The Influence of Pre-Existing Deformation and Alteration Textures on Rock Strength, Failure Modes and Shear Strength Parameters

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Failure Modes

3.1.1. Failure under Point Load

3.1.2. Failure under Uniaxial Compressive Test

3.1.3. Failure under Indirect Tensile Test

3.2. Young’s Modulus

3.3. Shear Strength Parameters

4. Discussion

4.1. Estimating the UCS from the ITS and the PLT

4.2. The Role of Pre-Existing Planes of Weakness

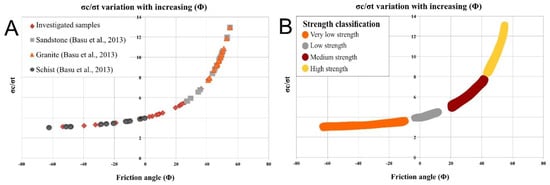

4.3. The Angle of Internal Friction and the Cohesion

4.4. The Role of Frictional Reactivation

5. Conclusions

- Deformed rocks fail by a variety of failure modes, but the dominant failure mode is the reactivation of pre-existing planes of weakness. Failure by shear is only rarely achieved.

- The UCS is significantly reduced if the sample fails along pre-existing weakness planes, compared to the sample failing along newly formed shear fractures.

- Thus, the failure mode and the change in sample anisotropy (due to size difference) controls whether or not the UCS can be related to the PLS and the ITS.

- The Young’s modulus and the UCS can be used to classify the strength of the rocks. Observations show that veined and breccia samples are medium to low strength rocks. Fractured and foliated samples are weak to very weak rocks. This strength difference is controlled by the cohesive strength of the pre-existing planes of weakness.

- The empirical equations derived by [15] for the friction angle and the cohesions from UTS and ITS tests can be used accurately to calculate the shear parameters for intact rock. However, they yield unrealistic results for foliated, fractured or veined rocks.

- The UCS/ITS ratio can be used to classify rock strength: UCS/ITS ≥8 indicates high strength rocks, 5 < UCS/ITS ≤ 8 indicates medium strengths rocks, 4 < UCS/ITS < 5 indicates low strength rocks and UCS/ITS <4 are very low strength rocks.

- This study confirms previous observations that samples with foliations, fractures or veins inclined more than 40° from the normal to the plane will fail along the planes of weakness as opposed to forming new fractures. However, this study subdivides, for the first time, the failure along pre-existing structures into two failure modes: (1) if the angle of the weakened plane is ≤20° from the maximum principal stress, the sample will fail only along the pre-existing weakness and (2) if the weakness plane is between 20° and 45° relative to the maximum principal stress, the sample will fail along a combination of pre-existing weakness planes and newly formed shear fractures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Himmelberg, G.R.; Haeussler, P.J.; Brew, D.A. Emplacement, rapid burial, and exhumation of 90-ma plutons in southeastern alaska. Can. J. Earth Sci. 2004, 41, 87–102. [Google Scholar] [CrossRef]

- Davis, B.K. Mechanism of emplacement of the cannibal creek granite with special reference to timing and deformation history of the aureole. Tectonophysics 1993, 224, 337–362. [Google Scholar] [CrossRef]

- Jayko, A.S.; Blake, M.C. Deformation of the eastern franciscan belt, Northern California. J. Struct. Geol. 1988, 11, 375–390. [Google Scholar] [CrossRef]

- Martinez, L.F.; Zuluaga, C.C.A. Thermal modeling of pluton emplacement and associated contact metamorphism: Parashi stock emplacement in the Serrania de Jarara (Alta Guajira, Colombia). Earth Sci. Res. J. 2010, 14, 16–23. [Google Scholar]

- Molina, P.G.; Parada, M.A.; Gutiérrez, F.J.; Ma, C.; Li, J.; Yuanyuan, L.; Reich, M.; Aravena, Á. Protracted late magmatic stage of the caleu pluton (central Chile) as a consequence of heat redistribution by diking: Insights from zircon data and thermal modeling. Lithos 2015, 227, 255–268. [Google Scholar] [CrossRef]

- Bell, T.H.; Sanislav, I.V.; Sapkota, J. The control of deformation partitioning and strain localization on porphyroblast behaviour in rocks and experiments. Geosci. J. 2018, 22, 65–77. [Google Scholar] [CrossRef]

- Sanislav, I.V. Porphyroblast rotation and strain localization: Debate settled!: Comment. Geology 2010, 38, e204. [Google Scholar] [CrossRef]

- Noronha, F.; Cathelineau, M.; Boiron, M.C.; Banks, D.A.; Doria, A.; Ribeiro, M.A.; Nogueira, P.; Guedes, A. A three stage fluid flow model for variscan gold metallogenesis in northern portugal. Geochem. Eng. 2000, 71, 209–224. [Google Scholar] [CrossRef]

- Zhang, Y.; Hobbs, B.E.; Ord, A.; Barnicoat, A.; Zhao, C.; Walshe, J.L.; Lin, G. The influence of faulting on host-rock permeability, fluid flow and ore genesis of gold deposits: A theoretical 2d numerical model. J. Geochem. Explor. 2003, 78–79, 279–284. [Google Scholar] [CrossRef]

- Rutqvist, J.; Rinaldi, A.P.; Cappa, F.; Moridis, G.J. Modeling of fault reactivation and induced seismicity during hydraulic fracturing of shale-gas reservoirs. J. Pet. Sci. Eng. 2013, 107, 31–44. [Google Scholar] [CrossRef]

- O’Brien, G.W.; Lisk, M.; Duddy, I.R.; Hamilton, J.; Woods, P.; Cowley, R. Plate convergence, foreland development and fault reactivation-primary controls on brine migration, thermal histories and trap breach in the timor sea, australia. Mar. Pet. Geol. 1999, 16, 533–560. [Google Scholar] [CrossRef]

- Klinger, Y.; Etchebes, M.; Tapponnier, P.; Narteau, C. Characteristic slip for five great earthquakes along the fuyun fault in china. Nat. Geosci. 2011, 4, 389–392. [Google Scholar] [CrossRef]

- Brady, B.H.G.; Brown, E.T. Rock Mechanics for Underground Mining; Springer: Dordrecht, The Netherlands, 2006; Volume 628. [Google Scholar]

- Nomikos, P.P.; Sofianos, A.I. An analytical probability distribution for the factor of safety in underground rock mechanics. Int. J. Rock Mech. Min. Sci. 2011, 48, 597–605. [Google Scholar] [CrossRef]

- Sivakugan, N.; Das, B.M.; Lovisa, J.; Patra, C.R. Determination of c and φ of rocks from indirect tensile strength and uniaxial compression tests. Int. J. Geotech. Eng. 2014, 8, 59–65. [Google Scholar] [CrossRef]

- Amini, M.; Majdi, A.; Veshadi, M.A. Stability analysis of rock slopes against block-flexure toppling failure. Rock Mech. Rock Eng. 2012, 45, 519–532. [Google Scholar] [CrossRef]

- Sivakugan, N.; Shukla, S.K.; Das, B.M. Rock Mechanics an Introduction; Taylor and Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kožušníková, A.; Marečková, K. Analysis of rock failure after triaxial testing. Int. J. Rock Mech. Min. Sci. 1999, 36, 243–251. [Google Scholar] [CrossRef]

- Haimson, B.; Chang, C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of westerly granite. Int. J. Rock Mech. Min. Sci. 2000, 37, 285–296. [Google Scholar] [CrossRef]

- Hoek, E. Rock mechanics laboratory testing in the context of a consulting engineering organization. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1977, 14, 93–101. [Google Scholar] [CrossRef]

- Singh, T.N.; Kainthola, A.; Venkatesh, A. Correlation between point load index and uniaxial compressive strength for different rock types. Rock Mech. Rock Eng. 2011, 45, 259–264. [Google Scholar] [CrossRef]

- Kaya, A.; Karaman, K. Utilizing the strength conversion factor in the estimation of uniaxial compressive strength from the point load index. Bull. Eng. Geol. Environ. 2015, 75, 341–357. [Google Scholar] [CrossRef]

- Karaman, K.; Cihangir, F.; Ercikdi, B.; Kesimal, A.; Demirel, S. Utilization of the brazilian test for estimating the uniaxial compressive strength and shear strength parameters. J. South. Afr. Inst. Min. Metall. 2015, 115, 185–192. [Google Scholar] [CrossRef]

- Broch, E.; Franklin, J.A. The point-load strength test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 669–676. [Google Scholar] [CrossRef]

- Greminger, M. Experimental studies of the influence of rock anisotropy on size and shape effects in point-load testing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1982, 19, 241–246. [Google Scholar] [CrossRef]

- Forster, I.R. The influence of core sample geometry on the axial point-load test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 291–295. [Google Scholar] [CrossRef]

- Doglioni, C.; Carminati, E. Structural Style and Dolomites Field Trip; Memorie Descrittive della Carta Geologica d’Italia; ISPRA: Roma, 2008; Volume LXXXII ed APATI, p. 301. [Google Scholar]

- Attewell, P.B.; Sandford, M.R. Intrinsic shear strength of a brittle, anisotropic rock—I: Experimental and mechanical interpretation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1974, 11, 423–430. [Google Scholar] [CrossRef]

- Lei, X.L.; Nishizawa, O.; Kusunose, K.; Cho, A.; Satoh, T.; Nishizawa, O. Compressive failure of mudstone samples containing quartz veins using rapid AE monitoring: The role of asperities. Tectonophysics 2000, 328, 329–340. [Google Scholar] [CrossRef]

- Cao, R.-H.; Cao, P.; Lin, H.; Pu, C.-Z.; Ou, K. Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach. Rock Mech. Rock Eng. 2015, 49, 763–783. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, D. Mechanical properties and failure modes of rock samples with grout-infilled flaws: A particle mechanics modeling. J. Nat. Gas Sci. Eng. 2016, 34, 702–715. [Google Scholar] [CrossRef]

- Australia, S. Methods of testing concrete. In Method 10: Determination of Indirect Tensile Strength of Concrete Cylinders (‘Brazil’ or Splitting Test); Standards Australia International Ltd.: Strathfield, Australia, 2014; Volume 10, pp. 1–5. [Google Scholar]

- Australia, S. Methods of testing rocks for engineering purposes. In Methods 4.2.2: Rock Strength Tests—Determination of Uniaxial Compressive Strength-Rock Strength Less Than 50 MPa; Standards Australia Limited: Sydney, Australia, 2013; Volume 4.2.2, pp. 1–3. [Google Scholar]

- Australia, S. Methods of testing rocks for engineering purposes. In Method 4.2.1: Rock Strength Tests—Determination of Uniaxial Compressive Strength of 50 MPa and Greater; Australia Standards Limited: Sydney, Australia, 2007; Volume 4.2.1, pp. 1–3. [Google Scholar]

- Australia, S. Methods of testing rocks for engineering purposes. In Method 4.1: Rock Strength Test—Determination of Point Load Strength Index; Standards Australia Limited: Sydney, Australia, 2007; Volume 4.1, pp. 1–5. [Google Scholar]

- Basu, A.; Mishra, D.A.; Roychowdhury, K. Rock failure modes under uniaxial compression, brazilian, and point load tests. Bull. Eng. Geol. Environ. 2013, 72, 457–475. [Google Scholar] [CrossRef]

- Deere, D.U.; Miller, R.P.; Dentith, M.; Clark, D.; Featherstone, W. Engineering Classification and Index Properties of Intact Rock; Technical Report; No. AFWL-TR-65-116 AFWL-TR; No. 65–116; Air Force Weapons Laboratory: Dayton, OH, USA, 1966; Volume 308. [Google Scholar]

- Hawkes, I.; Mellor, M. Uniaxial testing in rock mechanics laboratories. Eng. Geol. 1970, 4, 179–285. [Google Scholar] [CrossRef]

- Akram, M.; Bakar, M.A.A. Correlation between uniaxial compressive strength and point load index for salt-range rocks. Pak. J. Eng. Appl. Sci. 2007, 1, 1–7. [Google Scholar]

- Kohno, M.; Maeda, H. Relationship between point load strength index and uniaxial compressive strength of hydrothermally altered soft rocks. Int. J. Rock Mech. Min. Sci. 2012, 50, 147–157. [Google Scholar] [CrossRef]

- Nazir, R.; Momeni, E.; Armaghani, D.J.; Amin, M.F.M. Correlation between unconfined compressive strength and indirect tensile strength of limestone rock samples. Electr. J. Geotech. Eng. 2013, 18, 1737–1746. [Google Scholar]

- Basu, A.; Kamran, M. Point load test on schistose rocks and its applicability in predicting uniaxial compressive strength. Int. J. Rock Mech. Min. Sci. 2010, 47, 823–828. [Google Scholar] [CrossRef]

- Sheorey, P.R. Empirical Rock Failure Criteria; A. A. Balkema: Rotterdam, The Netherlands, 1997. [Google Scholar]

- Vutukuri, V.S.; Lama, R.D.; Saluja, S.S. Handbook on Mechanical Properties of Rocks: Testing Techniques and Results, 1st ed.; Trans Tech Publications: Bay Village, OH, USA, 1974. [Google Scholar]

- Suppe, J. Principles of Structural Geology; Prentice-Hall: Englewood Cliffs, NJ, USA, 1985. [Google Scholar]

- Perkins, R.D.; Green, S.J.; Friedman, M. Uniaxial stress behavior of porphyritic tonalite at strain rates to 103/second. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1970, 7, 527–535. [Google Scholar] [CrossRef]

- Nicholas, H.S.O.; Paul, D.B. Mechanisms of fluid flow and fluid-rock interaction in fossil metamorphic hydrothermal systems inferred from vein-wallrock patterns, geometry and microstructure. Geofluids 2001, 1, 137–162. [Google Scholar]

- Saliu, M.A.; Akindoyeni, A.F.; Okewale, I.A. Correlation between blast efficiency and uniaxial compressive strength. Eng. Technol. 2013, 3, 799–805. [Google Scholar]

- Jaeger, J.C.; Cook, N.G. Fundamentals of Rock Mechanics; Chapman and Hall: London, UK, 1979; p. 593. [Google Scholar]

- Labuz, J.F.; Zang, A. Mohr–coulomb failure criterion. Rock Mech. Rock Eng. 2012, 45, 975–979. [Google Scholar] [CrossRef]

- Byerlee, J. Friction of rocks. Pure Appl. Geophys. 1978, 116, 615–626. [Google Scholar] [CrossRef]

| Group | Sample ID | Texture | Pre-Existing Structures |

|---|---|---|---|

| 1 | TE1A | Medium-grained (anorthosite) | Weak foliation and calcite veins visible under microscope |

| 1 | TE/2A | Medium-grained (anorthosite) | Calcite veins visible under microscope |

| 1 | TE3A | Coarse-grained, phaneritic (tonalite) | Weakly developed fractures visible only under microscope |

| 2 | TE1C | Foliated | Well-developed foliation at a high angle to the axis; one carbonate-sulfide vein ~parallel to the axis |

| 2 | TE1D | Foliated | Well-developed foliation at a low angle to the axis |

| 2 | TE/FO1 | Foliated | Moderately developed foliation parallel to the vein network |

| 2 | TE/FO2 | Foliated | Well-developed foliation at a moderate angle to the axis; few carbonate veins ~parallel to the axis |

| 2 | TE/FO3 | Foliated | Moderate foliation with carbonate deposited along the foliation planes |

| 2 | TE/FO4 | Foliated | Well-developed foliation overprinted by small ~1 mm carbonate veins |

| 3 | TE/2B | Mylonitic, veins | Veins are coalesced; multiple orientations |

| 3 | TE/VO1 | Medium-grained, veins | Two vein types (actinolite and calcite) up to 5 mm width |

| 3 | TE/VO2 | Medium-grained, veins | Two vein types (actinolite and calcite) up to 5 mm width; multiple orientations |

| 3 | TE/VO3 | Medium-grained, veins | Fine and dense micro-vein network, mostly calcite; multiple orientations |

| 3 | TE/VO4 | Medium-grained, veins | Fine to coarse calcite veins; mainly one orientation |

| 3 | TE/VO5 | Medium-grained, veins | Fine to coarse carbonate veins; one preferred orientation |

| 3 | TE/VO6 | Medium-grained, veins | Fine to coarse calcite veins; mainly one orientation |

| 3 | TE/VO7 | Medium-grained, veins | Fine calcite and actinolite vein network; multiple orientations; one vein ~parallel to the axis |

| 3 | TE/VO8 | Medium-grained, veins | Two main vein orientations: ~parallel to axis and ~perpendicular to the axis |

| 4 | TE2C | Medium-grained; fracture network | Multiple orientations; fractures and veins |

| 4 | TE/FR1 | Medium-grained; fracture network | Two main fracture networks. One ~parallel to the axis and one conjugate set at low-angle to the axis |

| 4 | TE/FR2 | Medium-grained; fracture network | Multiple orientations; fractures and veins |

| 4 | TE/FR3 | Medium-grained; fracture network | Multiple orientations; fractures and veins; calcite veins ~parallel to the axis |

| 4 | TE/FR4 | Medium-grained; fracture network | One preferred orientation; low angle to the axis |

| 4 | TE/FR5 | Medium-grained; fracture network | Two main fracture networks. One ~parallel to the axis and one conjugate set at a low-angle to the axis |

| 4 | TE/FR6 | Medium-grained; fracture network | Multiple orientations; fractures and veins; Low angle fractures better developed |

| 4 | TE/FR7 | Medium-grained; fracture network | Two main fracture networks. One ~parallel to the axis and one conjugate set at a low-angle to the axis |

| 5 | TE2D | Brecciated | Polymict; poorly sorted; clast-supported breccia; rounded clasts; few overprinting veins |

| 5 | TE/BO1 | Brecciated | Polymict; clast-supported breccia with large clast size |

| 5 | TE/BO2 | Brecciated | Polymict; poorly sorted; clast-supported breccia; rounded clasts; |

| 5 | TE/BO3 | Brecciated | Polymict; poorly sorted; clast-supported breccia; rounded clasts; fine overprinting vein network |

| 5 | TE/BO4 | Brecciated | Monomict, matrix-supported breccia; large angular clasts; calcite infill; |

| 5 | TE/BO5 | Brecciated | Monomict, matrix-supported breccia; large angular clasts; calcite infill; clast-dominated |

| 5 | TE/BO6 | Brecciated | Monomict, matrix-supported breccia; large angular clasts; calcite infill; clast-dominated |

| 5 | TE/BO7 | Brecciated | Monomict, matrix-supported breccia; large angular clasts; calcite infill; infill-dominated |

| 5 | TE/BO8 | Brecciated | Monomict, matrix-supported breccia; large angular clasts; calcite infill; clast-dominated |

| 5 | TE/BO9 | Brecciated | Polymict; poorly sorted; clast-supported breccia; rounded clasts; few overprinting veins |

| 6 | TE1B | Altered; phaneritic texture mostly preserved | Fractures visible only under microscope; carbonate, chlorite altered and weakly silicified |

| 6 | TE3B | Altered; phaneritic texture weakly preserved | Fractures visible under microscope; highly silicified and weak carbonate alteration |

| 6 | TE3C | Altered; phaneritic texture weakly preserved | Moderately to highly silicified; weak foliation; rare calcite veins |

| 6 | TE/AL1 | Altered; phaneritic texture well preserved | Weakly silicified; micro-fracture network |

| Test Type | Failure Mode | No. of Samples Failed |

|---|---|---|

| PLT | Single plane | 4 |

| PLT | Triple junction | 5 |

| PLT | Invalid | 2 |

| PLT | Twisted | 11 |

| PLT | Along pre-existing weakness (fracture, vein or foliation) | 4 |

| Total | 26 |

| Test Type | Failure Mode | Number |

|---|---|---|

| UCS | Along pre-existing weakness (fracture, vein or foliation) | 29 |

| UCS | Axial splitting | 4 |

| UCS | Shear along single plane | 2 |

| UCS | Double shear | 4 |

| UCS | Multiple fractures | 1 |

| Total | 40 |

| Test Type | Failure Mode | No. of Samples Failed |

|---|---|---|

| ITS | Central | 15 |

| ITS | Central + layer activation | 19 |

| ITS | Multiple central | 5 |

| ITS | Non-central | 5 |

| Total | 44 |

| Specimens | Measured Parameters | Estimated Parameters | Ratios | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Group | Sample ID | PLT/Mpa | σt/MPa | σc/MPa | E/GPa | Φ° | C/MPa | E/σc | σc/σt |

| 1 | TE1A | 6.37 | 14.68 | 48.49 | 7.4 | −32.3 | 44 | 152.61 | 3.3 |

| 1 | TE/2A | 6.13 | 16.27 | 42.26 | 15.2 | - | - | 359.68 | 2.6 |

| 1 | TE3A | 8.42 | 19.62 | 49.65 | 9.6 | - | - | 193.35 | 2.53 |

| 2 | TE1C | 4.14 | 17.90 | 23.16 | 6.6 | - | - | 284.97 | 1.29 |

| 2 | TE1D | 2.09 | 7.24 | 23.33 | 4.8 | −39.5 | 24.7 | 205.74 | 3.22 |

| 2 | TE/FO1 (PA) | - | 12.65 | 44.37 | 1.1 | −19.07 | 31.14 | 24.79 | 3.51 |

| 2 | TE/FO1 (PE) | - | 15.69 | 44.37 | 1.1 | - | - | 24.79 | 2.83 |

| 2 | TE/FO2 (PA) | - | 21.61 | 90.25 | 1.7 | 4.65 | 41.61 | 18.84 | 4.18 |

| 2 | TE/FO2 (PA2) | - | 17.33 | 90.25 | 1.7 | 22.12 | 30.37 | 18.84 | 5.21 |

| 2 | TE/FO3 (PA) | - | 15.45 | 15.4 | 4.7 | - | - | 305.19 | 1 |

| 2 | TE/FO3 (PE) | - | 18.13 | 15.4 | 4.7 | - | - | 305.19 | 0.85 |

| 2 | TE/FO4 (PE) | - | 17.07 | 45.36 | 10.8 | - | - | 238.1 | 2.84 |

| 2 | TE/FO4 (PE2) | - | 15.99 | 45.36 | 10.8 | - | - | 238.1 | 2.66 |

| 3 | TE/2B | 6.39 | 14.09 | 55.11 | 16.1 | −2.7 | 28.9 | 292.14 | 3.91 |

| 3 | TE/VO1 | - | 13.86 | 62.16 | 15.8 | 11.25 | 25.51 | 254.18 | 4.48 |

| 3 | TE/VO2 | - | 14.95 | 64.08 | 15.7 | 7.19 | 28.25 | 245.01 | 4.29 |

| 3 | TE/VO3 | 2.37 | 15.87 | 106.66 | 18.9 | 35.2 | 27.6 | 177.2 | 6.72 |

| 3 | TE/VO4 | 4.7 | 14.68 | 81.63 | 17.9 | 26 | 25.5 | 219.3 | 5.56 |

| 3 | TE/VO5 | 5.33 | 22.69 | 70.93 | 18.3 | −50.9 | 99.9 | 258.0 | 3.13 |

| 3 | TE/VO6 | 8.21 | 23.99 | 52.32 | 11.2 | - | - | 214.1 | 2.18 |

| 3 | TE/VO7 | 11.71 | 31.66 | 70.16 | 10.3 | - | - | 146.8 | 2.22 |

| 3 | TE/VO8 | 11.86 | 26.81 | 54.97 | 11.3 | - | - | 205.6 | 2.05 |

| 4 | TE2C | 6.52 | 19.74 | 40.00 | 13 | - | - | 325 | 2.03 |

| 4 | TE/FR1 | - | 5.88 | 6.81 | 3.9 | - | - | 572.69 | 1.16 |

| 4 | TE/FR2 | - | 22.05 | 73.64 | 12.8 | −29.53 | 63.18 | 173.82 | 3.34 |

| 4 | TE/FR3 | 2.57 | 10.34 | 29.33 | 2.8 | - | - | 95.47 | 2.84 |

| 4 | TE/FR4 | 1.82 | 21.2 | 24.9 | 7 | - | - | 281.12 | 1.17 |

| 4 | TE/FR5 | 2.97 | 14.88 | 35.96 | 6 | - | - | 166.85 | 2.42 |

| 4 | TE/FR6 | 8.42 | 14.78 | 34.23 | 6.8 | - | - | 198.66 | 2.32 |

| 4 | TE/FR7 | 5.64 | 24.4 | 63.52 | 7.5 | - | - | 118.07 | 2.6 |

| 5 | TE2D | 2.00 | 7.79 | 53.56 | 17.1 | 36.1 | 13.6 | 319.27 | 6.88 |

| 5 | TE/BO1 | - | 10.76 | 59.41 | 11.2 | 25.6 | 18.17 | 188.52 | 5.52 |

| 5 | TE/BO2 | - | 14.59 | 45.37 | 12.4 | −53.35 | 68.5 | 273.31 | 3.11 |

| 5 | TE/BO3 | - | 15.45 | 60.71 | 14.3 | −2.1 | 31.49 | 235.55 | 3.93 |

| 5 | TE/BO4 | - | 13.86 | 69.53 | 16.9 | 19.69 | 24.48 | 243.06 | 5.02 |

| 5 | TE/BO5 | - | 8.36 | 34.26 | 13.1 | 2.68 | 16.35 | 382.37 | 4.1 |

| 5 | TE/BO6 | - | 11.03 | 85.55 | 17.9 | 40.73 | 19.61 | 209.23 | 7.76 |

| 5 | TE/BO7 | 3.52 | 8.35 | 44.04 | 9.9 | 22.9 | 14.6 | 224.80 | 5.27 |

| 5 | TE/BO8 | 5.29 | 11.85 | 63.66 | 11.5 | 24 | 20.7 | 180.65 | 5.37 |

| 5 | TE/BO9 | 5.54 | 9.59 | 23.94 | 5.7 | - | - | 238.1 | 2.5 |

| 6 | TE1B | 6.82 | 17.97 | 78.84 | 3.1 | 9.3 | 33.5 | 39.32 | 4.39 |

| 6 | TE3B | 4.81 | 13.70 | 40.59 | 9.6 | - | - | 236.51 | 2.96 |

| 6 | TE3C | 2.77 | 14.01 | 60.81 | 15.5 | 8.4 | 26.3 | 254.89 | 4.34 |

| 6 | TE/AL1 | 3.01 | 16.4 | 45.95 | 8.7 | - | - | 189.34 | 2.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Everall, T.J.; Sanislav, I.V. The Influence of Pre-Existing Deformation and Alteration Textures on Rock Strength, Failure Modes and Shear Strength Parameters. Geosciences 2018, 8, 124. https://doi.org/10.3390/geosciences8040124

Everall TJ, Sanislav IV. The Influence of Pre-Existing Deformation and Alteration Textures on Rock Strength, Failure Modes and Shear Strength Parameters. Geosciences. 2018; 8(4):124. https://doi.org/10.3390/geosciences8040124

Chicago/Turabian StyleEverall, Tamara J., and Ioan V. Sanislav. 2018. "The Influence of Pre-Existing Deformation and Alteration Textures on Rock Strength, Failure Modes and Shear Strength Parameters" Geosciences 8, no. 4: 124. https://doi.org/10.3390/geosciences8040124

APA StyleEverall, T. J., & Sanislav, I. V. (2018). The Influence of Pre-Existing Deformation and Alteration Textures on Rock Strength, Failure Modes and Shear Strength Parameters. Geosciences, 8(4), 124. https://doi.org/10.3390/geosciences8040124