The automotive industry is being steadily pushed to pursue economic and environmental efficiency. Powder metallurgy (P/M) offers a powerful means to achieve this target, as (near) net-shape mechanical components can be fabricated on a large scale, with high geometrical accuracy and minimum waste of raw material compared to conventional chip-generating machining processes. Flodin [

1] reviewed the increasing employment of P/M parts in automotive transmissions, mainly in the form of synchronizer sleeves, shift fingers, carriers of epicyclical automatic transmissions, and oil pump gears. Attempts are now made to replace conventionally machined gears with P/M gears, at least in the least-loaded gear stages of car transmissions. However, bringing the mechanical performance of P/M gears to the level of their wrought counterparts is a tremendous technological challenge because this particular manufacturing route inevitably affects the resulting microstructure and mechanical properties. The main microstructural characteristic that differentiates P/M from wrought parts is residual porosity. Despite constant improvements in the compaction and sintering of metallic powders, P/M parts still display a relative density lower than 1. This clearly impacts on the stiffness, tensile, fatigue and wear properties of such components [

2,

3,

4]. In the context of P/M gears, (i) the lower stiffness is detrimental to the mesh precision and mesh power loss factor [

5], (ii) inferior fatigue properties negatively affect tooth root bending fatigue strength [

6] and pitting resistance [

7], and (iii) sintered tooth flanks have higher wear rates [

8]. To combat these adverse effects, many treatments have been devised so far, such as shot peening [

9], surface rolling [

10], sinter-forging [

11], and the double press double sinter process [

12]. These treatments lead to tooth flank and root densification, which significantly improves the gear load capacity [

13,

14]. However, both bulk and surface densification treatments have a cost that is not always sustainable if compared to the profit margin of these automotive components. In this framework, the leanest and most cost-efficient process is powder compaction followed by sinter-hardening. Thereby, two processes are done in one single step, thus reducing the manufacturing time and cost. In addition, since martensite is directly formed during the cooling stage of the sintering process, no quenching is required, thus, problems related to oil retention and distortions associated with severe cooling rates are avoided [

15]. To facilitate the formation of a martensitic or lower bainitic microstructure at cooling rates (1–10 °C s

−1) typical of the sinter-hardening process, special pre-mixed, diffusion-bonded or pre-alloyed powder blends have been devised to achieve adequate hardenability through the control of carbon content and the addition of alloying elements, such as Mo, Ni, and Cu. However, during sintering these elements are not distributed uniformly along the sinter-necks, resulting in a heterogenous microstructure. For instance, the slow diffusion rate between iron and nickel leads to the formation of nickel rich areas (NRAs), which are a combination of soft austenite and hard martensite [

16], in general surrounding critical pores [

17].

From the above discussion, it is clear that the tooth root bending fatigue strength of P/M gears, the focus of the present article, is the result of a complex interplay between porosity and microstructural constituents. Devising suitable fatigue calculation tools that are able to capture these phenomena is therefore of paramount importance for the fatigue prognosis of such P/M parts. In this regard, Danninger and Weiss [

18] carried out fundamental investigations on the influence of porosity on the mechanical properties. They found that up to relative density levels of 94%, the porosity is mostly or completely open and interconnected, forming a spongy structure with a continuous pore network. However, at higher density levels, the structure is composed of isolated and more or less rounded pores in a continuous matrix. This means that in the former case, the sintering contacts are isolated and the area of the real metallic contacts, the ‘load bearing cross-section’ Ac is markedly smaller than the volume fraction of the metallic phase. In [

18], the authors were able to rationalize the fatigue endurance of high-strength steels just by scaling the fatigue strength of the fully dense reference material by Ac. In such spongy materials, fatigue damage usually occurs very early and is located at the necks between powder particles, which are the weakest point of the microstructure. In this way, the fatigue is diffused rather than localized as it is in conventional materials and proceeds until eventual failure by coalescence of widespread defects [

19,

20].

In this context, it is clear that the key parameter for improving fatigue performance is the increment in relative density. Accordingly, when the porosity drops to levels below 6%, fatigue damage is delayed and localized in the correspondence of isolated pores with low shape factor or clusters of near-superficial pores [

21]. Under these circumstances, fatigue calculation models originally developed for bulk metallic materials, can be applied to P/M steels. In this regard, the pores are treated in some papers [

18,

22,

23] as pre-existing cracks and a linear-elastic fracture mechanics approach is applied for identifying the propagation conditions of crack-like defects. Furthermore, the Murakami model [

24], initially proposed for determining the fatigue limit of steels containing inclusions, has been successfully applied to predict the fatigue strength of P/M steels [

22,

23] and additively manufactured metals [

25]. In its most general formulation, this approach permits the estimation of the fatigue limit of the material with the following equation, which also includes the effect of the load ratio

R:

where the microstructure-dependent mechanical properties of the material are quantified by the Vickers hardness (

HV), and the detrimental effect of the fatigue damage triggering defect is expressed by its

area projected on the plane experiencing the highest normal stress. The location factor

Floc is related to the defect location with respect to the outer surface, being equal to 1.41 and 1.56 for surface and internal defects, respectively. The exponent α is also a function of the material microhardness, being expressed as α = 0.226 +

HV × 10

−4.

Since the Murakami model was devised for materials whose fatigue strength is dictated by isolated defects, Bergmark [

22] proposed an adaption of its formulation when applied to P/M materials affected by widespread defectiveness by introducing a corrective factor. This is a function of the loss in elastic modulus with respect to the fully dense material, which is in turn, a measure of the material porosity. In this way, it is possible to link the Murakami model, which is suitable for continuous materials, to the Ac model devised in [

18] for sponge materials with interconnected porosity. Nevertheless, it is still unclear how to define the critical pore and the material hardness to be considered in the application of such a model to P/M materials.

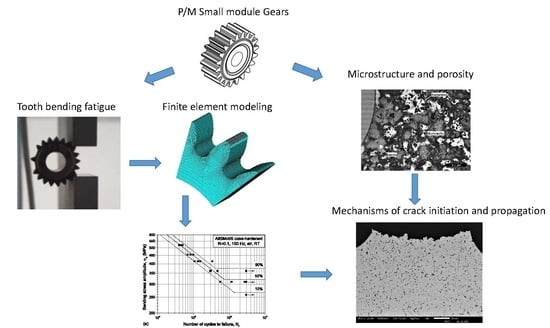

To shed further light on this research topic, the present paper investigates the tooth root bending fatigue strength of small module high-density spur gears produced by P/M using different pre-alloyed powders and subjected to diverse heat treatments. The main goal of this paper is to understand whether sinter-hardening is able to impart fatigue properties comparable to those achieved by conventional case-hardening post-sintering treatments. Moreover, the paper investigates the synergic effect of pore structure and heterogeneous microstructure (typical of sinter-hardened materials) on the fatigue strength. Therefore, the fatigue behaviour was examined by starting with an in-depth fractographic analysis aimed at exploring the influence of porosity and microstructure on the nucleation and propagation of cracks. Special care was taken to adapt the formulation of the Murakami model so as to capture the particular characteristics of the sintered materials.