Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of 2024 Aluminum Matrix Composite Reinforced with Al2O3 Nanoparticles

2.2. Microstructure Observation and Measurement of Mechanical and Wear Properties

3. Results and Discussion

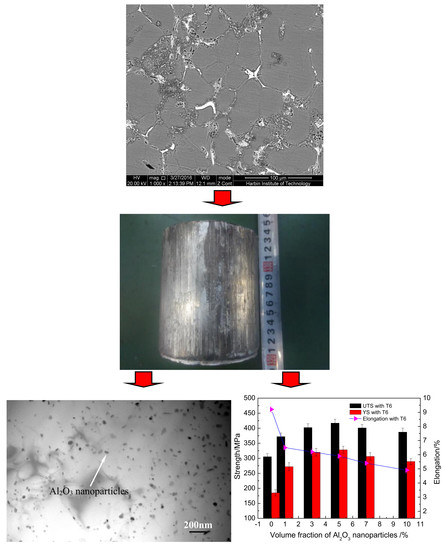

3.1. Macrograph and Microstructure of the Rheoformed Composite Component

3.2. Influence of Stirring Temperature and Stirring Time on Mechanical Properties

3.3. Influence of Volume Fraction of Al2O3 Nanoparticles on Mechanical Properties

3.4. Microstructure Characterization of the Rheoformed Composite Components

3.5. Influence of T6 Heat Treatment on Mechanical Properties

3.6. Wear Behavior of the Rheoformed Composite Components

4. Conclusions

- (1)

- 2024 aluminum matrix composite components reinforced by Al2O3 nanoparticles were rheoformed successfully. Complete filling status and good surface quality were achieved in the rheoformed composite components. Microstructure at the top and middle side wall consisted of near spheroidal grains and liquid phase, indicating dependence of deformation on liquid incorporating solid grains (FLS) and sliding between solid grains (SSG). However, obvious elongated grains were noted in the low side wall and at bottom of the rheoformed composite components. It illustrated that deformation in these locations was dominated by plastic deformation of solid grains (PDS).

- (2)

- Mechanical properties of the rheoformed composite components were influenced by stirring temperature, stirring time, and volume fraction of Al2O3 nanoparticles of composite semisolid slurries. The optimal UTS of 358 MPa and YS of 245 MPa were obtained at the bottom of the rheoformed composite components with 5% Al2O3 nanoparticles at 620 °C for 25 min stirring time. The increasing degrees of UTS are 17.5% and 31.7% as compared to the matrix component. Uniform dispersed Al2O3 nanoparticles and high density dislocations and dislocation tangles caused by PDS led to an improvement of mechanical properties. Needle-like Al2CuMg phase and short-rod-like Al2Cu phase were found in the microstructure of the rheoformed composite components due to natural ageing. MgAl2O4 phase has no effect on mechanical properties due to good wetting and high properties.

- (3)

- T6 heat treatment led to an improvement of mechanical properties of the rheoformed composite components. UTS of 417MPa and YS of 328 MPa were achieved at bottom of the rheoformed composite components with 5% Al2O3 nanoparticles at 620 °C for 25 min stirring time. UTS, YS, and elongation of the composite components with T6 heat treatment were increased by 16.5%, 20.6%, and 5.6% respectively as compared to the composite component without T6 heat treatment. UTS and YS of the composite components with T6 heat treatment were increased by 36.7% and 49.1% respectively as compared to the matrix components with T6 heat treatment. Improvement of mechanical properties of the rheoformed composite components with T6 was attributed to a large amount of precipitated needle-like Al2CuMg phase and short-rod-like Al2Cu phase.

- (4)

- Wear resistance of the rheoformed composite components increased as compared to that of the matrix component. Furthermore, wear resistance of the rheoformed composite components increased with an increase of Al2O3 nanoparticles from 1% to 7%. A slight decrease in wear rate of the rheoformed composite components resulted from 10% Al2O3 nanoparticles due to a decrease in effective dispersion of Al2O3 nanoparticles caused by greater agglomeration. The delamination and shallow ploughing grooves illustrate that the dominant wear mechanism was a combination mechanism of adhesion and delamination. To sum up, the optimal process parameters to obtain best comprehensive mechanical properties and resistance to wear are a stirring temperature of 620 °C, a stirring time of 25 min, and a volume fraction of 5% nano-sized Al2O3 nanoparticles.

Author Contributions

Funding

Conflicts of Interest

References

- Mandal, D.; Viswanathan, S. Effect of heat treatment on microstructure and interface of SiC particle reinforced 2124 Al matrix composite. Mater. Charact. 2013, 85, 73–81. [Google Scholar] [CrossRef]

- Mindivan, H.; Kayali, E.S.; Cimenoglu, H. Tribological behavior of squeeze cast aluminum matrix composites. Wear 2008, 265, 645–654. [Google Scholar] [CrossRef]

- Bharath, V.; Nagaral, M.; Auradi, V.; Kori, S.A. Preparation of 6061Al-Al2O3 MMC’s by stir casting and evaluation of mechanical and wear properties. Procedia Mater. Sci. 2014, 6, 1658–1667. [Google Scholar] [CrossRef]

- Natarajan, N.; Vijayarangan, S.; Rajendran, I. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear 2006, 261, 812–822. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. High-temperature creep behaviour of powder-metallurgy aluminium composites reinforced with SiC particles of various sizes. Compos. Sci. Technol. 1999, 59, 1117–1125. [Google Scholar] [CrossRef]

- Bajpai, G.; Purohit, R.; Rana, R.S.; Rajpurohit, S.S.; Rana, A. Investigation and testing of mechanical properties of Al-nano SiC composites through cold isostatic compaction process. Mater. Today Proc. 2017, 4, 2723–2732. [Google Scholar] [CrossRef]

- Tatar, C.; Özdemir, N. Investigation of thermal conductivity and microstructure of the α-Al2O3 particulate reinforced aluminum composites (Al/Al2O3-MMC) by powder metallurgy method. Phys. B Condensed Matter 2010, 405, 896–899. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, G.H.; Chen, G.Q.; Jiang, L.T.; Luan, B.F. The thermal expansion and mechanical properties of high reinforcement content SiCp/Al composites fabricated by squeeze casting technology. Compos. Part A-Appl. S. 2003, 34, 1023–1027. [Google Scholar] [CrossRef]

- Chou, S.N.; Huang, J.L.; Lii, D.F.; Lu, H.H. The mechanical properties of Al2O3/aluminum alloy A356 composite manufactured by squeeze casting. J. Alloy. Compd. 2006, 419, 98–102. [Google Scholar] [CrossRef]

- Chen, W.P.; Liu, Y.X.; Yang, C.; Zhu, D.Z.; Li, Y.Y. (SiCp + Ti)/7075Al hybrid composites with high strength and large plasticity fabricated by squeeze casting. Mater. Sci. Eng. A 2014, 609, 250–254. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Zou, Q.; Yang, D.L.; Tang, J.; Gao, Y.Y.; Li, Q.; Han, X.; Shu, S.L.; Chang, F.; et al. Microstructures and tensile properties of nano-sized SiCp/Al-Cu composites fabricated by semisolid stirring assisted with hot extrusion. Mater. Charact. 2017, 131, 195–200. [Google Scholar] [CrossRef]

- Guan, L.N.; Geng, L.; Zhang, H.W.; Huang, L.J. Effects of stirring parameters on microstructure and tensile properties of (ABOw + SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferrous Met. Soc. China 2011, 21, s274–s279. [Google Scholar] [CrossRef]

- Sameer, K.D.; Sumanm, K.N.S.; Tara, S.C.; Ravindra, K.; Palash, P.; Venkata, S.S.B. Microstructure, mechanical response and fractography of AZ91E/Al2O3 (p) nano composite fabricated by semi solid stir casting method. J. Magn. Alloys 2017, 5, 48–55. [Google Scholar]

- Prashanth, K.G.; Scudino, S.; Chaubey, A.K.; Löber, L.; Wang, P.; Attar, H.; Schimansky, F.P.; Pyczak, F.; Eckert, J. Processing of Al–12Si–TNM composites by selective laser melting and evaluation of compressive and wear properties. J. Mater. Res. 2016, 31, 55–65. [Google Scholar] [CrossRef]

- Prashantha, K.G.; Shahabia, H.S.; Attara, H.; Srivastavac, V.C.; Ellendtd, N.; Uhlenwinkeld, V.; Eckerta, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium—Titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Cui, Y.N.; Wang, L.F.; Ren, J.Y. Multi-functional SiC/Al Composites for aerospace applications. Chin. J. Aeronaut. 2008, 21, 578–584. [Google Scholar]

- Lee, S.S.; Yeo, J.S.; Hong, S.H.; Yoon, D.J.; Na, K.H. The fabrication process and mechanical properties of SiCp/Al-Si metal matrix composites for automobile air-conditioner compressor piston. J. Mater. Process. Technol. 2001, 113, 202–208. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. A review on properties, behaviour and processing methods for Al-nano Al2O3 composites. Procedia Mater. Sci. 2014, 6, 567–589. [Google Scholar] [CrossRef]

- Raju, P.R.M.; Siriyala, R.; Raju, K.S.; Raju, R.V.R. Evaluation of fatigue life of Al2024/Al2O3 particulate nano composite fabricated using stir casting technique. Mater. Today Proc. 2017, 4, 3188–3196. [Google Scholar] [CrossRef]

- Raturi, A.; Mer, K.K.S.; Pant, P.K. Synthesis and characterization of mechanical, tribological and micro structural behaviour of Al 7075 matrix reinforced with nano Al2O3 particles. Mater. Today Proc. 2017, 4, 2645–2658. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Parizi, M.T.; Ezatpour, H.R.; Sedghi, A. Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties. J. Alloy. Compd. 2012, 511, 226–231. [Google Scholar] [CrossRef]

- Akbari, M.K.; Baharvandi, H.R.; Mirzaee, O. Fabrication of nano-sized Al2O3 reinforced casting aluminum composite focusing on preparation process of reinforcement powders and evaluation of its properties. Compos. Part B-Eng. 2013, 55, 426–432. [Google Scholar] [CrossRef]

- Akbari, M.K.; Baharvandi, H.R.; Mirzaee, O. Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: Evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos. Part B-Eng. 2013, 52, 262–268. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, J.; Li, X.C. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Kandemir, S.; Atkinson, H.V.; Weston, D.P.; Hainsworth, S.V. Thixoforming of A356/SiC and A356/TiB2 nanocomposites fabricated by a combination of green compact nanoparticle incorporation and ultrasonic treatment of the melted compact. Metall. Mater. Trans. A 2014, 45, 5782–5798. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y. Microstructure and mechanical properties of the rheoformed cylindrical part of 7075 aluminum matrix composite reinforced with nano-sized SiC particles. Mater. Des. 2015, 79, 32–41. [Google Scholar] [CrossRef]

- Kandemir, S. Microstructure and mechonicol properties of A357/SiC nonocomposites fobricated by ultrosonic covitotion-based dispersion of ball-milled nonoparticles. J. Compo. Mater. 2017, 51, 395–404. [Google Scholar] [CrossRef]

- ASTM Standard E8M. Standard Test Methods for Tension Testing of Metallic Materials [Metric]; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Chen, C.P.; Tsao, C.-Y.A. Semi-solid deformation of non-dendrtic structure-I. Phemonological behavior. Acta Mater. 1997, 45, 1955–1968. [Google Scholar] [CrossRef]

- Kubotak, K.; Mabuchi, M.; Higashi, K. Review processing and mechanical properties of fine-grained Mg alloys. J. Mater. Sci. 1999, 34, 2255–2262. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H. Microstructure and mechanical properties of Al-Al2O3 micro and nanocomposites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Yar, A.A.; Montazerian, M.; Abdizadeh, H.; Baharvandi, H.R. Microstructure and mechanical properties of aluminum alloy matrix composite reinforced with nano-particle MgO. J. Alloy. Compd. 2009, 484, 400–404. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Enhancing compressive response of AZ31B using nano-Al2O3 and copper additions. J. Alloy. Compd. 2010, 490, 382–387. [Google Scholar] [CrossRef]

- Sastry, S.; Krishnab, M.; Uchil, J. A study on damping behaviour of aluminite particulate reinforced ZA-27 alloy metal matrix composites. J. Alloy. Compd. 2001, 314, 268–274. [Google Scholar] [CrossRef]

- Su, H.; Gao, W.L.; Feng, Z.H.; Lu, Z. Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Des. 2012, 36, 590–596. [Google Scholar] [CrossRef]

- Zhong, X.L.; Wong, W.L.E.; Gupta, M. Enhancing strength and ductility of magnesium by integrating it with aluminum nanoparticles. Acta Mater. 2007, 55, 6338–6344. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elasticmoduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Johanns, K.E.; Pharr, G.M. Effects of indenter angle on micro-scale fracture toughness measurement by pillar splitting. J. Am. Ceram. Soc. 2017, 100, 5731–5738. [Google Scholar] [CrossRef]

- Mazahery, A.; Abdizadeh, H.; Baharvandi, H.R. Development of high-performance A356/nano-Al2O3 composites. Mater. Sci. Eng. A 2009, 518, 61–64. [Google Scholar] [CrossRef]

- Lan, J.; Yang, Y.; Li, X.C. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method. Mater. Sci. Eng. A 2004, 386, 284–290. [Google Scholar] [CrossRef]

- Korgul, P.; Wilson, D.R.; Lee, W.E. Microstructural analysis of corroded alumina-spine1 castable refractories. J. Eur. Ceram. Soc. 1997, 17, 77–84. [Google Scholar] [CrossRef]

- Ghosha, A.; Sarkar, R.; Mukerjee, B.; Das, S.K. Effect of spinel content on the properties of magnesia-spinel composite refractory. J. Eur. Ceram. Soc. 2004, 24, 2079–2085. [Google Scholar] [CrossRef]

- Zang, J. Wetting and Adhesion at Al/MgAl2O4 Interface and the Effect of Substrate Crystallographic Orientation. Ph.D. Thesis, Jilin University, Changchun, China, 2014. [Google Scholar]

- Alhawari, K.S.; Omar, M.Z.; Ghazali, M.J.; Salleh, M.S.; Mohammed, M.N. Wear properties of A356/Al2O3 metal matrix composites produced by semisolid processing. Procedia Eng. 2013, 68, 186–192. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanthb, K.G.; Attar, H.; Chaubey, A.K.; Caod, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

| Serial Number | Stirring Time (Min) | Stirring Temperature (°C) | Al2O3 Volume Fraction (%) | Ultrasonic Treatment Time (Min) | Force (kN) | Dwell Time (s) | Preheated Temperature of Die (°C) |

|---|---|---|---|---|---|---|---|

| 1 | 5 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 2 | 10 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 3 | 15 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 5 | 20 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 6 | 25 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 7 | 30 | 620 | 5 | 10 | 2000 | 20 | 400 |

| 8 | 25 | 610 | 5 | 10 | 2000 | 20 | 400 |

| 9 | 25 | 615 | 5 | 10 | 2000 | 20 | 400 |

| 10 | 25 | 625 | 5 | 10 | 2000 | 20 | 400 |

| 11 | 25 | 630 | 5 | 10 | 2000 | 20 | 400 |

| 12 | 25 | 620 | 0 | 10 | 2000 | 20 | 400 |

| 13 | 25 | 620 | 1 | 10 | 2000 | 20 | 400 |

| 14 | 25 | 620 | 3 | 10 | 2000 | 20 | 400 |

| 15 | 25 | 620 | 7 | 10 | 2000 | 20 | 400 |

| 16 | 25 | 620 | 10 | 10 | 2000 | 20 | 400 |

| 17 | 25 | 610 | 0 | 10 | 2000 | 20 | 400 |

| 18 | 25 | 615 | 0 | 10 | 2000 | 20 | 400 |

| 19 | 25 | 625 | 0 | 10 | 2000 | 20 | 400 |

| 20 | 25 | 630 | 0 | 10 | 2000 | 20 | 400 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Xiao, G.; Che, C.; Wang, Y. Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles. Metals 2018, 8, 460. https://doi.org/10.3390/met8060460

Jiang J, Xiao G, Che C, Wang Y. Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles. Metals. 2018; 8(6):460. https://doi.org/10.3390/met8060460

Chicago/Turabian StyleJiang, Jufu, Guanfei Xiao, Changjie Che, and Ying Wang. 2018. "Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles" Metals 8, no. 6: 460. https://doi.org/10.3390/met8060460

APA StyleJiang, J., Xiao, G., Che, C., & Wang, Y. (2018). Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles. Metals, 8(6), 460. https://doi.org/10.3390/met8060460