Ore Petrography Using Optical Image Analysis: Application to Zaruma-Portovelo Deposit (Ecuador)

Abstract

:1. Introduction

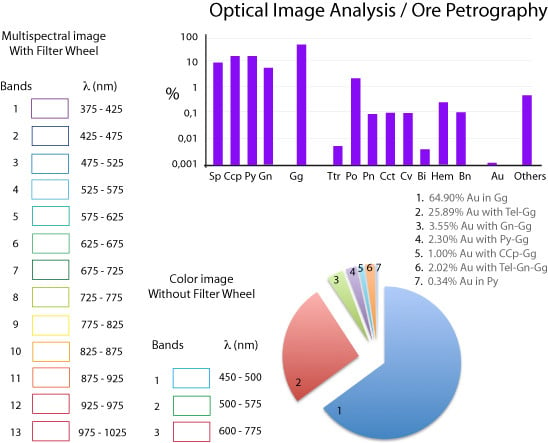

- Case I: Quantifying abundance (area) of the principal ore minerals in polished section using microscope objective lens 20×.

- Case II: Quantifying gold mineral abundance (area), its relation with other minerals (i.e., mineral association) and other geometrical parameters (equivalent circle diameter (diameter), minimum feret diameter (breadth)) in polished sections where gold was identified using objective lens 20×.

2. Geological Setting and Ore Mineralogy

3. Materials and Methods

3.1. Sample Selection and Techniques

3.2. Setup of Equipment

3.3. Image Acquisition

- Selection of region of interest by manual focusing under non-polarized reflected light conditions. The ore samples were studied using objective lens 20× (N.A. 0.5). Total magnification was 460× (Table 2).

- Automated establishment of the initial filter light conditions in the optical microscope. For each of the 13 filters an image of the same mineral scene is produced (noted as band 1 to 13). The image with the first filter corresponding to band 1 (375–425 nm bandwidth) is acquired (Figure 3b).

- Time averaging: Eight images of the same scene with the first filter in a t-interval of 100 ms were acquired and averaged into a primary average image of band 1. This automated operation reduces electronic noise generated by the camera.

- Saving the image in .tif format.

- Automated movement of filter wheel to filter 2 (425–475 nm bandwidth), generating an image of band 2. This is followed by Steps 3 and 4 again. This operation was performed using all filters, producing 13 primary average images (Figure 3b).

- Selection a new region of interest with automated (X-Y) displacements and focus (Z). The sequence is repeated until all regions of interest (≈200) are studied. Acquisition and quantification of 200 frames take about 4 h (each frame: 1.2 min).

- 7.

- Selection of region of interest by manual focusing under non polarized reflected light conditions. The ore samples were studied using objective lens 20× (N.A. 0.5). Total magnification was 460× (Table 2).

- 8.

- Time averaging: Images of the same scene in a t-interval of 100 ms were considered as a primary average image. This operation reduces electronic noise generated by the camera.

- 9.

- Saving the image in .tif format.

- 10.

- Automated separation of the color image into three channels: R, G and B.

- 11.

- Selection a new region of interest with automated (X-Y) displacements and focus (Z). We repeated the sequence until all regions of interest (gold) were studied.

3.4. Image Segmentation

- Grey levels of each ore mineral in the polished section were calculated using a supervised training step. Sampling windows (10 × 10 pixels) were placed on regions that could be clearly considered as a specific ore mineral (mineral 1) in a primary average image (band 1). Normal distributions of grey levels were defined for the studied population.

- For the mineral studied in band 1, mean (x) and standard deviation (σ) parameters were calculated. Segmentation ranges were defined as (x ± 3σ), with significance level of Y: 99.9%.

- Saving the segmentation ranges for mineral 1 in band 1.

- Selecting a new ore mineral (mineral 2) on an image in band 1 and repeating Steps 1 to 3 until covering all minerals (14 ore minerals + gangue) in this band.

- Selecting a new image (band 2) and repeating Steps 1 to 4. This operation is executed until all 13 bands or 3 bands are studied in multispectral image analysis or RGB image analysis, respectively.

3.5. Feature Extraction

4. Results

4.1. Microscopic Identification of Ore Minerals

4.2. Ore Characterization by OIA (Case I)

4.3. Gold Characterization by OIA (Case II)

5. Discussion

5.1. OIA System

5.2. OIA Measures

6. Conclusions

- The application, as well for optical as for SEM-based systems, should be supervised by an expert, and not be understood as a blackbox. A prior qualitative description of the mineralogy and information about the mineral deposit from which the ore samples come from may be welcome inputs, since the introduction of these mineralogical and metallogenetic criteria in the process of automated identification of mineral phases may avoid confusion in the recognition of mineral phases with equivalent GL response.

- Equipment set-up ensuring optimum acquisition of images. Control of physical and electronic factors (polishing quality, stability-intensity light source, noise removal, etc.) during image acquisition limits the GL variation in the mineral phases, facilitating proper identification.

- A preliminary study of GL responses (R, G and B bands in the color image and 13 bands in multispectral image) of the identified mineral phases to check ore identities with segmentation ranges defined in the literature, or available at [6,43]. The application of segmentation ranges for minerals of interest is performed for each of the distinct bands composing the images (color/multispectral), guaranteeing a correct classification.

- The OIA systematic described in this paper can be applied in the study of other mineral deposits in the world. OIA could be used to provide initial ore mineral quantification at polished section scale with relatively low economic investment. It is a simple and accessible method that ensures the reproducibility of measurements and processes by following clearly defined protocols.

- Automated identification and quantification of 15 mineral phases using multispectral images (Case 1) was carried out. These phases were previously identified with reflected light optical microscopy and by visual inspection with a binocular microscope, and they agreed with the expectations based on previous studies. The results of this experiment show that the ore mineral quantification on polished sections is possible applying OIA methods, allowing obtaining complementary information to traditional (qualitative) ore petrographic studies.

- Detailed characterization of gold present in two of the polished samples (Case 2) was carried out using RGB images. Color images were acquired with 20× magnification of all the grains of gold present (299). These quantifications may provide an important contribution to more detailed studies focused on geometallurgical optimization through measurements of mineral associations, mineral liberation grade, mineral grain size and distribution and textural data.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Amp | amphibole |

| Au | gold |

| Bi | bismuth native |

| Gn | galena |

| Au | gold |

| Hem | hematite |

| Bi | bismuth native |

| Lm | limonite |

| Bn | bornite |

| Py | pyrite |

| Ccp | chalcopyrite |

| Pn | pentlandite |

| Cct | chalcocite |

| Po | pyrrhotite |

| Chl | chlorite |

| Sp | sphalerite |

| Cv | covellite |

| Tel | tellurides |

| Ep | epidote |

| Ttr | tetrahedrite |

| Gg | gangue |

| Qz | quartz (Whitney and Evans, 2010) |

| OIA | Optical Image Analysis |

| MLA | Mineral liberation analyzer |

| QEMSCAN | Quantitative evaluation of minerals by scanning electron microscopy |

| CCD | Charge-coupled device |

| GL | Grey levels |

| RGB | Red, green and blue system |

| B/W | Black and white |

| OpM | Optical microscopy |

| SEM | Scanning electron microscopy |

| ETSIM | Escuela Superior de Ingenieros de Minas |

| IGME | Instituto Geológico y Minero de España |

| IR | Infrared |

| UV | UltraViolet |

| CAMEVA | Automated system for the identification and quantitative measurement of ore minerals |

| VNIR | The visible and near-infrared |

| CSD | Crystal size distribution |

References

- Agarwal, J.C.; Schapiro, N.; Mallio, M.J. Process petrography and ore deposits. Min. Congr. J. 1976, 62, 28–35. [Google Scholar]

- Amstutz, G.C. How microscopy can increase recovery in your milling circuit. Min. World 1962, 24, 19–23. [Google Scholar]

- Schwartz, G.M. Solving metallurgical problems with the reflecting microscope. Eng. Min. J. 1923, 116, 237–238. [Google Scholar]

- Craig, J.; Vaughan, D. Ore Microscopy & Ore Petrography, 1st ed.; John Wiley and Sons. Inc.: New York, NY, USA, 1981; p. 406. [Google Scholar]

- Poliakov, A.; Donskoi, E. Automated relief-based discrimination of non-opaque minerals in optical image analysis. Miner. Eng. 2013, 55, 111–124. [Google Scholar] [CrossRef]

- Berrezueta, E.; Castroviejo, R. Automated microscopic characterization of metallic ores with image analysis: A key to improve ore processing. I: Test of the methodology. Rev. Metal. 2007, 43, 294–309. [Google Scholar] [CrossRef] [Green Version]

- Castroviejo, R.; Berrezueta, E. Automated microscopic characterization of metallic ores with image analysis: A key to improve ore processing. II. Metallogenetic discriminating criteria. Rev. Metal. 2009, 45, 439–456. [Google Scholar] [CrossRef] [Green Version]

- Ehrlich, R.; Kennedy, S.K.; Crabtree, S.J.; Cannon, R.L. Petrographic image analysis: Analysis of reservoir pore complexes. J. Sediment. Petrol. 1984, 54, 1365–1378. [Google Scholar]

- Grove, C.; Jerram, D.A. jPOR: An ImageJ macro to quantify total optical porosity from blue-stained thin sections. Comput. Geosci. 2011, 37, 1850–1859. [Google Scholar] [CrossRef]

- Russ, J.C. Computer Assisted Microscopy the Measurement and Analysis of Images, 1st ed.; Plenum Press: New York, NY, USA, 1990; p. 453. [Google Scholar]

- Pirard, E.; Lebrun, V.; Nivart, J.F. Optimal image acquisition of video images of reflected light. Eur. Microsc. Anal. 1999, 60, 9–11. [Google Scholar]

- Reedy, C.L. Review of digital image analysis of petrographic thin sections in conservation research. J. Am. Inst. Conserv. 2006, 45, 127–146. [Google Scholar] [CrossRef]

- Anderson, K.F.E.; Wall, F.; Rollinson, G.K.; Moon, C.J. Quantitative mineralogical and chemical assessment of the Nkout iron ore deposit, Southern Cameroon. Ore Geol. 2014, 62, 25–39. [Google Scholar] [CrossRef]

- Rollinson, G.K.; Andersen, J.C.O.; Stickland, R.J.; Boni, M.; Fairhurst, R. Characterisation of non-sulphide zinc deposits using QEMSCAN®. Miner. Eng. 2011, 24, 778–787. [Google Scholar] [CrossRef]

- Santoro, L.; Boni, M.; Rollinston, G.K.; Mondillo, G.; Balassone, G.; Clegg, A.M. Mineralogical characterization of the Hakkari nonsulfide Zn(Pb) deposit (Turkey): The benefits of QEMSCAN®. Miner. Eng. 2014, 69, 29–39. [Google Scholar] [CrossRef]

- Donskoi, E.; Suthers, S.P.; Fradd, S.B.; Young, J.M.; Campbell, J.J.; Raynlyn, T.D.; Clout, J.M.F. Utilization of optical image analysis and automatic texture classification for iron ore particle characterisation. Miner. Eng. 2007, 20, 461–471. [Google Scholar] [CrossRef]

- Lane, G.R.; Martin, C.; Pirard, E. Techniques and applications for predictive metallurgy and ore characterization using optical image analysis. Miner. Eng. 2008, 21, 568–577. [Google Scholar] [CrossRef]

- Spring, K.R. Cameras for digital microscopy. Methods Cell Biol. 2007, 81, 171–186. [Google Scholar] [PubMed]

- Köse, C.; Alp, I.; Ikibas, C. Statistical methods for segmentation and quantification of minerals in ore microscopy. Miner. Eng. 2012, 30, 19–32. [Google Scholar] [CrossRef]

- Berrezueta, E.; Castroviejo, R.; Pantoja, F.; Álvarez, R. Mineralogical study and digital image analysis quantification of gold ores from Nariño (Colombia). Application to the improvement of the ore processing. Bol. Geol. Min. 2002, 113, 369–379. [Google Scholar]

- Castroviejo, R.; Berrezueta, E.; Lastra, R. Microscopic digital image analyses of gold ores. A critical test of the methodology, comparing Reflected Light and SEM. Miner. Metall. Process. 2002, 19, 102–109. [Google Scholar]

- Goodall, W.R.; Scales, P.J. An overview of the advantages and disadvantages of the determination of gold mineralogy by automated mineralogy. Miner. Eng. 2007, 20, 506–517. [Google Scholar] [CrossRef]

- Petersen, K.R.P.; Aldrich, C.; Van Deventer, J.S.J. Analysis of ore particles based on textural pattern recognition. Miner. Eng. 1998, 11, 959–977. [Google Scholar] [CrossRef]

- Castroviejo, R.; Brea, C.; Pérez-Barnuevo, L.; Catalina, J.C.; Segundo, F.; Bernhard, H.J.; Pirard, E. Using computer vision for microscopic identification of ores with reflected light: Preliminary results. In Proceedings of the 10th biennial SGA Meeting, Smart Science for exploration and Mining, Townsville, Australia, 17–20 August 2009; pp. 682–684.

- Delbem, I.D.; Galéry, R.; Brandão, P.R.G.; Peres, A.E.C. Semi-automated iron ore characterisation based on optical microscope analysis: Quartz/resin classification. Miner. Eng. 2015, 82, 2–13. [Google Scholar] [CrossRef]

- Bartolacci, G.; Pelletier, P.; Tessier, J.; Duchesne, C.; Bosse, P.A.; Fournier, J. Application of numerical image analysis to process diagnosis and physical parameter measurement in mineral processes-Part I: Flotation control base on froth textural characteristics. Miner. Eng. 2006, 19, 734–747. [Google Scholar] [CrossRef]

- Pérez-Barnuevo, L.; Pirard, E.; Castroviejo, R. Textural descriptors for multiphasic ore particles. Image Anal. Stereol. 2012, 31, 175–184. [Google Scholar] [CrossRef]

- Benvie, B. Mineralogical imaging of Kimberlites using SEM-based techniques. Miner. Eng. 2007, 20, 435–443. [Google Scholar] [CrossRef]

- Pirard, E. Multispectral imaging of ore minerals in optical microscopy. Mineral. Mag. 2004, 68, 323–333. [Google Scholar] [CrossRef]

- Rivard, B.; Feng, J.; Gallie, A. Continuous wavelets for the improved use of spectral libraries and hyperspectral data. Remote Sens. Environ. 2008, 112, 2850–2862. [Google Scholar] [CrossRef]

- Criddle, A.J.; Stanley, C.J. Quantitative Data File for Minerals, 3rd ed.; Chapman Hall: London, UK, 1993; p. 635. [Google Scholar]

- Catalina, J.C.; Sagundo, F.; Brea, C.; Pérez-Barnuevo, L.; Samper, J.; Espí, J.A.; Sánchez, L.; Castoviejo, R. Use of multi-spectral analysis for automatic identification of ores. Geogaceta 2009, 46, 47–50. [Google Scholar]

- Pirard, E.; Bernhardt, H.D.; Catalina, J.C.; Brea, C.; Segundo, F.; Castroviejo, C. From Spectrophotometry to Multiespectral Image of Ore Minerals in Visible and Near Infrared (VNIR) Microscopy. In Proceedings of the Ninth International Congress for Applied Mineralogy, Brisbane, Australia, 8–10 September 2008.

- Donskoi, E.; Poliakov, A.; Holmes, R.; Suthers, S.; Ware, N.; Manuel, J.; Clout, J. Iron ore textural information is the key for prediction of downstream process performance. Miner. Eng. 2016, 86, 10–23. [Google Scholar] [CrossRef]

- Bonifazi, G. Digital multispectral techniques and automated image analysis procedures for industrial ore modeling. Miner. Eng. 1995, 8, 779–794. [Google Scholar] [CrossRef]

- Chiaradia, M.; Fontbote, L.; Beate, B. Cenozoic continental arc magmatism and associated mineralization in Ecuador. Miner. Deposita 2004, 39, 204–222. [Google Scholar] [CrossRef]

- Litherland, M.; Aspen, J.A. Terrane-boundary reactivation: A control on the evolution of the Northern Andes. J. S. Am. Earth Sci. 1992, 5, 71–76. [Google Scholar] [CrossRef]

- Van Thournout, F.; Salemink, J.; Valenzuela, G.; Merlyn, M.; Boven, A.; Muchez, P. Portovelo: A volcanic-hosted epithermal vein-system in Ecuador, South America. Miner. Deposita 1996, 31, 269–276. [Google Scholar] [CrossRef]

- Banda, R.; Vikentyév, I.V.; Nosik, L.P. Sulfur Isotopic Composition of the Vizcaya and Nikol Veins, Portovelo Zaruma Deposits, Ecuador. Dokl. Earth Sci. 2005, 405A, 1388–1392. [Google Scholar]

- Spencer, R.M.; Montenegro, J.L.; Gaibor, A.; Pérez, E.P.; Mantilla, G.; Viera, F.; Spencer, C.E. The Portovelo-Zaruma mining camp, SW Ecuador: Porphyry and epithermal environments. SEG Newsl. 2002, 49, 8–14. [Google Scholar]

- Vikentyev, I.; Banda, R.; Tsepin, A.; Prokofiev, V.; Vikentyeva, O. Mineralogy and formation conditions of Portovelo-Zaruma gold-sulphide veins deposit, Ecuador. Geochem. Mineral. Petrol. 2005, 43, 148–154. [Google Scholar]

- Bonilla, W. Metalogenia del distrito minero Zaruma-Portovelo, República del Ecuador. Ph.D. Thesis, Universidad de Buenos Aires, Buenos Aires, Argentina, 2009. [Google Scholar]

- Castroviejo, R.; Catalina, J.C.; Bernhardt, H.J.; Pirard, E.; Brea, C.; Pérez-Barnuevo, L.; Segundo, F.; Espí, J.A. Multispectral (Visible and Near Infra-Red, 400–1000 nm Range) Reflectance Data File from Common Ore Minerals. 2014. Available online: http://projects.gtk.fi/com/results/reflectance_data.html (accessed on 10 April 2016).

- Pérez-Barnuevo, L. Ensayo Metodológico para la Caracterización Automatizada de Menas Metálicas Mediante Análisis Digital de Imagen. Aplicación Geometalúrgica. Master’s Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2008. [Google Scholar]

- Castroviejo, R.; Chacón, E.; Muzquiz, C.; Tarquini, S. A preliminary Image Analysis characterization of massive sulphide ores from the SW Iberian Pyrite Belt (Spain). In Proceedings of the International Symposium on Imaging Applications in Geology, Liege, Belgium, 6–7 May 1999.

- Chayes, F.; Fairbairn, H.W. A test of the precision of thin section analysis by point counter. Am. Mineral. 1951, 36, 704–712. [Google Scholar]

- Evans, C.L.; Napier-Munn, T.J. Estimating error in measurements of mineral grain size distribution. Miner. Eng. 2013, 52, 198–203. [Google Scholar] [CrossRef]

- Berrezueta, E.; González-Menéndez, L.; Ordóñez-Casado, B.; Olaya, P. Pore network quantification of sandstones under experimental CO2 injection using image analysis. Comput. Geosci. 2015, 77, 97–110. [Google Scholar] [CrossRef]

- González, R.C.; Woods, R.C. Digital Image Processing, 3rd ed.; Addison-Wesley Publishing Co.: New York, NY, USA, 2008; p. 943. [Google Scholar]

- Whitney, D.; Evans, B. Abbreviations for names of rock-forming minerals. Am. Mineral. 2010, 96, 185–187. [Google Scholar] [CrossRef]

- Martínez-Martínez, J.; Benavente, D.; García del Cura, M.A. Petrographic quantification of brecciated rocks by image analysis. Application to the interpretation of elastic wave velocities. J. Eng. Geol. 2007, 90, 41–54. [Google Scholar] [CrossRef]

- Shapiro, L.; Stockman, G. Computer Vision, 1st ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2001; p. 609. [Google Scholar]

- Higgings, M. Measurement of crystal size distributions. Am. Mineral. 2000, 85, 105–1116. [Google Scholar]

- Higgings, M. CSD Corrections 1.52. CSD Correction software. 2016. Available online: http://www.uqac.ca/mhiggins/csdcorrections.html (accessed on 14 June 2016).

- Lastra, R.; Wilson, D.; Cabri, J. Automated gold search and applications in process mineralogy. Trans. Inst. Min. Metall. 1999, 108, 75–84. [Google Scholar]

- Berrezueta, E. Caracterización de Menas Mediante Análisis Digital de Imagen. Investigación y Diseño de un Sistema Experto Aplicable a Problemas Mineros. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2004. [Google Scholar]

- Donskoi, E.; Manuel, J.; Austin, P.; Poliakov, A.; Peterson, M.; Hapugoda, S. Comparative study of iron ore characterisation by optical image analysis and QEMSCAN(TM). In Proceedings of the Iron Ore 2011, Perth, Australia, 11–13 July 2011.

- Donskoi, E.; Poliakov, A.; Manuel, J. Automated optical image analysis of natural and sintered iron ore. In Iron Ore: Mineralogy, Processing and Environmental Issues; Lu, L., Ed.; Elsevier: Perth, Australia, 2015; Volume 1, pp. 101–159. [Google Scholar]

| Mine | Location (UTM) | Vein | Hand-Samples | |

|---|---|---|---|---|

| Guabo Verde | 651806 E | 9603394 N | Guabo Verde | MGV-1 and MGV-2 |

| Malvas | 652882 E | 9594683 N | La Y | MM-3 and MM-4 |

| San Antonio | 655434 E | 9592607 N | Azul | MSA-5 MSA-6, MSA-7 and MSA-8 |

| Sansón | 655485 E | 9592398 N | Sansón | MS-9, MS-10, MS-11, MS-12 and MS-13 |

| Bira | 653994 E | 9592737 N | Vizcaya | MB-14, MB-15, MB-16, MB-17, MB-18, MB-19, MB-20, MB-21 and MB-22 |

| Problems | Solutions | Configuration | Information |

|---|---|---|---|

| Microscopes | |||

| Size of the object (mineral) vs. field of view | (1 and 2) Objectives that allow the optimal view of the mineral | Objective: 20×; Lens: 1× c. mount: 0.63× monitor 17 inch: 36x | Total magnification: 460× |

| Over-saturation of transmitted light | (1) Appropriate lighting to avoid saturation of images | 12 V 100 W Intensity: 116 (Crossed); Intensity: 78 (Parallel) | Hal. Lamp; Color temperature: 3200 K |

| Electronic Noise | (1 and 2) Warm-up time | Time: 40 min | Optimal warm-up time |

| Defocus | (1) Manual focus (2) Automatic focus | (1) Expert experience (2) Macro for focus | |

| Optical Resolution (R) | (1 and 2) R = ë/2*NA | 0.4 µm/pixel | ë = wave length = 550 nm NA = aperture = 0.5 ë = wave length = 400 nm NA = aperture = 0.5 |

| CCD Cameras | |||

| Short-term Electronic Noise | (1) Image integration | 8 images; T: 100 ms | Period for integration |

| Periodic Electronic Noise | (1) Average a sequence of images | 8 images; T: 16 s. | Optimal period |

| Long-term Electronic Noise | (1 and 2) Warm-up time | 90 min | Optimal warm-up time of the CCD |

| Dark current | (1) Numerical correction | Black reference image Black_image.tif | Image acquired with microscope light off |

| Spatial drift | (1) Numerical correction | White reference image White_image.tif | Image acquired without thin section |

| Color Calibration | (1) Color balance Manual configuration | White balance R: 1.20; G: 0.90; B: 1.20 | Gain: 1; Gamma: 0 Brightness: 0.50 |

| Geometric Calibration | (1 and 2) Pixel/µm | Calibration 20×: 0.312 µm/pixel | Micrometer image Pixel size: 3.4 × 3.4 µm |

| Image Configuration | (1 and 2) Standard Image configuration | Color RGB.tif; Grey Multispectral.tif; 8 bits; 1290 × 972 VGA pixels; | Grey Level (GL) Min.: 0 Max.: 255 |

| Association | Breadth Range (µm) | |||||||

|---|---|---|---|---|---|---|---|---|

| [0–6) | [6–12) | [12–18) | [18–24) | [24–30) | [30–36) | [36–42) | [42–48) | |

| Au in Gg | 159 | 65 | 22 | 7 | 1 | 1 | 1 | |

| Au with Tel_Gg | 7 | 8 | 5 | 1 | 4 | 1 | ||

| Au with Gn-Gg | 2 | 2 | 1 | |||||

| Au with Py-Gg | 1 | 1 | ||||||

| Au with Ccp-Gg | 1 | 3 | ||||||

| Au with Tel-Gn-Gg | 3 | 1 | 1 | |||||

| Au in Py | 1 | |||||||

| Au total | 170 | 80 | 31 | 10 | 5 | 1 | 2 | |

| Association | Breadth Range (µm) | |||||||

|---|---|---|---|---|---|---|---|---|

| [0–6) | [6–12) | [12–18) | [18–24) | [24–30) | [30–36) | [36–42) | [42–48) | |

| Au in Gg | 1495 | 5740 | 5025 | 2944 | 527 | 626 | 1295 | |

| Au with Tel_Gg | 196 | 789 | 1235 | 520 | 3147 | 1156 | ||

| Au with Gn-Gg | 203 | 441 | 322 | |||||

| Au with Py-Gg | 202 | 424 | ||||||

| Au with Ccp-Gg | 20 | 252 | ||||||

| Au with Tel-Gn-Gg | 41 | 216 | 292 | |||||

| Au in Py | 94 | |||||||

| Au total | 1752 | 7200 | 7194 | 4211 | 3674 | 626 | 2451 | |

| Minerals | Multispectral Characteristics | RGB Characteristics | |||

|---|---|---|---|---|---|

| Average % | Ratio B13/B1 | Ratio B7/B2 | Average % | Ratio R/B | |

| Chalcopyrite | 42.72 | 2.28 | 1.51 | 47.10 | 1.06 |

| Pyrite | 50.19 | 1.14 | 1.17 | 54.33 | 1.03 |

| Sphalerite | 17.92 | 0.76 | 0.89 | 18.33 | 0.98 |

| Galena | 42.77 | 0.78 | 0.86 | 43.11 | 0.99 |

| Pyrrhotite | 43.77 | 1.59 | 1.38 | 41.66 | 1.10 |

| Pentlandite | 48.92 | 1.75 | 1.39 | 47.78 | 1.10 |

| Covellite | 31.46 | 2.50 | 1.90 | 16.94 | 0.89 |

| Chalcocite | 30.62 | 0.78 | 0.78 | 30,16 | 0.90 |

| Bornite | 30.85 | 2.00 | 1.84 | 27.01 | 1.25 |

| Hematite | 23.77 | 0.71 | 0.76 | 25.67 | 0.90 |

| Tetrahedrite | 26.85 | 0.86 | 0.90 | 28.55 | 0.98 |

| Bismuth | 63.38 | 1.23 | 1.17 | 63.89 | 1.02 |

| Gangue | 5.46 | 1.01 | 0.80 | 6.00 | 1.00 |

| Gold | 78.62 | 2.47 | 2.46 | 83.66 | 1.20 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berrezueta, E.; Ordóñez-Casado, B.; Bonilla, W.; Banda, R.; Castroviejo, R.; Carrión, P.; Puglla, S. Ore Petrography Using Optical Image Analysis: Application to Zaruma-Portovelo Deposit (Ecuador). Geosciences 2016, 6, 30. https://doi.org/10.3390/geosciences6020030

Berrezueta E, Ordóñez-Casado B, Bonilla W, Banda R, Castroviejo R, Carrión P, Puglla S. Ore Petrography Using Optical Image Analysis: Application to Zaruma-Portovelo Deposit (Ecuador). Geosciences. 2016; 6(2):30. https://doi.org/10.3390/geosciences6020030

Chicago/Turabian StyleBerrezueta, Edgar, Berta Ordóñez-Casado, Wilson Bonilla, Richard Banda, Ricardo Castroviejo, Paul Carrión, and Stalin Puglla. 2016. "Ore Petrography Using Optical Image Analysis: Application to Zaruma-Portovelo Deposit (Ecuador)" Geosciences 6, no. 2: 30. https://doi.org/10.3390/geosciences6020030

APA StyleBerrezueta, E., Ordóñez-Casado, B., Bonilla, W., Banda, R., Castroviejo, R., Carrión, P., & Puglla, S. (2016). Ore Petrography Using Optical Image Analysis: Application to Zaruma-Portovelo Deposit (Ecuador). Geosciences, 6(2), 30. https://doi.org/10.3390/geosciences6020030