On the Improvement of AA2024 Wear Properties through the Deposition of a Cold-Sprayed Titanium Coating

Abstract

:1. Introduction

2. Experimental Section

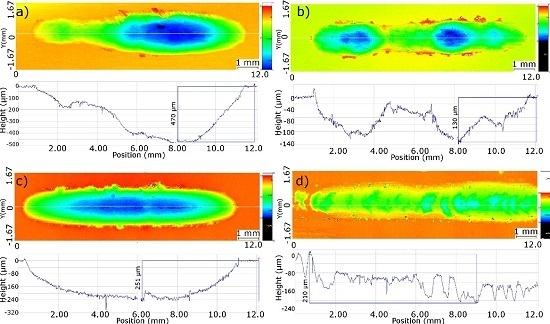

3. Results and Discussion

- (1)

- Oxidised zone: the region of the cold-sprayed layer that was oxidised by the laser treatment;

- (2)

- Heat-affected zone: similarly to what happens in laser beam welding, this is the region of the cold-sprayed layer that was affected by the heat generated during the treatment;

- (3)

- Base material: the region of the cold-sprayed layer that was not affected by the laser treatment;

- (4)

- Substrate: the aluminium plate used as a substrate for the deposition process.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schmidt, T.; Gaertner, F.; Kreye, H. New Developments in Cold Spray Based on Higher Gas and Particle Temperatures. J. Therm. Spray Technol. 2006, 15, 488–494. [Google Scholar] [CrossRef]

- Morgan, R.; Fox, P.; Pattison, J.; Sutcliffe, C.; O′Neill, W. Analysis of cold gas dynamically sprayed aluminium deposits. Mater. Lett. 2004, 58, 1317–1320. [Google Scholar] [CrossRef]

- Marrocco, T.; McCartney, D.; Shipway, P.; Sturgeon, A. Production of titanium deposits by cold-gas dynamic spray: Numerical modeling and experimental characterization. J. Therm. Spray Technol. 2006, 15, 263–272. [Google Scholar] [CrossRef]

- Astarita, A.; Durante, M.; Langella, A.; Montuori, M.; Squillace, A. Mechanical characterization of low pressure cold-sprayed metal coatings on aluminium. Surf. Interface Anal. 2013, 45, 1530–1535. [Google Scholar] [CrossRef]

- Irissou, E.; Legoux, J.G.; Arsenault, B.; Moreau, C. Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties. J. Therm. Spray Technol. 2007, 16, 661–668. [Google Scholar] [CrossRef]

- Bell, T.; Dong, H. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar]

- Wang, Y.; Li, C.; Guo, L.; Tian, W. Laser remelting of plasma sprayed nanostructured Al2O3-TiO2 coatings at different laser power. Surf. Coat. Technol. 2010, 204, 3559–3566. [Google Scholar] [CrossRef]

- Sidhu, B.S. Laser surface remelting to improve the erosion-corrosion resistance of nickel-chromium-aluminium-yttrium (NiCrAlY) plasma spray coatings. In Laser Surface Modifications of Alloys for Corrosion and Erosion Resistance; Kwok, C.T., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 355–366. [Google Scholar]

- Chikarakara, E.; Aqida, S.; Brabazon, D.; Naher, S.; Picas, J.A.; Punset, M.; Forn, A. Surface modification of HVOF thermal sprayed WC-CoCr coatings by laser treatment. Int. J. Mater. Form. 2010, 3, 801–804. [Google Scholar] [CrossRef] [Green Version]

- Chikarakara, E.; Naher, S.; Brabazon, D. High speed laser surface modification of Ti-6Al-4V. Surf. Coat. Technol. 2012, 206, 3223–3229. [Google Scholar] [CrossRef]

- Chikarakara, E.; Naher, S.; Brabazon, D. Process mapping of laser surface modification of AISI 316L stainless steel for biomedical applications. Appl. Phys. A Mater. Sci. Process. 2010, 101, 367–371. [Google Scholar] [CrossRef] [Green Version]

- Rubino, F.; Astarita, A.; Carlone, P.; Genna, S.; Leone, C.; Minutolo, F.M.C.; Squillace, A. Selective Laser Post-Treatment on Titanium Cold Spray Coatings. Mater. Manuf. Process. 2015. [Google Scholar] [CrossRef]

- Zhang, E.; Xu, L.; Yang, K. Formation by ion plating of Ti-coating on pure Mg for biomedical applications. Scr. Mater. 2005, 53, 523–527. [Google Scholar] [CrossRef]

- Zhang, X.H.; Liu, D.X.; Tan, H.B.; Wang, X.F. Effect of TiN/Ti composite coating and shot peening on fretting fatigue behaviour of TC17 alloy at 350 °C. Surf. Coat. Technol. 2009, 203, 2315–2321. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Watkins, T.R.; Cavin, O.B.; Kulkarni, N.S. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 2005, 258, 1348–1356. [Google Scholar] [CrossRef]

- Nieslony, P.; Cichosz, P.; Krolczyk, G.M.; Legutko, S.; Smyczek, D.; Kolodziej, M. Experimental studies of the cutting force and surface morphology of explosively clad Ti-steel plates. Measurement 2016, 78, 129–137. [Google Scholar] [CrossRef]

- Ruggiero, A.; D′Amato, R.; Gómez, E.; Merola, M. Experimental comparison on tribological pairs UHMWPE/TIAL6V4 alloy, UHMWPE/AISI316L austenitic stainless and UHMWPE/Al2O3 ceramic, under dry and lubricated conditions. Tribol. Int. 2016, 96, 349–360. [Google Scholar] [CrossRef]

- Ruggiero, A.; D′Amato, R.; Gómez, E. Experimental analysis of tribological behaviour of UHMWPE against AISI420C and against TiAl6V4 alloy under dry and lubricated conditions. Tribol. Int. 2015, 92, 154–161. [Google Scholar] [CrossRef]

- Bloyce, A.; Morton, P.H.; Bell, T. ASM Handbook; ASM Int.: Materials Park, OH, USA, 1994; Volume 5, p. 835. [Google Scholar]

- Bell, T.; Dong, H. Tribological enhancement of titanium alloys. In Proceedings of the First Asian Conference on Tribology, Beijing, China, 12–15 October 1998; pp. 421–427.

- Dong, H.; Bell, T. Towards designer surfaces for titanium components. Ind. Lubr. Tribol. 1998, 50, 282–289. [Google Scholar] [CrossRef]

- Friction, Lubrication, and Wear Technology. In ASM Handbook; Blau, P.J. (Ed.) ASM Int.: Materials Park, OH, USA, 1994; Volume 18, p. 1879.

- Astarita, A.; Durante, M.; Langella, A.; Squillace, A. Elevation of tribological properties of alloy Ti-6% Al-4%V upon formation of a rutile layer on the surface. Met. Sci. Heat Treat. 2013, 54, 662–666. [Google Scholar] [CrossRef]

- Kataria, S.; Kumar, N.; Dash, S.; Tyagi, A.K. Tribological and deformation behaviour of titanium coating under different sliding contact conditions. Wear 2010, 269, 797–803. [Google Scholar] [CrossRef]

- Khun, N.W.; Li, R.T.; Loke, K.; Khor, K.A. Effects of Al-Cr-Fe Quasicrystal Content on Tribological Properties of Cold-Sprayed Titanium Composite Coatings. Tribol. Trans. 2015, 58, 616–624. [Google Scholar] [CrossRef]

- Cassar, G.; Wilson, J.C.A.-B.; Banfield, S.; Housden, J.; Matthews, A.; Leyland, A. Surface modification of Ti-6Al-4V alloys using triode plasma oxidation treatments. Surf. Coat. Technol. 2012, 206, 4553–4561. [Google Scholar] [CrossRef]

- Wang, S.; Liao, Z.; Liu, Y.; Liu, W. Influence of thermal oxidation duration on the microstructure and fretting wear behaviour of Ti6Al4V alloy. Mater. Chem. Phys. 2015, 159, 139–151. [Google Scholar] [CrossRef]

- Davis, J.R. (Ed.). ASM Specialty Handbook: Aluminium and Aluminium Alloys; ASM Int.: Materials Park, OH, USA, 1993. [Google Scholar]

- Hanson, B. The Selection and Use of Titanium: A Design Guide; Institute of Materials: London, UK, 1995. [Google Scholar]

- Ruggiero, A.; Valasek, P.; Merola, M. Friction and Wear Behaviours of Al/Epoxy Composites during Reciprocating Sliding Tests. Manuf. Technol. 2015, 15, 684–689. [Google Scholar]

- Ruggiero, A.; Merola, M.; Carlone, P.; Archodoulaki, V.-M. Tribo-mechanical characterization of reinforced epoxy resin under dry and lubricated contact conditions. Compos. B Eng. 2015, 79, 595–603. [Google Scholar] [CrossRef]

- Carlone, P.; Astarita, A.; Rubino, F.; Pasquino, N.; Aprea, P. Selective Laser Treatment on Cold-Sprayed Titanium Coatings: Numerical Modeling and Experimental Analysis. Metall. Mater. Trans. B 2016. [Google Scholar] [CrossRef]

- Wong, W.; Rezaeian, A.; Irissou, E.; Legoux, J.-G.; Yue, S. Cold Spray Characteristics of Commercially Pure Ti and Ti-6Al-4V. Adv. Mater. Res. 2010, 89–91, 639–644. [Google Scholar] [CrossRef]

- Cassar, G.; Wilson, J.C.A.-B.; Banfield, S.; Housden, J.; Matthews, A.; Leyland, A. A study of the reciprocating-sliding wear performance of plasma surface treated titanium alloy. Wear 2010, 269, 60–70. [Google Scholar] [CrossRef]

- Miller, P.D.; Holladay, J.W. Friction and Wear Properties of Titanium. Wear 1958, 2, 133–140. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Krishna, D.S.R.; Brama, Y.L.; Sun, Y.R. Thick rutile layer on titanium for tribological applications. Tribol. Int. 2007, 40, 329–334. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Farokhzadeh, K.; Li, J.; Lo, J.; Riahi, A.R. Improving the wear resistance of Ti-6Al-4V/TiC composites through thermal oxidation (TO). Wear 2010, 269, 590–601. [Google Scholar] [CrossRef]

- Kim, K.; Geringer, J. Analysis of energy dissipation in fretting corrosion experiments with materials used as hip prosthesis. Wear 2012, 296, 497–503. [Google Scholar] [CrossRef]

- Fouvry, S.; Kapsa, P.; Vincent, L. Analysis of sliding behaviour for fretting loadings: Determination of transition criteria. Wear 1995, 185, 35–46. [Google Scholar] [CrossRef]

- Sun, Y. Thermally oxidised titanium coating on aluminium alloy for enhanced corrosion resistance. Mater. Lett. 2004, 58, 2635–2639. [Google Scholar] [CrossRef]

- Sun, Y. Tribological rutile-TiO2 coating on aluminium alloy. Appl. Surf. Sci. 2004, 233, 328–335. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Astarita, A.; Rubino, F.; Carlone, P.; Ruggiero, A.; Leone, C.; Genna, S.; Merola, M.; Squillace, A. On the Improvement of AA2024 Wear Properties through the Deposition of a Cold-Sprayed Titanium Coating. Metals 2016, 6, 185. https://doi.org/10.3390/met6080185

Astarita A, Rubino F, Carlone P, Ruggiero A, Leone C, Genna S, Merola M, Squillace A. On the Improvement of AA2024 Wear Properties through the Deposition of a Cold-Sprayed Titanium Coating. Metals. 2016; 6(8):185. https://doi.org/10.3390/met6080185

Chicago/Turabian StyleAstarita, Antonello, Felice Rubino, Pierpaolo Carlone, Alessandro Ruggiero, Claudio Leone, Silvio Genna, Massimiliano Merola, and Antonino Squillace. 2016. "On the Improvement of AA2024 Wear Properties through the Deposition of a Cold-Sprayed Titanium Coating" Metals 6, no. 8: 185. https://doi.org/10.3390/met6080185

APA StyleAstarita, A., Rubino, F., Carlone, P., Ruggiero, A., Leone, C., Genna, S., Merola, M., & Squillace, A. (2016). On the Improvement of AA2024 Wear Properties through the Deposition of a Cold-Sprayed Titanium Coating. Metals, 6(8), 185. https://doi.org/10.3390/met6080185