Microstructure-Based Modelling of Flow and Fracture Behavior of Tailored Microstructures of Ductibor® 1000-AS Steel

Abstract

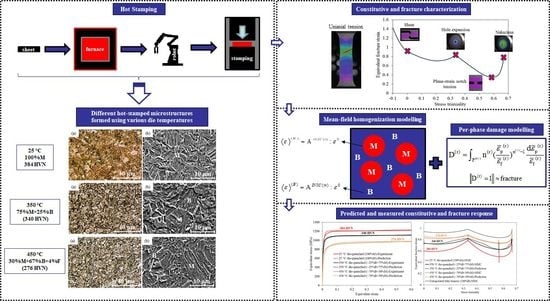

:1. Introduction

2. Experiments

3. Microstructure-Based Modelling

3.1. Flow Response

3.1.1. Flow Curves of Reference Microstructures

3.2. Fracture Response

Fracture Loci of Reference Microstructures

4. Results and Discussion

4.1. Microstructures and Hardness

4.2. Measured Constitutive Behavior

4.3. Fracture Behavior

4.4. MFH Predictions

4.4.1. Predicted Flow Response

4.4.2. Predicted Fracture Response

5. Conclusions

- (1)

- The microstructure, flow, and fracture response of Ductibor® 1000-AS are quench-rate sensitive within the range of cooling rates considered during hot stamping. A decrease in the cooling rate from 243 °C/s to 21 °C/s resulted in a 70% drop in the martensite content of the microstructure, a 26% reduction in UTS, and a 40–60% increase in the fracture strain for most of the investigated loading conditions.

- (2)

- The established numerical scheme based upon a hybrid micromechanical and phenomenological methodology predicted the hardening and fracture response in the multi-phase microstructures of the 350 °C and 450 °C die-quenched Ductibor® 1000-AS with reasonable accuracy.

- (3)

- Predictions for the hardening and fracture curves of the Ductibor® 1000-AS bainitic-martensitic microstructures with varied phase quantities revealed that a higher fraction of martensite results in the strengthening of the steel but at the expense of ductility.

- (4)

- Microscopic predictions demonstrated that with an increased martensite content in bainitic-martensitic microstructures of Ductibor® 1000-AS, the martensitic phase weakens, while the bainitic phase exhibits a transition from weakening to strengthening at a low martensite volume fraction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Material Anisotropy in Hardening Response

| Direction | Stress Ratio a | Lankford’s Coefficient (r-Value) b |

|---|---|---|

| Rolling (tensile) | 1.000 ± 0.008 c | 0.83 ± 0.01 |

| Diagonal (tensile) | 0.978 ± 0.005 | 1.00 ± 0.02 |

| Transverse (tensile) | 1.003 ± 0.008 | 0.85 ± 0.02 |

| Transverse (shear) | 0.587 ± 0.006 | - |

| 1.1082 | 0.9891 | 1.5816 | 1.3191 | −0.7266 | −0.8481 | 1.3505 | 0.9996 | 0.9996 |

| 0.3065 | 0.8068 | 0.7831 | 1.0162 | 1.1144 | 0.8287 | 0.6107 | 0.9996 | 0.9996 |

Appendix B. Validation of Hardening Curves

| Material Condition | (MPa) | (MPa) | (MPa) | R-Squared | ||

|---|---|---|---|---|---|---|

| 25 °C die-quenched | 415.39 | 1183.06 | 18.08 | 0.49 | 59.66 | 0.9946 |

| 350 °C die-quenched | 471.70 | 1079.40 | 11.93 | 0.41 | 49.27 | 0.9896 |

| 450 °C die-quenched | 325.93 | 895.25 | 8.32 | 0.38 | 106.54 | 0.9962 |

References

- Karbasian, H.; Tekkaya, A. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Samadian, P.; Parsa, M.H.; Shakeri, A. Determination of Proper Austenitization Temperatures for Hot Stamping of AISI 4140 Steel. J. Mater. Eng. Perform. 2014, 23, 1138–1145. [Google Scholar] [CrossRef]

- Samadian, P.; Parsa, M.H.; Mirzadeh, H. Prediction of Proper Temperatures for the Hot Stamping Process Based on the Kinetics Models. J. Mater. Eng. Perform. 2014, 24, 572–585. [Google Scholar] [CrossRef]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2015, 228, 11–24. [Google Scholar] [CrossRef]

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A review on tailored blanks—Production, applications and evaluation. J. Mater. Process. Technol. 2013, 214, 151–164. [Google Scholar] [CrossRef]

- ArcelorMittal. Steels for Hot Stamping; Technical Report; ArcelorMittal: Luxembourg City, Luxembourg, 2008. [Google Scholar]

- ArcelorMittal. Steels for Hot Stamping—Usibor®; Technical Report; ArcelorMittal: Luxembourg City, Luxembourg, 2016. [Google Scholar]

- Samadian, P.; Butcher, C.; Worswick, M.J. Microstructures and Flow Behavior of Ductibor® 500-AS Steel for a Range of As-Quenched Conditions. J. Mater. Eng. Perform. 2020, 29, 7153–7169. [Google Scholar] [CrossRef]

- Naderi, M.; Uthaisangsuk, V.; Prahl, U.; Bleck, W. A Numerical and Experimental Investigation into Hot Stamping of Boron Alloyed Heat Treated Steels. Steel Res. 2008, 79, 77–84. [Google Scholar] [CrossRef]

- Bardelcik, A.; Vowles, C.J.; Worswick, M.J. A Mechanical, Microstructural, and Damage Study of Various Tailor Hot Stamped Material Conditions Consisting of Martensite, Bainite, Ferrite, and Pearlite. Met. Mater. Trans. A 2018, 49, 1102–1120. [Google Scholar] [CrossRef]

- Eller, T.; Greve, L.; Andres, M.; Medricky, M.; Hatscher, A.; Meinders, V.; Boogaard, A.V.D. Plasticity and fracture modeling of quench-hardenable boron steel with tailored properties. J. Mater. Process. Technol. 2014, 214, 1211–1227. [Google Scholar] [CrossRef]

- Turetta, A.; Bruschi, S.; Ghiotti, A. Investigation of 22MnB5 formability in hot stamping operations. J. Mater. Process. Technol. 2006, 177, 396–400. [Google Scholar] [CrossRef]

- Barcellona, A.; Palmeri, D. Effect of Plastic Hot Deformation on the Hardness and Continuous Cooling Transformations of 22MnB5 Microalloyed Boron Steel. Met. Mater. Trans. A 2009, 40, 1160–1174. [Google Scholar] [CrossRef]

- Taylor, T.; Fourlaris, G.; Evans, P.; Bright, G. New generation ultrahigh strength boron steel for automotive hot stamping technologies. Mater. Sci. Technol. 2013, 30, 818–826. [Google Scholar] [CrossRef]

- Mohr, D.; Ebnoether, F. Plasticity and fracture of martensitic boron steel under plane stress conditions. Int. J. Solids Struct. 2009, 46, 3535–3547. [Google Scholar] [CrossRef] [Green Version]

- Abdollahpoor, A.; Chen, X.; Pereira, M.P.; Xiao, N.; Rolfe, B.F. Sensitivity of the final properties of tailored hot stamping components to the process and material parameters. J. Mater. Process. Technol. 2016, 228, 125–136. [Google Scholar] [CrossRef]

- Hagenah, H.; Merklein, M.; Lechner, M.; Schaub, A.; Lutz, S. Determination of the Mechanical Properties of Hot Stamped Parts from Numerical Simulations. Procedia CIRP 2015, 33, 167–172. [Google Scholar] [CrossRef] [Green Version]

- Srithananan, P.; Kaewtatip, P.; Uthaisangsuk, V. Micromechanics-based modeling of stress–strain and fracture behavior of heat-treated boron steels for hot stamping process. Mater. Sci. Eng. A 2016, 667, 61–76. [Google Scholar] [CrossRef]

- Östlund, R.; Golling, S.; Oldenburg, M. Microstructure based modeling of ductile fracture initiation in press-hardened sheet metal structures. Comput. Methods Appl. Mech. Eng. 2016, 302, 90–108. [Google Scholar] [CrossRef]

- Golling, S.; Östlund, R.; Oldenburg, M. Characterization of ductile fracture properties of quench-hardenable boron steel: Influence of microstructure and processing conditions. Mater. Sci. Eng. A 2016, 658, 472–483. [Google Scholar] [CrossRef] [Green Version]

- Golling, S.; Östlund, R.; Oldenburg, M. A stress-based fracture criteria validated on mixed microstructures of ferrite and bainite over a range of stress triaxialities. Mater. Sci. Eng. A 2016, 674, 232–241. [Google Scholar] [CrossRef] [Green Version]

- Mishra, K. Effects of Microstructure and Strain Rate on Deformation Behavior in Advanced High Strength Steels. Master’s Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2017. [Google Scholar]

- Samadian, P.; Butcher, C.; Worswick, M.J. A mean-field homogenization approach to predict fracture in as-quenched microstructures of Ductibor® 500-AS steel: Characterization and modelling. Int. J. Solids Struct. 2021, 229, 111137. [Google Scholar] [CrossRef]

- Güner, A.; Sonntag, M.; Philippot, C.; Bittendiebel, J.; Sarre, B.; Dormegny, L.; Reihani, A.; Heibel, S. Assuring Final Product Properties in BIW Applications Using Ductibor ® 1000 AS. In Proceedings of the 16th Erlanger Workshop Warmblechumformung, Erlangen, Germany, 9 November 2021. [Google Scholar]

- Sarkar, S.; Drillet, P.; Beauvais, M.; Ramisetti, N.; Dormegny, L. Ductibor® 1000 AlSi: A New PHS Development for a Crash Ductility Optimization. In Proceedings of the 6th International Conference—Hot Sheet Metal Forming of High-Performance Steel, Atlanta, GA, USA, 4 June 2017; pp. 591–600. [Google Scholar]

- Lee, S.H.; Peister, C.; Abedini, A.; Imbert, J.; Butcher, C.; Worswick, M.; Soldaat, R.; Bernert, W.; Famchon, E.; Penner, P.; et al. Dynamic Axial Crush Response of Ductibor® 1000-AS—Effect of Fold Initiator Pattern on Performance. In Proceedings of the 7th International Conference—Hot Sheet Metal Forming of High-Performance Steel, Luleå, Sweden, 2–5 June 2019. [Google Scholar]

- Mohamadizadeh, A.; Biro, E.; Worswick, M. Novel Double-Half Spot Weld Testing Technique For Damage Progress And Failure Analysis Using Digital Image Correlation Techniques. Exp. Mech. 2021, 61, 1405–1418. [Google Scholar] [CrossRef]

- Caron, E.J.; Daun, K.J.; Wells, M.A. Experimental heat transfer coefficient measurements during hot forming die quenching of boron steel at high temperatures. Int. J. Heat Mass Transf. 2014, 71, 396–404. [Google Scholar] [CrossRef]

- Omer, K.; Butcher, C.; Worswick, M. Characterization of heat transfer coefficient for non-isothermal elevated temperature forming of metal alloys. Int. J. Mater. Form. 2019, 13, 177–201. [Google Scholar] [CrossRef]

- ASTM E562-11; Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count. ASTM: West Conshohocken, PA, USA, 2011; pp. 1–7. [CrossRef]

- Sulamet-Ariobimo, R.D.; Soedarsono, J.W.; Sukarnoto, T.; Rustandi, A.; Mujalis, Y.; Prayitno, D. Tensile properties analysis of AA1100 aluminium and SS400 steel using different JIS tensile standard specimen. J. Appl. Res. Technol. 2016, 14, 148–153. [Google Scholar] [CrossRef] [Green Version]

- Peirs, J.; Verleysen, P.; Degrieck, J. Novel Technique for Static and Dynamic Shear Testing of Ti6Al4V Sheet. Exp. Mech. 2011, 52, 729–741. [Google Scholar] [CrossRef] [Green Version]

- ISO 16630:2017(E); Metallic Materials—Sheet and Strip—Hole Expanding Test. ISO: London, UK, 2017.

- Abedini, A.; Butcher, C.; Worswick, M. Influence of Strain Rate on Fracture Behaviour of Ultra-High Strength Steel Sheet; DYMAT: Stresa, Italy, 2019. [Google Scholar]

- Nakazima, K.; Kikuma, T.; Hasaku, K. Study on the formability of steel sheets. Yawata Tech. Rep. 1971, 284, 678–680. [Google Scholar]

- Rahmaan, T.; Abedini, A.; Butcher, C.; Pathak, N.; Worswick, M.J. Investigation into the shear stress, localization and fracture behaviour of DP600 and AA5182-O sheet metal, alloys under elevated strain rates. Int. J. Impact Eng. 2017, 108, 303–321. [Google Scholar] [CrossRef]

- Huang, G.; Tihay, K.; Sriram, S.; Weber, B.; Dietsch, P.; Cornette, D. Fracture characterization of AHSS using two different experimental methods. IOP Conf. Series Mater. Sci. Eng. 2018, 418, 012080. [Google Scholar] [CrossRef] [Green Version]

- Gorji, M.; Berisha, B.; Hora, P.; Barlat, F. Modeling of localization and fracture phenomena in strain and stress space for sheet metal forming. Int. J. Mater. Form. 2015, 9, 573–584. [Google Scholar] [CrossRef]

- Samadian, P.; Kortenaar, L.T.; Omer, K.; Butcher, C.; Worswick, M.J. Fracture characterization of tailored Usibor® 1500-AS and damage modelling based on a coupled-micromechanical-phenomenological strategy. Eng. Fract. Mech. 2019, 223, 106785. [Google Scholar] [CrossRef]

- Samadian, P.; Butcher, C.; Worswick, M.J. New mean-field homogenization schemes for the constitutive modelling of the elastic and elastoplastic deformation behavior of multi-phase materials. Mater. Today Commun. 2019, 24, 100707. [Google Scholar] [CrossRef]

- Lielens, G.; Pirotte, P.; Couniot, A.; Dupret, F.; Keunings, R. Prediction of thermo-mechanical properties for compression moulded composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 63–70. [Google Scholar] [CrossRef]

- Weng, G. The overall elastoplastic stress-strain relations of dual-phase metals. J. Mech. Phys. Solids 1990, 38, 419–441. [Google Scholar] [CrossRef]

- Rodriguez, R.-M.; Gutiérrez, I. Unified Formulation to Predict the Tensile Curves of Steels with Different Microstructures. Mater. Sci. Forum 2003, 426–432, 4525–4530. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Prahl, U.; Schleser, M.; Reisgen, U.; Bleck, W. Micro–macro-characterisation and modelling of mechanical properties of gas metal arc welded (GMAW) DP600 steel. Mater. Sci. Eng. A 2014, 589, 1–14. [Google Scholar] [CrossRef]

- Simo, J.C.; Hughes, T.J.R. Computational Inelasticity; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar] [CrossRef]

- Noder, J.; Butcher, C. A comparative investigation into the influence of the constitutive model on the prediction of in-plane formability for Nakazima and Marciniak tests. Int. J. Mech. Sci. 2019, 163, 105138. [Google Scholar] [CrossRef]

- Butcher, C.; Abedini, A. Shear confusion: Identification of the appropriate equivalent strain in simple shear using the logarithmic strain measure. Int. J. Mech. Sci. 2017, 134, 273–283. [Google Scholar] [CrossRef]

- Neukamm, F.; Feucht, M.; Haufe, A.; Ag, D. Considering damage history in crashworthiness simulations. In Proceedings of the 7th European LS-DYNA Conference, Salzburg, Austria, 14–15 May 2009. [Google Scholar]

- Bai, Y.; Wierzbicki, T. Application of extended Mohr–Coulomb criterion to ductile fracture. Int. J. Fract. 2009, 161, 1–20. [Google Scholar] [CrossRef]

- Abadie, J.; Carpentier, J. Generalization of the Wolfe Reduced Gradient Method to the Case of Nonlinear Constraints; Fletcher, R., Ed.; Academic Press: London, UK, 1969; pp. 37–47. [Google Scholar]

- Andrews, K.W. Empirical Formulae for the Calculation of Some Transformation Temperatures. J. Iron. Steel Inst. 1965, 203, 721–727. [Google Scholar]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 273–275, 40–57. [Google Scholar] [CrossRef]

- Morsdorf, L.; Tasan, C.; Ponge, D.; Raabe, D. 3D structural and atomic-scale analysis of lath martensite: Effect of the transformation sequence. Acta Mater. 2015, 95, 366–377. [Google Scholar] [CrossRef]

- VDA 238-100; Plate Bending Test for Metallic Materials. VDA: Eisenach, Germany, 2010; pp. 1–13.

- Samadian, P.; O’Keeffe, C.; Butcher, C.; Worswick, M.J. Fracture Response in Hot-Stamped Tailor-Welded Blanks of Ductibor® 500-AS and Usibor® 1500-AS: Experiments and Modelling. Eng. Fract. Mech. 2021, 253, 107864. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Strength of mixtures of bainite and martensite. Mater. Sci. Technol. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Seol, J.-B.; Raabe, D.; Choi, P.-P.; Im, Y.-R.; Park, C.-G. Atomic scale effects of alloying, partitioning, solute drag and austempering on the mechanical properties of high-carbon bainitic–austenitic TRIP steels. Acta Mater. 2012, 60, 6183–6199. [Google Scholar] [CrossRef]

- Clarke, A.J.; Speer, J.G.; Miller, M.K.; Hackenberg, R.E.; Edmonds, D.V.; Matlock, D.K.; Rizzo, F.C.; Clarke, K.D.; De Moor, E. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment. Acta Mater. 2008, 56, 16–22. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Liss, K.D.; Raabe, D.; Rakha, K.; Beladi, H.; Xiong, X.Y.; Hodgson, P.D. Growth of bainitic ferrite and carbon partitioning during the early stages of bainite transformation in a 2 mass% silicon steel studied by in situ neutron diffraction, TEM and APT. J. Appl. Crystallogr. 2016, 49, 399–414. [Google Scholar] [CrossRef] [Green Version]

- Bhadeshia, H.K.D.H.; Christian, J.W. Bainite in steels. Metall. Trans. A 1990, 21, 767–797. [Google Scholar] [CrossRef]

- Ramazani, A.; Chang, Y.; Prahl, U. Characterization and Modeling of Failure Initiation in Bainite-Aided DP Steel. Adv. Eng. Mater. 2014, 16, 1370–1380. [Google Scholar] [CrossRef] [Green Version]

- Golling, S.; Östlund, R.; Oldenburg, M. A study on homogenization methods for steels with varying content of ferrite, bainite and martensite. J. Mater. Process. Technol. 2016, 228, 88–97. [Google Scholar] [CrossRef] [Green Version]

- Davoudi, K.M.; Vlassak, J.J. Dislocation evolution during plastic deformation: Equations vs. discrete dislocation dynamics study. J. Appl. Phys. 2018, 123, 085302. [Google Scholar] [CrossRef]

- Ramazani, A.; Pinard, P.; Richter, S.; Schwedt, A.; Prahl, U. Characterisation of microstructure and modelling of flow behaviour of bainite-aided dual-phase steel. Comput. Mater. Sci. 2013, 80, 134–141. [Google Scholar] [CrossRef]

- Barlat, F.; Aretz, H.; Yoon, J.; Karabin, M.; Brem, J.; Dick, R. Linear transfomation-based anisotropic yield functions. Int. J. Plast. 2005, 21, 1009–1039. [Google Scholar] [CrossRef]

- Abedini, A.; Butcher, C.; Rahmaan, T.; Worswick, M. Evaluation and calibration of anisotropic yield criteria in shear Loading: Constraints to eliminate numerical artefacts. Int. J. Solids Struct. 2018, 151, 118–134. [Google Scholar] [CrossRef] [Green Version]

- Butcher, C.; Abedini, A. On anisotropic plasticity models using linear transformations on the deviatoric stress: Physical constraints on plastic flow in generalized plane strain. Int. J. Mech. Sci. 2019, 161–162, 105044. [Google Scholar] [CrossRef]

- Narayanan, A.; Bourque, C.; Fast-Irvine, C.; Abedini, A.; Anderson, D.; Butcher, C. Identification of the Plane Strain Yield Strength of Anisotropic Sheet Metals Using Inverse Analysis of Notch Tests; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Abspoel, M.; Scholting, M.E.; Lansbergen, M.; An, Y.; Vegter, H. A new method for predicting advanced yield criteria input parameters from mechanical properties. J. Mater. Process. Technol. 2017, 248, 161–177. [Google Scholar] [CrossRef]

| C | Mn | Ti | Nb | Cr | Si | P | S | B | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.081 | 1.643 | 0.015 | 0.055 | 0.073 | 0.362 | 0.011 | 0.001 | 0.003 | balance |

| Material Condition | F (%v) | B (%v) | M (%v) | Hardness (HVN) |

|---|---|---|---|---|

| As-received | 88.0 ± 2.1 * | - | 12.0 ± 2.1 | 226 ± 2 |

| 25 °C die-quenched | - | - | 100 | 384 ± 4 |

| 350 °C die-quenched | - | 24.9 ± 3.4 | 75.1 ± 3.4 | 340 ± 5 |

| 450 °C die-quenched | 3.0 ± 0.4 | 67.4 ± 5.3 | 29.6 ± 5.5 | 276 ± 10 |

| Material Condition | UTS (MPa) | Uniform Elongation (%) | Elongation to Fracture (%) |

|---|---|---|---|

| 25 °C die-quenched | 1122 ± 9 * | 4.3 ± 0.1 | 7.0 ± 0.4 |

| 350 °C die-quenched | 1009 ± 9 | 3.9 ± 0.1 | 7.1 ± 0.2 |

| 450 °C die-quenched | 833 ± 13 | 6.1 ± 0.4 | 10.8 ± 0.6 |

| Material Condition | Shear | Hole Expansion | Plane-Strain Notch Tension | Nakazima |

|---|---|---|---|---|

| 25 °C die-quenched | ||||

| 350 °C die-quenched | ||||

| 450 °C die-quenched |

| Material Condition | |||

|---|---|---|---|

| 25 °C die-quenched | 1.1742 | 0.1196 | −3.1888 |

| 350 °C die-quenched | 1.1735 | 0.1883 | −1.8950 |

| 450 °C die-quenched | 1.1573 | 0.2042 | −1.2428 |

| Material Condition/Microstructure | Carbon in Bainite (wt.%) | Carbon in Martensite (wt.%) |

|---|---|---|

| 25 °C die-quenched (100%M) | - | 0.081 ≈ total steel carbon |

| 350 °C die-quenched (~25%B + 75%M) | 0.063 (from Equation (12)) | 0.087 (from calibration) |

| 450 °C die-quenched (~70%B + 30%M) | 0.035 (from Equation (12)) | 0.189 (from calibration) |

| Fully bainitic (100%B) | 0.081 ≈ total steel carbon | - |

| Micro-Constituent | Dislocation Mean Free Path (m) | Recovery Rate |

|---|---|---|

| Bainite | 1.80 × 10−6 | 4.30 |

| Martensite | 4.40 × 10−8 | 45.73 |

| Parameter | |||

|---|---|---|---|

| (wt.%) | 0.6391 | 5.8713 | 0.0792 |

| −0.1202 | 6.4922 | 1.1744 | |

| −0.0001 | −6.5147 | 0.2051 | |

| −0.0430 | −3.8798 | −1.1050 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samadian, P.; Abedini, A.; Butcher, C.; Worswick, M.J. Microstructure-Based Modelling of Flow and Fracture Behavior of Tailored Microstructures of Ductibor® 1000-AS Steel. Metals 2022, 12, 1770. https://doi.org/10.3390/met12101770

Samadian P, Abedini A, Butcher C, Worswick MJ. Microstructure-Based Modelling of Flow and Fracture Behavior of Tailored Microstructures of Ductibor® 1000-AS Steel. Metals. 2022; 12(10):1770. https://doi.org/10.3390/met12101770

Chicago/Turabian StyleSamadian, Pedram, Armin Abedini, Clifford Butcher, and Michael J. Worswick. 2022. "Microstructure-Based Modelling of Flow and Fracture Behavior of Tailored Microstructures of Ductibor® 1000-AS Steel" Metals 12, no. 10: 1770. https://doi.org/10.3390/met12101770

APA StyleSamadian, P., Abedini, A., Butcher, C., & Worswick, M. J. (2022). Microstructure-Based Modelling of Flow and Fracture Behavior of Tailored Microstructures of Ductibor® 1000-AS Steel. Metals, 12(10), 1770. https://doi.org/10.3390/met12101770