Systematic Literature Review on Data-Driven Models for Predictive Maintenance of Railway Track: Implications in Geotechnical Engineering

Abstract

:1. Introduction

- Corrective maintenance happens only when the track needs to be repaired. It is performed after a fault has occurred, resulting in the need for a backup transport service to be organized and dispatched as soon as possible. These factors lead to remarkably high costs and fees from the incurred service interruptions.

- Preventive maintenance happens periodically with a planned schedule before track failures, which reduces the useful life of track components due to early replacement. Unnecessary maintenance actions may be taken, leading to additional cost.

- Condition-based maintenance aims to optimize maintenance strategies based on the estimation of the track status. Recent advancements in smart sensors enable railway engineers to estimate the real-time track conditions. Components are then repaired or replaced only when conditions exceed some thresholds.

- Predictive maintenance is a predictive framework to estimate the time when a fault is likely to occur and to adopt maintenance interventions accordingly. It is a proactive process that requires the development of a predictive model. The maintenance can be carried out whenever it is convenient for the railway asset managers before the predicted failure time.

- What are the measurement methods and data sets used in railway track engineering?

- How are data-driven models employed in the predictive maintenance of railway track?

- How should one choose suitable methods for different data types, track defects, and maintenance strategies?

2. Systematic Literature Review

2.1. Material Collection

2.2. Literature Statistical Analysis

3. Results of the Systematic Literature Review

3.1. Data Acquisition in Railway Track Engineering

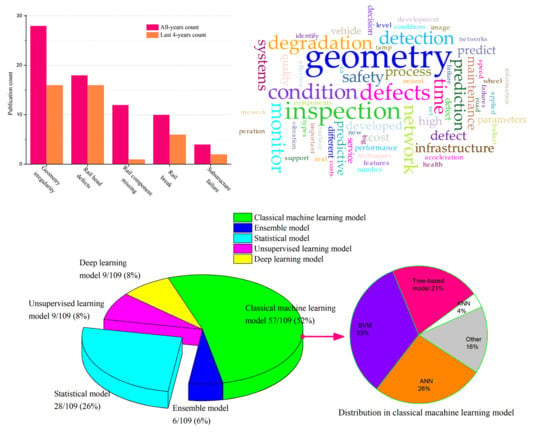

3.2. Publication Distribution among the Data-Driven Methods

3.3. Publication Trend Analysis

3.4. Classical Data-Driven Models in Railway Predictive Maintenance

3.5. Advanced Machine Learning Models in Predictive Maintenance of Railway Track

3.5.1. Deep Learning Models

3.5.2. Unsupervised Learning Models

3.5.3. Ensemble Models

4. Data-Driven Model Application in Predictive Maintenance of Railway Track

4.1. Models for Different Measurement Methods

4.1.1. Time Series-Based Measurement Data Sets

4.1.2. Image-Based Measurement Data Sets

4.1.3. Discrete Value-Based Measurement Data Sets

4.1.4. Text-Based Measurement Data Sets

4.2. Models for Different Railway Track Defects

4.3. Models for Maintenance Strategy

5. Future Challenges and Suggestions

- Pay more attention to the advanced machine learning methods. The advanced methods, such as the deep learning, ensemble, and unsupervised learning methods, are able to better utilize and handle the large-volume, multi-source, highly-imbalanced, and high noise of modern railway measurement datasets. These methods have proven to be immensely useful in other fields, yet are rarely used in railway predictive maintenance.

- Make use of the text-based data in the railway industry. Narrative descriptions are widely used in the railway industry, but there are still only a small number of applications in the predictive maintenance of railway track. Text mining techniques can tackle the problems of text representation, classification, clustering, information extraction, or the search for and modeling of hidden patterns [127]. In this way, the recorded narrative descriptions can be utilized as a valuable source of information to combine with other data types.

- Develop automatic data labeling methods. The performance of the data-driven models depends on high-quality labeled samples. Although large volumes of data are collected from sensors in the railway industry, most of the data needs to be labeled manually. Data-driven algorithms, such as unsupervised learning models, can contribute by labeling the data automatically [13]. In addition, as mentioned in Table 1, one of the important characteristics of the railway measurement data is highly imbalanced. High quality automatic data labeling algorithms help to identify more faulty samples, which alleviates the extreme imbalance distribution in railway defects data.

- Enhance the interpretability of the models. As mentioned in the Section 3, data-driven methods, such as deep learning models, are “black box” methods [54]. It is hard to justify the classification or prediction basis to end users. Much attention has been given to attempting to improve the interpretability of these machine learning methods in the research community [128]. More details about the relevant methods can be found in Reference [129].

- Consider cost information in model performance evaluation. To evaluate the model performance of track defects detection or prediction, the defects detection accuracy is commonly used, which measures the proportion of track status correctly identified. In general, there are two common errors in track status prediction. One is false alarm prediction, and the other is false safe prediction. False alarm prediction means that the actual safe condition is falsely predicted as a problem. False safe prediction means that the actual problem is falsely identified as a safe condition. From the engineer’s perspective, high false alarm prediction usually leads to ineffective and unnecessary decision-making, while false safe prediction would cause huge loss for the railway service suspensions, putting the maintenance organization in reactive mode. Thus, compared to the prediction accuracy, railway managers care more about the percentage of the false safe prediction. A scientific evaluation system should take cost information into account, considering the huge and asymmetric cost for false safe predictions in railway engineering [130]. The further work is expected to take the various costs (false safe, early replacement, false alerts) into account and return the expected gain in dollars as an evaluated metrics instead of only considering the accuracy of the prediction.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FRA. 2015 FRA Office of Safety Analysis. Available online: http://safetydata.fra.dot.gov/officeofsafety/default.aspx (accessed on 31 August 2020).

- Lyngby, N. Railway Track Degradation: Shape and Influencing Factors. Int. J. Perform. Eng. 2009, 5, 177. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hajizadeh, S.; Su, Z.; Naeimi, M.; Núñez, A.; Dollevoet, R.; De Schutter, B.; Li, Z. A decision support approach for condition-based maintenance of rails based on big data analysis. Transp. Res. Part C Emerg. Technol. 2018, 95, 185–206. [Google Scholar] [CrossRef] [Green Version]

- Sheeran, R.; Kay, M. A Short Guide to Network Rail; National Audit Office: London, UK, 2015. [Google Scholar]

- López-Pita, A.; Teixeira, P.F.; Casas, C.; Bachiller, A.; Bachiller, P.A. Maintenance Costs of High-Speed Lines in Europe State of the Art. Transp. Res. Rec. 2008, 2043, 13–19. [Google Scholar] [CrossRef]

- Dhillon, B.S. Engineering Maintenance: A Modern Approach; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal. Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Budai-Balke, G. Operations Research Models for Scheduling Railway Infrastructure Maintenance; Rozenberg Publishers: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Jezzini, A.; Ayache, M.; Elkhansa, L.; Makki, B.; Zein, M. Effects of predictive maintenance (PdM), Proactive maintenace (PoM) & Preventive maintenance (PM) on minimizing the faults in medical instruments. In Proceedings of the 2013 2nd International Conference on Advances in Biomedical Engineering, Tripoli, Lebanon, 11–13 September 2013; pp. 53–56. [Google Scholar]

- Marino, F.; Distante, A.; Mazzeo, P.L.; Stella, E. A Real-Time Visual Inspection System for Railway Maintenance: Automatic Hexagonal-Headed Bolts Detection. IEEE Trans. Syst. Man Cybern. Part C 2007, 37, 418–428. [Google Scholar] [CrossRef]

- Mohammadi, R.; He, Q.; Ghofrani, F.; Pathak, A.; Aref, A. Exploring the impact of foot-by-foot track geometry on the occurrence of rail defects. Transp. Res. Part C Emerg. Technol. 2019, 102, 153–172. [Google Scholar] [CrossRef]

- Li, Z.; He, Q. Prediction of Railcar Remaining Useful Life by Multiple Data Source Fusion. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2226–2235. [Google Scholar] [CrossRef]

- Hajizadeh, S.; Núñez, A.; Tax, D.M.J. Semi-supervised Rail Defect Detection from Imbalanced Image Data. IFAC PapersOnLine 2016, 49, 78–83. [Google Scholar] [CrossRef]

- Falamarzi, A.; Moridpour, S.; Nazem, M. A review of rail track degradation prediction models. Aust. J. Civil. Eng. 2019, 17, 152–166. [Google Scholar] [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Kumar, U. Track geometry degradation and maintenance modelling: A review. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 73–102. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; D’Angelo, G. Review of the design and maintenance technologies used to decelerate the deterioration of ballasted railway tracks. Constr. Build. Mater. 2017, 157, 402–415. [Google Scholar] [CrossRef]

- Weston, P.; Roberts, C.; Yeo, G.; Stewart, E. Perspectives on railway track geometry condition monitoring from in-service railway vehicles. Veh. Syst. Dyn. 2015, 53, 1063–1091. [Google Scholar] [CrossRef]

- Elkhoury, N.; Hitihamillage, L.; Moridpour, S.; Robert, D. Degradation Prediction of Rail Tracks: A Review of the Existing Literature. TOTJ 2018, 12, 88–104. [Google Scholar] [CrossRef] [Green Version]

- Higgins, C.; Liu, X. Modeling of track geometry degradation and decisions on safety and maintenance: A literature review and possible future research directions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1385–1397. [Google Scholar] [CrossRef]

- Chenariyan Nakhaee, M.; Hiemstra, D.; Stoelinga, M.; van Noort, M. The Recent Applications of Machine Learning in Rail Track Maintenance: A Survey. In Reliability, Safety, and Security of Railway Systems. Modelling, Analysis, Verification, and Certification; Collart-Dutilleul, S., Lecomte, T., Romanovsky, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 91–105. [Google Scholar]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Keele, UK, 2004; Volume 33, pp. 1–26. [Google Scholar]

- Carvalho, T.P.; Soares, F.A.; Vita, R.; Francisco, R.P.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Rockwell, G.; Sinclair, S. Hermeneutica: Computer-Assisted Interpretation in the Humanities; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Edwards, J.R.; Hart, J.M.; Sawadisavi, S.; Resendiz, E.; Barkan, C.P.L.; Ahuja, N. Advancements in Railroad Track Inspection Using Machine-Vision Technology. In Proceedings of the AREMA Conference Proceedings on American Railway and Maintenance of Way Association, Chicago, IL, USA, 20–23 September 2009. [Google Scholar]

- Li, Q.; Zhong, Z.; Liang, Z.; Liang, Y. Rail Inspection Meets Big Data: Methods and Trends. In Proceedings of the 2015 18th International Conference on Network-Based Information Systems, Taipei, Taiwan, 2–4 September 2015; pp. 302–308. [Google Scholar]

- Podofillini, L.; Zio, E.; Vatn, J. Risk-informed optimisation of railway tracks inspection and maintenance procedures. Reliab. Eng. Syst. Saf. 2006, 91, 20–35. [Google Scholar] [CrossRef]

- McNamara, J.; Di Scalea, F.L.; Fateh, M. Automatic defect classification in long-range ultrasonic rail inspection using a support vector machine-based smart system. Insight Non Destr. Test. Cond. Monit. 2004, 46, 331–337. [Google Scholar] [CrossRef]

- Ravitharan, R. Instrumented Revenue Vehicles Drive Track Maintenance Efficiencies. Available online: https://www.monash.edu/irt/news/news/year-2018/instrumented-revenue-vehicles-drive-track-maintenance-efficiencies (accessed on 31 August 2020).

- Lingamanaik, S.N.; Thompson, C.; Nadarajah, N.; Ravitharana, R.; Widyastutib, H.; Chiuc, W.K. Using Instrumented Revenue Vehicles to Inspect Track Integrity and Rolling Stock Performance in a Passenger Network During Peak Times. Procedia Eng. 2017, 188, 424–431. [Google Scholar] [CrossRef]

- Tam, H.; Lee, K.; Liu, S.; Cho, L.; Cheng, K. Intelligent Optical Fibre Sensing Networks Facilitate Shift to Predictive Maintenance in Railway Systems. In Proceedings of the 2018 International Conference on Intelligent Rail Transportation (ICIRT), Singapore, 12–14 December 2018; pp. 1–4. [Google Scholar]

- An, R.; Sun, Q.; Wang, F.; Bai, W.; Zhu, X.; Liu, R. Improved Railway Track Geometry Degradation Modeling for Tamping Cycle Prediction. J. Transp. Eng. Part A Syst. 2018, 144, 04018025. [Google Scholar] [CrossRef]

- PHM for Rail Maintenance Management: At the Cross-Roads between Data Science and Physics. Available online: https://www.zhaw.ch/storage/engineering/institute-zentren/iamp/sp_acss/1._Dersin_PHM_Rail.pdf (accessed on 31 August 2020).

- Neapolitan, R.E. Artificial Intelligence: With an Introduction to Machine Learning, 2nd ed.; Chapman and Hall/CRC: London, UK, 2018. [Google Scholar]

- Sadeghi, J.; Askarinejad, H. Development of improved railway track degradation models. Struct. Infrastruct. Eng. 2010, 6, 675–688. [Google Scholar] [CrossRef]

- Audley, M.; Andrews, J. The effects of tamping on railway track geometry degradation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 376–391. [Google Scholar] [CrossRef]

- Chaolong, J.; Weixiang, X.; Futian, W.; Hanning, W. Track irregularity time series analysis and trend forecasting. Discret. Dyn. Nat. Soc. 2012, 2012, 1–15. [Google Scholar] [CrossRef]

- Lam, H.F.; Yang, J.H.; Hu, Q.; Ng, C.T. Railway ballast damage detection by Markov chain Monte Carlo-based Bayesian method. Struct. Health Monit. 2018, 17, 706–724. [Google Scholar] [CrossRef]

- Bai, L.; Liu, R.; Sun, Q.; Wang, F.; Xu, P. Markov-based model for the prediction of railway track irregularities. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2015, 229, 150–159. [Google Scholar] [CrossRef]

- Guler, H. Prediction of railway track geometry deterioration using artificial neural networks: A case study for Turkish state railways. Struct. Infrastruct. Eng. 2014, 10, 614–626. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, H.; Tian, G.; Yi, Q.; Zhao, J.; Zhen, K. Fast classification for rail defect depths using a hybrid intelligent method. Optik 2019, 180, 455–468. [Google Scholar] [CrossRef]

- Falamarzi, A.; Moridpour, S.; Nazem, M. Development of a tram track degradation prediction model based on the acceleration data. Struct. Infrastruct. Eng. 2019, 15, 1308–1318. [Google Scholar] [CrossRef]

- Tan, C.W.; Webb, G.; Petitjean, F.; Reichl, P. Machine learning approaches for tamping effectiveness prediction. In Proceedings of the International Heavy Haul Association Conference, Cape Town, South Africa, 2–6 September 2017. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Szegedy, C.; Toshev, A.; Erhan, D. Deep Neural Networks for Object Detection. In Advances in Neural Information Processing Systems 26; Burges, C.J.C., Bottou, L., Welling, M., Ghahramani, Z., Weinberger, K.Q., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2013; pp. 2553–2561. [Google Scholar]

- Ji, S.; Xu, W.; Yang, M.; Yu, K. 3D Convolutional Neural Networks for Human Action Recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 221–231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Faghih-Roohi, S.; Hajizadeh, S.; Núñez, A.; Babuska, R.; De Schutter, B. Deep convolutional neural networks for detection of rail surface defects. In Proceedings of the 2016 International Joint Conference on Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; pp. 2584–2589. [Google Scholar]

- Zauner, G.; Mueller, T.; Theiss, A.; Buerger, M.; Auer, F. Application of Semantic Segmentation for an Autonomous Rail Tamping Assistance System. Electron. Imaging 2019, 2019, 462-1–462-6. [Google Scholar] [CrossRef]

- Deng, L.; Yu, D. Deep Learning: Methods and Applications. SIG 2014, 7, 197–387. [Google Scholar] [CrossRef] [Green Version]

- Heidarysafa, M.; Kowsari, K.; Barnes, L.; Brown, D. Analysis of Railway Accidents’ Narratives Using Deep Learning. In Proceedings of the 2018 17th IEEE International Conference on Machine Learning and Applications (ICMLA), Orlando, FL, USA, 17–20 December 2018; pp. 1446–1453. [Google Scholar]

- Lopes Gerum, P.C.; Altay, A.; Baykal-Gürsoy, M. Data-driven predictive maintenance scheduling policies for railways. Transp. Res. Part C Emerg. Technol. 2019, 107, 137–154. [Google Scholar] [CrossRef]

- Pascanu, R.; Mikolov, T.; Bengio, Y. On the difficulty of training recurrent neural networks. In Proceedings of the 30th International Conference on Machine Learning, Atlanta, GA, USA, 16–21 June 2013; pp. III-1310–III-1318. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Ma, S.; Gao, L.; Liu, X.; Lin, J. Deep Learning for Track Quality Evaluation of High-Speed Railway Based on Vehicle-Body Vibration Prediction. IEEE Access 2019, 7, 185099–185107. [Google Scholar] [CrossRef]

- Huang, G.-B.; Wang, D.H.; Lan, Y. Extreme learning machines: A survey. Int. J. Mach. Learn. Cybern. 2011, 2, 107–122. [Google Scholar] [CrossRef]

- Schalk, R.; Vicencio, A.N.; Zoeteman, A.; Wolfert, R. Data Analytics for the of RCF Damages on the Dutch High Speed Line. In Proceedings of the 1st International Conference on Rail Transportation, Chengdu, China, 10–12 July 2017. [Google Scholar]

- Boutsidis, C.; Zouzias, A.; Mahoney, M.W.; Drineas, P. Randomized Dimensionality Reduction for $k$ -Means Clustering. IEEE Trans. Inf. Theory 2015, 61, 1045–1062. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Peng, Q.; Liu, R.; Liu, L.; Bai, L. Track grid health index for grid-based, data-driven railway track health evaluation. Adv. Mech. Eng. 2019, 11, 1687814019889768. [Google Scholar] [CrossRef]

- Blömer, J.; Lammersen, C.; Schmidt, M.; Sohler, C. Theoretical Analysis of the k-Means Algorithm—A Survey. In Algorithm Engineering: Selected Results and Surveys; Kliemann, L., Sanders, P., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 81–116. [Google Scholar]

- Rokach, L. Ensemble-based classifiers. Artif. Intell. Rev. 2010, 33, 1–39. [Google Scholar] [CrossRef]

- Cárdenas-Gallo, I.; Sarmiento, C.A.; Morales, G.A.; Bolivar, M.A.; Akhavan-Tabatabaei, R. An ensemble classifier to predict track geometry degradation. Reliab. Eng. Syst. Saf. 2017, 161, 53–60. [Google Scholar] [CrossRef]

- Lasisi, A.; Attoh-Okine, N. Machine Learning Ensembles and Rail Defects Prediction: Multilayer Stacking Methodology. ASCE ASME J. Risk Uncertain. Eng. Syst. Part A Civil. Eng. 2019, 5, 04019016. [Google Scholar] [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Arasteh Khouy, I.; Letot, C. Evaluation of the effect of tamping on the track geometry condition: A case study. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 232, 408–420. [Google Scholar] [CrossRef]

- Sharma, S.; Cui, Y.; He, Q.; Mohammadi, R.; Li, Z. Data-driven optimization of railway maintenance for track geometry. Transp. Res. Part C Emerg. Technol. 2018, 90, 34–58. [Google Scholar] [CrossRef]

- Lee, J.S.; Hwang, S.H.; Choi, I.Y.; Choi, Y. Deterioration Prediction of Track Geometry Using Periodic Measurement Data and Incremental Support Vector Regression Model. J. Transp. Eng. Part A Syst. 2020, 146, 04019057. [Google Scholar] [CrossRef]

- Li, D.; Meddah, A.; Hass, K.; Kalay, S. Relating track geometry to vehicle performance using neural network approach. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2006, 220, 273–281. [Google Scholar] [CrossRef]

- Bergmeir, C.; Sáinz, G.; Martínez Bertrand, C.; Benítez, J.M. A Study on the Use of Machine Learning Methods for Incidence Prediction in High-Speed Train Tracks. In Recent Trends in Applied Artificial Intelligence; Ali, M., Bosse, T., Hindriks, K.V., Hoogendoorn, M., Jonker, C.M., Treur, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 674–683. [Google Scholar]

- Molodova, M.; Li, Z.; Núñez, A.; Dollevoet, R. Automatic Detection of Squats in Railway Infrastructure. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1980–1990. [Google Scholar] [CrossRef] [Green Version]

- Schenkendorf, R.; Dutschk, B.; Lüddecke, K.; Groos, J.C. Improved Railway Track Irregularities Classification by a Model Inversion Approach. In Proceedings of the Third European Conference of the Prognostics and Health Management Society 2016; Eballard, I., Bregon, A., Eds.; Prognostics and Health Management Society: Bilbao, Spain, 2016; pp. 62–69. [Google Scholar]

- Tsunashima, H. Condition Monitoring of Railway Tracks from Car-Body Vibration Using a Machine Learning Technique. Appl. Sci. 2019, 9, 2734. [Google Scholar] [CrossRef] [Green Version]

- Oukhellou, L.; Côme, E.; Bouillaut, L.; Aknin, P. Combined use of sensor data and structural knowledge processed by Bayesian network: Application to a railway diagnosis aid scheme. Transp. Res. Part C Emerg. Technol. 2008, 16, 755–767. [Google Scholar] [CrossRef]

- Ni, Y.-Q.; Zhang, Q.-H. A Bayesian Machine Learning Approach for Online Wheel Condition Detection Using Track-side Monitoring. In Proceedings of the 2018 International Conference on Intelligent Rail Transportation (ICIRT), Singapore, 12–14 December 2018; pp. 1–6. [Google Scholar]

- Wang, Q.-A.; Ni, Y.-Q. Measurement and Forecasting of High-Speed Rail Track Slab Deformation under Uncertain SHM Data Using Variational Heteroscedastic Gaussian Process. Sensors 2019, 19, 3311. [Google Scholar] [CrossRef] [Green Version]

- Mazzeo, P.L.; Nitti, M.; Stella, E.; Distante, A. Visual recognition of fastening bolts for railroad maintenance. Pattern Recognit. Lett. 2004, 25, 669–677. [Google Scholar] [CrossRef]

- Resendiz, E.; Molina, L.F.; Hart, J.M.; Edwards, J.R. Development of a machine-vision system for inspection of railway track components. In Proceedings of the 12th World Conference on Transport Research, Lisbon, Portugal, 11–15 July 2010; p. 22. [Google Scholar]

- Santur, Y.; Karaköse, M.; Akın, E. Condition Monitoring Approach Using 3D-Modelling of Railway Tracks With Laser Cameras. In Proceedings of the International Conference on Advanced Technology & Sciences (ICAT’16), Konya, Turkey, 1–3 September 2016; pp. 132–135. [Google Scholar]

- Lu, S.; Liu, Z.; Shen, Y. Automatic Fault Detection of Multiple Targets in Railway Maintenance Based on Time-Scale Normalization. IEEE Trans. Instrum. Meas. 2018, 67, 849–865. [Google Scholar] [CrossRef]

- Berggren, E.G. Efficient Track Maintenance: Methodology for Combined Analysis of Condition Data. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2010, 224, 353–360. [Google Scholar] [CrossRef]

- Santur, Y.; Karakose, M.; Akin, E. A new rail inspection method based on deep learning using laser cameras. In Proceedings of the 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), Malatya, Turkey, 16–17 September 2017; pp. 1–6. [Google Scholar]

- Li, Y.; Otto, C.; Haas, N.; Fujiki, Y.; Pankanti, S. Component-based track inspection using machine-vision technology. In Proceedings of the 1st ACM International Conference on Multimedia Retrieval, Trento, Italy, 17–20 April 2011; pp. 1–8. [Google Scholar]

- Resendiz, E.; Hart, J.M.; Ahuja, N. Automated Visual Inspection of Railroad Tracks. IEEE Trans. Intell. Transp. Syst. 2013, 14, 751–760. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Parikh, D.; He, Q.; Qian, B.; Li, Z.; Fang, D.; Hampapur, A. Improving rail network velocity: A machine learning approach to predictive maintenance. Transp. Res. Part C Emerg. Technol. 2014, 45, 17–26. [Google Scholar] [CrossRef]

- Wang, G.; Xu, T.; Tang, T.; Yuan, T.; Wang, H. A Bayesian network model for prediction of weather-related failures in railway turnout systems. Expert Syst. Appl. 2017, 69, 247–256. [Google Scholar] [CrossRef]

- Xie, W.; Nunez, A.; Maas, R.; Li, Z. Decision support tool based on multi-source data analysis for the tram wheel-rail interface. IFAC PapersOnLine 2018, 51, 118–123. [Google Scholar] [CrossRef]

- Hu, C.; Liu, X. Modeling Track Geometry Degradation Using Support Vector Machine Technique. Am. Soc. Mech. Eng. Digit. Collect. 2016. [Google Scholar] [CrossRef]

- Bukhsh, Z.A.; Saeed, A.; Stipanovic, I. A machine learning approach for maintenance prediction of railway assets. Transp. Res. Arena 2018, 2018. [Google Scholar] [CrossRef]

- Andrade, A.R.; Teixeira, P.F. A Bayesian model to assess rail track geometry degradation through its life-cycle. Res. Transp. Econ. 2012, 36, 1–8. [Google Scholar] [CrossRef]

- Lasisi, A.; Martey, E.N.; Guillot, D.; Attoh-Okine, N. A three-step agglomerated Machine Learning: An alternative to Weibull Defect Analysis of Rail Infrastructure. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 4508–4515. [Google Scholar]

- Allah Bukhsh, Z.; Saeed, A.; Stipanovic, I.; Doree, A.G. Predictive maintenance using tree-based classification techniques: A case of railway switches. Transp. Res. Part C Emerg. Technol. 2019, 101, 35–54. [Google Scholar] [CrossRef]

- Li, H.; Qian, B.; Parikh, D.; Hampapur, A. Alarm prediction in large-scale sensor networks—A case study in railroad. In Proceedings of the 2013 IEEE International Conference on Big Data, Silicon Valley, CA, USA, 6–9 October 2013; pp. 7–14. [Google Scholar]

- Tsui, K.L.; Chen, N.; Zhou, Q.; Hai, Y.; Wang, W. Prognostics and Health Management: A Review on Data Driven Approaches. Math. Probl. Eng. 2015, 2015, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Lederman, G.; Chen, S.; Garrett, J.; Kovačević, J.; Noh, H.Y.; Bielak, J. Track-monitoring from the dynamic response of an operational train. Mech. Syst. Signal. Process. 2017, 87, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Gröchenig, K. Foundations of Time-Frequency Analysis; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- El-Sibaie, M.; Zhang, Y.-J. Objective Track Quality Indices. Transp. Res. Rec. 2004, 1863, 81–87. [Google Scholar] [CrossRef]

- Berawi, A.R.B.; Delgado, R.; Calçada, R.; Vale, C. Evaluating track geometrical quality through different methodologies. Int. J. Technol. 2010, 1, 38–47. [Google Scholar]

- Madejski, J.; Grabczyk, J. Continuous geometry measurement for diagnostics of tracks and switches. In Proceedings of the International Conference on Switches, Delft, The Netherlands, 19–22 March 2002; p. 20. [Google Scholar]

- Talukdar, K.; Arulmozhi, U.; Prabhakar, K.; Satyanarayan. Project Presentation Improvement of TGI Value by Computer Analysis; Ministry of Railways, Indian Railways Institute of Civil Engineering: Pune, India, 2006.

- EN 13848-5. Railway Applications-Track-Track Geometry Quality-Part. 5: Geometric Quality Assessment; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Lasisi, A.; Attoh-Okine, N. Principal components analysis and track quality index: A machine learning approach. Transp. Res. Part C Emerg. Technol. 2018, 91, 230–248. [Google Scholar] [CrossRef]

- Nadarajah, N.; Shamdani, A.; Hardie, G. Prediction of railway vehicles’ dynamic behaviour with machine learning algorithms. In Proceedings of the CORE 2018: Conference on Railway Excellence, Sydney, Australia, 30 April–2 May 2018; p. 452. [Google Scholar]

- Sun, Y.; Liu, Y.; Yang, C. Railway Joint Detection Using Deep Convolutional Neural Networks. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 235–240. [Google Scholar]

- Sakoe, H.; Chiba, S. Dynamic programming algorithm optimization for spoken word recognition. IEEE Trans. Acoust. Speech Signal Process. 1978, 26, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Narezo Guzman, D.; Hadzic, E.; Samson, H.; van den Broek, S.; Groos, J.C. Detecting anomalous behavior of railway switches under real operation conditions: Workflow and implementation. In Proceedings of the Transport Research Arena 2020, Helsinki, Finland, 27–30 April 2020. [Google Scholar]

- Zhang, G.P. Time series forecasting using a hybrid ARIMA and neural network model. Neurocomputing 2003, 50, 159–175. [Google Scholar] [CrossRef]

- Gibert, X.; Patel, V.M.; Chellappa, R. Robust Fastener Detection for Autonomous Visual Railway Track Inspection. In Proceedings of the 2015 IEEE Winter Conference on Applications of Computer Vision, Waikoloa, HI, USA, 5–9 January 2015; pp. 694–701. [Google Scholar]

- Li, Y.; Trinh, H.; Haas, N.; Otto, C.; Pankanti, S. Rail Component Detection, Optimization, and Assessment for Automatic Rail Track Inspection. IEEE Trans. Intell. Transp. Syst. 2014, 15, 760–770. [Google Scholar] [CrossRef]

- Voulodimos, A.; Doulamis, N.; Doulamis, A.; Protopapadakis, E. Deep learning for computer vision: A brief review. Comput. Intell. Neurosci. 2018, 2018. [Google Scholar] [CrossRef] [PubMed]

- Jamshidi, A.; Faghih-Roohi, S.; Hajizadeh, S.; Núñez, A.; Babuska, R.; Dollevoet, R.; Li, Z.; De Schutter, B. A Big Data Analysis Approach for Rail Failure Risk Assessment: Big Data Analysis Approach for Rail Failure Risk Assessment. Risk Anal. 2017, 37, 1495–1507. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, L.; Wang, L.; Zhang, Z.; Tsui, K.L. Automated vision inspection of rail surface cracks: A double-layer data-driven framework. Transp. Res. Part C Emerg. Technol. 2018, 92, 258–277. [Google Scholar] [CrossRef]

- Zhang, H.; William, D.; Marsh, R. Bayesian network models for making maintenance decisions from data and expert judgment. In Risk, Reliability and Safety: Innovating Theory and Practice; Walls, L., Revie, M., Bedford, T., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 1056–1063. [Google Scholar]

- Mercy, K.G.; Srinivasa, R.; Sri, K. A Framework for Rail Surface Defect Prediction Using Machine Learning Algorithms. In Proceedings of the 2018 International Conference on Inventive Research in Computing Applications (ICIRCA), Coimbatore, India, 11–12 July 2018; pp. 972–977. [Google Scholar]

- Soleimani, S.; Mohammadi, A.; Chen, J.; Leitner, M. Mining the Highway-Rail Grade Crossing Crash Data: A Text Mining Approach. In Proceedings of the 18th IEEE International Conference On Machine Learning And Applications (ICMLA), Boca Raton, FL, USA, 16–19 December 2019; pp. 1063–1068. [Google Scholar]

- Ghofrani, F.; He, Q.; Goverde, R.M.P.; Liu, X. Recent applications of big data analytics in railway transportation systems: A survey. Transp. Res. Part C Emerg. Technol. 2018, 90, 226–246. [Google Scholar] [CrossRef]

- Ishida, M.; Akama, M.; Kashiwaya, K.; Kapoor, A. The current status of theory and practice on rail integrity in Japanese railways—rolling contact fatigue and corrugations. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 909–919. [Google Scholar] [CrossRef]

- Andrade, A.R.; Teixeira, P.F. Hierarchical Bayesian modelling of rail track geometry degradation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 364–375. [Google Scholar] [CrossRef]

- Falamarzi, A.; Moridpour, S.; Nazem, M.; Hesami, R. Rail Degradation Prediction Models for Tram System: Melbourne Case Study. J. Adv. Transp. 2018, 2018, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Falamarzi, A.; Moridpour, S.; Nazem, M.; Cheraghi, S. Development of Random forests regression model to predict track degradation index: Melbourne case study. In Proceedings of the 40th Australian Transport Research Forum, Darwin, Australia, 30 October–1 November 2018; Volume 13. [Google Scholar]

- Santur, Y.; Karakose, M.; AKIN, E. An adaptive fault diagnosis approach using pipeline implementation for railway inspection. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 987–998. [Google Scholar] [CrossRef]

- Jamshidi, A.; Roohi, S.F.; Núñez, A.; Babuska, R.; De Schutter, B.; Dollevoet, R.; Li, Z. Probabilistic Defect-Based Risk Assessment Approach for Rail Failures in Railway Infrastructure. IFAC PapersOnLine 2016, 49, 73–77. [Google Scholar] [CrossRef]

- Molodova, M.; Oregui, M.; Núñez, A.; Li, Z.; Dollevoet, R. Health condition monitoring of insulated joints based on axle box acceleration measurements. Eng. Struct. 2016, 123, 225–235. [Google Scholar] [CrossRef] [Green Version]

- Arasteh Khouy, I. Cost-Effective Maintenance of Railway Track Geometry: A Shift from Safety Limits to Maintenance Limits. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2013. [Google Scholar]

- Mercier, S.; Meier-Hirmer, C.; Roussignol, M. Bivariate Gamma wear processes for track geometry modelling, with application to intervention scheduling. Struct. Infrastruct. Eng. 2012, 8, 357–366. [Google Scholar] [CrossRef] [Green Version]

- Meghoe, A.; Loendersloot, R.; Tinga, T. Rail wear and remaining life prediction using meta-models. Int. J. Rail Transp. 2020, 8, 1–26. [Google Scholar] [CrossRef]

- Famurewa, S.M.; Juntti, U.; Nissen, A.; Kumar, U. Augmented utilisation of possession time: Analysis for track geometry maintenance. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1118–1130. [Google Scholar] [CrossRef]

- Consilvio, A.; Di Febbraro, A.; Meo, R.; Sacco, N. Risk-based optimal scheduling of maintenance activities in a railway network. Eur. J. Transp. Logist. 2019, 8, 435–465. [Google Scholar] [CrossRef]

- Consilvio, A.; Febbraro, A.D.; Sacco, N. A Rolling-Horizon Approach for Predictive Maintenance Planning to Reduce the Risk of Rail Service Disruptions. IEEE Trans. Reliab. 2020, 1–13. [Google Scholar] [CrossRef]

- Adey, B.T.; Jamali, A. On the role of inspections and interventions in infrastructure management. Mater. Corros. 2012, 63, 1134–1146. [Google Scholar] [CrossRef]

- Hotho, A.; Nürnberger, A.; Paaß, G. A brief survey of text mining. Ldv Forum 2015, 20, 19–62. [Google Scholar]

- Lipton, Z.C. The mythos of model interpretability. Queue 2018, 16, 31–57. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, S. Visual interpretability for deep learning: A survey. Front. Inf. Technol. Electron. Eng. 2018, 19, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Létourneau, S. Learning to predict train wheel failures. In Proceedings of the Eleventh ACM SIGKDD International Conference on Knowledge Discovery in Data Mining; Association for Computing Machinery: Chicago, IL, USA, 2005; pp. 516–525. [Google Scholar]

| Characteristics | Descriptions | Examples |

|---|---|---|

| Large-volume | Collecting huge amounts of data from two aspects: Time domain (real-time, nearly real-time or streamlines). Space domain (thousands of miles). | More than 60 million records of track geometry measurement data set were collected in a U.S. Class I rail network for 100 miles from 2012 to 2017 [11]. |

| Multi-source | Multi-source refers to the various measurement methods from which data can be generated in multiple types. | Predict the remaining useful life of railcar by fusing data from wheel impact load detector, machine vision systems and optical geometry detectors [12]. |

| Highly-imbalanced | The rail defects are highly skewed in the collected data sets. Majority of observations belong to the normal states while only a small portion are related to defects. | Pre-process the imbalanced rail image data by sampling techniques and semi-supervised techniques before rail defect detection [13]. |

| High noise | Noise come from two aspects during the data collection: The inherent environmental uncertainty along the track: soil type, climate condition, track profile, and materials. The precision of sensors. | Use of derivatives and smoothing can reduce the noise present in the raw measurements and thus improve the quality of the signal [12]. |

| Methods | Technologies | Monitoring Objects | Advantages | Disadvantages | |

|---|---|---|---|---|---|

| Walking patrols | Visual, ultrasonic testing | Ballast section, ties, fasteners, rail head | Flexible | Time-consuming, unsafe | |

| Mechanized track patrols | Specific inspection cars | Camera-based measurement, ultrasonic testing, vibration acoustic, eddy, laser, magnetic | Track geometry, rail head, ties, fasteners, substructure | Efficient, multi-channel data verification, periodic | High-cost, low frequency |

| In-service vehicles | Camera-based measurement, ultrasonic testing, vibration, displacement | Track geometry, rail head, ties, fasteners | Efficient, flexible, multi-channel data verification, real-time monitoring | High-noise level | |

| Wayside detectors | Fiber, meteorological sensor, impact load detector | Rail head, wheel-rail interactions, temperature, weather | High stability | High-cost | |

| Data-Driven Models | Advantage | Disadvantage | Application | |

|---|---|---|---|---|

| Statistical models | Regression modeling (e.g., multivariable regression, multi-stage regression) | Simple; interpretability | Prior knowledge of the data is needed to select the best fitting model | Estimating the remaining useful life of railway track [34] |

| Probability distribution model (e.g., Weibull, normal, lognormal and extreme value distributions) | Simple; interpretability | Based on specific hypotheses | Prediction of track failure time [35] | |

| Time series model (e.g., autoregressive (AR), autoregressive integrated moving average (ARIMA)) | Interpretability | Time series is required to be stationary | Prediction of the short-term trend of track irregularity [36] | |

| Bayesian methods (e.g., Bayesian inference, Markov Chain Monte Carlo (MCMC)) | Stable; better performance for small dataset size | Predictors are required to be independent; prior distribution assumption needed | Investigation of the rail squat failure probability using Bayesian inference [37] | |

| Stochastic process (e.g., Markov process, Gaussian process, Gamma process) | Better performance in process status prediction | Based on specific hypotheses; not suitable for mid to long-term system prediction | Evaluating the deterioration of track geometry based on Markov process [38] | |

| Classical machine learning model | ANN | Robust; no expert knowledge is needed | Time-consuming; poor interpretability | Prediction of average track degradation rates [39] |

| SVM | Efficiency in small data size; ability to deal with nonlinear characteristics | Poor interpretability; sensitive to kernel function | Fast classification and evaluation of rolling contact fatigue (RCF) defects in tracks [40] | |

| Tree-based model (e.g., decision tree, random forest) | Interpretability | Overfitting on noisy data | Prediction of tram track degradation index [41] | |

| K-nearest neighbors (KNN) | Simple; interpretability | Not easy to determine hyper-parameter k; sensitive to data distribution | Classification of tamping effectiveness [42] | |

| Data type | Measurement | Recent Applications |

|---|---|---|

| Time series | Track geometry recording car | [62,63,64] |

| Ultrasonic | [27,40,55,65] | |

| In-service vehicles | [66,67,68,69] | |

| Eddy | [55,70] | |

| Fiber | [30,71,72] | |

| Image | Camera | [73,74,75,76] |

| Ground penetrating radar | [74,77] | |

| Laser | [40,75,78] | |

| Video | Camera | [13,24,79,80] |

| Discrete value | Temperature, weather | [30,81,82,83] |

| Rail condition | [81,84,85] | |

| Tonnage | [11,86,87] | |

| Text record | Accident/maintenance records | [49,81,88] |

| Track Defects | Equipment | Feature | Data-Driven Method | Reference |

|---|---|---|---|---|

| Geometry irregularity | Track geometry recording car, operation records, maintenance records | Standard deviation of longitudinal level, tonnage, past maintenance, and renewal actions | Bayesian method | [114] |

| Track geometry recording car | Geometric defect type, class of track, tonnage | Ensemble of gamma process, logistic regression, and SVM | [60] | |

| Track geometry recording car | Gauge deviation | ANN | [115] | |

| Track geometry recording car | Track degradation index based on gauge deviation | Random forest | [116] | |

| In-service vehicles on-board sensing device | Vertical and lateral accelerations and the roll rate of the car body | SVM | [69] | |

| Rail head defects | Camera | Adaptive blur removal for images | CNN | [117] |

| Laser-ultrasonic technology | Wavelet packet time-frequency coefficient, energy and local entropy (using wavelet packet transform and kernel principal component) | SVM | [40] | |

| Ultrasonic and rail surface photos | Severity categories of the squats | Bayesian inference method | [118] | |

| Sperry’s eddy current walking stick | Maintenance, track geometry, and rolling stock parameters | Clustering | [55] | |

| Missing rail component | Camera | Hog features | SVM | [104] |

| Gabor-filtered images | Multiple signal classification | [80] | ||

| Rail break | In-service vehicles | Axle box acceleration | Continuous wavelet transform | [119] |

| Eddy current sensor | Eddy current signals | Bayesian network | [70] | |

| Substructure failure: sleeper and ballast | Fiber bragg grating | Track slab deformation | Variational heteroscedastic Gaussian process | [72] |

| Camera | Stiffness of the ballast | Bayesian method | [37] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Huang, J.; Zeng, C.; Jiang, S.-H.; Podlich, N. Systematic Literature Review on Data-Driven Models for Predictive Maintenance of Railway Track: Implications in Geotechnical Engineering. Geosciences 2020, 10, 425. https://doi.org/10.3390/geosciences10110425

Xie J, Huang J, Zeng C, Jiang S-H, Podlich N. Systematic Literature Review on Data-Driven Models for Predictive Maintenance of Railway Track: Implications in Geotechnical Engineering. Geosciences. 2020; 10(11):425. https://doi.org/10.3390/geosciences10110425

Chicago/Turabian StyleXie, Jiawei, Jinsong Huang, Cheng Zeng, Shui-Hua Jiang, and Nathan Podlich. 2020. "Systematic Literature Review on Data-Driven Models for Predictive Maintenance of Railway Track: Implications in Geotechnical Engineering" Geosciences 10, no. 11: 425. https://doi.org/10.3390/geosciences10110425

APA StyleXie, J., Huang, J., Zeng, C., Jiang, S. -H., & Podlich, N. (2020). Systematic Literature Review on Data-Driven Models for Predictive Maintenance of Railway Track: Implications in Geotechnical Engineering. Geosciences, 10(11), 425. https://doi.org/10.3390/geosciences10110425