1. Introduction

The currently decreasing quality and increasing variability of anode raw materials (coke and pitch) make it challenging to manufacture the anodes with consistent overall quality. Intercepting faulty anodes before they are set in reduction cells and deteriorate their performance (i.e., energy consumption and efficiency) requires testing all or the majority of the manufactured anodes. However, even in modern and well-instrumented anode manufacturing plants, the traditional lab inspection strategy based on core sampling can, at best, evaluate the properties of about 1% of the manufactured anodes due to the costly, time-consuming, and destructive nature of the analytical methods. In addition, the core sample properties are typically available after the anode is set in the reduction cells due to the long lab delays. For economical and logistics reasons, it is generally not possible to improve the rate of anode testing by increasing the lab work load. Furthermore, the properties obtained from core samples are not necessarily representative of the whole anode block, as reported by Sinclair and Sadler [

1,

2], who provide a complete list of issues related to the use of core samples for quality control and decision-making. Indeed, anode blocks are heterogeneous materials that may contain different types of internal defects (i.e., coke particles not penetrated by pitch, regions of high/low pitch concentration, pores and cracks) which can lead to the anisotropic distribution of properties within the block. The current strategy may completely miss these defects if the core is not sampled where the defects are located. Hence, the mechanical properties and electrical resistivity obtained from core samples may only reflect localized properties. Therefore, rapid and non-destructive techniques to inspect anode blocks should be investigated in order to provide a better picture of the anode quality in a timely fashion. This would allow anode sorting strategies to be put in place and feedback-corrective adjustments to be implemented on the paste plant and baking furnace operation parameters.

Recent research efforts were focused on developing systems for measuring the anode resistivity distribution online based on the work of Seger [

3,

4] and/or Haldemann and Fawzi [

5]. For example, a device called MIREA (Mesure Instantanée de la Résistivité Électrique Anodique) was proposed to measure the anodic electrical resistance [

6,

7]. Basically, an electrical current entering by the stub holes is passed through the anode in a similar way to if the anode was rodded while several voltage drop measurements are collected at different locations on the anode surface. A numerical model of the anode is then used together with the voltage drop measurements to estimate the anode resistivity distribution. Alternatively, the resistivity distribution can be measured using an array of electrical contact points placed at the top and bottom of the anode and by measuring the voltage drop at each of these points [

8,

9]. In addition to providing resistivity measurements, these systems should allow detecting the presence of defects within the anodes since damage within the carbon block should, in principle, disturb the electrical current distribution. However, their ability to discriminate between different types of defects (e.g., pores vs. cracks) has not been demonstrated.

Alternatively, the internal structure of the anodes could be inspected by acousto-ultrasonic (AU) techniques. These non-destructive methods have been widely used in the inspection of composite materials, such as concrete and refractories [

10,

11,

12]. However, applications of AU for testing complex porous materials naturally containing pores and cracks, such as baked carbon anodes, are not as common as for denser materials such as parts made of metal alloys or highly graphitized carbon materials, which are expected to be free of internal voids. The main issue with the anodes is separating defects affecting their performance in the reduction cells from the internal porosity, which is always present, when both types of voids attenuate the acoustic waves propagating through the materials. The only publicly available reports on the application of acoustic methods on carbon electrodes appear to be those of Allaire [

13] and Allaire et al. [

14] using the SonicByte™ system [

15]. Their work mainly focused on measuring the elastic properties of refractory and carbonaceous materials as a means of detecting defects. Although this technique may help identify faulty anodes, it only provides an estimate of the overall material properties. Inspecting the anode block at different positions should provide more information about the distribution of pores and cracks within the volume, and provide a clearer diagnostic. This is essential for taking appropriate corrective actions on the anode manufacturing plant operations. In addition to detecting and discriminating the internal anode defects, the AU signals could provide measurements of the anode density distribution, which is complementary information to electrical resistivity measurements.

The objective of this work is to investigate the sensitivity of the acousto-ultrasonic techniques to defects within the internal structure of carbon anode materials. It focuses especially on the detection and identification of two types of internal voids, namely pores and cracks, using the attenuated acoustic signal propagating through the material. To prove the concept, a baked anode was sliced along its length and analyzed by X-ray Computed Tomography (CT scan) to reveal its internal structure [

16]. Acoustic excitation waves at different frequencies were sent through the materials and the attenuated signals were measured at different positions on a certain number of slices. Several features were computed from the AU signals and collected in a data matrix which was then analyzed using principal component analysis (PCA) [

17]. The clustering patterns obtained in the PCA score space suggest that the proposed approach is sensitive to the concentration of pores and the presence of cracks, and that both types of voids can be distinguished. The results were validated qualitatively using CT scan images.

The paper is organized as follows. The experimental details about the acoustic inspection set-up as well as the baked anode samples are presented first. The methods used for processing and analyzing the acoustic signals are then described. The results obtained with the proposed approach are presented and discussed. Finally, some conclusions are drawn.

4. Results and Discussion

The mechanical wave exciting a porous material, such as carbon anode materials, usually has complex propagation characteristics. PCA was applied to the attenuated acoustic signal feature matrix X to assess whether the anode samples (corridors) located at different positions within the block could be distinguished based on their attenuation behavior (quantified by temporal features at different frequencies).

A total of 15 principal components (i.e., latent variables) were found statistically significant by a cross-validation procedure [

23]. The cumulative sum of squares explained (R

2) and predicted (Q

2) by the first two PCA components are provided in

Table 1. Only those two components are discussed since they were found sufficient to discriminate the samples. They explain 65% of the variance of the attenuation features (

X) and maintained a relatively good performance in prediction by cross-validation (Q

2 = 56%).

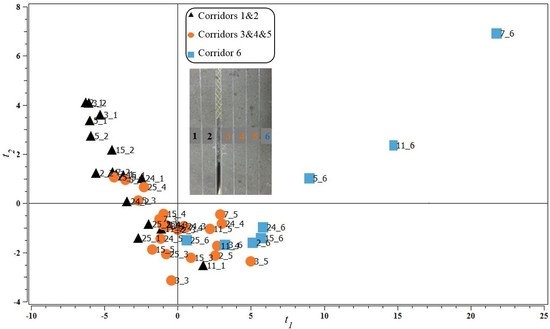

Figure 6 presents the latent variable score space (

t1 vs.

t2) for the first two components of the PCA model. Each marker corresponds to the attenuation behavior of one particular corridor (one row in

X). Those were labeled in the plot using the slice and corridor numbers (slice#_corridor#) presented in

Figure 2. The clustering pattern in the

t1–

t2 score space reveals that corridors 1–2, 3–5, and 6 of any slice roughly cluster in three groups (black, orange and blue markers, respectively). At this point, it is important to make a note that the corridors labeled #1 are located at the center of the anode and #6 at the outer surface. It can also be observed that the attenuation features of corridors 1–2 and 6 seem more variable than those of corridors 3–5 (the orange cluster is tighter than the black and blue clusters).

In order to interpret the differences between the three clusters based on the internal structure of the corridors, the CT scan images of the eight slices were examined first. To support the discussion, the images of four of these slices are provided in

Figure 7. In general, it was found that the central/upper regions of corridors 1–2 in most slices were showing several cracks, whereas the lower part of these corridors had a high density of pores. Corridors 3–5 were much denser with a few cracks, sometimes extending from corridors 1–2 in the transverse direction. Finally, corridor 6 rarely showed cracks but had a variable density of pores. Therefore, the clustering pattern shown in the score plot (

Figure 6) suggests that the first component (

t1) is sensitive to the presence of cracks because, from right to left in the score plot (along the

t1 direction), the corridors cluster according to the increasing presence of cracks. The second component (

t2), on the other hand, seems to distinguish dense from porous regions. Corridors 3–5 (orange markers) are denser and cluster in the negative

t2 region as opposed to those corridors characterized by a high pore density (most of the corridors 1–2 and some 6) fall in the positive

t2 region.

These results are also in agreement with carbon plant knowledge. The region below the stub holes corresponding to corridors 1–2 in slices #5, #7, #11, and #15 are generally expected to show a higher concentration of cracks, as shown in

Figure 8. Most of these corridors fall in the cluster formed by the black markers. Corridors 1–2 in slices #24 and #25 (edges) project closer to the denser region (orange markers), which is normally expected unless cracks extend in the longitudinal direction from the center of the anode towards its surface, as seems to be the case for the other edge of the anode (slices #2 and #3). Finally, it is important to understand that the overlap between the clusters should not be interpreted as a misclassification as it was not attempted to do so. Although cracks and pores are expected to concentrate in certain regions within the anode block, they may very well be found in locations where they are less or not expected (hence the overlap between clusters) but still need to be detected by the inspection system. The color code used to distinguish the corridors and slices in

Figure 6 was selected for illustration purposes only.

The relationships between the clusters in the score space (

Figure 6) and the attenuation features are now interpreted using the

p1–

p2 loading plot shown in

Figure 9. As discussed previously, each score vector

ta is defined as a linear combination of the attenuation features (i.e.,

ta =

X ×

pa), and the loading vector

pa contains the weights of each feature in that linear combination. The weights of each feature in both components are presented in the form of a scatter plot (

Figure 9). Each point in this graph corresponds to one feature calculated at one excitation frequency (i.e., one column of

X). The label of each point identifies the feature name followed by the excitation frequency.

The loading plot is interpreted as follows. The absolute value of the loading weights indicates the importance of the feature in a given component, whereas the sign of the weights informs about the sign of the correlation between pairs of features. Those features with loading values of the same sign are positively correlated while those with opposite signs are negatively correlated.

Figure 9 reveals that the first component is mainly driven by the mean and the variance-related features (MAX, E, RMS and STD). In addition, the mean features have an opposite sign compared to the others, indicating that they are negatively correlated with MAX, E, RMS, and STD. This means that moving from the positive

t1 region (a low concentration of cracks) towards negative

t1 values (a high concentration of cracks) involves lower values of the variance-related features (MAX, E, RMS and STD) and higher values of the mean of the signal. This is consistent with AU signal attenuation by an increasing concentration of cracks. The second component (orthogonal to the first) involves most features except for the kurtosis and skewness (K and S) in particular, which were not as important in the first component. These features are negatively correlated at all frequencies, except for at 200 kHz. In addition, their loading values switch signs around that frequency. This suggests that the presence of pores modifies the shape of the distribution of the AU signal (as opposed to simple attenuation of the signal by cracks). Furthermore, the fact that the loading values for K and S are frequency-dependent may indicate that

t2 is not only sensitive to pore concentration, but also to their size. For example, corridor #6 of slice 7 (see

Figure 3) has a high concentration of large pores, corridors #1–2 are also characterized by large pores but they are fewer in number compared to corridor #6, and corridors #3–5 have smaller pores. In the score plot (

Figure 6), corridor #6 has the highest

t2 value, corridors #1–2 have intermediate values, and corridors #3–5 have the lowest values for this slice. Hence, the larger the pore size, the higher the

t2 values. The relationship between pore size and the shape of the AU signals at different frequencies is currently being investigated further.