer for melting, and meanwhile the parameter set does not lead to any evaporation at any part of the powder layer, this may be considered as a proper and satisfactory parameter set which does not cause any defects due to temperature deficiency or excess. Formation of the spatter and residual porosities are related and promoted by instability regimes at high energy density [

39]. For this purpose, in this study, the maximum temperature was recorded at the depth of

, since the powder layer thickness in experiments was

. To reveal the effects of different process parameters on the SLM additive manufacturing of stainless steel, the simulations have been carried out for the various sets of parameters.

6.3. Experimental Confirmation

Using stainless steel 316L powders, ten samples were manufactured in a Concept Laser M2 Cusing Machine. Samples were fabricated with ten various sets of parameters, which are listed in

Table 7. Scanning velocities of 0.6 m/s,

,

, and

were used during the experimental study. Fabricated samples were categorized into two groups of constant laser spot diameter and constant laser power (for more details, please see the

Supplementary Materials). Based on the simulation results obtained from the multiphysics software Comsol, three regions were specified which are: “below melting temperature line”, “between melting temperature and evaporation temperature lines”, and “above the evaporation temperature line”. The emphasis was given to the region that offers defectless and usable structures, which is “between melting and evaporation temperature lines”. This rich area shows the variety of parameters presented by the research. In addition, samples were fabricated employing parameters from sensitive areas with a potential of lack of fusion, “below melting temperature line”, and over melting, “above the evaporation temperature line”, to show the kind of results obtained by selecting parameters from these sensitive areas. Microstructures were examined and results with respect to the selected parameters were obtained.

Referring to optic micrographs of the fabricated samples in

Figure 9, defects are seen in samples (a), (b), (g), and (j). Voids in samples (a) and (b) are mainly circular. Defects in the samples (g) and (j), are large irregular defects that are the result of lack of fusion and not having sufficient energy in melting. The large irregular defects indicate insufficient layer–layer or track–track bonding [

38]. These defects spread unevenly in the 20–250

length range in cases (g) and (j) in

Figure 9. There are some defects in the sample (e), which may not be, in general, related to parameter selection. They could be related to the inert gas trapped in the powder production process, powder bed packing or equipment-related defects such as the deflection of the beam and the calibration error of beam and also insufficiently qualified Galvano mirrors [

41].

As cases (a) and (b) show in

Figure 9, extreme laser power triggers various defects. Powder denudation is one of them, which causes large and grooved defects. Another defect could be spatter that occurs with high energy inputs, and details are provided in the

Figure 9. Spatter occurs when the metal vapor force overcomes the surface tension force and it is difficult to be melted in the next layers; usually spatters are larger than powder size, and would remain as inclusions [

42]. Keyholes are one of the most common defects with high energy inputs, which are a result of the vaporization of metal [

38]. In cases (a) and (b) of

Figure 9, the defects are generally in the 35–55

range and are typically larger than the powder size. At high energies, crack defects are another defect that is related to high-temperature gradients. Excessive energy input increases cracking ability by decreasing the cracking stress threshold (see

Supplementary Materials) [

38]. Two spatters with a total length of close to 100 μm are shown in

Figure 9 as a result of excessive energy implementation in sample (a). A crack about 50 μm long caused by the same factor in sample (b) is shown in

Figure 9; also, voids could be observed with a diameter of 30–50

with an interlayered morphology. The lines are related to the melt-pool boundaries, and they possibly are the result of high residual stress in the high-speed cooling process. It could encourage the formation of the crack along melt-pool boundaries (

Figure 10) [

43].

Unmelted regions that belong to the sample j are shown more accurately in

Figure 10. Unmelted powders are evident, and those pores could have two causes. One of them is the lack of sufficient energy to melt them, and another reason is the balling. The balling is the agglomeration of powders to minimize the surface energy due to high viscosity or high wetting angle of the molten track [

43]. Regarding the selected parameter set for the fabrication of sample j and

Figure 10, in this case, the reason for the phenomena is insufficient laser energy to melt powders.

There are some other defects which may not depend on the parameters of fabrication, and could probably occur during any fabrication parameters. One of them is gas bubbles, which are entrapped in the melt. Another common defect is due to reusing powder from the previous fabrications [

38,

43,

44,

45,

46,

47,

48,

49,

50,

51].

The samples of (c), (d), (e), (f), (h), and (i) have minimum defects and are almost clean. These samples have parameter sets located in the area between the melting and evaporation lines in the diagram of the simulation results. Their SEM images show favorable structures (see

Supplementary Materials, Figures S3 and S4). Reflection of SEM images of experimental results on simulation results is shown more conveniently in

Supplementary Materials.

It is also important to note that the melt-pool lifetime, the duration in which the powder melts and eventually solidifies, is a determinative factor in the melting process. Insufficient lifetime could result in incomplete melting and insufficient wetting of neighboring powders. It hinders the melting phase to propagate. Consequently, this inability will weaken melting the powders to ensure the stable and continuous melt-pool and satisfy hatch space. Sample (g) could be an example of this phenomena. Although the relative temperature for the parameter set of this sample is approximately on the melting temperature line, nevertheless there are unmelted powders in its microstructure. Based on the few previous sentences, most likely, these unmelted powders are a result of an insufficient lifetime ( based on the simulation for sample (g) of the melt-pool). Due to this issue, the area near the melting temperature line is a delicate area for the process fluctuations and therefore should be avoided for a guaranteed result.

Appearance of the lack of fusion defects in samples (g) and (j) with energy densities of and and relevant temperatures near to the melting point, reveals that process parameters should be selected outside of this insecure area. Process parameters that result in a temperature of more than almost and an energy density above , and also do not exceed the evaporation temperature, will be safe and will allow adequate melt-pool temperature, life-time duration and, as a result, a high-density final product.

Compared with the energy densities reported for producing stainless steel 316L in the literature, in which Yusuf, Shahir Mohd, et al. [

52] reported

, Kamath, Spierings, Adriaan B., and Gideon Levy [

53] reported

, and Li, Ruidi, et al. [

54] reported

, the abovementioned milestones show acceptable conformity.

Additionally, the corresponding energy density to the standard parameter set that the Concept Laser company has given for the machine employed for the experimental study here is .