Evolutionary Algorithms in Modeling Aerodynamic Properties of Spray-Dried Microparticulate Systems

Abstract

:1. Introduction

2. Materials and Methods

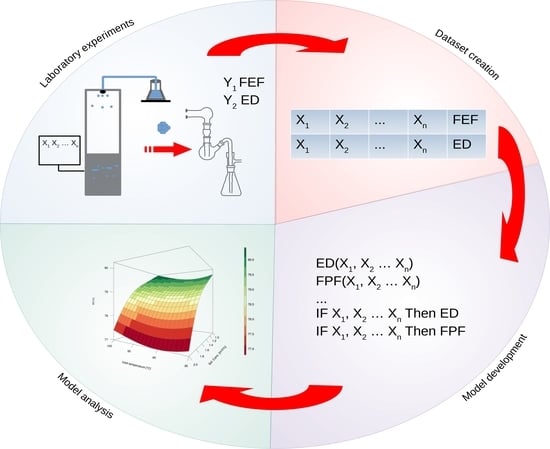

2.1. Models Development and Assessment

2.2. Evolutionary Algorithms

2.2.1. fugeR

2.2.2. rgp

3. Results and Discussion

3.1. Models for Prediction of FPF

- C1–C5: constants; C1 = 5.298; C2 = −524.223; C3 = −135.864; C4 = −13.842; C5 = 120.661,

- X1: API to excipient ratio [m/m%],

- X2: concentration of feed solution [m/V%],

- X3: ethanol to water ratio in solvent applied in the process [V/V%],

- X4: inlet air temperature during spray drying process [°C],

- M: mass,

- V: volume.

3.2. Models for Prediction of ED

- C1–C2: constants C1 = −5.029; C2 = 8.417,

- X1: API to excipient ratio [m/m%],

- X2: concentration of feed solution [m/V%],

- X3: ethanol to water ratio in solvent applied in the process [V/V%],

- X4: inlet air temperature during spray drying process [°C],

- X5: air flow during spray drying process [L/min],

- X6: pressure inside spray dryer during the process [mbar].

3.3. Model-Based Problem Analysis—Single Variable Impact

3.4. Model-Based Problem Analysis—Multi-Variables Impact

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Department of Health and Human Services, Food and Drug Administration. Guidance for Industry, PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance; CDER: Rockville, MD, USA, 2004.

- U.S. Department of Health and Human Services, Food and Drug Administration. Guidance for Industry, Q8(R2), Pharmaceutical Development; CDER: Silver Spring, MD, USA, 2009.

- Huang, S.M.; Zineh, I. Model-Informed Drug Development (MIDD): Opportunities and Challenges. Center for Drug Evaluation and Research US FDA, 2017. Available online: https://www.fda.gov/media/104616/download (accessed on 1 August 2020).

- Littringer, E.M.; Zellnitz, S.; Hammernik, K.; Adamer, V.; Friedl, H.; Urbanetz, N.A. Spray Drying of Aqueous Salbutamol Sulfate Solutions Using the Nano Spray Dryer B-90—The Impact of Process Parameters on Particle Size. Dry. Technol. 2013, 31, 1346–1353. [Google Scholar] [CrossRef]

- Karimi, K.; Pallagi, E.; Szabó-Révész, P.; Csóka, I.; Ambrus, R. Development of a microparticle-based dry powder inhalation formulation of ciprofloxacin hydrochloride applying the quality by design approach. Drug Des. Dev. Ther. 2016, 10, 3331–3343. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, X.; Zhang, W.; Hayes, D., Jr.; Mansour, H.M. Physicochemical characterization and aerosol dispersion performance of organic solution advanced spray-dried cyclosporine A multifunctional particles for dry powder inhalation aerosol delivery. Int. J. Nanomed. 2013, 8, 1269–1283. [Google Scholar] [CrossRef] [Green Version]

- Kulvanich, P.; Sinsuebpol, C.; Chatchawalsaisin, J. Preparation and in vivo absorption evaluation of spray dried powders containing salmon calcitonin loaded chitosan nanoparticles for pulmonary delivery. Drug Des. Dev. Ther. 2013, 7, 861–873. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maa, Y.F.; Costantino, H.R.; Nguyen, P.A.; Hsu, C.C. The effect of operating and formulation variables on the morphology of spray-dried protein particles. Pharm. Dev. Technol. 1997, 2, 213–223. [Google Scholar] [CrossRef] [PubMed]

- Taki, M.; Marriott, C.; Zeng, X.-M.; Martin, G.P. Aerodynamic deposition of combination dry powder inhaler formulations in vitro: A comparison of three impactors. Int. J. Pharm. 2010, 388, 40–51. [Google Scholar] [CrossRef] [PubMed]

- Council of Europe. Preparations for Inhalation: Aerodynamic Assessment of Fine Particles. In European Pharmacopoeia, 10th ed.; Council of Europe: Strasbourg, France, 2020; pp. 347–360. [Google Scholar]

- Pilcer, G.; Amighi, K. Formulation strategy and use of excipients in pulmonary drug delivery. Int. J. Pharm. 2010, 392, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Grasmeijer, N.; De Waard, H.; Hinrichs, W.L.J.; Frijlink, H.W. A User-Friendly Model for Spray Drying to Aid Pharmaceutical Product Development. PLoS ONE 2013, 8, e74403. [Google Scholar] [CrossRef] [Green Version]

- Goula, A.M.; Adamopoulos, K.G. Influence of Spray Drying Conditions on Residue Accumulation—Simulation Using CFD. Dry. Technol. 2004, 22, 1107–1128. [Google Scholar] [CrossRef]

- Amaro, M.I.; Tajber, L.; Corrigan, O.I.; Healy, A.M. Optimisation of spray drying process conditions for sugar nanoporous microparticles (NPMPs) intended for inhalation. Int. J. Pharm. 2011, 421, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Mazzoli, A.; Favoni, O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technol. 2012, 225, 65–71. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018; Available online: http://www.R-project.org/ (accessed on 1 August 2020).

- Mendyk, A.; Szlęk, J.; Pacławski, A. R Scripts for Multivariate Analysis 2020. Available online: https://sourceforge.net/projects/rscriptsmultivariate/files/ (accessed on 1 August 2020).

- Mendyk, A.; Szlęk, J.; Pacławski, A. R Scripts for Multivariate Analysis: fugeR. 2020. Available online: https://sourceforge.net/projects/rscriptsmultivariate/files/fugeR/ (accessed on 1 August 2020).

- Mendyk, A.; Szlęk, J.; Pacławski, A. R Scripts for Multivariate Analysis: rgp. 2020. Available online: https://sourceforge.net/projects/rscriptsmultivariate/files/rgp/ (accessed on 1 August 2020).

- Holland, J.H. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Khan, M.W.; Alam, M. A Survey of Application: Genomics and Genetic Programming, a New Frontier. Genomics 2012, 2, 65–71. [Google Scholar]

- Koza, J.R. Genetic Programming: On the Programming of Computers by Means of Natural Selection; MIT Press: Massachusetts, MA, USA, 1992. [Google Scholar]

- Polak, S.; Wiśniowska, B.; Mendyk, A.; Pacławski, A.; Szlęk, J. Quantitative Assessment of the Physiological Parameters Influencing QT Interval Response to Medication: Application of Computational Intelligence Tools. Comput. Math. Methods Med. 2018, 2018, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bujard, A. Fuger: Fuzzy Genetic, a Machine Learning Algorithm to Construct Prediction Model Based on Fuzzy Logic. R package version0.1.2. 2012. Available online: http://CRAN.R-project.org/package=fugeR (accessed on 1 August 2020).

- Zadeh, L.A. Fuzzy Sets. Inf. Control. 1965, 3, 338–353. [Google Scholar]

- Flasch, O.; Mersmann, O.; Bartz-Beielstein, T.; Stork, J.; Zaefferer, J. rgp: R genetic programming framework. R. package version0.4-1. 2014. Available online: https://cran.r-project.org/src/contrib/Archive/rgp/ (accessed on 1 August 2020).

- Shearer, C. The CRISP-DM Model: The New Blueprint for Data Mining. J. Data Warehous. 2000, 5, 13–22. [Google Scholar]

- Neustein, A. Text Mining of Web-Based Medical Content; Walter de Gruyter: Berlin, Germany, 2014; 100p. [Google Scholar]

- Pacławski, A.; Szlęk, J.; Nguyen, T.Q.N.; Lau, R.; Jachowicz, R.; Mendyk, A. Carrier optimization of pulmonary powder systems with using computational intelligence tools. Powder Technol. 2018, 329, 76–84. [Google Scholar] [CrossRef]

- Bosquillon, C.; Lombry, C.; Préat, V.; Vanbever, R. Influence of formulation excipients and physical characteristics of inhalation dry powders on their aerosolization performance. J. Control. Release 2001, 70, 329–339. [Google Scholar] [CrossRef]

- Corrigan, D.O.; Corrigan, O.I.; Healy, A. Physicochemical and in vitro deposition properties of salbutamol sulphate/ipratropium bromide and salbutamol sulphate/excipient spray dried mixtures for use in dry powder inhalers. Int. J. Pharm. 2006, 322, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Chew, N.Y.K.; Tang, P.; Chan, H.K.; Raper, J.A. How Much Particle Surface Corrugation Is Sufficient to Improve Aerosol Performance of Powders? Pharm. Res. 2005, 22, 148–152. [Google Scholar] [CrossRef] [PubMed]

- Murtomaa, M.; Mellin, V.; Harjunen, P.; Lankinen, T.; Laine, E.; Lehto, V.-P. Effect of particle morphology on the triboelectrification in dry powder inhalers. Int. J. Pharm. 2004, 282, 107–114. [Google Scholar] [CrossRef] [PubMed]

| API Content [m/m%] | Sol. Conc. [m/V%] | Ethanol [V/V%] | Inlet Air Temperature [°C] | Airflow [L/min] | Pressure [mbar] | FPF [%] | ED [%] |

|---|---|---|---|---|---|---|---|

| 50 | 2 | 40 | 85 | 95 | 50 | 64.88 | 77.00 |

| 50 | 1 | 30 | 85 | 95 | 50 | 85.80 | 98.55 |

| 50 | 2 | 30 | 85 | 110 | 65 | 68.73 | 81.97 |

| 95 | 1 | 40 | 100 | 95 | 50 | 35.95 | 69.56 |

| 72.5 | 1.5 | 35 | 93 | 103 | 58 | 46.42 | 74.22 |

| 50 | 2 | 30 | 100 | 110 | 50 | 55.04 | 79.72 |

| 95 | 2 | 30 | 100 | 95 | 50 | 37.06 | 74.90 |

| 95 | 2 | 40 | 85 | 110 | 50 | 33.84 | 76.38 |

| 50 | 1 | 40 | 100 | 110 | 50 | 56.44 | 72.35 |

| 95 | 1 | 40 | 85 | 95 | 65 | 26.96 | 68.13 |

| 50 | 2 | 40 | 100 | 95 | 65 | 51.42 | 73.64 |

| 95 | 1 | 30 | 85 | 110 | 50 | 27.36 | 71.44 |

| 95 | 1 | 30 | 100 | 110 | 65 | 50.06 | 84.02 |

| 50 | 1 | 40 | 85 | 110 | 65 | 76.45 | 103.23 |

| 95 | 2 | 40 | 100 | 110 | 65 | 39.30 | 83.67 |

| 50 | 1 | 30 | 100 | 95 | 65 | 58.45 | 98.69 |

| 95 | 2 | 30 | 85 | 95 | 65 | 34.50 | 75.71 |

| RMSE | R2 | NRMSE [%] | |

|---|---|---|---|

| lm() | 12.03 | 0.62 | 20.44 |

| fugeR | 5.21 | 0.84 | 8.86 |

| rgp | 4.88 | 0.91 | 8.29 |

| RMSE | R2 | NRMSE [%] | |

|---|---|---|---|

| lm() | 11.30 | 0.15 | 32.20 |

| fugeR | 5.17 | 0.39 | 14.73 |

| rgp | 2.88 | 0.95 | 8.14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacławski, A.; Szlęk, J.; Jachowicz, R.; Giovagnoli, S.; Wiśniowska, B.; Polak, S.; Czub, N.; Mendyk, A. Evolutionary Algorithms in Modeling Aerodynamic Properties of Spray-Dried Microparticulate Systems. Appl. Sci. 2020, 10, 7109. https://doi.org/10.3390/app10207109

Pacławski A, Szlęk J, Jachowicz R, Giovagnoli S, Wiśniowska B, Polak S, Czub N, Mendyk A. Evolutionary Algorithms in Modeling Aerodynamic Properties of Spray-Dried Microparticulate Systems. Applied Sciences. 2020; 10(20):7109. https://doi.org/10.3390/app10207109

Chicago/Turabian StylePacławski, Adam, Jakub Szlęk, Renata Jachowicz, Stefano Giovagnoli, Barbara Wiśniowska, Sebastian Polak, Natalia Czub, and Aleksander Mendyk. 2020. "Evolutionary Algorithms in Modeling Aerodynamic Properties of Spray-Dried Microparticulate Systems" Applied Sciences 10, no. 20: 7109. https://doi.org/10.3390/app10207109

APA StylePacławski, A., Szlęk, J., Jachowicz, R., Giovagnoli, S., Wiśniowska, B., Polak, S., Czub, N., & Mendyk, A. (2020). Evolutionary Algorithms in Modeling Aerodynamic Properties of Spray-Dried Microparticulate Systems. Applied Sciences, 10(20), 7109. https://doi.org/10.3390/app10207109