Real-Time Investigation of Recovery, Recrystallization and Austenite Transformation during Annealing of a Cold-Rolled Steel Using High Energy X-ray Diffraction (HEXRD)

Abstract

:1. Introduction

- Fast and easy determination of residual stresses. For instance, it has been used by Oliveira et al. [10] to determine the residual stresses field across the bulk heat affected zone of a laser weld with a superior spatial resolution. In transmission or in reflection, it enables measurements on films [11,12], which are not imaginable with laboratory diffractometers.

- In situ studies of solid-solid phase transformations mechanisms under thermomechanical treatments. The 2D diffraction patterns serve to track the respective evolution of phase fractions but also their lattice parameters, which depend on their local compositions and internal stresses (Please refer, for instance, to References [15,16,17,18,19,20] for in situ thermal treatments or to References [13,21] for strain induced transformation during in situ tensile tests). It has been proven that the HEXRD experiment is the sole reliable method to measure carbon enrichment in austenite in real time during a Quenching and Partitioning treatment of steel thanks to a high acquisition rate (10Hz) and it allows the unambiguous deconvolution of the chemical and mechanical contribution in austenite lattice parameters’ evolution [17].

- In situ estimates of the density and the arrangements of defects. Sallez et al. have, for instance, studied the recovery and nano-crystallization of oxide dispersion-strengthened ferritic steel [22]. The density of dislocations and the nano-crystallite sizes were determined using modified Williamson-Hall and Warren–Averbach methods [23]. More advanced post-treatment methods can be used as extended convolutional multiple-whole-profile (eCMWP) [24,25,26], as shown by Li et al. [27].

2. Materials and Methods

2.1. As-Received Material

2.2. Microsctructure Observations

2.3. Diffraction Set-Ups and Furnace Used for the In Situ Experiment

2.4. Processing of Synchrotron Diffraction Experiments

2.4.1. Phase Transformation Kinetics

2.4.2. Recovery Kinetics

2.4.3. Recrystallization Kinetics—A New Methodology

3. Results

3.1. Phase Transformation Kinetics

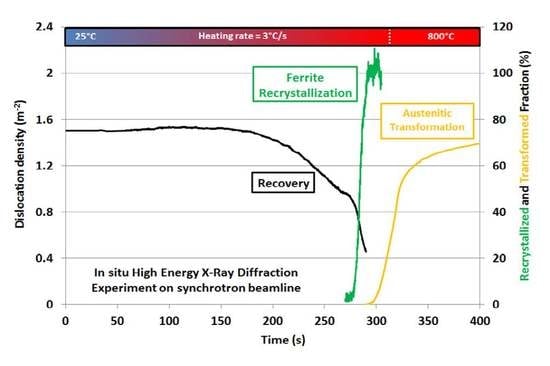

3.2. Recovery Kinetics

- Stage 1: No evolution—constant density for temperatures lower than 380 °C.

- Stage 2: Decrease in ρ0 by one-third between 380 °C and 650 °C.

- Stage 3: Sharp decrease up to Ac1 (710 °C). ρ0 is reduced again by one-third.

3.3. Recrystallization Kinetics

3.4. Validation by Microstructure Observations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kulakov, M.; Poole, W.J.; Militzer, M. The effect of the initial microstructure on recrystallization and austenite formation in a DP600 steel. Metall. Mater. Trans. A 2013, 44, 3564–3576. [Google Scholar] [CrossRef]

- Fonstein, N. Advanced High Strength Sheet Steels, 1st ed.; Springer: Cham, Switzerland, 2015; ISBN 978-3-319-19165-2. [Google Scholar]

- Allain, S.Y.P.; Bouaziz, O.; Pushkareva, I.; Scott, C.P. Towards the microstructure design of DP steels: A generic size-sensitive mean-field mechanical model. Mater. Sci. Eng. A 2015, 637, 222–234. [Google Scholar] [CrossRef]

- Huang, J.; Poole, W.J.; Militzer, M. Austenite formation during intercritical annealing. Metall. Mater. Trans. A 2004, 35, 3363–3375. [Google Scholar] [CrossRef]

- Li, P.; Li, J.; Meng, Q.; Hu, W.; Xu, D. Effect of heating rate on ferrite recrystallization and austenite formation of cold-roll dual phase steel. J. Alloys Compd. 2013, 578, 320–327. [Google Scholar] [CrossRef]

- Barbier, D.; Germain, L.; Hazotte, A.; Gouné, M.; Chbihi, A. Microstructures resulting from the interaction between ferrite recrystallization and austenite formation in dual-phase steels. J. Mater. Sci. 2015, 50, 374–381. [Google Scholar] [CrossRef]

- Chbihi, A.; Barbier, D.; Germain, L.; Hazotte, A.; Gouné, M. Interactions between ferrite recrystallization and austenite formation in high-strength steels. J. Mater. Sci. 2014, 49, 3608–3621. [Google Scholar] [CrossRef]

- Ollat, M.; Massardier, V.; Fabregue, D.; Buscarlet, E.; Keovilay, F.; Perez, M. Modeling of the Recrystallization and Austenite Formation Overlapping in Cold-Rolled Dual-Phase Steels During Intercritical Treatments. Metall. Mater. Trans. A 2017, 48, 4486–4499. [Google Scholar] [CrossRef]

- Zheng, C.; Raabe, D. Interaction between recrystallization and phase transformation during intercritical annealing in a cold-rolled dual-phase steel: A cellular automaton model. Acta Mater. 2013, 61, 5504–5517. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Cavaleiro, A.J.; Schell, N.; Stark, A.; Miranda, R.M.; Ocana, J.L.; Fernandes, F.B. Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing. Scr. Mater. 2018, 152, 122–126. [Google Scholar] [CrossRef]

- Geandier, G.; Renault, P.O.; Teat, S.; Le Bourhis, E.; Lamongie, B.; Goudeau, P. Benefits of two-dimensional detectors for synchrotron X-ray diffraction studies of thin film mechanical behavior. J. Appl. Crystallogr. 2008, 41, 1076–1088. [Google Scholar] [CrossRef]

- Renault, P.O.; Krauss, C.; Le Bourhis, E.; Geandier, G.; Benedetto, A.; Grachev, S.Y.; Barthel, E. In situ thermal residual stress evolution in ultrathin ZnO and Ag films studied by synchrotron X-ray diffraction. Thin Solid Films 2011, 520, 1390–1394. [Google Scholar] [CrossRef]

- Song, C.; Yu, H.; Lu, J.; Zhou, T.; Yang, S. Stress partitioning among ferrite, martensite and retained austenite of a TRIP-assisted multiphase steel: An in-situ high-energy X-ray diffraction study. Mater. Sci. Eng. A 2018, 726, 1–9. [Google Scholar] [CrossRef]

- Young, M.L.; Almer, J.D.; Daymond, M.R.; Haeffner, D.R.; Dunand, D.C. Load partitioning between ferrite and cementite during elasto-plastic deformation of an ultrahigh-carbon steel. Acta Mater. 2007, 55, 1999–2011. [Google Scholar] [CrossRef]

- Esin, V.A.; Denand, B.; Le Bihan, Q.; Dehmas, M.; Teixeira, J.; Geandier, G.; Denis, S.; Sourmail, T.; Aeby-Gautier, E. In situ synchrotron X-ray diffraction and dilatometric study of austenite formation in a multi-component steel: Influence of initial microstructure and heating rate. Acta Mater. 2014, 80, 118–131. [Google Scholar] [CrossRef]

- Allain, S.Y.P.; Geandier, G.; Hell, J.C.; Soler, M.; Danoix, F.; Gouné, M. In-situ investigation of quenching and partitioning by High Energy X-ray Diffraction experiments. Scr. Mater. 2017, 131, 15–18. [Google Scholar] [CrossRef]

- Allain, S.Y.P.; Gaudez, S.; Geandier, G.; Hell, J.C.; Gouné, M.; Danoix, F.; Soler, M.; Aoued, S.; Poulon-Quintin, A. Internal stresses and carbon enrichment in austenite of Quenching and Partitioning steels from high energy X-ray diffraction experiments. Mater. Sci. Eng. A 2018, 710, 245–250. [Google Scholar] [CrossRef]

- Allain, S.Y.P.; Geandier, G.; Hell, J.C.; Soler, M.; Danoix, F.; Gouné, M. Effects of Q&P Processing Conditions on Austenite Carbon Enrichment Studied by In Situ High-Energy X-ray Diffraction Experiments. Metals 2017, 7, 232. [Google Scholar] [CrossRef]

- Bénéteau, A.; Aeby-Gautier, E.; Geandier, G.; Weisbecker, P.; Redjaïmia, A.; Appolaire, B. Tempering of a martensitic stainless steel: Investigation by in situ synchrotron X-ray diffraction. Acta Mater. 2014, 81, 30–40. [Google Scholar] [CrossRef]

- Niessen, F.; Villa, M.; Danoix, F.; Hald, J.; Somers, M.A.J. In-situ analysis of redistribution of carbon and nitrogen during tempering of low interstitial martensitic stainless steel. Scr. Mater. 2018, 154, 216–219. [Google Scholar] [CrossRef]

- Hell, J.C.; Dehmas, M.; Allain, S.; Prado, J.M.; Hazotte, A.; Chateau, J.P. Microstructure–properties relationships in carbide-free bainitic steels. ISIJ Int. 2011, 51, 1724–1732. [Google Scholar] [CrossRef]

- Sallez, N.; Boulnat, X.; Borbély, A.; Béchade, J.L.; Fabrègue, D.; Perez, M.; de Carlan, Y.; Hennet, L.; Thiaudière, D.; Bréchet, Y. In situ characterization of microstructural instabilities: Recovery, recrystallization and abnormal growth in nanoreinforced steel powder. Acta Mater. 2015, 87, 377–389. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Ungár, T.; Ribárik, G.; Zilahi, G.; Mulay, R.; Lienert, U.; Balogh, L.; Agnew, S. Slip systems and dislocation densities in individual grains of polycrystalline aggregates of plastically deformed CoTi and CoZr alloys. Acta Mater. 2014, 71, 264–282. [Google Scholar] [CrossRef]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al–Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 387, 343–347. [Google Scholar] [CrossRef]

- Ribárik, G.; Ungár, T. Characterization of the microstructure in random and textured polycrystals and single crystals by diffraction line profile analysis. Mater. Sci. Eng. A 2010, 528, 112–121. [Google Scholar] [CrossRef]

- Li, L.; Ungár, T.; Wang, Y.D.; Morris, J.R.; Tichy, G.; Lendvai, J.; Yang, Y.L.; Ren, Y.; Choo, H.; Liaw, P.K. Microstructure evolution during cold rolling in a nanocrystalline Ni–Fe alloy determined by synchrotron X-ray diffraction. Acta Mater. 2009, 57, 4988–5000. [Google Scholar] [CrossRef]

- Lauridsen, E.M.; Poulsen, H.F.; Nielsen, S.F.; Jensen, D.J. Recrystallization kinetics of individual bulk grains in 90% cold-rolled aluminium. Acta Mater. 2003, 51, 4423–4435. [Google Scholar] [CrossRef]

- Poulsen, S.O.; Lauridsen, E.M.; Lyckegaard, A.; Oddershede, J.; Gundlach, C.; Curfs, C.; Jensen, D.J. In situ measurements of growth rates and grain-averaged activation energies of individual grains during recrystallization of 50% cold-rolled Aluminium. Scr. Mater. 2011, 64, 1003–1006. [Google Scholar] [CrossRef]

- Lauridsen, E.M.; Schmidt, S.; Nielsen, S.F.; Margulies, L.; Poulsen, H.F.; Jensen, D.J. Non-destructive characterization of recrystallization kinetics using three-dimensional X-ray diffraction microscopy. Scr. Mater. 2006, 55, 51–56. [Google Scholar] [CrossRef]

- Bouaziz, O.; Le Corre, C. Flow stress and microstructure modelling of ferrite-pearlite steels during cold rolling. In Materials Science Forum; Trans Tech Publications Ltd.: Zurich-Uetikon, Switzerland, 2003; Volume 426, pp. 1399–1404. [Google Scholar]

- Allain, S.; Bouaziz, O. Microstructure based modeling for the mechanical behavior of ferrite–pearlite steels suitable to capture isotropic and kinematic hardening. Mater. Sci. Eng. A 2008, 496, 329–336. [Google Scholar] [CrossRef]

- Radwański, K. Application of FEG-SEM and EBSD Methods for the Analysis of the Restoration Processes Occurring During Continuous Annealing of Dual-Phase Steel Strips. Steel Res. Int. 2015, 86, 1379–1390. [Google Scholar] [CrossRef]

- Ayad, A.; Allain-Bonasso, N.; Rouag, N.; Wagner, F. Grain Orientation Spread values in IF steels after plastic deformation and recrystallization. Mater. Sci. Forum 2012, 702, 269–272. [Google Scholar] [CrossRef]

- Peranio, N.; Li, Y.J.; Roters, F.; Raabe, D. Microstructure and texture evolution in dual-phase steels: Competition between recovery, recrystallization, and phase transformation. Mater. Sci. Eng. A 2010, 527, 4161–4168. [Google Scholar] [CrossRef]

- Hammersley, A.P.; Svensson, S.O.; Hanfland, M.; Fitch, A.N.; Hausermann, D. Two-dimensional detector software: From real detector to idealised image or two-theta scan. Int. J. High Press. Res. 1996, 14, 235–248. [Google Scholar] [CrossRef]

- The FIT2D Home Page. Available online: http://www.esrf.eu/computing/scientific/FIT2D/ (accessed on 11 April 2017).

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Physica B 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Zak, A.K.; Majid, W.A.; Abrishami, M.E.; Yousefi, R. X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar] [CrossRef]

- Smallman, R.E.; Westmacott, K.H. Stacking faults in face-centred cubic metals and alloys. Philos. Mag. 1957, 2, 669–683. [Google Scholar] [CrossRef]

- Savran, V.I.; Offerman, S.E.; Sietsma, J. Austenite nucleation and growth observed on the level of individual grains by three-dimensional X-ray diffraction microscopy. Metall. Mater. Trans. A 2010, 41, 583–591. [Google Scholar] [CrossRef]

- Renzetti, R.A.; Sandim, H.R.Z.; Bolmaro, R.E.; Suzuki, P.A.; Möslang, A. X-ray evaluation of dislocation density in ODS-Eurofer steel. Mater. Sci. Eng. A 2012, 534, 142–146. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 1st ed.; Elsevier Science Ltd.: Oxford, UK, 1995; ISBN 9780080983882. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno, M.; Teixeira, J.; Geandier, G.; Hell, J.-C.; Bonnet, F.; Salib, M.; Allain, S.Y.P. Real-Time Investigation of Recovery, Recrystallization and Austenite Transformation during Annealing of a Cold-Rolled Steel Using High Energy X-ray Diffraction (HEXRD). Metals 2019, 9, 8. https://doi.org/10.3390/met9010008

Moreno M, Teixeira J, Geandier G, Hell J-C, Bonnet F, Salib M, Allain SYP. Real-Time Investigation of Recovery, Recrystallization and Austenite Transformation during Annealing of a Cold-Rolled Steel Using High Energy X-ray Diffraction (HEXRD). Metals. 2019; 9(1):8. https://doi.org/10.3390/met9010008

Chicago/Turabian StyleMoreno, Marc, Julien Teixeira, Guillaume Geandier, Jean-Christophe Hell, Frédéric Bonnet, Mathieu Salib, and Sébastien Y.P. Allain. 2019. "Real-Time Investigation of Recovery, Recrystallization and Austenite Transformation during Annealing of a Cold-Rolled Steel Using High Energy X-ray Diffraction (HEXRD)" Metals 9, no. 1: 8. https://doi.org/10.3390/met9010008

APA StyleMoreno, M., Teixeira, J., Geandier, G., Hell, J. -C., Bonnet, F., Salib, M., & Allain, S. Y. P. (2019). Real-Time Investigation of Recovery, Recrystallization and Austenite Transformation during Annealing of a Cold-Rolled Steel Using High Energy X-ray Diffraction (HEXRD). Metals, 9(1), 8. https://doi.org/10.3390/met9010008