Effect of Welding Speed on Defect Features and Mechanical Performance of Friction Stir Lap Welded 7B04 Aluminum Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

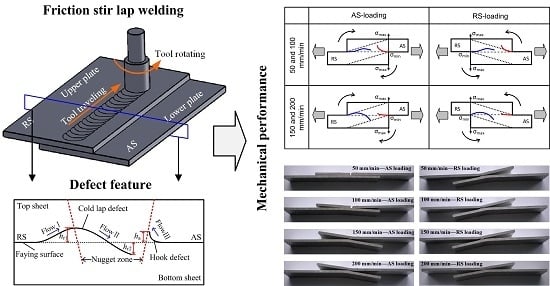

3.1. Defect Features of Lap Joints

3.2. Mechancial Performance of Lap Joints

4. Discussion

4.1. Evolution of Tensile Properties with Welding Speed

4.2. Effect of Loading Configuration on Joint Properties

5. Conclusions

- (1)

- The increase of welding speed can remarkably limit the upward motion of the initial faying surface, which lowers the level of top sheet thinning induced by the hook defect. The cold lap defect can result in the reduction of effective thickness in both the top and bottom sheets. The height of the cold lap defect is decreased in the top sheet but gradually increased in the bottom sheet when the welding speed is increased, leading to a slight variation in the total height of the cold lap defect with the welding speed.

- (2)

- The tensile properties of FSLW joints are largely related to the level of sheet thinning caused by the hook and cold lap defects. In the AS loading configuration, the fracture strength of AS-loaded lap joints is significantly increased with increasing welding speed, while for the RS loading configuration, the fracture strength of RS-loaded lap joints varies slightly with the welding speed. Local bending and rotating occurred in the lap joints during the tensile test. The rotating angle of the lap sheets and the fracture strength of the lap joints exhibit similar evolving trends with the welding speed in both AS and RS loading configurations.

- (3)

- The affecting characteristic of loading configuration on joint performance is dependent on the welding speed. At lower welding speeds, the AS-loaded lap joints show lower fracture strength than the RS-loaded lap joints. When the welding speed is high, the AS-loaded lap joints then present larger tensile properties than RS-loaded lap joints. In order to obtain the high performance of lap joints, a relatively high welding speed should be applied during FSLW. Meanwhile, the loading side of the joint, AS or RS, should possess a larger effective thickness in the joint.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Buffa, G.; Fratini, L.; Ruisi, V. Friction stir welding of tailored joints for industrial applications. Int. J. Mater. Form. 2009, 2, 311–314. [Google Scholar] [CrossRef]

- Cam, G.; Mistikoglu, S. Recent developments in friction stir welding of Al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Cederqvist, L.; Reynolds, A.P. Factors affecting the properties of friction stir welded aluminum lap joints. Weld. J. 2001, 80, 281–287. [Google Scholar]

- Lee, C.Y.; Lee, W.B.; Kim, J.W.; Choi, D.H.; Yeon, Y.M.; Jung, S.B. Lap joint properties of FSWed dissimilar formed 5052 Al and 6061 Al alloys with different thickness. J. Mater. Sci. 2008, 43, 3296–3304. [Google Scholar] [CrossRef]

- Yadava, M.K.; Mishra, R.S.; Chen, Y.L.; Carlson, B.; Grant, G.J. Study of friction stir joining of thin aluminium sheets in lap joint configuration. Sci. Technol. Weld. Join. 2010, 15, 70–75. [Google Scholar] [CrossRef]

- Yazdanian, S.; Chen, Z.W.; Littlefair, G. Effects of friction stir lap welding parameters on weld features on advancing side and fracture strength of AA6060-T5 welds. J. Mater. Sci. 2012, 47, 1251–1261. [Google Scholar] [CrossRef]

- Babu, S.; Ram, G.D.J.; Venkitakrishnan, P.V.; Reddy, G.M.; Rao, K.P. Microstructure and mechanical properties of friction stir lap welded aluminum alloy AA2014. J. Mater. Sci. Technol. 2012, 28, 414–426. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, H.J.; Zhang, J.B.; Zhang, X.; Yang, L. Effect of pin length on hook size and joint properties in friction stir lap welding of 7B04 aluminum alloy. J. Mater. Eng. Perform. 2014, 23, 1881–1886. [Google Scholar] [CrossRef]

- Urso, G.D.; Giardini, C. The influence of process parameters and tool geometry on mechanical properties of friction stir welded aluminum lap joints. Int. J. Mater. Form. 2010, 3, 1011–1014. [Google Scholar]

- Buffa, G.; Campanile, G.; Fratini, L.; Prisco, A. Friction stir welding of lap joints: Influence of process parameters on the metallurgical and mechanical properties. Mater. Sci. Eng. A 2009, 519, 19–26. [Google Scholar] [CrossRef]

- Yang, Q.; Li, X.; Chen, K.; Shi, Y.J. Effect of tool geometry and process condition on static strength of a magnesium friction stir lap linear weld. Mater. Sci. Eng. A 2011, 528, 2463–2478. [Google Scholar] [CrossRef]

- Yuan, W.; Carlson, B.; Verma, R.; Szymanski, R. Study of top sheet thinning during friction stir lap welding of AZ31 magnesium alloy. Sci. Technol. Weld. Join. 2012, 17, 375–380. [Google Scholar] [CrossRef]

- Xu, X.D.; Yang, X.Q.; Zhou, G.; Tong, J.H. Microstructures and fatigue properties of friction stir lap welds in aluminum alloy AA6061-T6. Mater. Des. 2012, 35, 175–183. [Google Scholar] [CrossRef]

- Dubourg, L.; Merati, A.; Jahazi, M. Process optimization and mechanical properties of friction stir lap welds of 7075-T6 stringers on 2024-T3 skin. Mater. Des. 2010, 31, 3324–3330. [Google Scholar] [CrossRef]

- Fersini, D.; Pirondi, A. Fatigue behavior of Al 2024-T3 friction stir welded lap joints. Eng. Fract. Mech. 2007, 74, 468–480. [Google Scholar] [CrossRef]

- Starink, M.J.; Seschamps, A.; Wang, S.C. The strength of friction stir welded and friction stir processed aluminum alloys. Scr. Mater. 2008, 58, 377–382. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Shivpuri, R. Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints. Acta Mater. 2010, 58, 2056–2067. [Google Scholar] [CrossRef]

| Chemical Compositions (wt. %) | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Al | Zn | Mg | Cu | Mn | Fe | Cr | Tensile Strength | Elongation |

| Bal. | 5.75 | 2.51 | 1.68 | 0.26 | 0.20 | 0.15 | 486 MPa | 11% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wang, M.; Zhang, X.; Zhu, Z.; Yu, T.; Yang, G. Effect of Welding Speed on Defect Features and Mechanical Performance of Friction Stir Lap Welded 7B04 Aluminum Alloy. Metals 2016, 6, 87. https://doi.org/10.3390/met6040087

Zhang H, Wang M, Zhang X, Zhu Z, Yu T, Yang G. Effect of Welding Speed on Defect Features and Mechanical Performance of Friction Stir Lap Welded 7B04 Aluminum Alloy. Metals. 2016; 6(4):87. https://doi.org/10.3390/met6040087

Chicago/Turabian StyleZhang, Huijie, Min Wang, Xiao Zhang, Zhi Zhu, Tao Yu, and Guangxin Yang. 2016. "Effect of Welding Speed on Defect Features and Mechanical Performance of Friction Stir Lap Welded 7B04 Aluminum Alloy" Metals 6, no. 4: 87. https://doi.org/10.3390/met6040087

APA StyleZhang, H., Wang, M., Zhang, X., Zhu, Z., Yu, T., & Yang, G. (2016). Effect of Welding Speed on Defect Features and Mechanical Performance of Friction Stir Lap Welded 7B04 Aluminum Alloy. Metals, 6(4), 87. https://doi.org/10.3390/met6040087