Investigation on the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel Based on Austenite–Ferrite Transformation Kinetics

Abstract

:1. Introduction

2. Materials and Experiments

3. Modeling of Austenite–Ferrite Transformation Kinetics

3.1. Para Equilibrium

3.2. Local Equilibrium

4. Results and Discussion

4.1. Determination of Austenite–Ferrite Transformation Kinetic Mode

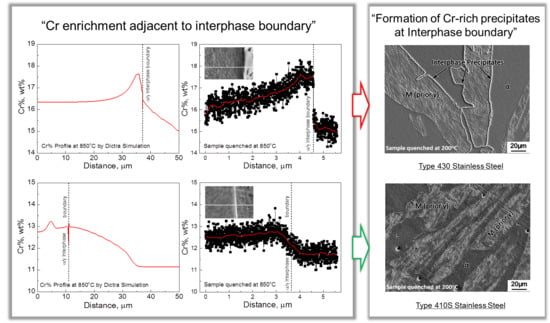

4.2. Mechanism for the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel

5. Conclusions

- 1)

- The microstructure from cyclic transformation was largely affected by the rate of temperature change, which is in well accordance with the DICTRA simulation of austenite–ferrite transformation under the LE condition.

- 2)

- In contrast to type 410S stainless steel, a noticeable enrichment of Cr adjacent to the interphase boundary which facilitated the formation of interphase Cr-rich precipitates in type 430 stainless steel was revealed by EDS analysis and interpreted by DICTRA simulation under the LE condition. This has provided solid evidence for the correlation between the formation of interphase Cr-rich precipitates and austenite–ferrite transformation kinetics.

Author Contributions

Funding

Conflicts of Interest

References

- Hu, C.L.; Xia, S.; Li, H.; Liu, T.G.; Zhou, B.; Chen, W.J.; Wang, N. Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros. Sci. 2011, 53, 1880–1886. [Google Scholar] [CrossRef]

- Dayal, R.K.; Parvathavarthini, N.; Raj, B. Influence of metallurgical variables on sensitisation kinetics in austenitic stainless steels. Int. Mater. Rev. 2005, 50, 129–155. [Google Scholar] [CrossRef]

- Du Toit, M.; Van Rooyen, G.T.; Smith, D. Heat-affected zone sensitization and stress corrosion cracking in 12% chromium type 1.4003 ferritic stainless steel. Corrosion 2007, 63, 395–404. [Google Scholar] [CrossRef]

- Kim, J.K.; Lee, B.-J.; Lee, B.H.; Kim, Y.H.; Kim, K.Y. Intergranular segregation of Cr in Ti-stabilized low-Cr ferritic stainless steel. Scr. Mater. 2009, 61, 1133–1136. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, Y.H.; Lee, B.H.; Kim, K.Y. New findings on intergranular corrosion mechanism of stabilized stainless steels. Electrochim. Acta 2011, 56, 1701–1710. [Google Scholar] [CrossRef]

- Park, J.H.; Seo, H.S.; Kim, K.Y. Alloy design to prevent intergranular corrosion of low-Cr ferritic stainless steel with weak carbide formers. J. Electrochem. Soc. 2015, 162, C412–C418. [Google Scholar] [CrossRef]

- Sedriks, A.J. Corrosion of Stainless Steels, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1996; p. 110. [Google Scholar]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Carboneras, M.; Arrabal, R. Influence of Ti, C and N concentration on the intergranular corrosion behavior of AISI 316Ti and 321 stainless steel. Acta Mater. 2007, 55, 2239–2251. [Google Scholar] [CrossRef]

- Yin, Y.F.; Faulkner, R.G.; Moreton, P.; Armson, I.; Coyle, P. Grain boundary chromium depletion in austenitic alloys. J. Mater. Sci. 2010, 45, 5872–5882. [Google Scholar] [CrossRef]

- Kim, J.K.; Kim, Y.H.; Uhm, S.H.; Lee, J.S.; Kim, K.Y. Intergranular corrosion of Ti-stabilized 11 wt% Cr ferritic stainless steel for automotive exhaust systems. Corros. Sci. 2009, 51, 2716–2723. [Google Scholar] [CrossRef]

- Lv, J.L.; Liang, T.X.; Dong, L.M.; Wang, C. Influence of sensitization on microstructure and passive property of AISI 2205 duplex stainless steel. Corros. Sci. 2016, 104, 144–151. [Google Scholar]

- Shankar, P.; Shaikh, H.; Sivakumar, S.; Venugopal, S.; Sundararaman, D.; Khatak, H.S. Effect of thermal aging on the room temperature tensile properties of AISI type 316LN stainless steel. J. Nucl. Mater. 1999, 264, 29–34. [Google Scholar] [CrossRef]

- Ghosh, S.; Kain, V.; Ray, A.; Roy, H.; Sivaprasad, S.; Tarafder, S.; Ray, K.K. Deterioration in fracture toughness of 304LN austenitic stainless steel due to sensitization. Metall. Mater. Trans. A 2009, 40, 2938–2949. [Google Scholar] [CrossRef]

- Hilders, O.A.; Santana, M.G. Toughness and fractography of austenitic type 304 stainless steel with sensitization treatments at 973 K. Metallography 1988, 21, 151–164. [Google Scholar] [CrossRef]

- Kumar, S.; Shahi, A.S. Studies on metallurgical and impact toughness behavior of variably sensitized weld metal and heat affected zone of AISI 304L welds. Mater. Des. 2016, 89, 399–412. [Google Scholar] [CrossRef]

- Gilmour, J.B.; Purdy, G.R.; Kirkaldy, J.S. Thermodynamics controlling the proeutectoid ferrite transformations in Fe-C-Mn alloys. Metall. Trans. 1972, 3, 1455–1464. [Google Scholar] [CrossRef]

- Coates, D.E. Diffusional growth limitation and hardenability. Metall. Trans. 1973, 4, 2313–2325. [Google Scholar] [CrossRef]

- Borgenstam, A.; Engstrom, A.; Hoglund, L.; Ågren, J. DICTRA, a tool for simulation of diffusional transformations in alloys. J. Phase Equilib. 2000, 21, 269–280. [Google Scholar] [CrossRef]

- Saha, A.; Ghosh, G.; Olson, G.B. An assessment of interfacial dissipation effects at reconstructive ferrite–austenite interfaces. Acta Mater. 2005, 53, 141–149. [Google Scholar] [CrossRef]

- Dmitrieva, O.; Ponge, D.; Inden, G.; Millan, J.; Choi, P.; Sietsma, J.; Raabe, D. Chemical gradients across phase boundaries between martensite and austenite in steel studied by atom probe tomography and simulation. Acta Mater. 2011, 59, 364–374. [Google Scholar] [CrossRef] [Green Version]

| Stainless Steel | C | N | Si | Mn | Cr | Ni |

|---|---|---|---|---|---|---|

| 430 | 0.04 | 0.04 | 0.25 | 0.32 | 16.32 | 0.16 |

| 410S | 0.026 | 0.025 | 0.28 | 0.27 | 12.6 | 0.15 |

| Stainless Steels | Value Type | 10 °C/min | 100 °C/min | 200 °C/min |

|---|---|---|---|---|

| 430 | Measured 1 | 23.7% | 16.3% | 16.7% |

| Fe-C-N-Cr system | simulated (LE) 2 | 29.1% | 24.3% | 23.6% |

| simulated (PE) 2 | 28.4% | 28.2% | 28.0% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, T.; Ni, R.; Wang, H.; Shen, J.; Wang, Z. Investigation on the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel Based on Austenite–Ferrite Transformation Kinetics. Metals 2019, 9, 1045. https://doi.org/10.3390/met9101045

Jia T, Ni R, Wang H, Shen J, Wang Z. Investigation on the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel Based on Austenite–Ferrite Transformation Kinetics. Metals. 2019; 9(10):1045. https://doi.org/10.3390/met9101045

Chicago/Turabian StyleJia, Tao, Run Ni, Hanle Wang, Jicheng Shen, and Zhaodong Wang. 2019. "Investigation on the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel Based on Austenite–Ferrite Transformation Kinetics" Metals 9, no. 10: 1045. https://doi.org/10.3390/met9101045

APA StyleJia, T., Ni, R., Wang, H., Shen, J., & Wang, Z. (2019). Investigation on the Formation of Cr-Rich Precipitates at the Interphase Boundary in Type 430 Stainless Steel Based on Austenite–Ferrite Transformation Kinetics. Metals, 9(10), 1045. https://doi.org/10.3390/met9101045