High-Velocity Impact Performance of Aluminum and B4C/UHMW-PE Composite Plate for Multi-Wall Shielding

Abstract

:1. Introduction

2. Experimental Procedure

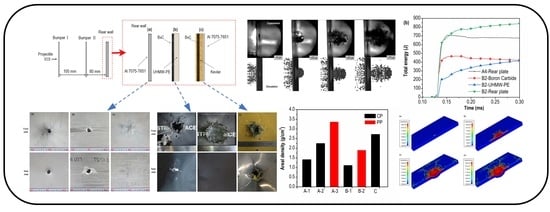

2.1. The Design of Shield Configurations

2.2. Measurement Method and Test Equipment

3. Numerical Modeling

4. Results and Discussion

4.1. Experiment Results

4.2. Numerical Modeling Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Whipple, F.L. Meteorites and Space Travel. Astron. J. 1947, 52, 131. [Google Scholar] [CrossRef] [Green Version]

- Christiansen, E.L. Meteoroid/Debris Shielding; National Aeronautics and Space Administration, Lyndon B. Johnson Space Center: Houston, TX, USA, 2003.

- Cherniaev, A.; Telichev, I. Sacrificial Bumpers with High-Impedance Ceramic Coating for Orbital Debris Shielding: A Preliminary Experimental and Numerical Study. Int. J. Impact Eng. 2018, 119, 45–56. [Google Scholar] [CrossRef]

- Huang, X.; Yin, C.; Huang, J.; Wen, X.; Zhao, Z.; Wu, J.; Liu, S. Hypervelocity Impact of Tib2-Based Composites as Front Bumpers for Space Shield Applications. Mater. Des. 2016, 97, 473–482. [Google Scholar] [CrossRef]

- Wang, B.; Xiong, J.; Wang, X.; Ma, L.; Zhang, G.; Wu, L.; Feng, J. Energy Absorption Efficiency of Carbon Fiber Reinforced Polymer Laminates Under High Velocity Impact. Mater. Des. 2013, 50, 140–148. [Google Scholar] [CrossRef]

- Johnson, N.L.; Stansbery, E.; Liou, J.C.; Horstman, M.; Stokely, C.; Whitlock, D. The Characteristics and Consequences of the Break-Up of the Fengyun-1C Spacecraft. Acta Astronaut 2008, 63, 128–135. [Google Scholar] [CrossRef] [Green Version]

- Cour-Palais, B.G. The Shape Effect of Non-Spherical Projectiles in Hypervelocity Impacts. Int. J. Impact Eng. 2001, 26, 129–143. [Google Scholar] [CrossRef]

- Hu, K.F.; Schonberg, W.P. Ballistic Limit Curves for Non-Spherical Projectiles Impacting Dual-Wall Spacecraft Systems. Int. J. Impact Eng. 2003, 29, 345–355. [Google Scholar] [CrossRef]

- Domnich, V.; Reynaud, S.; Haber, R.A.; Chhowalla, M. Boron Carbide: Structure, Properties, and Stability Under Stress. J. Am. Ceram. Soc. 2011, 94, 3605–3628. [Google Scholar] [CrossRef]

- Deng, M.; Shalaby, S.W. Properties of Self-Reinforced Ultra-High-Molecular-Weight Polyethylene Composites. Biomaterials 1997, 18, 645–655. [Google Scholar] [CrossRef]

- Schonberg, W.P.; Tullos, R.J. Spacecraft Wall Design for Increased Protection against Penetration by Orbital Debris Impacts. AIAA J. 1991, 29, 2207–2214. [Google Scholar] [CrossRef]

- Schäfer, F.; Lambert, M.; Christiansen, E.; Kibe, S.; Stokes, H.; Reimerdes, H.; Meshcheryakov, S.A.; Angrilli, F.; Zengyao, H. The Inter-Agency Space Debris Coordination Committee (Iadc) Protection Manual. In Proceedings of the 4th European Conference on Space Debris, Darmstadt, Germany, 18–20 April 2005. [Google Scholar]

- M. Standard, V50 ballistic test for armor[R], MIL-STD-662E. Department of Defense Test Method Standard. 1984.

- ANSYS AUTODYN 14.0; Theory Manual ANSYS Inc.: Pittsburgh, PA, USA, 2013.

- Kim, Y.; Choi, C.; Kumar, S.K.S.; Kim, C. Behavior of Dragon Skin Flexible Metal Bumper Under Hypervelocity Impact. Int. J. Impact Eng. 2019, 125, 13–26. [Google Scholar] [CrossRef]

- Johnson, G.R. A Constitutive Model and Data for Materials Subjected to Large Strains, High Strain Rates, and High Temperatures. In Proceedings of the Seventh International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Brar, N.S.; Joshi, V.S.; Harris, B.W. Constitutive Model Constants for Al7075-T651 and Al7075-T6. Aip Conf. Proc. 2009, 1195, 945–948. [Google Scholar]

- Johnson, G.R.; Holmquist, T.J. Response of Boron Carbide Subjected to Large Strains, High Strain Rates, and High Pressures. J. Appl. Phys. 1999, 85, 8060–8073. [Google Scholar] [CrossRef]

- Holmquist, T.J.; Johnson, G.R. Response of Boron Carbide Subjected to High-Velocity Impact. Int. J. Impact Eng. 2008, 35, 742–752. [Google Scholar] [CrossRef]

- Hayhurst, C.J.; Hiermaier, S.J.; Clegg, R.A.; Riedel, W.; Lambert, M. Development of Material Models for Nextel and Kevlar-Epoxy for High Pressures and Strain Rates. Int. J. Impact Eng. 1999, 23, 365–376. [Google Scholar] [CrossRef]

- Clegg, R.A.; White, D.M.; Riedel, W.; Harwick, W. Hypervelocity Impact Damage Prediction in Composites: Part 1—Material Model and Characterisation. Int. J. Impact Eng. 2006, 33, 190–200. [Google Scholar] [CrossRef]

- Riedel, W.; Nahme, H.; White, D.M.; Clegg, R.A. Hypervelocity Impact Damage Prediction in Composites: Part II—Experimental Investigations and Simulations. Int. J. Impact Eng. 2006, 33, 670–680. [Google Scholar] [CrossRef]

- Wicklein, M.; Ryan, S.; White, D.M.; Clegg, R.A. Hypervelocity Impact on CFRP: Testing, Material Modelling, and Numerical Simulation. Int. J. Impact Eng. 2008, 35, 1861–1869. [Google Scholar] [CrossRef] [Green Version]

- Anderson, C.E.; Cox, P.A.; Johnson, G.R.; Maudlin, P.J. A Constitutive Formulation for Anisotropic Materials Suitable for Wave Propagation Computer Programs II. Comput. Mech. 1994, 15, 201–223. [Google Scholar] [CrossRef]

- Chen, J.K.; Allahdadi, F.A.; Sun, C.T. A Quadratic Yield Function for Fiber-Reinforced Composites. J. Compos. Mater. 1997, 31, 788–811. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Läessig, T.R.; Ryan, S.; Riedel, W.; Mouritz, A.P.; Orifici, A.C. A Methodology for Hydrocode Analysis of Ultra-High Molecular Weight Polyethylene Composite Under Ballistic Impact. Compos. Part A Appl. Sci. Manuf. 2016, 84, 224–235. [Google Scholar] [CrossRef]

| Configuration No. | Composition of the Rear Plate | Areal Density (g/cm2) |

|---|---|---|

| A-1 | 5 mm Al7075-T651 | 1.402 |

| A-2 | 8 mm Al7075-T651 | 2.243 |

| A-3 | 12 mm Al7075-T651 | 3.365 |

| B-1 | 2 mm B4C/6 mm UHMW-PE | 1.091 |

| B-2 | 4 mm B4C/8 mm UHMW-PE | 1.790 |

| C | 2 mm Kevlar/6 mm B4C/2 mm Kevlar/2 mm Al7075-T651 | 2.730 |

| Parameter | Symbol | Values |

|---|---|---|

| Density (g/cm3) | ρ0z | 2.804 |

| Shear modulus (GPa) | G | 29 |

| Static yield strength (GPa) | A | 527 |

| Strain-hardening coefficient (GPa) | B | 575 |

| Strain-hardening exponent | n | 0.72 |

| Strain rate coefficient | C | 0.017 |

| Reference strain rate (s−1) | 1.0 | |

| Thermal softening exponent | m | 1.61 |

| Reference temperature (K) | t0 | 298 |

| Melting temperature | tm | 900 |

| Damage constant | D1 | 0.11 |

| Damage constant | D2 | 0.572 |

| Damage constant | D3 | −3.446 |

| Damage constant | D4 | 0.016 |

| Damage constant | D5 | 1.099 |

| Parameter | Symbol | Values |

|---|---|---|

| Density (g/cm3) | ρ0z | 2.508 |

| Bulk modulus (GPa) | K1 | 233 |

| Pressure coefficient (GPa) | K2 | −593 |

| Pressure coefficient (GPa) | K3 | 2800 |

| Shear modulus (GPa) | G | 197 |

| Hugoniot elastic limit (HEL) (GPa) | HEL | 19.0 |

| Intact strength coefficient | A | 0.9637 |

| Intact strength exponent | N | 0.67 |

| Strain rate coefficient | C | 0.005 |

| Fracture strength coefficient | B | 0.7311 |

| Fracture strength exponent | M | 0.85 |

| Maximum fracture strength | Sfmax | 0.2045 |

| Damage coefficient | D1 | 0.001 |

| Damage exponent | D2 | 0.5 |

| Bulking factor | β | 1.0 |

| Tensile strength (GPa) | σhyd | 0.26 |

| Parameter | Symbol | Values |

|---|---|---|

| EOS: Orthotropic | ||

| Density (g/cm3) | ρ | 0.98 |

| Young’s modulus 11 (GPa) | E11 | 3.62 |

| Young’s modulus 22 (GPa) | E22 | 51.1 |

| Young’s modulus 33 (GPa) | E33 | 51.1 |

| Poisson’s ratio 12 | v12 | 0.013 |

| Poisson’s ratio 23 | v23 | 0 |

| Poisson’s ratio 31 | v31 | 0.5 |

| Shear modulus 12 (GPa) | G12 | 2.0 |

| Shear modulus 23 (GPa) | G23 | 0.192 |

| Shear modulus 31 (GPa) | G31 | 2.0 |

| Volumetric response: Shock | ||

| Grüneisen coefficient | Γ | 1.64 |

| Parameter C1 (m/s) | c0 | 3570 |

| Parameter S1 | S | 1.3 |

| Reference temperature (K) | T0 | 293 |

| Specific heat (J/kg·K) | cv | 1850 |

| Failure: Orthotropic softening | ||

| Tensile failure stress 11 (GPa) | S11 | 1.01 × 1020 |

| Tensile failure stress 22 (GPa) | S22 | 1.15 |

| Tensile failure stress 33 (GPa) | S33 | 1.15 |

| Maximum shear stress 12 (GPa) | S12 | 0.575 |

| Maximum shear stress 23 (GPa) | S23 | 0.12 |

| Maximum shear stress 31 (GPa) | S31 | 0.575 |

| Fracture energy 11 (J/m2) | G11C | 790 |

| Fracture energy 22 (J/m2) | G22C | 30 |

| Fracture energy 33 (J/m2) | G33C | 30 |

| Fracture energy 12 (J/m2) | G12C | 1460 |

| Fracture energy 23 (J/m2) | G23C | 1460 |

| Fracture energy 31 (J/m2) | G31C | 1460 |

| Damage coupling coefficient | C | 0 |

| Strength: Orthotropic yield | ||

| Plasticity constant 11 | A11 | 0.016 |

| Plasticity constant 22 | A22 | 6 × 10−4 |

| Plasticity constant 33 | A33 | 6 × 10−4 |

| Plasticity constant 12 | A12 | 0 |

| Plasticity constant 13 | A13 | 0 |

| Plasticity constant 23 | A23 | 0 |

| Plasticity constant 44 | A44 | 1 |

| Plasticity constant 55 | A55 | 1.7 |

| Plasticity constant 66 | A66 | 1.7 |

| Eff. stress #1 (GPa) | σeff#1 | 1.48 × 10−3 |

| Eff. stress #2 (GPa) | σeff#2 | 7.0 × 10−3 |

| Eff. stress #3 (GPa) | σeff#3 | 0.027 |

| Eff. stress #4 (GPa) | σeff#4 | 0.04 |

| Eff. stress #5 (GPa) | σeff#5 | 0.05 |

| Eff. stress #6 (GPa) | σeff#6 | 0.06 |

| Eff. stress #7 (GPa) | σeff#7 | 0.08 |

| Eff. stress #8 (GPa) | σeff#8 | 0.098 |

| Eff. stress #9 (GPa) | σeff#9 | 0.2 |

| Eff. stress #10 (GPa) | σeff#10 | 1 |

| Eff. plastic strain #1 | εeff#1 | 0 |

| Eff. plastic strain #2 | εeff#2 | 0.01 |

| Eff. plastic strain #3 | εeff#3 | 0.1 |

| Eff. plastic strain #4 | εeff#4 | 0.15 |

| Eff. plastic strain #5 | εeff#5 | 0.175 |

| Eff. plastic strain #6 | εeff#6 | 0.19 |

| Eff. plastic strain #7 | εeff#7 | 0.2 |

| Eff. plastic strain #8 | εeff#8 | 0.205 |

| Eff. plastic strain #9 | εeff#9 | 0.21 |

| Eff. plastic strain #10 | εeff#10 | 0.215 |

| Configuration No. | Velocity (km/s) | Results |

|---|---|---|

| A-1 | 1.70 | CP |

| A-2 | 1.64 | CP |

| A-3 | 1.62 | PP |

| B-1 | 1.61 | CP |

| B-2 | 1.86 | PP |

| C | 1.61 | CP |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Zhang, Q.; Xue, Y.; Liu, W.; Long, R. High-Velocity Impact Performance of Aluminum and B4C/UHMW-PE Composite Plate for Multi-Wall Shielding. Appl. Sci. 2020, 10, 721. https://doi.org/10.3390/app10020721

Lu Y, Zhang Q, Xue Y, Liu W, Long R. High-Velocity Impact Performance of Aluminum and B4C/UHMW-PE Composite Plate for Multi-Wall Shielding. Applied Sciences. 2020; 10(2):721. https://doi.org/10.3390/app10020721

Chicago/Turabian StyleLu, Yangyu, Qingming Zhang, Yijiang Xue, Wenjin Liu, and Renrong Long. 2020. "High-Velocity Impact Performance of Aluminum and B4C/UHMW-PE Composite Plate for Multi-Wall Shielding" Applied Sciences 10, no. 2: 721. https://doi.org/10.3390/app10020721

APA StyleLu, Y., Zhang, Q., Xue, Y., Liu, W., & Long, R. (2020). High-Velocity Impact Performance of Aluminum and B4C/UHMW-PE Composite Plate for Multi-Wall Shielding. Applied Sciences, 10(2), 721. https://doi.org/10.3390/app10020721