2. Adsorptive Removal of Uranium and Thorium

After the oil crisis in the 1970s, the recovery of uranium from sea water received a considerable amount of attention in Japan. From such interest, Sakaguchi and Nakajima found that some tannin compounds such as Chinese gallotannin (tannic acid) immobilized on cellulosic matrices such as cellulose powder are effective for the recovery of uranium from sea water [

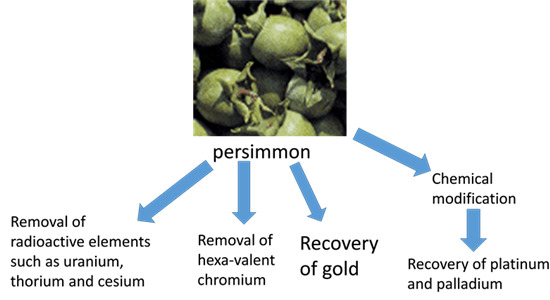

3]. They further discovered that persimmon extract exhibits an extremely high affinity for uranium, and subsequently prepared an adsorption gel for the recovery of uranium by crosslinking it using glutaraldehyde [

6]. They attempted to employ this gel not only for the recovery of uranium from sea water but also for the removal of trace amounts of uranium from uranium milling wastewater. Environmental pollution by radioactive elements such as uranium and thorium is not limited to uranium mines and nuclear facilities. Rare earth ores, monazite, bastnaesite and xenotime, contain some quantities of these elements, which are removed in the mineral dressing stage at mine sites. However, unfavorable treatment and management of tailings of these ores may bring about serious environmental contamination. For instance, in the early 1980s a serious environmental pollution problem took place at a rare earth plant at Ipoh, Malaysia. As seen from this case, selective removal of uranium and thorium from rare earths has been required in order to avoid such environmental problems.

From such a viewpoint, studies were conducted on the selective removal of uranium(VI) and thorium(IV) from lutetium(III) (the heaviest rare earth exhibiting similar chemical behaviors with these actinide elements) using three kinds of adsorbents [

7,

8]. These are as follows: (1) A persimmon peel gel (PP gel) prepared from persimmon peel waste generated in the production of dried persimmon fruits by boiling in concentrated sulfuric acid for the dehydration condensation reaction for crosslinking between polyphenols and polysaccharides such as cellulose; (2) a gallic acid resin prepared by interacting gallic acid with a commercially available weak base anion exchange resin (DIAION WA30, Mitsubishi Chemical Corp., Tokyo, Japan); and (3) a kakishibu resin, which was prepared by impregnating persimmon extract (kakishibu) into a high porous resin without any functional groups (DIAION HP 20, Mitsubishi Chemical Corp., Tokyo, Japan), kindly donated by Tomiyama Corp., Kyoto, Japan.

Figure 1.

Percentage adsorption of uranium(VI) at varying equilibrium pH on PP gel, gallic acid resin and kakishibu resin.

Figure 1 shows the pH dependency of % adsorption of uranium(VI) on the PP gel, the gallic acid resin and the kakishibu resin for comparison. For all adsorbents, the adsorption increases with increasing pH, indicating that adsorption takes place according to a cation exchange mechanism with the phenolic hydroxyl groups of the persimmon tannin releasing hydrogen ions as suggested by Sakaguchi and Nakajima [

6] (a similar adsorption mechanism will be discussed in

Section 4 (chromium(VI) adsorption) by the reaction equation shown in

Scheme 2b) wherein nearly quantitative adsorption is achieved at pH values greater than 4.5. The adsorption on the PP gel appears to be nearly equal to that on the gallic acid resin and higher than that of the kakishibu resin. On the other hand, the adsorption behavior for thorium(IV) was found to be nearly equal for all of the three adsorbents while the adsorption of lutetium(III) on the PP gel was found to be higher than that on other two adsorbents.

Figure 2 shows the comparison of the % adsorption of uranium(VI), thorium(IV) and lutetium(III) on the PP gel to compare the order of selectivity among these three metal ions. As seen from this figure, it is as follows: Th(IV) > U(VI) > Lu(III). That is, uranium(VI) and thorium(IV) are selectively adsorbed on the gel over lutetium(III), supporting the feasibility of selective adsorptive removal of the radioactive elements, uranium(VI) and thorium(IV), contained in rare earth ores using this gel.

Figure 2.

Percentage Adsorption of uranium(VI), thorium(IV) and lutetium(III) at varying equilibrium pH on PP gel [

8] (with permission for reuse from TMS).

From the study of the adsorption isotherms of uranium(VI), thorium(IV) and lutetium(III) on the PP gel, it was found that the adsorption appears to exhibit the Langmuir type adsorption;

i.e., it increases with increasing metal concentration and tends to approach constant values corresponding to each metal ion, from which maximum adsorption capacities were evaluated for uranium(VI), thorium(IV) and lutetium(III) as follows, respectively: 1.29, 0.49 and 0.28 mol·kg

−1-dry gel. In contrast to the selectivity order, uranium(VI) is much more greatly adsorbed than thorium(IV) and lutetium(III). Compared with the adsorption capacities of commercially available chelating resins, that of uranium(VI) on the PP gel is very high as in the case of the persimmon tannin gel reported by Sakaguchi and Nakajima [

6].

Based on experimental results of the above-mentioned batch wise adsorption tests, mutual separation between uranium(VI) and lutetium(III) was tested using a small glass column packed with PP gel and model solution containing 0.21 mmol·dm−3 uranium(VI) and 0.29 mmol·dm−3 lutetium(III) at pH = 3.81.

Figure 3 shows the breakthrough profiles of these two metal ions;

i.e., a plot of the relative concentration of these ions in the effluent (their outlet concentrations) compared with their feed concentrations against contact time after the initiation of the flow. As seen from this figure, breakthrough of lutetium(III) began at the contact time before 10 h just after the initiation of the feed while that of uranium(VI) began at 20 h, suggesting that the mutual separation of uranium(VI) from lutetium(III) can be successfully achieved using the column packed with the PP gel.

Figure 3.

Breakthrough profile of uranium(VI) and lutetium(III) from the column packed with persimmon peel (PP) gel.

Figure 4.

Elution profiles of uranium(VI) and lutetium(III) from the PP gel packed column after breakthrough using 1 mol·dm−3 hydrochloric acid solution.

Figure 4, on the other hand, shows the elution profiles for these two metal ions from the column after eluting the loaded column with a 1 mol·dm

−3 hydrochloric acid solution. As seen from this figure, uranium(VI) was eluted at a concentration greater than 25 times that of the feed solution for the breakthrough test, though a small amount of lutetium(III) coexisted as a contaminant in the eluted solution.

Further, from the results of the cycle test, it was apparent that repeating the adsorption of uranium(VI) followed by elution did not compromise the adsorption capacity of the PP gel for uranium(VI) even after 10 cycles, further supporting its feasibility for practical application.

3. Adsorptive Removal of Cesium

Cesium (137Cs) is one of the fission products of nuclear fuels contained in radioactive wastes. Due to its long half life (30 years) and bio-toxicity, its separation and removal from aquatic environments has always attracted special attention, and this has become much more important in recent days after the nuclear plant accident at Fukushima, Japan.

Studies on the removal of cesium(I) ion from aqueous solution have been focused largely on adsorption and ion-exchange methods [

9,

10,

11,

12]. Natural and synthetic zeolites, clay minerals and synthetic organic or inorganic ion-exchangers have been employed for large scale separation of

137Cs from low and intermediate-level radioactive waste effluents or contaminated water [

9,

10,

13,

14]. However, the majority of these materials appear to be uneconomical as a consequence of their high operational cost and poor performance. It has been reported that the phenolic resins such as Duolite S-30 (phenolic), and Duolite CS-100 (phenolic-carboxylic), can selectively remove cesium(I) from alkaline solutions [

15,

16]. The phenolic OH groups are, however, ionizable and only effective at high pH. Because of their comparatively lower p

Ka

versus the monohydroxy phenols, the polyhydroxyphenols are ionizable and can function as metal chelators at relatively lower pH than the monohydroxyphenols. Based on such findings, we anticipated that bioadsorbents having polyphenolic moieties would exhibit adsorption selectivity towards cesium(I) ions at approximately neutral pH. From this perspective, our focus was towards developing highly effective adsorption materials for cesium(I) removal using a persimmon extract rich in persimmon tannin [

17,

18]. That is, the adsorbent in the present case, which is abbreviated as CPT (cross-linked persimmon tannin) gel hereafter, was prepared from commercially available dried persimmon tannin extract powder (Persimmon-Kaki Technology Development Co. Ltd., Jincheng, China) also by means of crosslinking in boiling concentrated in sulfuric acid at 100 °C.

Figure 5 shows the effect of initial pH on the adsorption behavior of CPT gel towards cesium(I) and sodium(I) ions. It is clear from this figure that the adsorption of these metal ions is also greatly affected by pH similar to the adsorption of uranium(VI), thorium(IV) and lutetium(III) as described in the preceding section. Although cesium(I) is negligibly adsorbed on this adsorbent in acidic region, its adsorption increases with increasing pH, achieving near quantitative removal at pH higher than 4.5 with moderate adsorption of sodium(I) ion (around 40%), which supports the applicability of this adsorbent for the selective removal of cesium(I) at around neutral pH.

Figure 5.

Percentage adsorption of cesium(I) and sodium(I) ions on crosslinked persimmon tannin (CPT) gel at varying initial pH [

17] (with permission for reuse from Elsevier B.V.).

Figure 6 shows the isotherm plots for the adsorption of cesium(I) (plot of amount of adsorption (

q)

vs. equilibrium concentration (Ce)) as well as sodium(I) on CPT gel. The plots indicate the typical Langmuir’s monolayer type of adsorption. From the Langmuir plot using these data, the maximum adsorption capacities for cesium(I) and sodium(I) on this adsorbent were evaluated as 1.33 and 0.45 mol·kg

−1, respectively.

Figure 6.

Adsorption isotherms of cesium(I) and sodium(I) ions on CPT gel [

17] (with permission for reuse from Elsevier B.V.).

A comparative evaluation of the maximum adsorption capacity of this adsorbent towards cesium(I) ion was carried out with those of different adsorbents reported in literatures as listed in

Table 1. From this table, it is deduced that the present adsorbent containing polyphenolic groups as ionizable and coordinating functional group have significant adsorption potential for cesium(I) removal from aqueous solutions compared with other adsorbents.

Table 1.

Cesium(I) ion adsorption capacity comparison of the CPT gel and other adsorbents.

| Adsorbent | Adsorption Capacity (mol·kg−1) | pH of the Solution | Reference |

|---|

| Zeolite A | 1.57 | 6.0 | [10] |

| Phosphate-modified montmorillonite | 0.70 | 5.0 | [9] |

| Ammonium molybdophosphate-polyacrylonitrile | 0.61 | 6.5 | [19] |

| Copper ferrocyanide functionalized mesoporous silica | 0.12 | 7.8 | [9] |

| Prussian blue | 0.09 | 7.8 | [9] |

| Natural clinoptilolite | 0.37 | 6.5 | [13] |

| Brewery waste biomass | 0.07 | 4.0 | [12] |

| Arca shell biomass | 0.03 | 5.5 | [11] |

| Sulfuric acid crosslinked Pseudochoricystis ellipsoidea | 1.36 | 6.5 | [20] |

| CPT gel | 1.34 | 6.5 | [17] |

Taking into account the remarkable selectivity and adsorption capacity of CPT gel towards cesium(I) over sodium(I), practical applicability of this adsorbent for selective adsorption, preconcentration and removal/recovery of cesium(I) from the mixture of both the ions was studied by continuous column experiment.

Figure 7 shows the breakthrough profiles of cesium(I) and sodium(I) ions using a small glass column packed with CPT gel. In this figure, relative concentrations at outlet to the feed concentration (

Ct/

Ci) are plotted against the bed volume (B.V.) which is defined as the ratio of the total volume of the feed solution passed though the column to the volume of the adsorbent packed in the column. As expected from the results of batch wise experiment, breakthrough of sodium(I) took place after a few hours while that of cesium(I) began to take place after 100 h (996 B.V.), suggesting satisfactory separation between these two metal ions.

Figure 7.

Breakthrough profiles of cesium(I) and sodium(I) ions from the column packed with CPT gel [

17] (with permission for reuse from Elsevier B.V.).

After the adsorption bed was saturated, elution test was carried out by using 1 mol·dm−3 hydrochloric acid solution in order to recover the adsorbed cesium(I) in concentrated form. It was found that the elution was quite fast and the concentration of cesium(I) in the elute was much higher than that of the feed solution, i.e., the preconcentration factor (=outlet concentration of the column/feed concentration) for cesium(I) was evaluated as 140. Adsorptive separation of cesium(I) with high preconcentration factor and quantitative elution in a short period of time suggest that the CPT gel can be used repeatedly and effectively for the separation and removal of cesium(I) from the mixture of sodium(I) ions.

4. Adsorptive Removal of Chromium(VI)

Chromium exists as chromium(III) and chromium(VI) in aqueous medium. Chromium(VI) is 500 times more toxic than chromium(III). Its toxicity includes lung cancer as well as kidney, liver and gastric damage [

21]. The maximum level of chromium(VI) permitted in waste water is 0.5 mg·dm

−3. Industrial effluents from plating industries, leather tanning and so on sometimes contain higher levels of chromium(VI) than the permitted level [

22]. It is essential for such industries to treat their effluents to reduce the chromium(VI) content to the acceptable level. In conventional chromium plating, chromium is plated as a thin layer on zinc-coated steel plate. This generates post treatment wastewater containing a high concentration of zinc(II) and a small amount of chromium(VI). In the present work, persimmon waste generated in the production of persimmon extract as the residue has been tested for the removal of chromium(VI), taking account of chromium(VI)-containing effluents from the plating industry [

23]. That is, the adsorbent was prepared from the persimmon extract residue also by boiling in concentrated sulfuric acid at high temperature for cross-linking in this case. This adsorbent is abbreviated as CPW (crosslinked persimmon waste) gel, hereafter.

Chromium(VI) exist in aqueous solution as HCrO4−, H2CrO4, HCr2O7− and CrO42− depending on the pH of the solution and the total chromium concentration.

Figure 8 shows the % adsorption of several metal ions as a function of equilibrium pH on CPW gel. This figure shows a high selectivity of this adsorbent for chromium(VI) at pH < 3. It also shows that the % adsorption of all metal ions investigated in this experiment, except for chromium(VI), was found to increase with increasing pH in the pH range of 1–5 whereas opposite behavior was observed for chromium(VI). That is, the % adsorption of chromium(VI) increased with increasing pH in the pH range of 1–3 and then decreased with further increases in pH. This contrasting behavior for chromium(VI) adsorption compared to the other metal ions can be attributed to a different adsorption mechanism shown in

Scheme 2 [

4]. As stated earlier, Cr(VI) exists in aqueous medium as HCrO

4−, H

2CrO

4, HCr

2O

7− and CrO

42−, among which the HCrO

4− is the dominant species up to pH 5 [

24].

Scheme 2a shows the adsorption mechanism of the oxo anionic form of chromium(VI) on CPW gel from an acidic solution in terms of an esterification reaction, which suggests that a high concentration of H

+ ion enhances chromium(VI) adsorption whereas a high concentration of OH

− ion suppresses chromium(VI) adsorption, thus accounting for the decrease in the % adsorption of chromium(VI) with increasing the pH of the solution at pH higher than 3. The reason for decreasing % adsorption with decreasing pH of the solution at pH less than 3 is due to the reduction of chromium(VI) to chromium(III) in acidic solution as will be discussed later.

On the other hand, the adsorption of other metal ions, except for chromium(VI), which exist as cationic species in aqueous solution, are adsorbed on CPW gel according to a cation exchange mechanism as shown in

Scheme 2b, which accounts for the increase in the % adsorption with increasing pH of the solution.

Figure 8.

Effect of equilibrium pH on the adsorption of different metal ions on CPW gel [

23] (with permission for reuse from Elsevier B.V.).

Scheme 2.

The binding mechanism of (a) chromium(VI) and (b) other metals to the hydroxyl groups of catechol units on the cross-linked persimmon gel.

Batch wise kinetic experiments were carried out in order to elucidate the equilibrium time and mechanism of the adsorption reaction of Cr(VI).

The time variation of % adsorption of total chromium at varying pH is shown in

Figure 9, which reveals that the chromium adsorption monotonously increases with increasing contact time until reaching constant values corresponding to pH values, except for the case at pH = 1. On the other hand, at pH = 1, after the adsorption rapidly increases at the initial stage similar to the cases at other pH values, it slightly decreases and tends to approach a constant value. This phenomenon was observed also in the adsorption on the crosslinked grape waste gel and it was concluded to be attributed to the adsorption coupled reduction mechanism of chromium(VI) to chromium(III) which is not adsorbed at low pH as seen from

Figure 8 [

25].

Figure 9.

Effect of contact time on the adsorption of total chromium on cross-linked persimmon waste (CPW) gel from chromium(VI) solution at different pH values [

23] (with permission for reuse from Elsevier B.V.).

In order to elucidate the actual mechanism of chromium(VI) adsorption by CPW gel, the rate of change of both chromium(VI) and chromium(III) concentrations in solution were measured at pH = 1 as shown in

Figure 10. The result shows that chromium(VI) ions were completely removed from the aqueous solution at this pH and chromium(III) ions were generated which were not present in the original solution. This result demonstrates that there is not only an adsorption mechanism of chromium(VI) but also a reduction mechanism taking place in this pH range. That is, the oxo anionic species of chromium(VI) that is adsorbed on the adsorbent by the esterification reaction as described earlier is reduced to chromium(III) by the electron rich polyphenolic aromatic ring that supplies electrons for the reduction reaction as described by the following reactions:

After reduction, the adsorbed chromium is released into the aqueous solution in the form of chromium(III) ions, thus increasing the concentration of chromium(III) in the solution with contact time.

Isotherm studies were carried out to investigate the effect of metal concentration on the adsorption of chromium(VI) on the CPW gel.

Figure 11 shows the experimental isotherm plots for chromium(VI) adsorption by the CPW gel at different pH values ranging from 1 up to 4. From the result in this figure, the adsorption of chromium(VI) at all the pH values tested appears to take place according to the Langmuir model, that is, the amount of adsorption increases with increasing chromium(VI) concentration at low concentration while it tends to approach constant values corresponding to each pH at high concentration in the aqueous solution.

Figure 10.

Time variation of the concentrations of chromium(VI) and chromium(III) as well as total chromium in the aqueous solution at pH = 1 during adsorption [

23] (with permission for reuse from Elsevier B.V.).

Figure 11.

Adsorption isotherms of chromium(VI) on CPW gel [

23] (with permission for reuse from Elsevier B.V.). ○ pH 1, ∆ pH 2, □ pH 3, ◊ pH 4.

From the Langmuir plots of these experimental results, the maximum adsorption capacities of chromium(VI) on the CPW gel were evaluated as 7.18, 6.11, 2.38 and 1.96 mol·kg−1 at pH = 1, 2, 3 and 4, respectively. This result demonstrates the increasing maximum adsorption capacity with decreasing pH, indicating that chromium(VI) removal by the CPW gel is greatly influenced by hydrogen ion.

Table 2 shows the maximum adsorption capacities reported for various adsorbents for comparison, which shows that the polyphenol-containing adsorbents such as mimosa tannin (condensed tannin) [

4] and persimmon tannin [

26] have higher adsorption capacities than other biomasses adsorbents such as grape gel [

25], chitosan [

27,

28] and sugarcane bagasse [

29]. It is noteworthy that the CPW gel containing polyphenol groups investigated in this study has the highest adsorption capacity among these, and it is also much higher than those of other tannin-containing gels.

Table 2.

The maximum adsorption capacity for chromium ion(VI) for different adsorbents.

| Adsorbent | pH | Temperature [K] | Maximum Adsorption Capacity (mol kg−1) | Reference |

|---|

| Mimoza tannin | 2.0 | 303 | 5.52 | [4] |

| Persimmon tannin | 3.0 | 303 | 5.27 | [26] |

| Quaternary chitosan | 4.5 | 298 | 0.58 | [27] |

| Sugarcane bagasse | 3.0 | 298 | 1.97 | [29] |

| Ocimun americanum | 1.5 | 300 | 1.60 | [30] |

| Crosslinked grape gel | 4 | 303 | 1.91 | [25] |

| Carbonized wheat straw | 2 | 303 | 1.67 | [31] |

| Carbonized barley straw | 3 | 303 | 1.68 | [31] |

| CPW gel | 1 | 303 | 7.18 | [23] |

Similar to the cases of other metals, mutual separation of chromium(VI) from other metals such as zinc(II), for example, was tested on the basis of the results of the batch wise experiments mentioned earlier.

Figure 12.

Breakthrough profiles of various chromium and zinc species from the column packed with CPW gel at pH = 1.0 [

23] (with permission for reuse from Elsevier B.V.). ○: Total Cr ∆: Cr(III) □: Cr(VI) ◊: Zn(II).

Figure 12 and

Figure 13 show the breakthrough profiles of zinc(II), total chromium and chromium(VI) at pH = 1 and 4, respectively, for a column packed with the CPW gel using an initial feed solution containing 0.5 mmol·dm

−3 chromium(VI) and 5 mmol·dm

−3 zinc(II). From these figures, it is seen that breakthrough of zinc(II) took place just after the initiation of the feed whereas that of chromium(VI) occurred later, suggesting that mutual separation between zinc(II) and chromium(VI) is feasible using the CPW gel. The breakthrough of zinc(II) ion just after the start of feeding is due to the non-adsorbing nature of this ion at this pH on the CPW gel. Although some amount of total chromium was found to have leaked from the column from the start of the feeding at pH = 1, no chromium(VI) was detected in the outlet solution;

i.e., the total chromium detected in the outlet solution is concluded to be chromium(III) reduced from chromium(VI) in the feed solution by the aid of the CPW gel as described earlier. Consequently, it is apparent that small or trace amounts of chromium(VI) can be completely removed from an excess concentration of zinc(II) by using the column packed with the CPW gel, indicating that it can be applicable for the treatment of effluent generating from chromium plating industries which contain high concentration of zinc(II) but low concentration of chromium(VI).

Figure 13.

Breakthrough profiles of various chromium and zinc species from the column packed with CPW gel at pH = 4.0 [

23] (with permission for reuse from Elsevier B.V.). ○: Total Cr ∆: Cr(III) □: Cr(VI) ◊: Zn(II).

5. Recovery of Gold from Acidic Chloride Media by Means of Coagulation Using Persimmon Tannin Extract Liquor

Nowadays, precious metals such as gold, silver and platinum group metals (PGM) are in extensive use not only as traditional jewelry materials but also as useful components in a variety of well-known advanced applications such as electric and electronic devices, catalysts, and medical instruments. Since these metals are limited resources existing only in small amounts on the earth, they should be effectively recovered from various wastes for recycling and reuse purposes. From an economical point of view, the recovery process should be such that the precious metals are highly selectively separated from base metals such as iron, copper, and zinc which often coexist with the precious metals in disproportionate amounts.

Due to the high price of precious metals, they have been recovered from various wastes for many years. According to the classical refining method of precious metals, feed materials including various wastes are leached using aqua regia, where gold, platinum and palladium are dissolved leaving other precious metals like silver as well as base metals in leach residue. From the leach liquor, gold is recovered at first as gold sponge by means of the reduction using various reducing agents like ferrous sulfate, followed by the recovery of platinum and palladium using ammonium chloride. However, because such conventional methods are tedious and require a significant amount of energy as well as long processing times, it is currently being replaced by new methods which involve the complete dissolution of feed materials using chlorine containing hydrochloric acid except for silver, followed by solvent extraction and ion exchange or distillation for selective separation into high purity of each precious metal. In this dissolution process, chlorine is dissociated into hydrochloric acid and hypochlorous acid which functions as oxidation agent and is converted into hydrochloric acid. Consequently, the mutual separation among precious metals by means of solvent extraction and ion exchange is carried out from hydrochloric acid. Solvent extraction reagents as well as diluents and ion exchange resins, synthetic organic materials, are not environmentally benign taking account of their dissolution in water and the treatments after their use. On such viewpoints, we attempted to employ persimmon tannin extract (kakishibu), a natural material, as a coagulating agent for the refining of gold while, as mentioned earlier, persimmon tannin extract has been employed as a coagulating agent for proteins for a long time [

32]. In the present work, persimmon tannin extract liquid was kindly donated by Tomiyama Corp., Kyoto, Japan, and employed by diluting with water into 10 (

V/

V) % aqueous solution.

As shown in

Figure 14, the minor addition of the persimmon tannin extract into hydrochloric acid solution containing gold(III) ions caused an observable color change of the solution, which gradually became turbid. In the course of time, such dark turbid materials were coagulated and sank down on the bottom of vessel. After the filtration of the coagulated materials, the filter cake was observed by using an optical microscope and by means of X-ray diffraction (XRD) analysis.

Figure 14.

Change in the hydrochloric acid solution containing small amount of gold(III) after the addition of trace volume of persimmon extract liquid [

32] (with permission for reuse from The Society of Chemical Engineers of Japan).

Figure 15.

Image of the filter cake of the precipitate generated by the addition of persimmon extract liquor into the gold(III) solution observed by optical microscope (×800).

Figure 15 shows the image of the filter cake observed by an optical microscope. Aggregates of brilliant yellow fine particles are observed in the filter cake.

From the observation by the X-ray diffraction pattern of the filter cake, 4 sharp peaks were confirmed at 2θ = 38.2, 44.4, 64.6 and 77.5 degree, surely suggesting the existence of metallic gold.

From these observations, it can be concluded that gold(III) ion was reduced into elemental gold (gold(0)) and coagulated into the aggregates by the aid of persimmon tannin extract.

Similar coagulation tests were carried out for hydrochloric acid solutions containing other metal ions.

Figure 16 shows the plots of % recovery as coagulated precipitates against hydrochloric acid concentration for the individual solutions of platinum(IV), palladium(II), copper(II), zinc(II), and iron(III) as well as gold(III).

Figure 16.

Percentage recovery of various metal ions by means of coagulation using persimmon extract liquor from varying concentration (mol·dm

−3) of hydrochloric acid solution [

32] (with permission for reuse from The Society of Chemical Engineers of Japan).

As seen from this figure, the recovery of other metal ions is negligible, suggesting that only gold is much selectively recovered by this method using persimmon tannin extract. The high selectivity to gold is attributable to the higher oxidation reduction potential (ORP) of gold(III) ion than other metal ions.

The reduction of gold(III) ions to metallic gold (gold(0)) is inferred to take place according to the following reactions where P stands for the polymer matrices of persimmon tannin.

Figure 17 shows the time variation of the % recovery of gold from 0.1 mol·dm

−3 hydrochloric acid solution at varying temperatures. As seen from this figure, although it takes very long time to reach the quantitative recovery at 293 and 303 K, such kinetic behavior of the gold recovery can be much improved by elevating temperature.

Figure 17.

Percentage recovery of gold(III) by means of coagulation using persimmon extract liquor from 0.1 mol·dm

−3 hydrochloric acid solution at varying temperatures [

32] (with permission for reuse from The Society of Chemical Engineers of Japan).

6. Adsorptive Recovery of Gold from Acidic Chloride Media Using Gels of Dried Persimmon Tannin Extract and Waste of Persimmon Peel

As mentioned in the preceding section, the liquid of persimmon tannin extract exhibits a strong reduction behavior for gold. On the basis of such observation, we carried out the adsorptive recovery of gold using a CPT gel [

33] which was employed for the adsorptive removal of cesium(I) as described in the former section and also using the gel prepared from persimmon peel waste generated in the production of dried persimmon fruit still containing large quantities of persimmon tannin [

34].

Figure 18 and

Figure 19 show the % adsorption of gold(III), platinum(IV) and palladium(II) as well as some base metals such as copper(II) from varying concentration of hydrochloric acid solution on CPT gel and crude persimmon tannin extract (PT) powder for comparison, respectively.

Quantitative adsorption of gold(III) was achieved on CPT gel over the whole concentration range of hydrochloric acid while the adsorption of gold(III) on crude PT powder decreased significantly in higher acid concentration regions (greater than 3.0 mol·dm−3). Although both adsorbents exhibited about 10%–20% adsorption for platinum(IV) and palladium(II), the adsorption of base metals was practically negligible under the present experimental conditions. The remarkably high selectivity of CPT gel for gold(III) over base metals as well as platinum(IV) and palladium(II) in a wide concentration range of hydrochloric acid is immensely useful for selective and quantitative recovery of gold(III) from acidic chloride media.

Figure 18.

Percentage adsorption of various metal ions on CPT gel as a function of concentration of hydrochloric acid [

33] (with permission for reuse from Elsevier B.V.).

Figure 19.

Percentage adsorption of various metal ions on crude PT powder as a function of concentration of hydrochloric acid [

33] (with permission for reuse from Elsevier B.V.).

Figure 20 shows the adsorption isotherms of gold(III) on CPT gel and crude PT powder. As seen from this figure, it is clear that the amount of gold(III) adsorption on both adsorbents increased with increasing metal concentration of the test solution and tended to approach the constant value. That is, the gold(III) adsorption capacity of both adsorbents tended to approach a constant value at around 4.5 mol·kg

−1. Interestingly, as can be seen in this figure, gold(III) adsorption capacity of both adsorbents again increased, after tending to approach the constant value, with further increase in gold(III) concentration in the test solution, resulting a typical BET type adsorption isotherm based on multilayer adsorption model. Consequently, the gold uptake capacity of CPT gel reached as high as 7.7 mol·kg

−1 (=1.52 kg-gold·kg

−1-dry adsorbent) and that of crude PT powder reached 5.8 mol·kg

−1 (=1.14 kg-gold·kg

−1-dry adsorbent), respectively, suggesting that greater quantities of gold(III) relative to the dry weight of these adsorbents were adsorbed. From this result, it is clear that CPT gel is more effective than the crude PT powder for uptake of gold(III) from hydrochloric acid solutions. The higher uptake of CPT gel than crude PT powder towards gold(III) may be attributable to the improvement of structure or surface morphology of the polymer matrices of the gel through crosslinking related to the adsorption coupled reduction mechanism. That is, it was found in our previous work that polysaccharides such as cellulose which have no functional groups for binding metal ions exhibit very high affinity only for gold to give rise to metallic gold particles by special reduction reaction after the crosslinking using concentrated sulfuric acid [

2]. In the case of CPT gel, in addition to the reductive adsorption of persimmon tannin itself, the crosslinked polysaccharides coexisting in CPT gel may exhibit the additional reductive adsorption for gold(III).

Figure 20.

Adsorption isotherms of gold(III) on CPT gel and crude persimmon extract tannin (PT) powder from 0.1 mol·dm

−3 hydrochloric acid solution [

33] (with permission for reuse from Elsevier B.V.).

Figure 21.

FT-IR spectra of CPT gel before and after the adsorption of gold(III) [

33] (with permission for reuse from Elsevier B.V.).

The above-mentioned mechanism of adsorption of gold(III) followed by reduction to elemental gold was supported by the observation of FT-IR spectra before and after the adsorption of Au(III) on CPT gel and crude PT powder as presented in

Figure 21 and

Figure 22, respectively. In the FT-IR spectrum after gold adsorption, the intensity of the band at 1709 cm

−1 assigned for quinine type C=O stretching was increased. It is interesting to note that the band at 1185 cm

−1 attributable to C=C–O asymmetrical stretching was also increased in intensity. These results support the fact that oxidation of phenolic hydroxyl groups has actually taken place as mentioned earlier during the adsorption of gold(III) on phenol-rich tannin matrix.

Figure 22.

FT-IR spectra of crude PT powder before and after the adsorption of gold(III) [

33] (with permission for reuse from Elsevier B.V.).

Once the adsorption occurs, reduction of gold(III) to elemental gold also takes place. The elemental gold is aggregated and released from the surface of the adsorbents creating active vacant sites for further adsorption, leading to an apparent uptake of higher amounts of gold(III). Consequently, it is not unreasonable to consider that the unique BET type of adsorption behaviors of CPT gel and crude PT powder towards gold(III) may be attributable to the adsorption-reduction cycles as such.

The details of the adsorption kinetics of gold(III) on both the adsorbents were studied by varying the solution temperature from 293 to 323 K and the results are presented in

Figure 23 for CPT gel as an example. Although similar kinetic behavior was observed for crude PT powder, it was relatively faster than that observed for the CPT gel at the initial stage of adsorption. However, it also required longer times to reach equilibrium. This result is attributable to the high aqueous solubility of crude PT powder since tannin molecules of low molecular weight existing in crude PT powder are dissolved in the solution at the initial stage of the contact. Because the interaction of these dissolved molecules with gold(III) ion in solution is the homogeneous reaction, it takes place more rapidly than does the heterogeneous reaction taking place in the case of gold(III) adsorption on solid surface of CPT gel particles.

Figure 23.

Time variation of the adsorption of gold(III) on CPT gel at different temperatures [

33] (with permission for reuse from Elsevier B.V.).

The adsorption rates for both adsorbents at different temperatures were analyzed in terms of the pseudo-first-order kinetic model according to the following equation:

where,

qe and

qt are the amount of adsorbed metal (mol·kg

−1) at equilibrium and any time, respectively, and

k1 (h

−1) is the pseudo-first-order rate constant. The fitting of this rate expression was checked by linear plot of ln{1−(

qt/

qe)}

vs. t at four different temperatures. It was confirmed that the plots were lying on proportional straight lines with the correlation coefficient greater than 0.96.

The relationships between the evaluated pseudo-first-order rate constant and temperature were rearranged according to the Arrehnius equation as shown below:

where

k1 is rate constant,

Ea is activation energy,

T is absolute temperature,

A is Arrehenius constant and

R is gas constant.

The results are shown in

Figure 24 for CPT gel as an example. From the slopes of the straight line in this figure, the apparent activation energy,

Ea, was evaluated as 73 kJ/mol for CPT gel. Similarly, that for crude PT powder was evaluated as 54 kJ/mol.

Similar experimental work was carried out using the adsorption gel prepared by the same method from persimmon peel waste generated in the production of dried persimmon fruit [

34]. Such waste still contains large quantities of persimmon tannin. This gel is abbreviated as PP (persimmon peel) gel, hereafter.

Figure 25 shows % adsorption of various metal ions including precious metals such as gold(III), platinum(IV) and palladium(II) as well as base metals such as copper(II) and iron(III) on PP gel from varying concentration of hydrochloric acid containing individual metal ions. Similar to the adsorption on CPT gel, selective adsorption nearly only to gold(III) was observed also in this case.

Figure 24.

Arrhenius plots for the pseudo-first-order rate constants for CPT gel where the straight line is expressed by the linear equation,

Y = −8.57

x + 26.7, with the correlation factor (

R2) = 0.9671 [

33] (with permission for reuse from Elsevier B.V.).

Figure 25.

Percentage adsorption of some metal ions on PP gel from varying concentration (mol·dm

−3) of hydrochloric acid [

34] (with permission for reuse from Elsevier B.V.).

Figure 26 shows the adsorption isotherm of gold(III) on PP gel from 1 mol·dm

−3 hydrochloric acid solution as well as those on the adsorption gels prepared from peels of lemon and grape by the same method for comparison.

Similar to the case of CPT gel, typical BET type adsorption isotherms based on multilayer adsorption model were also observed for these adsorption gels. Extraordinary high amounts of gold(III) adsorption are noteworthy on the adsorbents of PP gel and lemon gel in particular; i.e., the maximum adsorption amount observed for PP gel is as high as around 9 mol·kg−1 (=1.77 kg-gold·kg−1-dry adsorbent), suggesting that considerably greater quantity of gold(III) was adsorbed also on this gel relative to the dry weight of the adsorbent.

Also in this case, it was confirmed by XRD analysis that the adsorbed gold(III) existed as metallic gold on the adsorbent similar to the case of CPT gel.

Figure 27 shows the image of the filter cake observed by optical microscope, after the adsorption of gold(III) on PP gel followed by filtration. It is evident from this figure that the brilliant gold particles surely exist in the filter cake separated from the gel particles.

Figure 26.

Adsorption isotherms of gold(III) from 1 mol·dm

−3 hydrochloric acid solution on the adsorption gels prepared from peels of persimmon, lemon and grape treated in boiling concentrated sulfuric acid [

34] (with permission for reuse from Elsevier B.V.).

Figure 27.

Image of filter cake after the adsorption of gold(III) on PP gel observed by an optical microscope. Brilliant yellow is the particle of metallic gold while black materials are particles of PP gel.

It may be inferred that the surfaces of CPT and PP gels as well as PT powder function as catalysts for the reductive adsorption reaction of gold(III) as follows: (1) adsorption of gold(III) ion on the surface; (2) reduction of gold(III) ion into metallic gold (gold(0)); (3) release of nanoparticles of metallic gold from the surface and (4) formation of aggregates of nanoparticles of metallic gold. The extraordinary high selectivity and high adsorption capacity for gold(III) may be attributable to this mechanism. In the step (1), the adsorption takes place by the interaction of anionic tetrachloro-complex of gold(III), AuCl4−, with phenolic hydroxyl groups of persimmon tannin molecules, which is followed by the reduction of the step (2). Here, the phenolic hydroxyl groups are oxidized into quinone groups, which are again converted into phenolic hydroxyl groups by the aid of hydrogen ions and again take place the adsorption followed by the reduction reaction. Consequently, such reductive adsorption takes place only under acidic conditions.

7. Chemical Modification of Persimmon Tannin Extract and Persimmon Waste and the Adsorption Behaviors of the Modified Gels

Although, as mentioned earlier, CPT and PP gels were found to exhibit extraordinary high selectivity for gold(III), we further attempted to enhance the affinity also for platinum(IV) and palladium [

35,

36,

37,

38,

39,

40]. It is easy to chemically modify persimmon tannin extract and persimmon waste including persimmon peel by immobilizing a variety of functional groups which exhibit special affinities for some metal ions onto their surface similar to other biomass wastes [

41,

42]. In our research works, persimmon waste was chemically modified by immobilizing functional group of dimethylamine (DMA) to prepare the adsorption gel functioning as a typical weak base type of anion exchange material and investigated its adsorption behavior for some precious and base metals from hydrochloric acid solutions [

35,

36]. Further, a variety of adsorption gels were prepared from persimmon tannin extract powder by the chemical modifications immobilizing other functional groups such as tertiary amine where the immobilized tertiary amine groups function as quaternary ammonium compounds (QA) [

37], a typical strong base, as well as tetraethylenepentamine (TEPA) [

38], glycidyltrimethyl ammonium (GTA), aminoguanidine (AG) [

40], and bisthiourea (BTU) [

41]. These are abbreviated as DMA-PW gel and QAPT, BTU-PT, AG-PT, TEPA-PT and GTA-PT gels, respectively, hereafter.

DMA-PW gel was prepared according to

Scheme 3. Powder of PW, the same feed material employed for the adsorptive removal of chromium(VI) mentioned earlier, was interacted with para- formaldehyde, 1,4-dioxane, acetic acid, phosphoric acid and hydrochloric acid to prepare the chloromethylated intermediate product. Here, the polymer matrices of PT are not only chloromethylated but also crosslinked by the aid of paraformaldehyde under acidic condition. It was then interacted with dimethylamine to prepare the final product. The abundance of dimethylamine groups in the DMA-PW gel thus prepared was evaluated as 2.09 mol·kg

−1 dry gel.

Scheme 3.

Synthetic route of dimethylamine modified persimmon waste (DMA-PW) gel.

Figure 28 shows % adsorption of various metal ions on DMA-PW gel from varying concentration of hydrochloric acid solution. Although only gold(III) is selectively adsorbed on CPT and PP gels to any considerable extent as mentioned earlier, adsorption is observed not only for gold(III) but also for platinum(IV) and palladium(II) while no affinity was observed for base metals such as copper(II), iron(III), nickel(II), and zinc(II) in the case of DMA-PW. This result indicates that the precious metals can be selectively recovered from any other coexisting base metal ions in hydrochloric acid medium using the DMA-PW gel. Additionally, the % adsorption of the precious metals decreased with increasing hydrochloric acid concentration though nearly quantitative adsorption was observed for gold(III) over the whole concentration region of hydrochloric acid similar to the cases of CPT and PP gels.

Figure 28.

Percentage adsorption of various metal ions on DMA-PW gel from varying concentration (mol·dm

−3) of hydrochloric acid solution [

36] (with permission for reuse from Elsevier B.V.).

In acidic chloride media, tertiary amine group of DMA-PW gel is protonated as follows:

The protonated DMA-PW gel is interacted with anionic chloride complexes of gold(III), palladium(II) and platinum(IV), AuCl

4−, PtCl

62− and PdCl

42−, to form ion pair complexes on the gel surface as follows.

The decrease in the amount of adsorption of these metal ions with increasing hydrochloric acid concentration as shown in

Figure 28 can be reasonably interpreted by the above-described adsorption reaction equations. However, the adsorbed gold(III) ion is further reduced by the aid of the functional groups of polyphenols of persimmon tannin into metallic gold similar to the cases of CPT and PP gels.

Figure 29 shows the time variations of amount of the adsorption of gold(III) on CPW and DMA-PW gels for comparison, which clearly indicates that equilibrium is attained within 5 h in the case of DMA-PW whereas it takes much longer in the case of the CPW gel; that is, as a consequence of the chemical modification immobilizing the dimethylamine functional groups, the adsorption kinetics of gold(III) was significantly enhanced by the interactions between the protonated amine groups and anionic chloro-complex of gold(III).

Figure 29.

Time variation of the amount of gold(III) on CPW (●)gel and DMA-PW (■)gel from 0.1 mol·dm

−3 hydrochloric acid solution [

36] (with permission for reuse from Elsevier B.V.).

From the studies of adsorption isotherms of gold(III), platinum(IV) and palladium(II) on DMA-PW gel, it was found that all of these are satisfactorily fitted with the Langmuir’s adsorption isotherm and the maximum adsorption capacities were evaluated as 5.63, 0.26 and 0.42 mol·kg−1, respectively, while that of gold(III) on CPW gel was evaluated as 4.94 mol·kg−1. Compared with the adsorption of platinum(IV) and palladium(II), the extraordinary higher adsorption capacities of gold(III) are noteworthy, which is attributable to the reduction of the adsorbed gold(III) ion into metallic gold (gold(0)) by the polyphenolic functional groups of persimmon tannin as mentioned earlier. In addition, the adsorption capacity of gold(III) itself is also enhanced by this chemical modification.

On the basis of the above-mentioned results of the batch wise experimental works, an adsorption tests was conducted for the recovery of precious metals from actual industrial effluent sample, which is an acidic chloride solution dissolving various metal scraps generated in a precious metals industry. Since the CPW gel has exhibited high selectivity and capacity only for gold, while the DMA-PW has exhibited a high selectivity for palladium and platinum, the flow experiment was conducted using a column packed with PW gel at first for the separation of gold(III) from platinum(IV) and palladium(II), connected in series with the second column packed with DMA-PW gel for recovering platinum(IV) and palladium(II). Here, the acid concentration was around 1 mol·dm−3 and the concentrations of precious metals and some base metals in the actual test solution were as follows (in mg·dm−3): Cu 3360, Zn 1040, Fe 760, Au 100, Pd 6.3, and Pt 4.1.

Figure 30a and

Figure 31a show the breakthrough profiles from the first column packed with the CPW gel and from the second column packed with DMA-PW gel, respectively. As seen from these figures, gold(III) is selectively separated from platinum(IV), palladium(II) and base metals at the first column while platinum(IV) and palladium(II) are separated from all base metals at the second column. All precious metals adsorbed in these columns were effectively eluted using a mixture of 0.1 mol·dm

−3 thiourea in 1 mol·dm

−3 hydrochloric acid solution as shown in

Figure 30b and

Figure 31b. The % recovery of gold(III), platinum(IV) and palladium(II) were 94.2%, 92.9% and 96.1%, respectively. Almost complete recovery of the loaded precious metal ions including the metallic gold from the loaded gel using acidic thiourea solution verifies the easy regeneration of the gel for repeated use. These findings are highly encouraging in terms of consistent recovery of precious metals from actual complex mixtures.

Figure 30.

(

a) Breakthrough profiles of various metal ions contained in the sample solution of the actual effluent of the precious metals industry from the first column column packed with CPW gel; (

b) Elution profiles of various metal ions from the first column using aqueous mixture of 0.1 mol·dm

−3 thiourea in 1 mol·dm

−3 hydrochloric acid solution [

36] (with permission for reuse from Elsevier B.V.).

Figure 31.

(

a) Breakthrough profiles of various metal ions from the second column packed with DMA-PW gel; (

b) Elution profiles of various metal ions from the second column using aqueous mixture of 0.1 mol·dm

−3 thiourea in 1 mol·dm

−3 hydrochloric acid solution [

36] (with permission for reuse from Elsevier B.V.).

The chemical structures of QAPT, BTU-PT, AG-PT, TEPA-PT and GTA-PT gels are shown in

Scheme 4.

Scheme 4.

Chemical structures of the gels prepared from persimmon tannin extract powder via chemical modification immobilizing functional groups of quaternary ammonium (QA), bisthiourea (BTU), aminoguanidine (AG), tetraethylenepentamine (TEPA) and glycidyltrimethyl ammonium (GTA) where P stands for persimmon tannin moiety.

Figure 32 shows the % adsorption of various metal ions at varying concentrations of hydrochloric acid on these chemically modified gels for comparison. As seen from this figure, although platinum(IV), palladium(II) and gold(III) in particular are adsorbed on all of these modified gels, only negligible adsorption takes place for the base metals. Among these gels, it is noticeable that QAPT gel exhibits preferable adsorption behavior compared with other modified gels not only for gold(III) but also for platinum(IV) and palladium(II) over the relatively wide concentration range of hydrochloric acid. That is, the adsorption of gold(III) on QAPT gel is nearly quantitative over the whole concentration region of hydrochloric acid. Additionally, nearly quantitative adsorption of palladium(II) and platinum(IV) was achieved in the low concentration range (0.1–1.5 mol·dm

−3) of hydrochloric acid. From the comparison of this figure with

Figure 28, it is evident that the adsorption of palladium(II) and platinum(IV) on QAPT gel is much higher than that on DMA-PW gel. Both of tertiary amine functional groups of DMA-PW gel protonated in acidic solutions and quaternary ammonium functional groups of QAPT containing positive charges regardless of pH interact with negatively charged chloro-complexes of precious metals by electrostatic interactions. However, because the basicity of QAPT gel is stronger than that of MDA-PW gel, the interaction by the former is stronger than that by the latter. Furthermore, because precious metals such as gold(III), platinum(IV) and palladium(II) give rise to much more stable chloro-complexes with chloride ion, much more negatively charged complexes, than base metals such as iron(III), zinc(II) and copper(II), these precious metals are much more preferentially adsorbed on these modified gels, which may be inferred to be the origin of the high selectivity to precious metals over base metals.

Figure 32.

Percentage adsorption of various metal ions on some chemically modified PT gel from varying concentration of hydrochloric acid. ♦ Au(III), ○ Pd(II), ▲ Pt(IV), │ Cu(II), × Zn(II), Δ Ni(II), * Fe(III).

The results acquired from the adsorption isotherm studies of gold(III), palladium(II), and platinum(IV) on these modified gels suggested that they were adequately fitted with the Langmuir type adsorption isotherms. The maximum adsorption capacities of these precious metals on these modified gels as well as the DMA-PW gel evaluated according to the Langmuir’s equation are listed in

Table 3 together with those on other adsorbents for comparison.

Table 3.

The maximum adsorption capacities of gold(III), platinum(IV) and palladium(II) on various adsorbents.

| Adsorbent | Maximum Adsorption Capacity (mol·kg−1) | HCl Concentration (mol·dm−3) or pH | Reference |

|---|

| Au(III) | Pt(IV) | Pd(II) |

|---|

| Persimmon extract tannin (PT) powder | 5.89 | - | - | 0.1 | [33] |

| Crosslinked persimmon tannin (CPT) | 7.7 | - | - | 0.1 | [33] |

| Crosslinked persimmon waste (CPW) | 4.95 | - | - | 0.1 | [35,36] |

| Dimethylamine modified persimmon waste (DMA-PW) | 5.63 | 0.28 | 0.42 | 0.1 | [35,36] |

| Quaternary ammonium modified persimmon tannin (QAPT) | 4.16 | 0.52 | 0.84 | 0.1 | [37] |

| Tetraethylenepentamine- modified persimmon tannin (TEPA-PT) | 5.93 | 1.48 | 1.76 | 0.1 | [38] |

| Glycidyltrimethyl ammonium chloride modified persimmon tannin (GTA-PT) | 3.30 | 1.00 | 1.67 | 0.1 | [39] |

| Aminoguanidine modified persimmon tannin (AG-PT) | 8.90 | 1.00 | 2.00 | 0.1 | [40] |

| Bisthiourea modified persimmon tannin (BTU-PT) | 5.22 | 0.70 | 1.72 | 0.1 | [41] |

| Quaternary ammonium modified microalgal residue | | 1.33 | 2.95 | 0.1 | [43] |

| Crosslinked microalgal residue | 3.25 | 0.15 | 0.25 | 0.1 | [44] |

| Crosslinked chitosan | | 1.6 | 2.1 | 0.01 | [1] |

| Collagen fiber immobilized bayberry tannin | | 0.495 | 0.80 | pH = 5.6 | [45] |

| Lysine modified cross-linked chitosan | 0.35 | 0.66 | 1.03 | pH = 1 for Pt; pH = 2 for Pd, and Au | [46] |

| Glycine modified cross-linked chitosan | 0.86 | 0.62 | 1.13 | pH = 2 | [47] |

| PEI-modified corynebacterium glutamicum | | | 1.66 | 0.1 | [48] |

| Ethylenediamine modified chitosan nanoparticle | | 0.87 | 1.30 | pH = 2 | [49] |

| Thiourea-modified chitosan microsphere | | 0.66 | 1.06 | pH = 2 | [50] |

| Duolite GT-73 | 0.58 | 0.26 | | pH = 2 | [51] |

| Polyallylamine modified Escherichia coli biomass | | | 2.50 | pH = 3 | [52] |

| Dimethylamine modified waste paper | 4.60 | 0.90 | 2.10 | 1 | [42] |

Among these modified persimmon tannin gels, the high adsorption capacities of TEPA-PT, GTA-PT, AG-PT and BTU-PT not only for gold(III) but also for platinum(IV) and palladium(II) are noteworthy though the concentration range of hydrochloric acid effective for the high adsorption is limited. Also for these modified persimmon tannin gels, the exceptionally high adsorption capacities for gold(III) are attributable to the combination of adsorption and reduction into metallic gold particles by the aid of polyphenolic groups of persimmon tannin, which was confirmed by the observations using optical microscope and XRD.

The adsorption kinetics of gold(III), palladium(II) and platinum(IV) on the QAPT gel were studied in detail and compared with that of gold(III) on crude PT powder. It was observed that equilibrium was attained within 2 h for palladium(II) and platinum(IV) for the adsorption on QAPT gel, whereas it was attained within 6 h for gold(III) adsorption. On the other hand, the crude PT powder requires 24 h to reach equilibrium of gold(III) adsorption under the same condition. The rapid kinetics of gold (III) adsorption with the QAPT gel is attributable to the effect of abundant quaternary ammonium groups, which concentrate the reactant species, AuCl4−, on the gel surface by anion exchange adsorption, enhancing the reduction rate of gold(III).