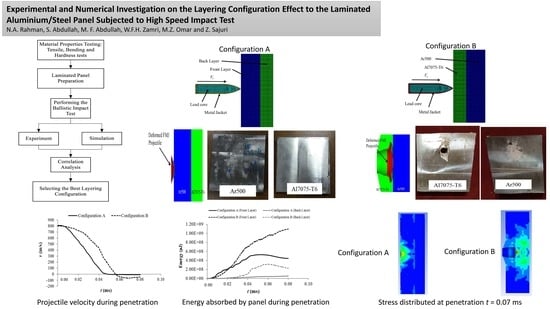

Experimental and Numerical Investigation on the Layering Configuration Effect to the Laminated Aluminium/Steel Panel Subjected to High Speed Impact Test

Abstract

:1. Introduction

2. Materials and Method

2.1. Material Characterisation

2.2. Experimental Ballistic Test

2.3. Computational Ballistic Test

3. Results and Discussion

3.1. Determination of Material Properties

3.2. Effect of Ballistic Impact on Different Layering Configuration

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jena, P.K.; Ramanjeneyulu, K.; Siva Kumar, K.; Balakrishna, B.T. Ballistic studies on layered structures. Mater. Des. 2009, 30, 1922–1929. [Google Scholar] [CrossRef]

- Teng, X.; Dey, S.; Børvik, T.; Wierzbicki, T. Protection performance of double-layered shields against projectile impact. J. Mech. Mater. Struct. 2007, 2, 1309–1329. [Google Scholar] [CrossRef]

- Volgas, D.A.; Stannard, J.P.; Alonso, J.E. Ballistics: A primer for the surgeon. Injury 2005, 36, 373–379. [Google Scholar] [CrossRef] [PubMed]

- Jena, P.K.; Mishra, B.; Siva, K.K.; Bhat, T.B. An experimental study on the ballistic impact behavior of some metallic armour materials against 7.62 mm deformable projectile. Mater. Des. 2010, 31, 3308–3316. [Google Scholar] [CrossRef]

- Liu, W.; Chen, Z.; Chen, Z.; Cheng, X.; Wang, Y.; Chen, X.; Liu, J. Influence of different back laminate layers on ballistic performance of ceramic composite armor. Mater. Des. 2015, 87, 421–427. [Google Scholar] [CrossRef]

- Børvik, T.; Forrestal, M.J.; Hopperstad, O.S.; Warren, T.L.; Langseth, M. Perforation of AA5083-H116 aluminium plates with conical-nose steel projectiles—Calculations. Int. J. Impact Eng. 2009, 36, 426–437. [Google Scholar] [CrossRef]

- Wei, Z.; Yunfei, D.; Sheng, C.Z.; Gang, W. Experimental investigation on the ballistic performance of monolithic and layered metal plates subjected to impact by blunt rigid projectiles. Int. J. Impact Eng. 2012, 49, 115–129. [Google Scholar] [CrossRef]

- Gupta, N. On microstructure and flexural strength of metal-ceramic composite cladding developed through microwave heating. Appl. Surf. Sci. 2012, 258, 5583–5592. [Google Scholar]

- Forrestal, M.J.; Børvik, T.; Warren, T.L. Perforation of 7075-T651 Aluminum armor plates with 7.62 mm APM2 bullets. Exp. Mech. 2010, 50, 1245–1251. [Google Scholar] [CrossRef]

- Flores-Johnson, E.A.; Saleh, M.; Edwards, L. Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. Int. J. Impact Eng. 2011, 38, 1022–1032. [Google Scholar] [CrossRef] [Green Version]

- Übeyli, M.; Balci, E.; Sarikan, B.; Sarikan, B.; Öztaş, M.K.; Camuşcu, N.; Yildirim, R.O.; Keleş, Ö. The ballistic performance of SiC-AA7075 functionally graded composite produced by powder metallurgy. Mater. Des. 2014, 56, 31–36. [Google Scholar] [CrossRef]

- Mansourinejad, M. Influence of sequence of cold working and aging treatment on mechanical behaviour of 6061 aluminum alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 2072–2079. [Google Scholar] [CrossRef]

- Hryha, E.; Zubko, P.; Dudrová, E.; Pešek, L.; Bengtsson, S. An application of universal hardness test to metal powder particles. J. Mater. Process. Technol. 2009, 209, 2377–2385. [Google Scholar] [CrossRef]

- Omar, M.Y.; Xiang, C.; Gupta, N.; Strbik, O.M.; Cho, K. Data characterizing flexural properties of Al/Al2O3 syntactic foam core metal matrix sandwich. Data Brief 2015, 5, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Rahman, N.A.; Abdullah, S.; Zamri, W.F.H.; Abdullah, M.F.; Omar, M.Z.; Sajuri, Z. Ballistic limit of high-strength steel and Al7075-T6 multi-layered plates under 7.62-mm Armour Piercing Impact. Lat. Am. J. Solids Struct. 2016, 13, 1658–1676. [Google Scholar] [CrossRef]

- Børvik, T.; Dey, S.; Clausen, A.H. Perforation resistance of five different high strength steel plates subjected to small-arms projectiles. Int. J. Impact Eng. 2009, 36, 948–964. [Google Scholar] [CrossRef]

- Abdulhamid, H.; Kolopp, A.; Bouvet, C.; Rivallant, S. Experimental and numerical study of AA5086-H111 aluminum plates subjected to impact. Int. J. Impact Eng. 2013, 51, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Børvik, T.; Langseth, M.; Hopperstad, O.S.; Malo, K. A perforation of 12mm thick steel plates by 20 mm diameter projectiles with flat, hemispherical and conical noses-Part I: Experimental study. Int. J. Impact Eng. 2001, 27, 19–35. [Google Scholar] [CrossRef]

- Wang, C.; Suo, T.; Li, Y.; Xue, P.; Tang, Z. A new experimental and numerical framework for determining of revised J-C failure parameters. Metals 2018, 8, 396. [Google Scholar] [CrossRef]

- Kumar, S.M.; Pramod, R.; Kumar, M.E.S.; Govindaraju, H.K. Evaluation of fracture toughness and mechanical properties of Aluminum alloy 7075-T6 with nickel coating. Procedia Eng. 2014, 97, 178–185. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, W.; Cao, Z. Experimental investigation on the ballistic resistance of monolithic and multi-layered plates against hemispherical-nosed projectiles impact. Mater. Des. 2012, 41, 266–281. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.C.; Yu, X.D.; Ma, Z.; Gao, J.B.; Kang, X.P. Effect of interlayer stress wave propagation in CMC/RHA multi-layered structure. Compos. Sci. Technol. 2010, 70, 1669–1673. [Google Scholar] [CrossRef]

- Kiliç, N.; Ekici, B. Ballistic resistance of high hardness armor steels against 7.62 mm armor piercing ammunition. Mater. Des. 2013, 44, 35–48. [Google Scholar] [CrossRef]

- Übeyli, M.; Yildirim, O.R.; Ögel, B. On the comparison of the ballistic performance of steel and laminated composite armors. Mater. Des. 2007, 28, 1257–1262. [Google Scholar] [CrossRef]

- Gupta, N.K.; Iqbal, M.A.; Sekhon, G.S. Effect of projectile nose shape, impact velocity and target thickness on the deformation behavior of layered plates. Int. J. Impact Eng. 2008, 35, 37–60. [Google Scholar] [CrossRef]

| Material Properties | RHA | Ar500 | Al7075-T6 | Copper Jacket | Lead Core |

|---|---|---|---|---|---|

| Density, ρ (kg/m3) | 7800 | 7860 | 2804 | 8520 | 10600 |

| Young’s Modulus E (GPa) | 7.690 | 7.69 | 2.69 | 3.7 | 0.56 |

| Poisson’s ratio, ν | 0.33 | 0.33 | 0.3 | 0.31 | 0.42 |

| Yield Strength, A (MPa) | 780 | 1250 | 480 | 206 | 24 |

| Strain Hardening, B (MPa) | 780 | 362 | 520 | 206 | 24 |

| Strain Hardening exponent, n | 0.106 | 1 | 0.52 | 0.42 | 1 |

| Strain rate constant, c | 0.004 | 0.0108 | 0.001 | 0.01 | 0.1 |

| Thermal softening constant, m | 1 | 1 | 1 | 1 | 1 |

| Melting temperature, Tm (K) | 1800 | 1800 | 893 | 1189 | 760 |

| Damage Constant | Ar500 [18] | Al7075-T6 [9] |

|---|---|---|

| D1 | 0.05 | −0.068 |

| D2 | 0.8 | 0.451 |

| D3 | −0.44 | −0.952 |

| D4 | −0.046 | 0.036 |

| D5 | −2.9 | 0.697 |

| Material | Modulus Elasticity (GPa) | Yield Strength, σy (MPa) | Ultimate Tensile Strength, σuts (MPa) | Stress at Break, σf (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| RHA | 213 | 1230 | 1737 | 1257 | 12.70 |

| Ar500 | 150 | 1410 | 1687 | 1293 | 12.07 |

| Al7075-T6 | 70 | 472 | 545 | 516 | 11.71 |

| Weldox 400E [9] | 145 | 1250 | 1680 | 1200 | 12.00 |

| Al7075-T651 [16] | 70 | 477 | 485 | 500 | 11.00 |

| Material | Rockwell Hardness Value (HRB) |

|---|---|

| RHA | 114 |

| Ar500 | 105 |

| Al7075-T6 | 87 |

| Material | Maximum Bending Stress, σB (MPa) | Bending Strain, εB | Bending Modulus, EB (MPa) |

|---|---|---|---|

| Ar500 | 1818 | 0.07 | 54 |

| Al7075-T6 | 624 | 0.1 | 34 |

| Plate | Ballistic Test | Simulation | Percentage Difference | |||

|---|---|---|---|---|---|---|

| Depth of Penetration (mm) | Crater Diameter (mm) | Depth of Penetration (mm) | Crater Diameter (mm) | Depth of Penetration (%) | Crater Diameter (%) | |

| Configuration A | 1.5 | 10 | 1.8 | 12 | 20 | 20 |

| Configuration B | 10.3 | 11 | 11.4 | 12 | 10.7 | 9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, N.A.; Abdullah, S.; Abdullah, M.F.; Zamri, W.F.H.; Omar, M.Z.; Sajuri, Z. Experimental and Numerical Investigation on the Layering Configuration Effect to the Laminated Aluminium/Steel Panel Subjected to High Speed Impact Test. Metals 2018, 8, 732. https://doi.org/10.3390/met8090732

Rahman NA, Abdullah S, Abdullah MF, Zamri WFH, Omar MZ, Sajuri Z. Experimental and Numerical Investigation on the Layering Configuration Effect to the Laminated Aluminium/Steel Panel Subjected to High Speed Impact Test. Metals. 2018; 8(9):732. https://doi.org/10.3390/met8090732

Chicago/Turabian StyleRahman, Najihah Abdul, Shahrum Abdullah, Mohamad Faizal Abdullah, Wan Fathul Hakim Zamri, Mohd Zaidi Omar, and Zainuddin Sajuri. 2018. "Experimental and Numerical Investigation on the Layering Configuration Effect to the Laminated Aluminium/Steel Panel Subjected to High Speed Impact Test" Metals 8, no. 9: 732. https://doi.org/10.3390/met8090732

APA StyleRahman, N. A., Abdullah, S., Abdullah, M. F., Zamri, W. F. H., Omar, M. Z., & Sajuri, Z. (2018). Experimental and Numerical Investigation on the Layering Configuration Effect to the Laminated Aluminium/Steel Panel Subjected to High Speed Impact Test. Metals, 8(9), 732. https://doi.org/10.3390/met8090732