Lattice Softening in Fe3Pt Exhibiting Three Types of Martensitic Transformations

Abstract

:1. Introduction

2. Materials and Methods

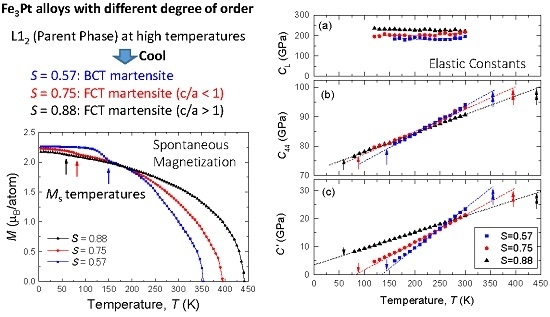

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nakanishi, N. Elastic constants as they relate to lattice properties and martensite formation. Prog. Mater. Sci. 1980, 24, 143–265. [Google Scholar] [CrossRef]

- Murakami, Y. Lattice softening, phase stability and elastic anomaly of the β-Au-Cu-Zn alloys. J. Phys. Soc. Jpn. 1972, 33, 1350–1360. [Google Scholar] [CrossRef]

- Gunton, D.J.; Sanuders, G.A. The elastic behavior of In-Tl alloys in the vicinity of the martensitic tansformation. Solid State Commun. 1974, 14, 865–868. [Google Scholar] [CrossRef]

- Enami, K.; Hasunuma, J.; Nagasawa, A.; Nenno, S. Elastic softening and electron-diffraction anomalies prior to the martensitic transformation in Ni-Al β1 alloy. Scr. Metall. 1976, 10, 879–884. [Google Scholar] [CrossRef]

- Nagasawa, A.; Ueda, Y. Elastic Soft Mode Preceeding Martensitic Phase Transition in β Phase Alloys. J. Phys. Soc. Jpn. 1978, 45, 1249–1252. [Google Scholar] [CrossRef]

- Verlinden, B.; Delay, L. On the elastic constants and Ms-temperatures in β-Hume-Rothery alloys. Acta Metall. 1988, 36, 1771–1779. [Google Scholar] [CrossRef]

- Muto, S.; Oshima, R.; Fujita, F.E. Elastic softening and elastic strain energy consideration in the fcc-fct transformation of FePd alloys. Acta Metall. Mater. 1990, 38, 685–694. [Google Scholar] [CrossRef]

- Ren, X.; Miura, N.; Zhang, N.; Otsuka, K.; Tanaka, K.; Koiwa, M.; Suzuki, T.; Chumlyakov, Yu.I.; Asai, M. A comparative study of elastic constants of Ti-Ni based alloys prior to martensitic transformation. Mater. Sci. Eng. A 2001, 312, 196–206. [Google Scholar] [CrossRef]

- Sedlák, P.; Seiner, H.; Landa, M.; Novák, V.; Šittner, P.; Mañosa, L.I. Elastic constants of bcc austenite and 2H orthorhombic martensite in CuAlNi shape memory alloy. Acta Mater. 2005, 53, 3643–3661. [Google Scholar] [CrossRef]

- Graczykowski, G.; Mielcarek, S.; Breczewski, T.; No, M.L.; San-Juan, J. Martensitic phase transition in Cu-14%Al-4%Ni shape memory alloys studied by Brillouin light scattering. Smart Mater. Struct. 2013, 22, 085027. [Google Scholar] [CrossRef]

- Warren, B.E. X-ray studies of order-disorder. In X-ray Diffraction; Dover: New York, NY, USA, 1990. [Google Scholar]

- Muto, S.; Oshima, R.; Fujita, F.E. Electron microscopy study on martensitic transformations in Fe–Pt alloys: General features of internal structure. Metall. Trans. A 1988, 19, 2723–2731. [Google Scholar] [CrossRef]

- Dunne, D.P.; Wayman, C.M. The effect of austenite ordering on the martensite transformation in Fe–Pt alloys near the composition Fe3Pt: I. Morphology and transformation characteristics. Metall. Trans. 1973, 4, 137–152. [Google Scholar] [CrossRef]

- Tadaki, T.; Shimizu, K. High tetragonality of thermoelastic Fe3Pt martensite and small volume change during the transformation. Scr. Metall. 1975, 9, 771–776. [Google Scholar] [CrossRef]

- Umemoto, M.; Wayman, C.M. The effect of austenite ordering on the transformation temperature, transformation hysteresis, and thermoelastic behavior in Fe–Pt alloys. Metall. Trans. A 1978, 9, 891–897. [Google Scholar] [CrossRef]

- Yamamoto, M.; Sekida, S.; Fukuda, T.; Kakeshita, T.; Takahashi, K.; Koyama, K.; Nojiri, H. A new type of FCT martensite in single-crystalline Fe3Pt Invar alloy. J. Alloys Compd. 2011, 509, 8530–8533. [Google Scholar] [CrossRef]

- Yamamoto, M.; Fukuda, T.; Kakeshita, T.; Takahashi, K. Orthorhombic martensite formed in L12-type Fe3Pt Invar alloys. J. Alloys Compd. 2013, 577, S503–S506. [Google Scholar] [CrossRef]

- Hausch, G. Elastic constants of Fe–Pt alloys. I. Single crystalline elastic constants of Fe72Pt28. J. Phys. Soc. Jpn. 1974, 37, 819–823. [Google Scholar] [CrossRef]

- Ling, H.C.; Owen, W.S. The magneto-elastic properties of the invar alloy, Fe3Pt. Acta Metall. 1983, 31, 1343–1352. [Google Scholar] [CrossRef]

- Kawald, U.; Zemke, W.; Bach, H.; Pelzl, J.; Saunders, G.A. Elastic constants and martensitic transformations in FePt and FeNiPt Invar alloys. Physica B 1989, 161, 72–74. [Google Scholar] [CrossRef]

- Owen, W. The influence of lattice softening of the parent phase on the martensitic transformation in FeNi and FePt alloys. Mater. Sci. Eng. A 1990, 127, 197–204. [Google Scholar] [CrossRef]

- Tajima, K.; Endoh, Y.; Ishikawa, Y. Acoustic-phonon softening in the invar alloy Fe3Pt. Phys. Rev. Lett. 1976, 37, 519–522. [Google Scholar] [CrossRef]

- Kästner, J.; Petry, W.; Shapiro, S.M.; Zheludev, A.; Neuhaus, J.; Wassermann, E.F.; Bach, H. Influence of atomic order on TA1[110] phonon softening and displacive phase transition in Fe72Pt28 Invar alloys. Eur. Phys. J. B 1999, 10, 641–648. [Google Scholar] [CrossRef]

- Noda, Y.; Endoh, Y. Lattice dynamics in ferromagnetic Invar alloys, Fe3Pt and Fe65Ni35. J. Phys. Soc. Jpn. 1988, 57, 4225–4231. [Google Scholar] [CrossRef]

- Fukuda, T.; Yamamoto, M.; Yamaguchi, T.; Kakeshita, T. Magnetocrystalline anisotropy and magnetic field-induced strain of three martensites in Fe3Pt ferromagnetic shape memory alloys. Acta Mater. 2014, 62, 182–187. [Google Scholar] [CrossRef]

- Migliori, A.; Sarrao, J.L.; Visscher, W.M.; Bell, T.M.; Lei, M.; Fisk, Z.; Leisure, R.G. Resonant ultrasound spectroscopic techniques for measurement of the elastic moduli of solids. Physica B 1993, 183, 1–24. [Google Scholar] [CrossRef]

- Tanaka, K.; Okamoto, K.; Inui, H.; Minonishi, Y.; Yamaguchi, M.; Koiwa, M. Elastic constants and their temperature dependence for the intermetallic compound Ti3Al. Philos. Mag. A 1996, 73, 1475–1488. [Google Scholar] [CrossRef]

- Gruner, M.E.; Adeagbo, W.A.; Zayak, A.T.; Hucht, A.; Entel, P. Lattice dynamics and structural stability of ordered Fe3Ni, Fe3Pt and Fe3Pt alloys using density functional theory. Phys. Rev. B 2010, 81, 064109. [Google Scholar] [CrossRef]

- Sternik, M.; Couet, S.; Łażewski, J.; Parlinski, P.T.; Vantomme, A.; Temst, K.; Piekarz, P. Dynamical properties of ordered Fe-Pt alloys. J. Alloys Compd. 2015, 651, 528–536. [Google Scholar] [CrossRef]

- Yamamoto, T.; Yamamoto, M.; Fukuda, T.; Kakeshita, T.; Akai, H. An interpretation of martensitic transformation in L12-type Fe3Pt from its electronic structure. Mater. Trans. 2010, 51, 896–898. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fukuda, T.; Kakeshita, T. Lattice Softening in Fe3Pt Exhibiting Three Types of Martensitic Transformations. Metals 2017, 7, 156. https://doi.org/10.3390/met7050156

Fukuda T, Kakeshita T. Lattice Softening in Fe3Pt Exhibiting Three Types of Martensitic Transformations. Metals. 2017; 7(5):156. https://doi.org/10.3390/met7050156

Chicago/Turabian StyleFukuda, Takashi, and Tomoyuki Kakeshita. 2017. "Lattice Softening in Fe3Pt Exhibiting Three Types of Martensitic Transformations" Metals 7, no. 5: 156. https://doi.org/10.3390/met7050156

APA StyleFukuda, T., & Kakeshita, T. (2017). Lattice Softening in Fe3Pt Exhibiting Three Types of Martensitic Transformations. Metals, 7(5), 156. https://doi.org/10.3390/met7050156