Effect of High-Pressure Torsion on Structure and Microhardness of Ti/TiB Metal–Matrix Composite

Abstract

:1. Introduction

2. Materials and Procedure

3. Results

3.1. Initial Microstructure

3.2. Microstructure Evolution during High-Pressure Torsion

3.3. Microhardness

4. Discussion

5. Conclusions

- (1)

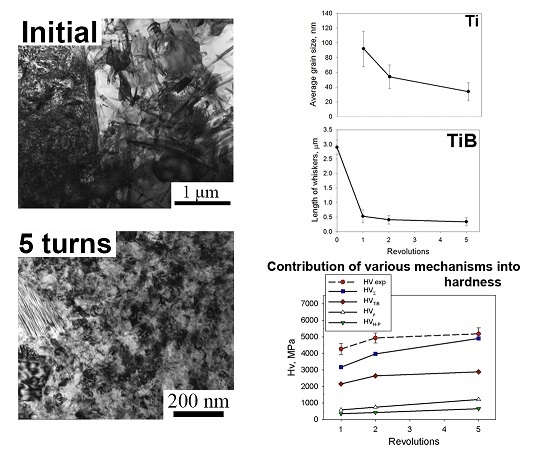

- Processing by HPT produced a microstructure with (sub)grains of ~34 nm after five revolutions (γ ≈ 157). The microstructure evolution was associated with an intensive increase in dislocation density and substructure development, resulting in a gradual microstructure refinement of the Ti matrix and shortening/redistribution of TiB whiskers.

- (2)

- The microhardness increased with strain attaining the maximum value (~520 HV) at the edge of the disk after five revolutions. Analysis of contributions of different hardening mechanisms into the hardness of the Ti/TiB metal–matrix composite shows that an increase in hardness can mostly be ascribed to a contribution of precipitation hardening. The combined effect of substructure and Hall–Petch hardening give approximately two times lower contribution.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys. Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003; pp. 1–499. [Google Scholar]

- Saito, T.; Furuta, T.; Yamaguchi, T. Development of low cost titanium matrix composite. In Advances in Titanium Metal Matrix Composites, the Minerals, Metals and Materials Society; Froes, F.H., Storer, J., Eds.; TMS: Warrendale, PA, USA, 1995; pp. 33–44. [Google Scholar]

- Radhakrishna Bhat, B.V.; Subramanyam, J.; Bhanu Prasad, V.V. Preparation of Ti-TiB-TiC & Ti-TiB composites by in-situ reaction hot pressing. Mater. Sci. Eng. A 2002, 325, 126–130. [Google Scholar]

- Li, S.; Sun, B.; Imaia, H.; Kondoh, K. Powder metallurgy Ti-TiC metal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon 2013, 61, 216–228. [Google Scholar] [CrossRef]

- Munir, K.S.; Zheng, Y.; Zhang, D.; Lin, J.; Li, Y.; Wen, C. Improving the strengthening efficiency of carbon nanotubes in titanium metal matrix composites. Mater. Sci. Eng. A 2017, 696, 10–25. [Google Scholar] [CrossRef]

- Godfrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium particulate metal matrix composites—Reinforcement, production methods, and mechanical properties. Adv. Eng. Mater. 2000, 2, 85–91. [Google Scholar] [CrossRef]

- Lindroos, V.K.; Talvitie, M.J. Recent advances in metal matrix composites. J. Mater. Process. Technol. 1995, 53, 273–284. [Google Scholar] [CrossRef]

- Yamamoto, T.; Otsuki, A.; Ishihara, K.; Shingu, P.H. Synthesis of near net shape high density TiB/Ti composite. Mater. Sci. Eng. A 1997, 239–240, 647–651. [Google Scholar] [CrossRef]

- Kumari, S.; Prasad, N.E.; Chandran, K.S.R.; Malakondaiah, G. High-temperature deformation behavior of Ti-TiBw in-situ metal-matrix composites. JOM 2004, 5, 51–55. [Google Scholar] [CrossRef]

- Tsang, H.T.; Chao, C.G.; Ma, C.Y. Effects of volume fraction of reinforcement on tensile and creep properties of in-situ TiBTi MMC. Scr. Mater. 1997, 37, 1359–1365. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium–titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Ravi Chandran, K.S.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application, prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q.; Rao, J. Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB/Ti metal matrix composites. Cryst. Growth Des. 2006, 6, 1626–1630. [Google Scholar] [CrossRef]

- Da Silva, A.A.M.; Dos Santos, J.F.; Strohaecker, T.R. Microstructural and mechanical characterisation of a Ti6Al4V/TiC/10p composite processed by the BE-CHIP method. Comp. Sci. Technol. 2005, 65, 1749–1755. [Google Scholar] [CrossRef]

- Ozerov, M.; Stepanov, N.; Kolesnikov, A.; Sokolovsky, V.; Zherebtsov, S. Brittle-to-ductile transition in a Ti-TiB metal-matrix composite. Mater. Lett. 2017, 187, 28–31. [Google Scholar] [CrossRef]

- Gaisin, R.A.; Imayev, V.M.; Imayev, R.M. Effect of hot forging on microstructure and mechanical properties of near α titanium alloy/TiB composites produced by casting. J. Alloys Compd. 2017, 723, 385–394. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Gaisina, E.; Imayev, R.; Fecht, H.-J.; Pyczak, F. Effect of hot forging on microstructure and tensile properties of Ti-TiB. Mater. Sci. Eng. A 2014, 609, 34–41. [Google Scholar] [CrossRef]

- Huang, L.; Cui, X.; Geng, L.; Fu, Y. Effects of rolling deformation on microstructure and mechanical properties of network structured TiBw/Ti composites. Trans. Nonferr. Met. Soc. China 2012, 22, 79–83. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Kolesnikov, A.; Stepanov, N.; Zherebtsov, S. Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests. Mater. Des. 2016, 112, 17–26. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zechetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. Processing nanocrystalline Ti and its nanocomposites from micrometer-sized Ti powder using high pressure torsion. Mater. Sci. Eng. A 2000, 282, 78–85. [Google Scholar] [CrossRef]

- Edalati, K.; Iwaoka, H.; Horita, Z.; Konno, M.; Sato, T. Unusual hardening in Ti/Al2O3 nanocomposites produced by high-pressure torsion followed by annealing. Mater. Sci. Eng. A 2011, 529, 435–441. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 2013, 58, 41–62. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Buchgraber, W.; Kolobov, Y.R.; Amirkhanov, N.M.; Sergueeva, A.V.; Ivanov, K.V.; Grabovetskaya, G.P. Deformation behavior of Cu-based nanocomposite processed by severe plastic deformation. Mater. Sci. Eng. A 2001, 319–321, 872–876. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Vyazmin, A.; Stepanov, N.; Zherebtsov, S. Orientation relationship in a Ti/TiB metal-matrix composite. Mater. Lett. 2017, 186, 168–170. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Kazyhanov, V.U.; Shestakova, L.O.; Sharafutdinov, A.V.; Valiev, R.Z. Microstructure and mechanical properties of titanium (Grade 4) processed by high-pressure torsion. Mater. Sci. Eng. A 2008, 493, 190–194. [Google Scholar] [CrossRef]

- Edalati, K.; Matsubara, E.; Horita, Z. Processing pure Ti by high-pressure torsion in wide ranges of pressures and strain. Metall. Mater. Trans. A 2009, 40, 2079–2086. [Google Scholar] [CrossRef]

- Hughes, D.; Hansen, N. Microstructure and strength of nickel at large strains. Acta Mater. 2000, 48, 2985–3004. [Google Scholar] [CrossRef]

- Humphreys, F.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004; pp. 1–605. [Google Scholar]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Frost, H.J.; Ashby, M.F. Deformation-Mechanism Maps; Pergamon Press: Oxford, UK, 1982; pp. 1–166. [Google Scholar]

- Conrad, H. Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 1981, 26, 123–403. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W.R. Tensile properties of fibre-reinforced metals: Copper/Tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–350. [Google Scholar] [CrossRef]

- Harrell, T.J.; Topping, T.D.; Wen, H.; Hu, T.; Schoenung, J.M.; Lavernia, E.J. Microstructure and strengthening mechanisms in an ultrafine grained Al-Mg-Sc alloy produced by powder metallurgy. Metall. Mater. Trans. A 2014, 45, 6329–6343. [Google Scholar] [CrossRef]

- Mishnev, R.; Shakhova, I.; Belyakov, A.; Kaibyshev, R. Deformation microstructures, strengthening mechanisms, and electrical conductivity in a Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2015, 629, 29–40. [Google Scholar] [CrossRef]

- Lukyanova, E.A.; Martynenko, N.S.; Shakhova, I.; Belyakov, A.N.; Rokhlin, L.L.; Dobatkin, S.V.; Estrin, Y.Z. Strengthening of age-hardenable WE43 magnesium alloy processed by high pressure torsion. Mater. Lett. 2016, 170, 5–9. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zherebtsov, S.; Ozerov, M.; Stepanov, N.; Klimova, M.; Ivanisenko, Y. Effect of High-Pressure Torsion on Structure and Microhardness of Ti/TiB Metal–Matrix Composite. Metals 2017, 7, 507. https://doi.org/10.3390/met7110507

Zherebtsov S, Ozerov M, Stepanov N, Klimova M, Ivanisenko Y. Effect of High-Pressure Torsion on Structure and Microhardness of Ti/TiB Metal–Matrix Composite. Metals. 2017; 7(11):507. https://doi.org/10.3390/met7110507

Chicago/Turabian StyleZherebtsov, Sergey, Maxim Ozerov, Nikita Stepanov, Margarita Klimova, and Yulia Ivanisenko. 2017. "Effect of High-Pressure Torsion on Structure and Microhardness of Ti/TiB Metal–Matrix Composite" Metals 7, no. 11: 507. https://doi.org/10.3390/met7110507

APA StyleZherebtsov, S., Ozerov, M., Stepanov, N., Klimova, M., & Ivanisenko, Y. (2017). Effect of High-Pressure Torsion on Structure and Microhardness of Ti/TiB Metal–Matrix Composite. Metals, 7(11), 507. https://doi.org/10.3390/met7110507