Applying Standard Industrial Components for Active Magnetic Bearings

Abstract

:1. Introduction

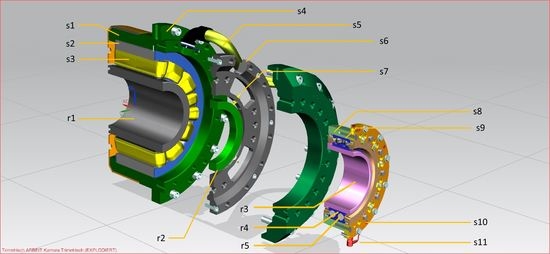

2. The Active Magnetic Bearing System and Its Components

3. The Advantages of Standard Industrial Components

- Robustness: Robustness refers to the ability to tolerate deviations from the actual design point. Examples of such deviations are deviations in the mechanical dimensions of the machine parts, assembly and mounting inaccuracies, or deviations in the thermal properties of the machine or the AMBs. The robustness of a magnetic bearing largely depends on the air gap between the AMB rotor and stator. A large air gap is beneficial during assembly and alignment of the machine, and in the event of an unplanned landing into the back-up bearings [5]. A sufficiently large air gap prevents the AMB rotor and stator from coming into contact with one another, which may occur due to rotor bending and deflections in exceptional loading situations. In addition to the possible unplanned events, a large air gap is necessary to be able to tolerate the thermal expansion of the AMB rotor diameter when operating at full load/high temperatures. As a consequence, defining the required air gap is a critical issue when designing a magnetic bearing, and needs to be based on detailed calculations and/or simulations. However, a large air gap requires high currents in order to keep the magnetic field at the required level. Modular motion control drive systems comprise a family of power amplifiers up to high power ratings, which provide maximum flexibility with respect to the configuration of the AMB control system. A fully scalable AMB control system ensures that the actual power requirements can be fully complied with.

- Availability: Availability is the probability of functioning at any given instant [9]. It can be estimated from the ratio of the average uptime to the sum of the average uptime and average downtime of a plant. The averages of uptime and downtime can be expressed in terms of mean time between failure (MTBF) and mean time to repair (MTTR), respectively. Industrial electronic components manufactured in large numbers are usually continuously optimized with respect to availability. Furthermore, due to the large statistical basis, there are reliable values available for the MTBF. These numbers allow the availability of the components to be estimated so that maintenance intervals and service tasks can be planned. In turn, the risk of AMB failure can be minimized, therefore minimizing unscheduled maintenance costs.

- Reliability: “Reliability is the probability of functioning properly over a given period” [9], or, as defined in [10], the probability of providing a specified performance level for a specified duration in a specified environment. There is no unique way of quantifying reliability; some definitions involve the accumulated rate of failure, the failure intensity, the MTBF, and the survival rate [10].

- Safety and functional safety: According to [9], safety is the absence of unacceptable risk. In general, when designing and operating a plant, it is required to perform risk assessments and to reduce the residual risk to an acceptable level by applying appropriate measures (e.g., by using inherently safe designs or by applying safety-related electronic components). Functional safety refers to the safety of the equipment and the control equipment, depending on the correct operation of the electrical/electronic/programmable electronic (E/E/PE) safety-related systems and other risk reduction measures [9]. Standard industrial components are thoroughly developed and tested according to standardized development and quality assurance processes before they are launched into the market. In this sense, they inherently have a low risk of failure provided they are operated within their specified operating range. In addition, industrial component families may include specifically designed (SIL certified) components which are used for monitoring, and which take the appropriate action in the case of failure to bring the whole system into a safe state. SIL-certified components can recognize their own failure and bring the plant—even in such a case—into a safe state. The advantage of using SIL-certified industrial components from the same electronics supplier is that these components can be seamlessly integrated into the overall AMB control concept.

- Security: For the configuration of a magnetic bearing control system, for monitoring, maintenance, and failure diagnostics, it cannot be avoided that this system can be accessed, therefore making it vulnerable to cyber-attacks. As a consequence, there is a strong demand for a secure, efficient, and comfortable access concept with roles, permissions according to access-levels, and security policies, as well as know-how protection, which allows full design flexibility so that an IT security concept can be fully integrated into an existing IT infrastructure. Such an overall concept allows an AMB control system to be accessed for monitoring, diagnostics, system control, and other service-related tasks—even remotely.

- Traceability: When developing and manufacturing standard industrial components, standardized processes must be strictly complied with. These processes have been put in place to fulfill the required quality issues, but also legal regulations. Traceability ensures that the composition of a product can always be traced, along with the processes, machines, etc. that have been involved in the manufacturing. In the case of a problem, it is therefore possible to retrace all manufacturing steps. This is a crucial prerequisite in conducting a root cause analysis and for initiating remedial action. Traceability requires a clearly structured development and manufacturing process, and hence inherently leads to an improvement of the product quality. Traceability involves strict tracking of software versions and hardware revisions—including design drawings and calculations.

- Certification: Standard industrial components are by default delivered with the certificates documenting important properties required by legislation, customers, or the applicable standards (e.g., [11]). Examples are certificates for explosion protection and electromagnetic compatibility. The required overall plant certification can be easily performed based on these documents.

- Handling: For manufacturing, commissioning, and operation, it is necessary to have a variety of interfaces that allow intuitive use and easy operation. Connectors should allow quick commissioning and for components to be quickly replaced in the case of service and maintenance. Standardized components provide debugging interfaces, which are useful during development and fault diagnostics. Standard industrial components are provided with thoroughly designed and tested engineering software, allowing the necessary parameters and system information to be fully accessed.

- Flexibility: Standard components can be combined and configured so that they can be adapted to address the needs of the application. In general, they provide several types of interfaces that allow additional devices and measurement equipment to be connected. Examples include Profibus, Profinet, Ethernet, analog/digital converters, and electrical input/output ports. Furthermore, standard industrial components are completely harmonized and coordinated with one another so that they can be combined without additional components (e.g., human–machine interface and process supervision equipment). Very often, changes can be simply made by adjusting configuration settings using the system’s engineering software. Employing standard components means that there are a high number of service engineers that are familiar with them.

- Reporting and condition monitoring: Analyzing process and machine data is becoming increasingly important. Standard components allow all of the relevant machine and process data to be accessed, and provide options for transferring and storing this kind of information. As a consequence, they support the application of modern techniques and frameworks such as big data for process and machine improvements.

- Costs: Since the development costs are distributed over a large number of units, the advantages of industrial standard components can be made available at a fraction of the cost of non-standard components. Further, spare parts can be simply managed using standardized lifecycle management systems.

- Delivery times: Since these electronic components are manufactured in large numbers, they are generally available off-the-shelf, thus keeping delivery times low. Spare parts that are required can often be ordered locally. The lifecycle management system guarantees that spare parts are available over a long period of time.

4. Using Standard Industrial Components

4.1. Example: Application of Standard Three-Phase Inverters for AMB Operation

4.2. Example: Evaluation and Implementation of Safety Requirements

4.3. Example: Flexibility by Using Standard Industrial Components

5. Discussion

- In order to achieve a certain level of robustness and safety, the development cycles are usually longer for standard industrial components. That is, most recent technical developments may not be available within a short time frame. However, for control units in particular, options are available that allow minor additional features such as filtering or diagnostic blocks to be quickly implemented. Relying on the high quality of the component’s software in general, these additional features can be implemented quickly with low costs associated with regression testing.

- Making a commitment to a certain family of industrial products requires acceptance of its potential limitations and restrictions. Demands from customers that cannot be fulfilled with components from this product family can either not be satisfied, or components from other product families have to be used. An extension of the product family itself is generally a time-consuming process, including all the steps from requirement engineering until the product is finally released. As the desired properties of standard industrial products—as listed in Section 3—require that defined processes are fully complied with, these restrictions are unavoidable and need to be accepted.

- Using standardized components may, in general, lead to a loss of optimization in comparison to a fully custom design. However, properly selected standard industrial components generally provide a great flexibility such that the performance degradation can be kept small.

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Hawkins, L. Application of Flywheel Energy Storage Systems as an Industrial Product. In Proceedings of the 15th International Symposium on Magnetic Bearings (ISMB15), Kitakyushu, Japan, 3–6 August 2016.

- Gilarranz, J.L.; Dave, M.; Jamison, T.; Festa, M.; Feichtinger, P.; Denk, J. Non-Hermetic, Oil-free Compression Solutions—A Reliable Approach to Reduce Life Cycle Costs for Compressor Applications. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 7–10 November 2016.

- Aeschlimann, B.; Hubatka, M.; Peter, M.E.; Stettler, R.; Housseini, R. Commissioning of Off-Shore Gas Compressor with 9-Axes Magnetic Bearing System: Controller Design. In Proceedings of the 15th International Symposium on Magnetic Bearings (ISMB15), Kitakyushu, Japan, 3–6 August 2016.

- Düsterhaupt, S.; Neumann, H.; Rottenbach, T.; Vanek, C.; Worlitz, F. High Temperature Active Magnetic Bearings in Industrial Steam Turbines. In Proceedings of the 15th International Symposium on Magnetic Bearings (ISMB15), Kitakyushu, Japan, 3–6 August 2016.

- Denk, J.; Köhler, B.-U.; Siegl, G.; Siebke, P. Landing Tests with a 6300 rpm, 9t AMB Rotor in Rolling Element Back-up Bearings. In Proceedings of the 14th International Symposium on Magnetic Bearings (ISMB14), Linz, Austria, 11–14 August 2014.

- Denk, J. Active Magnetic Bearing Technology running Successfully in Europe's Biggest Onshore Gas Field. OIL GAS Eur. Mag. 2015, 2, 91–92. [Google Scholar]

- Isles, J. Oil-free Bearings Demonstrated at Jänschwalde Power Station. Gas Turbine World 2016, 46, 32–36. [Google Scholar]

- SIEMENS. SIMOTICS Active Magnetic Bearing Technology. Available online: http://www.siemens.com/global/en/home/products/drives/motors/high-voltage-motors/simotics-active-magnetic-bearing-technology.html (accessed on 14 November 2016).

- International Electrotechnical Commission (IEC). International Standard IEC 61508 (Part 1–7): Functional Safety of Electrical/Electronic/Programmable Electronic Safety—Related Systems, 2nd ed.; IEC: Geneva, Switzerland, 2010. [Google Scholar]

- International Electrotechnical Commission (IEC). International Standard IEC 62308: Equipment Reliability—Reliability Assessment Methods, 1st ed.; IEC: Geneva, Switzerland, 2006. [Google Scholar]

- American Petroleum Institute (API). API Standard 617: Axial and Centrifugal Compressors and Expander-compressors for the Petroleum Chemical and Gas Industry, 7th ed.; API: Washington, DC, USA, 2002. [Google Scholar]

- Field Orientated Control of 3-Phase AC-Motors, Literature Number BPRA073, Texas Instruments Europe, February 1998. Available online: http://www.ti.com/general/docs/litabsmultiplefilelist.tsp?literatureNumber=bpra073 (accessed on 14 November 2016).

- International Electrotechnical Commission (IEC). International Standard IEC 61511 (Part 1–3): Functional Safety—Safety Instrumented Systems for the Process Industry Sector, 2nd ed.; IEC: Geneva, Switzerland, 2016. [Google Scholar]

- International Organization for Standardization (ISO). International Standard ISO 12100:2010(E): Safety of Machinery—General Principles for Design—Risk Assessment and Risk Reduction, 1st ed.; ISO: Geneva, Switzerland, 2010. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koehler, B.-U.; Denk, J.; Van Maanen, G.; Lang, M. Applying Standard Industrial Components for Active Magnetic Bearings. Actuators 2017, 6, 8. https://doi.org/10.3390/act6010008

Koehler B-U, Denk J, Van Maanen G, Lang M. Applying Standard Industrial Components for Active Magnetic Bearings. Actuators. 2017; 6(1):8. https://doi.org/10.3390/act6010008

Chicago/Turabian StyleKoehler, Bert-Uwe, Joachim Denk, Gijs Van Maanen, and Matthias Lang. 2017. "Applying Standard Industrial Components for Active Magnetic Bearings" Actuators 6, no. 1: 8. https://doi.org/10.3390/act6010008

APA StyleKoehler, B. -U., Denk, J., Van Maanen, G., & Lang, M. (2017). Applying Standard Industrial Components for Active Magnetic Bearings. Actuators, 6(1), 8. https://doi.org/10.3390/act6010008