Mechanical and Corrosion Behavior of Al-Zn-Cr Family Alloys

Abstract

:1. Introduction

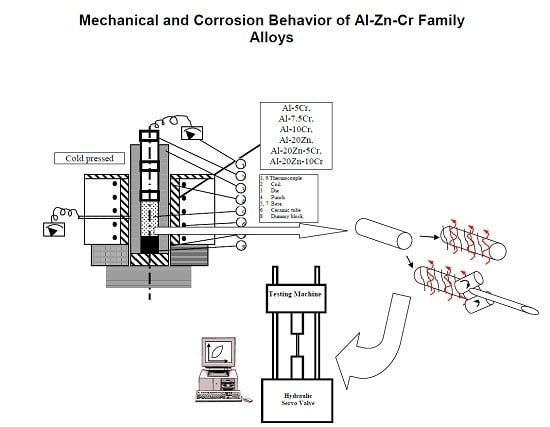

2. Materials and Methods

3. Results and Discussion

3.1. Densification Behavior

3.2. Microstructural Optical Investigations

3.3. Energy-Dispersive X-ray (EDX) Analysis

3.4. Mechanical Properties

3.5. Corrosion Rate

3.6. Wear Resistance

4. Conclusions

- Binary Al-Cr alloys from powders, heat-treated at different conditions, could not establish a homogenous microstructure.

- The presence of 20 wt. % Zn in the Al-Cr alloys enhanced the interdiffusion and densification process during heat treatment, due to the formation of a liquid phase leading to a homogenius microstructure.

- Both Zn addition and the heat treatment temperature affect the hardness values and the structure of the Al-base matrix

- Under tension load, improvement in the strength of Al-Cr alloys was obtained after Zn addition and the heat-treatment process.

- The increase of the Cr and Zn additives in the Al-based alloys would result in a decrease in the corrosion rate. As Al-20Zn-10Cr alloys have corrosion rate of 30% less than pure aluminum, the heat treated Al-based alloys had an approximate corrosion rate of 7% less than as-extruded Al-based alloys.

- The wear resistance of the ternary Al-Zn-Cr heat treated at 500 °C for one hour was about 5 times higher than that of the binary Al-Zn alloys. The alloy of Al-20Zn-5Cr, heat-treated at 500 °C for one hour followed by water quenching, exhibited the highest wear resistance among the investigated alloys.

Author Contributions

Conflicts of Interest

References

- Liu, S.; Zhong, Q.; Zhang, Y.; Liu, W.; Zhang, X.; Deng, D. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time–temperature-properties diagrams. Mater. Des. 2010, 31, 3116–3120. [Google Scholar] [CrossRef]

- Ezuber, H.; El-Houd, A.; El-Shawesh, F. A study on the corrosion behavior of aluminum alloys in seawater. Mater. Des. 2008, 29, 801–805. [Google Scholar] [CrossRef]

- Kalkanl, A.; Yılmaz, S. Synthesis and characterization of aluminum alloy 7075 reinforced with silicon carbide particulates. Mater. Des. 2008, 29, 775–780. [Google Scholar] [CrossRef]

- Nassef, A.; El-Hadek, M. Mechanics of hot pressed aluminum composites. Int. J. Adv. Manuf. Technol. 2015, 76, 1905–1912. [Google Scholar] [CrossRef]

- El-Hadek, M.; Kassem, M. Failure behavior of Cu-Ti-Zr-based bulk metallic glass alloys. J. Mater. Sci. 2009, 44, 1127–1136. [Google Scholar] [CrossRef]

- El-Hadek, M.; Kaytbay, S. Al2O3 Particle Size Effect on Reinforced Copper Alloys: An Experimental Study. Strain 2009, 45, 506–515. [Google Scholar] [CrossRef]

- Nassef, A.; El-Hadek, M. Microstructure and Mechanical Behavior of Hot Pressed Cu-Sn Powder Alloys. Adv. Mater. Sci. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Kurtuldu, G.; Jarry, P.; Rappaz, M. Influence of Cr on the nucleation of primary Al and formation of twinned dendrites in Al-Zn-Cr alloys: Can icosahedral solid clusters play a role? Acta Mater. 2013, 61, 7098–7108. [Google Scholar] [CrossRef]

- Kurtuldu, G.; Jarry, P.; Rappaz, M. Influence of icosahedral short range order on diffusion in liquids: A study on Al-Zn-Cr alloys. Acta Mater. 2016, 115, 423–433. [Google Scholar] [CrossRef]

- Del Arco, M.; Rives, V.; Trujillano, R.; Malet, P. Thermal behavior of Zn-Cr layered double hydroxides with hydrotalcite-like structures containing carbonate or decavanadate. J. Mater. Chem. 1996, 6, 1419–1428. [Google Scholar] [CrossRef]

- Peng, G.; Chen, K.; Fang, H.; Chen, S. Effect of Cr and Yb additions on microstructure and properties of low copper Al-Zn-Mg-Cu-Zr alloy. Mater. Des. 2012, 36, 279–283. [Google Scholar] [CrossRef]

- He, Z.; Su, X.; Peng, H.; Liu, L.; Wu, C.; Wang, J. 600 °C isothermal section of the Al-Cr-Zn ternary phase diagram. J. Alloys Compd. 2015, 649, 1239–1245. [Google Scholar] [CrossRef]

- Li, C.B.; Han, S.Q.; Liu, S.D.; Deng, Y.L.; Zhang, X.M. Grain structure effect on quench sensitivity of Al-Zn-Mg-Cu-Cr alloy. Trans. Nonferr. Met. Soc. China 2016, 26, 2276–2282. [Google Scholar] [CrossRef]

- Fourmentin, R.; Avettand-Fènoël, M.N.; Reumont, G.; Perrot, P. The Fe-Zn-Al-Cr system and its impact on the galvanizing process in chromium-added zinc baths. J. Mater. Sci. 2008, 43, 6872–6880. [Google Scholar] [CrossRef]

- Shaha, S.K.; Czerwinski, F.; Kasprzak, W.; Friedman, J.; Chen, D.L. Ageing characteristics and high-temperature tensile properties of Al-Si-Cu-Mg alloys with micro-additions of Cr, Ti, V and Zr. Mater. Sci. Eng. A 2016, 652, 353–364. [Google Scholar] [CrossRef]

- Shin, S.-S.; Lim, K.-M.; Park, I.-M. Effects of high Zn content on the microstructure and mechanical properties of Al-Zn-Cu gravity-cast alloys. Mater. Sci. Eng. A 2017, 679, 340–349. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Jenei, P.; Gubicza, J.; Bobrukb, E.V.; Valiev, R.Z.; Langdon, T.G. Influence of Zn content on the microstructure and mechanical performance of ultrafine-grained Al-Zn alloys processed by high-pressure torsion. Mater. Lett. 2017, 186, 334–337. [Google Scholar] [CrossRef]

- Staišiūnas, L.; Miečinskas, P.; Leinartas, K.; Selskis, A.; Grigucevičienė, A.; Juzeliūnas, E. Sputter-deposited Mg-Al-Zn-Cr alloys—Electrochemical characterization of single films and multilayer protection of AZ31 magnesium alloy. J. Corros. Sci. 2014, 80, 487–493. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, R.; Hu, X.; Wang, C.A.; Huang, Y. Characterization of a powder metallurgy SiC/Cu-Al composite. J. Mater. Process. Technol. 2008, 197, 43–48. [Google Scholar] [CrossRef]

- Ogel, B.; Gurbuz, R. Microstructural characterization and tensile properties of hot pressed Al-SiC composites prepared from pure Al and Cu powders. Mater. Sci. Eng. A 2001, 301, 213–220. [Google Scholar] [CrossRef]

- Chang, Y.; Sun, W.; Xiong, X.; Chen, Z.; Wang, Y.; Hao, Z.; Xu, Y. A novel design of Al-Cr alloy surface sealing for ablation resistant C/C-ZrC-SiC composite. J. Eur. Ceram. Soc. 2017, 37, 859–864. [Google Scholar] [CrossRef]

- El-Hadek, M.; Kassem, M. Characterization of strengthened rapidly quenched Zr-based alloys. Int. J. Mech. Mater. Des. 2008, 4, 279–289. [Google Scholar] [CrossRef]

- El-Hadek, M.; Kaytbay, S. Fracture properties of SPS tungsten copper powder composites. Metall. Mater. Trans. A 2013, 44, 544–551. [Google Scholar] [CrossRef]

- Ozyılmaz, A.T.; Kardas, G.; Erbil, M.; Yazici, B. The corrosion performance of polyaniline on nickel plated mild steel. Appl. Surf. Sci. 2005, 242, 97–106. [Google Scholar] [CrossRef]

- Kaytbay, S.; El-Hadek, M. Wear resistance and fracture mechanics of WC–Co composites. Int. J. Mater. Res. 2014, 105, 557–565. [Google Scholar] [CrossRef]

| Alloy Composition | As Extruded State | Heat Treated State | ||||||

|---|---|---|---|---|---|---|---|---|

| UTS (σu) MPa | SD | Fracture Strain (εf) % | SD | UTS (σu) MPa | SD | Fracture strain (εf) % | SD | |

| Al-5Cr | 75 | 0.1 | 12 | 1.2 | 105 | 1.4 | 10 | 1 |

| Al-7.5Cr | 70 | 0.3 | 10 | 1 | 101 | 1.4 | 8 | 0.78 |

| Al-10Cr | 65 | 0.3 | 8 | 0.78 | 96 | 0.7 | 6 | 0.7 |

| Al-20Zn | 188 | 5.8 | 18 | 1.7 | 185 | 5.7 | 16 | 1.5 |

| Al-20Zn-5Cr | 95 | 0.7 | 14 | 1.3 | 160 | 4.8 | 12 | 1.2 |

| Al-20Zn-10Cr | 80 | 1.4 | 10 | 1 | 143 | 3.4 | 8 | 0.78 |

| Chemical Composition | Rockwell Hardness As Extruded | SD | Rockwell Hardness Heat Treated at 500 °C | SD |

|---|---|---|---|---|

| Al-5Cr | 8.9 | 0.9 | 9.0 | 0.9 |

| Al-7.5Cr | 9.5 | 1 | 12.5 | 1.4 |

| Al-10Cr | 9.9 | 1 | 14.6 | 1.4 |

| Al-20Zn | 10.4 | 1 | 27.6 | 2.3 |

| Al-20Zn-5Cr | 17.4 | 1.6 | 30.6 | 2.5 |

| Al-20Zn-10Cr | 16.9 | 1.5 | 32.1 | 2.7 |

| Chemical Composition | As Extruded | Heat Treated at 500°C | ||

|---|---|---|---|---|

| CR mm/year | SD | CR mm/year | SD | |

| Al pure | 0.031 | 1 | -- | -- |

| Al-5Cr | 0.030 | 0.9 | 0.028 | 0.9 |

| Al-7.5Cr | 0.029 | 0.9 | 0.027 | 0.8 |

| Al-10Cr | 0.029 | 0.9 | 0.026 | 0.7 |

| Al-20Zn | 0.028 | 0.8 | 0.024 | 0.7 |

| Al-20Zn-5Cr | 0.026 | 0.7 | 0.022 | 0.6 |

| Al-20Zn-10Cr | 0.022 | 0.6 | 0.020 | 0.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nassef, A.; El-Garaihy, W.H.; El-Hadek, M. Mechanical and Corrosion Behavior of Al-Zn-Cr Family Alloys. Metals 2017, 7, 171. https://doi.org/10.3390/met7050171

Nassef A, El-Garaihy WH, El-Hadek M. Mechanical and Corrosion Behavior of Al-Zn-Cr Family Alloys. Metals. 2017; 7(5):171. https://doi.org/10.3390/met7050171

Chicago/Turabian StyleNassef, Ahmed, Waleed H. El-Garaihy, and Medhat El-Hadek. 2017. "Mechanical and Corrosion Behavior of Al-Zn-Cr Family Alloys" Metals 7, no. 5: 171. https://doi.org/10.3390/met7050171

APA StyleNassef, A., El-Garaihy, W. H., & El-Hadek, M. (2017). Mechanical and Corrosion Behavior of Al-Zn-Cr Family Alloys. Metals, 7(5), 171. https://doi.org/10.3390/met7050171