Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA)

Abstract

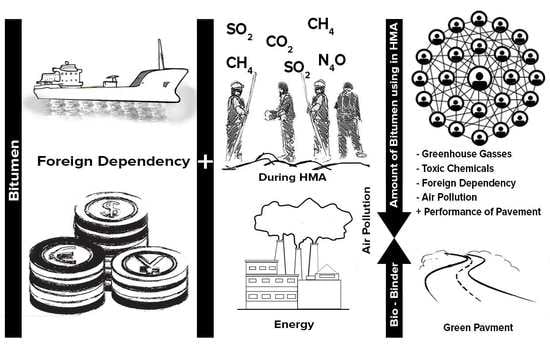

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Bitumen

2.1.2. Molasses

2.1.3. Aggregate

2.2. Methodologies

2.2.1. Effect of the Water Content of Molasses on MMBs

2.2.2. Distillation

2.2.3. Fourier Transform Infrared (FTIR) Spectrometer

2.2.4. Rolling Thin Film Oven (RTFO) Test

2.2.5. Dynamic Shear Rheometer (DSR) Test

2.2.6. Performance Grading (PG) Determination Test

2.2.7. Frequency Sweep Test (FST)

2.2.8. Dynamics Modulus Master Curve

2.2.9. Multiple Stress Creep Recovery (MSCR) Test

3. Results and Discussions

3.1. Effect of the Water Content of Molasses on MMBs

3.1.1. Penetration Resistance

3.1.2. Softening Point

3.1.3. Ductility

3.2. FTIR Test Results

3.3. RTFO Test Results

3.4. Performance Grade (PG)

3.5. FST Results

3.5.1. Low Temperature (Tref = 10 °C)

3.5.2. Intermediate Temperature (Tref = 37.8 °C)

3.5.3. High Temperature (Tree = 58 °C)

3.6. Multiple Stress Creep Recovery (MSCR) Test Result

4. Conclusions

- This research comprehensively evaluated the effect of using molasses as a modifier for neat bitumen in HMA using detailed experimental investigations. Based on the results obtained, the following conclusions have been made. The water content of molasses has a direct effect on the properties of the molasses’ modified binder. The properties of the binder are negatively affected by the increase in the moisture content of molasses.

- Within a wavenumber range of 3550 cm−1 and 3425 cm−1, the Alcohol (O-H stretching) fully reacted with the functional group and, around wave number 750 cm−1; Aromamins (C-H stretching) had partially reacted with the functional group.

- At low temperatures, the complex shear modulus of the molasses’ modified binders increased with the increase in the content of molasses. However, at high temperatures, the complex shear modulus decreased. Therefore, molasses improves the rutting resistance of the bitumen binder at a low temperature.

- PG determination tests confirmed that neat bitumen does not undergo a major change in the PG before and after RTFO aging. However, when the percentage of the bio-binder was increased, the complex shear modulus increased, which resulted in improving the PG from PG58 to PG64. After the RTFO aging condition, PG58 became PG70.

- The non-recoverable creep compliance (Jnr) of molasses’ modified binder increases as the temperature increases. A reduced Jnr value of the binders at 58 °C could result in improved rutting resistance potential.

- Overall, this study revealed that molasses treated for water content reduction could be used as a partial replacement for the bitumen binder to enhance the rheological properties of the binder and to produce a sustainable bio-asphalt binder.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D.M.; et al. Eco-Friendly Materials for a New Concept of Asphalt Pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; You, Z.; Mills-Beale, J. Asphalt Binders Blended with a High Percentage of Biobinders: Aging Mechanism Using FTIR and Rheology. J. Mater. Civ. Eng. 2014, 25, 864–870. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z.; Fini, E.; Zada, B.; Lee, C.H.; Yap, Y.K. Aging Influence on Rheology Properties of Petroleum-Based Asphalt Modified with Biobinder. J. Mater. Civ. Eng. 2014, 26, 358–366. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of Asphalt Binder Modified by Bio-Oil Derived from Waste Cooking Oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Du, Y.; Zhu, X.; Lu, T.; Pang, Q.; Shi, S.; Dai, Z. Evaluation of Optimized Bio-Asphalt Containing High Content Waste Cooking Oil Residues. Fuel 2017, 202, 529–540. [Google Scholar] [CrossRef]

- Dong, Z.; Yang, C.; Luan, H.; Zhou, T.; Wang, P. Chemical Characteristics of Bio-Asphalt and Its Rheological Properties after CR/SBS Composite Modification. Constr. Build. Mater. 2019, 200, 46–54. [Google Scholar] [CrossRef]

- Tayh, S.A.; Muniandy, R.; Hassim, S.; Jakarni, F.; Aburkaba, E. An Overview of Utilization of Bio-Oil in Hot Mix Asphalt. WALIA J. 2014, 30, 131–141. [Google Scholar]

- Gao, J.; Wang, H.; You, Z.; Hasan, M.R.M.; Lei, Y.; Irfan, M. Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef] [Green Version]

- Bahadori, A.; Li, R.; Zhang, K.; Xin, J.; Muhunthan, B.; Zhang, J. Performance Evaluation of Hot Mix Biobinder. In Airfield and Highway Pavements; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 255–265. [Google Scholar]

- Mose, G.Y.; Ponnurangam, P. Investigating the Effect of Cane Molasses on the Performance of Base Bitumen. Int. J. Res. Innov. Appl. Sci. 2019, III, 54–58. [Google Scholar]

- Abdulahi, T. Partial Replacement of Asphalt Bitumen with Sugarcane Molasses. Master’s Thesis, Addis Ababa Institute of Technology, Addis Ababa, Ethiopia, 2017. [Google Scholar]

- Prakash, K.S.; Phanindra, M.; Surya, S.R.; Naresh, J. Percentage Replacement of Bitumen with Sugarcane Waste Molasses. Int. J. Civ. Eng. Technol. 2014, 5, 188–197. [Google Scholar]

- M’Ndegwa, J.K. Diversifying the Use of Molasses Towards Improving the Infrastructure and Economy of Kenya. Civ. Environ. Res. 2016, 8, 37–42. [Google Scholar]

- Gürü, M.; Çubuk, M.; Arslan, D.; Aminbakhsh, S. Effects of Sugar Beet Molasses and Molasses-Based Boron Oxide Compound on Bitumen Properties. J. Mater. Civ. Eng. 2016, 4016252. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial Replacement of Asphalt Binder with Bio-Binder: Characterisation and Modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Walters, R.C.; Fini, E.H.; Abu-Lebdeh, T. Enhancing Asphalt Rheological Behavior and Aging Susceptibility Using Bio-Char and Nano-Clay. Am. J. Eng. Appl. Sci. 2014, 7, 66–76. [Google Scholar] [CrossRef]

- Rasman, M.; Hassan, N.A.; Hainin, M.R.; Putra Jaya, R.; Haryati, Y.; Shukry, N.A.M.; Abdullah, M.E.; Kamaruddin, N.H.M. Engineering Properties of Bitumen Modified with Bio-Oil. In Proceedings of the MATEC Web of Conferences, Johor, Malaysia, 27–28 August 2018; Volume 250. [Google Scholar] [CrossRef]

- Sun, D.; Lu, T.; Xiao, F.; Zhu, X.; Sun, G. Formulation and Aging Resistance of Modified Bio-Asphalt Containing High Percentage of Waste Cooking Oil Residues. J. Clean. Prod. 2017, 161, 1203–1214. [Google Scholar] [CrossRef]

- Wang, C.; Xue, L.; Xie, W.; You, Z.; Yang, X. Laboratory Investigation on Chemical and Rheological Properties of Bio-Asphalt Binders Incorporating Waste Cooking Oil. Constr. Build. Mater. 2018, 167, 348–358. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Chen, X.; Si, C.; Peng, C. Using Bio-Based Rejuvenator Derived from Waste Wood to Recycle Old Asphalt. Constr. Build. Mater. 2018, 189, 568–575. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q. Performance Evaluation of Asphalt Binder Modified by Bio-Oil Generated from Waste Wood Resources. Int. J. Pavement Res. Technol. 2013, 6, 431–439. [Google Scholar] [CrossRef]

- Vignesh, H.; Ramesh, N.G.; Manivasagan, V.; Suganya, S.; Eajas, M. Emerging Trends in Greener Pavements. Int. J. Eng. Res. Technol. 2013, 2, 1–4. [Google Scholar]

- Mizan, T.; Filimon, M.; Haftom, G.; Tsigereda, T.; Meseret, D.K.A.A.G. Assessing the Property of Molasses as a Bitumen Replacement; Dire Dawa University: Dire Dawa, Ethiopia, 2014. [Google Scholar]

- Shah, V.V.; Dave, H.K.; Raol, H.J.; Kalasareeya, D.D. A Study on Changes in Rheological Behaviour of Paving Grade Bitumen Using Admixtures. Int. J. Sci. Res. Dev. 2015, 3, 2024–2028. [Google Scholar]

- Mahlet, G. MahletGahsawMihretu and HabtamuMelese. Mapping Temperature Zone of Ethiopia for Binder Performance Grading System. Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2018. [Google Scholar]

- Francom, M.G.; Counselor, A. Ethiopia Aims to Become One of the World’ s Top 10 Sugar Producers; GAIN Report ET1532: Africa and Middle East, Ethiopia, 10 November 2015; p. 16. [Google Scholar]

- Melbourne. EcopaveAustralia GEO320 Technology. Available online: http://www.ecopave.com.au (accessed on 21 December 2015).

- U.S. Department of Transportation. Performance Testing for Superpave and Structural Validation; Georgetown Pike; United States Federal Highway Administration: Washington, DC, USA, 2012.

- Swami, B.L.; Mehta, Y.A.; Bose, S. A Comparison of the Marshall and Superpave Design Procedure for Materials Sourced in India. Int. J. Pavement Eng. 2004, 163–173. [Google Scholar] [CrossRef]

- Barco Carrión, A.J.; Lo Presti, D.; Pouget, S.; Airey, G.; Chailleux, E. Linear Viscoelastic Properties of High Reclaimed Asphalt Content Mixes with Biobinders. Road Mater. Pavement Des. 2017, 18, 241–251. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory Characterization of Asphalt Binders Modified with Waste Vegetable Oil Using SuperPave Specifications. Int. J. Pavement Res. Technol. 2018, 11, 68–76. [Google Scholar] [CrossRef]

- Mansourian, A.; Gholamzadeh, S. Moisture Susceptibility of Hot Mix Asphalt Containing Asphalt Binder Modified with Nanocomposite. Road Mater. Pavement Des. 2017, 18, 1434–1447. [Google Scholar] [CrossRef]

- Griffiths, P.R.; De Haseth, J.A. Fourier Transform Infrared Spectrometry, 2nd ed.; Wiley-Inter science: Hoboken, NJ, USA, 1967; Volume 42. [Google Scholar] [CrossRef]

- Berthomieu, C.; Hienerwadel, R. Fourier Transform Infrared (FTIR) Spectroscopy. Molecular Mechanisms of Uranium Tolerance View Project Radionuclide-Protein Interactions View Project Fourier Transform Infrared (FTIR) Spectroscopy. Photosynth. Res. 2009, 157–170. [Google Scholar] [CrossRef] [PubMed]

- Lamontagne, J.; Dumas, P.; Mouillet, V.; Kister, J. Comparison by Fourier Transform Infrared (FTIR) Spectroscopy of Different Ageing Techniques: Application to Road Bitumens. Fuel 2001, 80, 483–488. [Google Scholar] [CrossRef]

- AASHTO T 240. Standard Method of Test for Rolling Thin Film Oven Test for Asphalt Binders; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014; pp. 1–6. [Google Scholar]

- Zhang, R.; Wang, H.; Jiang, X.; You, Z.; Yang, X.; Ye, M. Thermal Storage Stability of Bio-Oil Modified Asphalt. J. Mater. Civ. Eng. 2018, 30, 04018054. [Google Scholar] [CrossRef]

- AASHTO T 315-10. Standard Method of Test for Determining the Rheological Properties of Asfhalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010. [Google Scholar]

- Witczak, M.W.; Kaloush, K.; Pellinen, T.; El-Basyouny, M.; Von Quintus, H. Simple Performance Test for Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2002. [Google Scholar] [CrossRef]

- ARA, Inc. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; ARA, Inc.: Lombard, IL, USA, 2003. [Google Scholar]

- Han, J.; Moraga, C. The influence of the sigmoid function parameters on the speed of backpropagation learning. Comput. Sci. 1995, 930, 195–201. [Google Scholar]

- Malcolm, L.W.; Robert, F.L.; John, D.F. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-forming Liquids. J. Am. Chem. Soc. 1995, 77, 3701–3707. [Google Scholar]

- Witczak, M.W. Development of Master Curve (G*) Data Base for Lime Modified Asphaltic Mixtures; Arizonasstat university: Tempe, AZ, USA, 2004. [Google Scholar]

- AASHTO T 350-19. Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019; p. 8. [Google Scholar]

- Subhy, A. Advanced Analytical Techniques in Fatigue and Rutting Related Characterisations of Modified Bitumen: Literature Review. Constr. Build. Mater. 2017, 156, 28–45. [Google Scholar] [CrossRef]

- Domingos, M.D.; Faxina, A.L. Susceptibility of Asphalt Binders to Rutting: Literature Review. J. Mater. Civ. Eng. 2015, 28, 04015134. [Google Scholar] [CrossRef]

- Zeng, M.; Pan, H.; Zhao, Y.; Tian, W. Evaluation of asphalt binder containing castor oil-based bioasphalt using conventional tests. Constr. Build. Mater. 2016, 126, 537–543. [Google Scholar] [CrossRef]

- AASHTO T 240. Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-film Oven Test); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- AASHTO M 320-16. Standard Specification for Performance-Graded Asphalt Binder; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016; p. 8. [Google Scholar]

- Anderson, M. Understanding the MSCR Test and its Use in the PG Asphalt Binder Specification 2011. Available online: https://docplayer.net/43840781-Understanding-the-mscr-test-and-its-use-in-the-pg-asphalt-binder-specification-r-michael-anderson-asphalt-institute-31-august-2011.html (accessed on 21 December 2015).

- AASHTO M 332-19. Standard Specification for Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2019; p. 7. [Google Scholar]

- Peralta, J.; Williams, R.C.; Silva, H.M.R.D.; Machado, A.V.A. Recombination of Asphalt with Bio-Asphalt: Binder Formulation and Asphalt Mixes Application. Asph. Paving Technol. Assoc. Asph. Paving Technol. Tech. Sess. 2014, 83, 1–36. [Google Scholar]

- Behnood, A.; McDaniel, R.; Shah, A.; Olek, J. Analysis of the Multiple Stress Creep Recovery Asphalt Binder Test and Specifications for Use in Indiana; (Joint Transportation Research Program Publication No. FHWA/IN/JTRP-2016/07); Purdue University: West Lafayette, IN, USA, 2016. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological Performance of Bio-Char Modified Asphalt with Different Particle Sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef] [Green Version]

| Sieve Size (mm) | Properties | Result | Specification | Test Method |

|---|---|---|---|---|

| 25–4.75 | Bulk specific gravity (SG) | 2.74 g/cm3 | * | ASTM C-127–68 |

| Apparent SG | 2.85g/cm3 | * | ASTM C-127–68 | |

| Water absorption | 1.1% | <2% | ASTM C-127–68 | |

| Soundness | 4.63% | 10–20% | ASTM C–88 | |

| Flakiness index | 4.00% | <10% | BS 812 | |

| Elongation index | 6.50% | <10% | BS 812 | |

| Impact value (IV) | 6.59% | <30% | BS 812:112 | |

| Crushing value (CV) | 12.65% | <35% | BS 812:110 | |

| Los-Angeles Abrasion LAT | 9.46% | 35–45% | ASTM C-131–69 | |

| 4.75–0.075 | SG | 2.71g/cm3 | * | ASTM C-127–68 |

| Apparent SG | 2.64 g/cm3 | * | ASTM C-127–68 | |

| Water absorption | 1.2% | <2% | ASTM C-127–68 | |

| Angularity | 78% | >45% | AASHTO T33 | |

| 0.075 | SG | 2.706 g/cm3 | * | ASTM C-127–68 |

| Binder Acronym | Definition |

|---|---|

| BB | Base bitumen(traditional petroleum asphalt) |

| M | Molasses |

| MMB | Molasses-modified binder |

| MMB5 | 95%Base Bitumen Blended with 5% Molasses |

| MMB10 | 90%Base Bitumen Blended With 10% Molasses |

| MMB15 | 85%Base Bitumen Blended with 15% Molasses |

| MMB20 | 80%Base Bitumen Blended With 20% Molasses |

| Test | Unit | MMB Containing Molasses with High &Low Moisture Contents | Spec. Requirement | Test Method | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MMB5 | MMB10 | MMB15 | MMB20 | ||||||||

| 24.9% | 5.02% | 24.9% | 5.02% | 24.9% | 5.02% | 24.9% | 5.02% | ||||

| Penetration (at 25 °C) | 0.1 mm | 95.4 | 86 | 101.6 | 88.6 | 108.3 | 91.3 | 131 | 112 | 80–100 | ASTM D5 |

| Softening | °C | 46.62 | 54.87 | 45.44 | 50.26 | 41.94 | 47.9 | 40.35 | 47.95 | 42–52 | ASTM D36 |

| Ductility (at 25 °C) | cm | 93 | 108 | 85 | 101 | 76 | 89 | 69 | 77 | >100 | ASTM D113 |

| water content | % | 1.32 | 0.97 | 2.56 | 1.94 | 3.8 | 2.05 | 5.05 | 2.12 | 1 | AASHTO T55 |

| Test | Unit | Molasses Modified Binder (MMB) | Spec. Requirement | Test Method ASTM | |||

|---|---|---|---|---|---|---|---|

| MMB5 | MMB10 | MMB15 | MMB20 | ||||

| Fire point | °C | 335 | 338 | 342 | 345 | >250 | D92 |

| Flash point | °C | 317 | 320 | 322 | 325 | >225 | D92 |

| Index | BB | Molasses | MMB5 | MMB10 |

|---|---|---|---|---|

| 0.0059 | 0.0068 | 0.0062 | 0.0067 | |

| 0.0011 | 0.0029 | 0.0013 | 0.0013 |

| Asphalt Binder | Region | Wave Number (cm−1) | Functional Group | Intensity | Signal | |

|---|---|---|---|---|---|---|

| BB | Diagnostic or functional group region (FGR) | 3600–3300 | O-H stretching | Alcohol | Strong | Broad |

| 3000–2840 | C-H Stretching | Alkanet | Strong | Broad | ||

| 2800–2750 | C-H Bend | Aldehyde | Weak | Sharp | ||

| 2720–2700 | C-H Stretching | Aldehyde | Weak | Sharp | ||

| 1680–1600 | C=C Stretching | Alkene | Medium | Sharp | ||

| Finger print region (FPR) | 1470–1450 | C-H Bend | Alkane | Strong | Sharp | |

| 1365–1350 | C-H Bend | Alkane | Strong | Sharp | ||

| 1300–1260 | C-N Bend | Aromamins | Weak | Sharp | ||

| 775–725 | C-H Bend | Aromatic | Medium | Sharp | ||

| M | FGR | 3600–3300 | O-H stretching | Alcohol | Strong | Broad |

| 3000–2840 | C-H Stretching | Alkane | Strong | Broad | ||

| 1680–1600 | C=C Stretching | Alkene | Weak | Board | ||

| FPR | 1470–1450 | C-H Bend | Alkane | Strong | Sharp | |

| 1365–1350 | C-H Bend | Alkane | Strong | Sharp | ||

| 775–725 | C-H Bend | Aromatic | Weak | Sharp | ||

| MMB5 | FGR | 2990–2940 | C-H Stretching | Alkane | Strong | Sharp |

| 2925–2875 | C-H Stretching | Alkane | Strong | Sharp | ||

| FPR | 1425–1375 | C-H Bend | Alkane | Strong | Sharp | |

| 1350–1320 | C-H Bend | Alkane | Strong | Sharp | ||

| 775–725 | C-H Bend | Aromatic | Weak | V. Sharp | ||

| MMB10 | FGR | 2960–2875 | C-H Stretching | Aldehyde | Strong | Broad |

| FPR | 1450–1400 | C-H Bend | Alkane | Medium | Sharp |

| Binder | BB | MMB5 | MMB10 | MMB15 | MMB20 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Specimen | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 |

| Change in mass (%) | 0.10 | 0.07 | 1.022 | 0.971 | 1.907 | 1.977 | 2.096 | 2.048 | 2.103 | 2.134 |

| Average loss (%) | 0.623 | 0.996 | 1.94 | 2.048 | 2.118 | |||||

| Binder | Temp. (°C) | Phase Angle (deg) | Complex Modulus (Pa) | G*/sinδ (kPa) | Pass/Fail Temp. (°C) | Remark | PG |

|---|---|---|---|---|---|---|---|

| BB | 58 | 86.90 | 1913 | 1.92 | 58 | Pass | 58 |

| 64 | 87.75 | 848 | 0.85 | 62.2 | Fail | ||

| MMB5 | 64 | 87.81 | 1261 | 1.26 | 64 | Pass | 64 |

| 70 | 88.49 | 595 | 0.60 | 65.9 | Fail | ||

| MMB10 | 64 | 86.94 | 1100 | 1.10 | 64 | Pass | 64 |

| 70 | 87.73 | 541 | 0.54 | 64.6 | Fail | ||

| MMB15 | 64 | 85.69 | 1022 | 1.03 | 64 | Pass | 64 |

| 70 | 85.79 | 507 | 0.51 | 64.2 | Fail | ||

| MMB20 | 64 | 87.37 | 1193 | 1.02 | 64 | Pass | 64 |

| 70 | 87.90 | 572 | 0.50 | 65.4 | Fail |

| Binder | Temp. (°C) | Phase Angle (deg) | Complex Modulus (Pa) | G*/sinδ (kPa) | Pass/ Fail Temp. (°C) | Remark | PG |

|---|---|---|---|---|---|---|---|

| BB | 58 | 83.26 | 4988 | 4.95 | 58 | Pass | 58 |

| 64 | 85.30 | 2067 | 2.04 | 63.6 | Fail | ||

| MMB5 | 76 | 87.71 | 4185 | 4.18 | 76 | Pass | 76 |

| 82 | 88.44 | 2099 | 2.10 | 82 | Fail | ||

| MMB10 | 70 | 86.83 | 3360 | 3.35 | 70 | Pass | 70 |

| 76 | 87.71 | 1620 | 1.62 | 73.5 | Fail | ||

| MMB15 | 70 | 86.40 | 3929 | 3.92 | 70 | Pass | 70 |

| 76 | 85.54 | 2105 | 2.10 | 75.6 | Fail | ||

| MMB20 | 70 | 85.16 | 2289 | 1.53 | 70 | Pass | 70 |

| 76 | 85.28 | 1087 | 1.08 | 70.4 | Fail |

| Binder Ration | BB | MMB5 | MMB10 | MMB15 | MMB20 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Description | Test Temperature (°C) | Test Temperature (°C) | Test Temperature (°C) | Test Temperature (°C) | Test Temperature (°C) | ||||||||||

| 52 | 58 | 64 | 52 | 58 | 64 | 52 | 58 | 64 | 52 | 58 | 64 | 52 | 58 | 64 | |

| Jnr at 3.2 (kPa) | 0.41 | 1.18 | 2.01 | 0.47 | 0.79 | 1.10 | 0.42 | 0.70 | 3.42 | 0.41 | 1.05 | 2.98 | 0.31 | 1.14 | 2.98 |

| Std. Deviation (kPa) | 0.28 | 0.44 | 1.22 | 0.04 | 0.02 | 0.01 | 0.02 | 0.02 | 0.04 | 0.08 | 0.10 | 0.03 | 0.02 | 0.03 | 0.18 |

| PG Grade | 52E | 58H | 64S | 52V | 58E | 64H | 52E | 58V | 64S | 52E | 58H | 64S | 52E | 58H | 64S |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hareru, W.; Ghebrab, T. Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA). Appl. Sci. 2020, 10, 1931. https://doi.org/10.3390/app10061931

Hareru W, Ghebrab T. Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA). Applied Sciences. 2020; 10(6):1931. https://doi.org/10.3390/app10061931

Chicago/Turabian StyleHareru, Werku, and Tewodros Ghebrab. 2020. "Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA)" Applied Sciences 10, no. 6: 1931. https://doi.org/10.3390/app10061931

APA StyleHareru, W., & Ghebrab, T. (2020). Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA). Applied Sciences, 10(6), 1931. https://doi.org/10.3390/app10061931