3.2.1. Hardness

In the next stage of research, the effects of sizing on the mechanical properties of the finished products were considered, beginning with apparent hardness (

Figure 3). In general, the hardness of the Size-Sol-Age specimens was largely unaffected by the extent of sizing, as all values hovered around the nominal measurement for the unsized, Sol-Age counterpart. However, the Sol-Size-Age samples showed a consistently lower hardness than both of these product forms, with the difference becoming more acute at sizing pressures >300 MPa.

To determine if changes in the precipitates formed during age hardening may have been responsible for the trends in hardness data, pertinent information was gathered via DSC analyses. Here, samples were processed into the Sol-Size and Size-Sol states and heated in the DSC. In this approach, each specimen was thereby aged in-situ so as to accentuate the thermal events associated with any precipitation hardening mechanism(s) that were operative. The resultant heat flow traces are shown in

Figure 4, with the principal peaks denoted A to D. With close consideration of the work by Ryum [

7,

8], Jiang et al. [

9], Ghosh et al. [

25], and Berg et al. [

26], the precipitation events believed to be associated with these peaks (summarized in

Table 3) were deduced. The first exothermic peak (A) was attributed to GP-zone (II) formation from vacancy rich clusters (VRC), which consist of regions enriched in vacancies and Zn atoms. It should be noted that GP-zone (I) (i.e., localized regions with heightened concentrations of Zn and Mg atoms) formation occurs at lower temperatures <323 K (50 °C) [

9], which is why an exothermic peak corresponding to their formation was not observed in

Figure 4. The second exothermic peak (B) was due to η’ and η formation/growth. Although some studies show discrete peaks associated with the formation of these two phases [

9,

27,

28], these could not be distinguished in the present study. The endothermic peak (C) was identified as the dissolution of η’ and η, whereas peak (D) was ascribed to the melting of the S or T phase.

It is common knowledge that the concentration of vacancies within a material scales in a positive and proportionate manner with rising temperature. Hence, water quenching from the solutionization temperature thereby locks in an excess concentration of vacancies within the matrix upon cooling to ambient. Ryum and Jiang’s models [

7,

8,

9] highlight the clear importance of these quenched-in vacancies on the precipitation strengthening of 7xxx series alloys. In particular, they highlight the notion that these vacancies will coalesce to create the VRCs required to activate the β precipitation reaction sequence. However, when sizing is applied to the as-quenched product, the associated deformation would annihilate a portion of the quenched-in vacancies by dislocation movement as a result of plastic deformation. This would then lower the volume fraction of VRCs, and in turn, the propensity for GP-zone (II) formation from the β-reaction. This concept was supported by the DSC results, as peak A within the trace acquired from the Sol-Size specimen (

Figure 4a) was significantly smaller than that developed from the Size-Sol counterpart (

Figure 4b). Furthermore, a suppression of the β-reaction sequence would be expected to increase the magnitude of peak B. In this sense, auxiliary solute atoms would now be available for use within the α precipitation sequence such that higher concentrations of η would now be precipitated directly from the SSSS. This concept was also obvious when comparing the Sol-Size and Size-Sol traces (

Figure 4). Similar DSC results have been reported by Ghosh et al. [

25] in a study looking at applying high pressure torsion to a 7150 alloy between quench and artificial aging, with a comparable, but much more intense decrease in the peak associated with GP-zone (II) formation along with an increase in intensity in the η’/η peak.

Additional samples were then prepared through the complete processing sequences (Sol-Size-Age and Size-Sol-Age) and run in the DSC (

Figure 5). Similar to the data gathered from unaged specimens, the reactions A’–D’ also stem from specific events related to in-situ changes to the underlying precipitates as summarized in

Table 4. The first endothermic peak (A’) was associated to the dissolution of GP-zones. It should be noted that this likely involved the dissolution of both GP-zone (I) and GP-zone (II), as these are indistinguishable events. Next, an exothermic doublet peak (B’) was noted. This was attributed to the formation/growth of η’ and formation of η. Similar to the Sol-Size and Size-Sol traces (

Figure 4), the endothermic peak (C’) was caused by the dissolution of these precipitates followed by endothermic peak (D’) representing the melting of a secondary phase; again, most likely the S or T phase. When comparing the traces shown in

Figure 5, one striking difference was that endothermic peak A’ was substantially smaller in the Sol-Size-Age data. This implied that a lower concentration of GP-zones was present within the starting T6 material, lending further support to the notion that sizing immediately after quench had supressed the formation of a GP-zone (II) through the same mechanism previously discussed. Along with the differences in the A’ peak, a clear doublet is present at peak B’ in the Size-Sol-Age material, where the Sol-Size-Age material showed a slight shoulder in the peak. DeIasi and Adler [

28] also saw a similar distinct doublet in AA7075-T651 along with a shoulder in the overaged AA7075-T7351, identifying the first peak as being the formation/growth of η’ as well as η formation and the second peak exclusively a result of η growth. This clear doublet in the Size-Sol-Age material, along with a shoulder in the Sol-Size-Age material, suggests the latter is closer to an overaged condition, with fully developed η present within the microstructure, leading to a reduced likelihood of η growth compared to the Size-Sol-Age material, where fine η formation and growth would take place.

In an effort to substantiate the DSC findings, more direct evidence on the nature of the precipitates was sought by TEM. Representative BF images of samples processed through Sol-Size-Age and Size-Sol-Age are provided in

Figure 6 along with accompanying <112> SADPs in

Figure 7. The BF images revealed stark differences between the two samples. The Sol-Size-Age material had precipitates of a high aspect ratio and uniform thickness lying parallel to the {111} planes. These were also quite coarse, with a width in the range of 5–6 nm and length of approximately 11–16 nm. Hence, it was postulated that these represented a plate-like morphology lying on the {111} planes of the aluminum matrix, consistent with the crystallographic orientation of η [

7]. In the case of Size-Sol-Age, a much finer, homogenously distributed precipitate structure was observed. Whereas some particles were round (nominal diameter ~2–6 nm), others were thin, rectangular features that lay on {111} planes and had a typical length of 4–6 nm and a uniform thickness (~1 nm). Based on work by Sha and Cerezo [

29], η’ will exist as plates on the {111} planes within the α-aluminum matrix. Hence, it was postulated that the rectangular precipitates were in fact plates of η’ viewed edge-on. Overall, the general appearance of the precipitates within the Size-Sol-Age material was in strong agreement with that found for wrought AA7075-T6 by Guo et al. [

30].

Beyond the BF images themselves, the corresponding electron diffraction patterns aligned close to the <112> axis for each sample also showed clear evidence that a secondary phase was present (

Figure 7). In the case of the Sol-Size-Age material (

Figure 7a), this came in the form of distinct secondary diffraction points that were thereby attributed to the presence of semi-coherent/incoherent precipitates. The secondary diffraction points lay in rows parallel to the <111> directions (indicated by arrow in

Figure 7a), such that the resultant pattern was in strong agreement with SADPs devised by Hansen et al. for an Al–Zn–Mg alloy containing η’ and η phases [

10]. In the SADP recorded from the Size-Sol-Age product (

Figure 7b), discrete secondary diffraction spots were less obvious, and relatively intense streaking within the pattern was present (location and direction shown in

Figure 7b by arrow), indicating that the diffracting phase now maintained an increased level of coherency with the α-aluminum matrix. This implied that fully coherent GP-zones and/or the semi-coherent precipitate η’ now dominated the structure.

Based on the combination of TEM and DSC findings, the Size-Sol-Age material appeared to have a microstructure largely comprised of an α-aluminum matrix along with a combination of GP-zone and η’ precipitates. This differed from the Sol-Size-Age material, as it was effectively in an overaged state given the increased size of the precipitates and a more acute presence of the fully incoherent η phase within the microstructure. These microstructural differences were in direct agreement with the hardness results (

Figure 3), as the Sol-Size-Age material was measurably softer.

3.2.2. Fatigue Testing

In the next phase of testing, the fatigue performance of PM7075 was evaluated under the different processing streams of interest. A summary of the staircase results is presented in

Table 5. The highest fatigue durability was noted when sizing was applied before the full heat-treatment cycle. Here, sizing was found to invoke a minor gain in fatigue strength (~5%) relative to the specimens processed without any sizing at all (Sol-Age). Prior data indicated that these two materials were comparable in terms of bulk density and hardness (

Figure 3), presumably eliminating these attributes as influential factors. The one tangible difference was in that of surface roughness (

Figure 2), whereby an improved value was noted for the Size-Sol-Age products compared to those of Sol-Age. This equated to a smoother exterior surface that would have contained a reduced presence of crack-inducing surface asperities and benefitted fatigue durability. It was also possible that sizing had closed a portion of the near-surface porosity, which has been shown to act as fatigue crack initiation sites within other aluminum PM materials [

31]. Overall, it was concluded that the surface condition differential was a key factor of influence.

Interestingly, a large decrease in fatigue behaviour ensued when sizing was implemented as an intermediate step between solutionization/quench and aging. When comparing the metallurgical attributes of the Sol-Size-Age and Size-Sol-Age specimens assessed to this point, the principal difference was a reduced hardness (

Figure 3) as driven by changes in the strengthening precipitates present (

Figure 6). As such, a drop in fatigue performance seemed logical. However, given the magnitude of the fatigue decline, it was prudent to complete additional characterization work to determine if auxiliary factors were at play. In particular, it was prudent to determine if sizing-derived microcracks and/or different states of residual stress existed within the materials. Regarding the former, the manner of sizing applied clearly resulted in plastic deformation. Furthermore, it was conceivable that this would be more acute at the surfaces of the bar, as lateral flow would be less constrained here than at regions within the bulk interior. This scenario could thereby facilitate microcracking and a concomitant decline in fatigue performance. To assess this possibility, specimens produced by Sol-Size-Age and Size-Sol-Age were mounted, polished, and examined extensively at high magnifications by SEM. No evidence of microcracking was discovered in any of these specimens, thereby confirming that this was not a contributing factor.

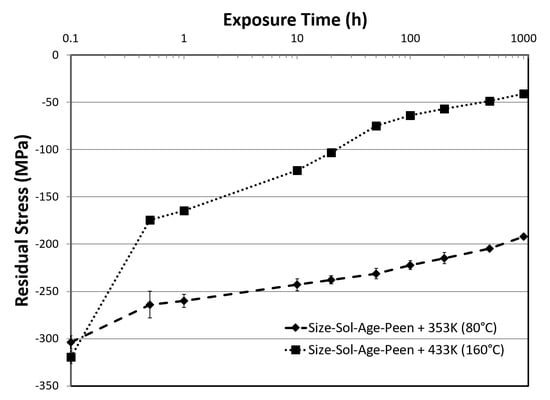

In standard T6 (i.e., Sol-Age) processing, it is well documented that 7xxx series aluminum alloys will have compressive residual stress within the surface of the part instilled by quenching after solution heat-treatment [

32,

33]. Such stresses are beneficial to fatigue behaviour, as they act to resist in-service tensile loads. During solution heat-treatment, the large thermal gradients created from water quenching from the solutionization temperature result in the surface of the sample cooling quicker than that of the interior. Once the interior begins to cool, the surface material will resist thermal contraction of the inner material, so that the surface is ultimately in a state of compression while the interior is in tension. The measured surface in-plane residual stresses within the samples processed by Sol-Size-Age and Size-Sol-Age are shown in

Figure 8. It can be seen that Sol-Size-Age yielded a product with a lower level of compressive surface residual stress. This drop upon sizing after quench was believed to be caused by the plastic deformation acting similar to a stress-relieving process (such as stretching). With regard to Size-Sol-Age processing with the sizing operation performed prior to the heat-treatment, the developed residual stresses within the compact are solely a result of the thermal gradients developed during quenching, and should therefore be similar to the case of a standard T6 treatment.

In the case of Sol-Size-Age processing, it was plausible that the reduction in this advantageous attribute had contributed to the noted decline in fatigue strength in the samples, along with the previously discussed effects of precipitation hardening differences within the system.

To determine if the fatigue differences were unique to PM7075, equivalent processing/testing was completed on the wrought counterpart AA7075. Here, test bars of the material were processed through Sol-Age and Sol-Size-Age sequences, utilizing the same sizing pressure applied during PM7075 Sol-Size-Age processing (400 MPa). The resultant data on fatigue performance are given in

Table 6. Akin to PM7075, Sol-Size-Age processing again resulted in lower fatigue strength. However, the drop was much less pronounced, which implied that the underlying mechanism was exacerbated in the PM system and/or that additional factors were contributing. As would be expected, the wrought alloy exhibited considerably higher fatigue strengths relative to the data previously acquired for the PM products studied (

Table 5).

It was postulated that these transitions in fatigue behaviour were underpinned by fundamental differences in microstructure. In this sense, aluminum PM and wrought materials differ in that the former contain higher concentrations of porosity as well as a network of oxides that stems from the starting raw powders. As both attributes are known to serve as preferential sites for crack initiation and thereby lower fatigue resistance, the general inferiority of PM7075 was as expected. However, these same features would also serve as stress concentrators during deformation (i.e., sizing). This would thereby prompt localized increases in the extent of plastic deformation, and concomitantly abnormally high levels of vacancy annihilation within their vicinity. The capacity to form vacancy rich clusters (VRC) would then be heterogeneously reduced, and in turn, so too would the net concentration of the most influential strengthening precipitate, GP-zone (II), as formed through the β-reaction sequence. This scenario would preferentially weaken the alloy near pores and oxides so as to further exacerbate the ease at which fatigue cracks would nucleate and grow. Given that wrought AA7075 is largely devoid of porosity and oxide networks, Sol-Size-Age processing thereby imparted a more prolific fatigue decline in the PM material.