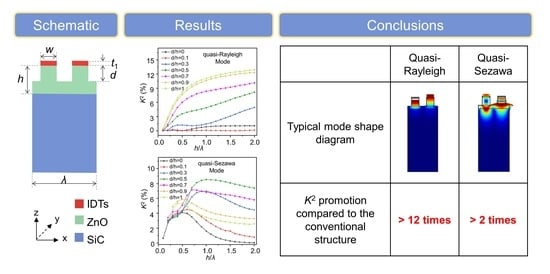

Enhanced Coupling Coefficient in Dual-Mode ZnO/SiC Surface Acoustic Wave Devices with Partially Etched Piezoelectric Layer

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Etching Ratio and Piezoelectric Film Thickness

3.2. Top Electrodes

3.3. Metallization Ratio

3.4. Bottom Electrodes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruby, R. A snapshot in time: The future in filters for cell phones. IEEE Microw. Mag. 2015, 16, 46–59. [Google Scholar] [CrossRef]

- Tong, J.; Jia, Y.; Wang, W.; Wang, Y.; Wang, S.; Liu, X.; Lei, Y. Development of a magnetostrictive FeNi coated surface acoustic wave current sensor. Appl. Sci. 2017, 7, 755. [Google Scholar] [CrossRef] [Green Version]

- Brick, D.; Emre, E.; Grossmann, M.; Dekorsy, T.; Hettich, M. Picosecond photoacoustic metrology of SiO2 and LiNbO3 layer systems used for high frequency surface-acoustic-wave filters. Appl. Sci. 2017, 7, 822. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Cai, Y.; Zhang, Y.; Tovstopyat, A.; Liu, S.; Sun, C. Materials, design, and characteristics of bulk acoustic wave resonator: A review. Micromachines 2020, 11, 630. [Google Scholar] [CrossRef]

- Shen, J.; Fu, S.; Su, R.; Xu, H.; Zeng, F.; Song, C.; Pan, F. Systematical study of the basic properties of surface acoustic wave devices based on zno and gan multilayers. Electronics 2021, 10, 23. [Google Scholar] [CrossRef]

- Mimura, M.; Ajima, D.; Konoma, C.; Murase, T. Small sized band 20 SAW duplexer using low acoustic velocity Rayleigh SAW on LiNbO3 substrate. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Fu, S.; Su, R.; Xu, H.; Lu, Z.; Xu, Z.; Luo, J. High-Performance Surface Acoustic Wave Devices Using LiNbO3/SiO2/SiC Multilayered Substrates. IEEE Trans. Microw. Theory Tech. 2021, 1–13. [Google Scholar] [CrossRef]

- Wang, L.; Chen, S.; Zhang, J.; Xiao, D.; Han, K.; Ning, X.; Liu, J.; Chen, Z.; Zhou, J. Enhanced performance of 17.7 GHz SAW devices based on AlN/diamond/Si layered structure with embedded nanotransducer. Appl. Phys. Lett. 2017, 111. [Google Scholar] [CrossRef]

- Su, R.; Fu, S.; Shen, J.; Chen, Z.; Lu, Z.; Yang, M.; Wang, R.; Zeng, F.; Wang, W.; Song, C.; et al. Enhanced Performance of ZnO/SiO2/Al2O3Surface Acoustic Wave Devices with Embedded Electrodes. ACS Appl. Mater. Interfaces 2020, 12, 42378–42385. [Google Scholar] [CrossRef]

- Lin, C.M.; Chen, Y.Y.; Felmetsger, V.V.; Senesky, D.G.; Pisano, A.P. AlN/3C-SiC composite plate enabling high-frequency and high-Q micromechanical resonators. Adv. Mater. 2012, 24, 2722–2727. [Google Scholar] [CrossRef]

- Fu, S.; Li, Q.; Gao, S.; Wang, G.; Zeng, F.; Pan, F. Quality-enhanced AlN epitaxial films grown on c-sapphire using ZnO buffer layer for SAW applications. Appl. Surf. Sci. 2017, 402, 392–399. [Google Scholar] [CrossRef]

- Mitsuyu, T.; Ono, S.; Wasa, K. Structures and SAW properties of rf-sputtered single-crystal films of ZnO on sapphire. J. Appl. Phys. 1980, 51, 2464–2470. [Google Scholar] [CrossRef]

- Cimalla, V.; Pezoldt, J.; Ambacher, O. Group III nitride and SiC based MEMS and NEMS: Materials properties, technology and applications. J. Phys. D. Appl. Phys. 2007, 40, 6386–6434. [Google Scholar] [CrossRef]

- Li, Q.; Fu, S.; Song, C.; Wang, G.; Zeng, F.; Pan, F. Sputtering power dependence of structure and photoluminescence of ZnO on 6H–SiC. J. Mater. Sci. Mater. Electron. 2017, 28, 17881–17888. [Google Scholar] [CrossRef]

- Fu, S.; Wang, W.; Qian, L.; Li, Q.; Lu, Z.; Shen, J.; Song, C.; Zeng, F.; Pan, F. High-frequency surface acoustic wave devices based on ZnO/SiC layered structure. IEEE Electron Device Lett. 2019, 40, 103–106. [Google Scholar] [CrossRef]

- Akiyama, M.; Kamohara, T.; Kano, K.; Teshigahara, A.; Takeuchi, Y.; Kawahara, N. Enhancement of piezoelectric response in scandium aluminum nitride alloy thin films prepared by dual reactive cosputtering. Adv. Mater. 2009, 21, 593–596. [Google Scholar] [CrossRef]

- Iborra, E.; Capilla, J.; Olivares, J.; Clement, M.; Felmetsger, V. Piezoelectric and electroacoustic properties of Ti-doped AlN thin films as a function of Ti content. IEEE Int. Ultrason. Symp. IUS 2012, 2734–2737. [Google Scholar] [CrossRef] [Green Version]

- Mayrhofer, P.M.; Riedl, H.; Euchner, H.; Stöger-Pollach, M.; Mayrhofer, P.H.; Bittner, A.; Schmid, U. Microstructure and piezoelectric response of YxAl1-xN thin films. Acta Mater. 2015, 100, 81–89. [Google Scholar] [CrossRef] [Green Version]

- Iborra, E.; Olivares, J.; Clement, M.; Capilla, J.; Felmetsger, V.; Mikhov, M. Piezoelectric and electroacoustic properties of V-doped and Ta-doped AlN thin films. In Proceedings of the 2013 Joint European Frequency and Time Forum & International Frequency Control Symposium (EFTF/IFC), Prague, Czech Republic, 21–25 July 2013; pp. 262–265. [Google Scholar] [CrossRef]

- Luo, J.T.; Yang, Y.C.; Zhu, X.Y.; Chen, G.; Zeng, F.; Pan, F. Enhanced electromechanical response of Fe-doped ZnO films by modulating the chemical state and ionic size of the Fe dopant. Phys. Rev. B Condens. Matter Mater. Phys. 2010, 82, 1–7. [Google Scholar] [CrossRef]

- Luo, J.T.; Zeng, F.; Pan, F.; Li, H.F.; Niu, J.B.; Jia, R.; Liu, M. Filtering performance improvement in V-doped ZnO/diamond surface acoustic wave filters. Appl. Surf. Sci. 2010, 256, 3081–3085. [Google Scholar] [CrossRef]

- Moreira, M.; Bjurström, J.; Katardjev, I.; Yantchev, V. Aluminum scandium nitride thin-film bulk acoustic resonators for wide band applications. Vacuum 2011, 86, 23–26. [Google Scholar] [CrossRef]

- Zhang, Q.; Han, T.; Chen, J.; Wang, W.; Hashimoto, K. Enhanced coupling factor of surface acoustic wave devices employing ScAlN/diamond layered structure with embedded electrodes. Diam. Relat. Mater. 2015, 58, 31–34. [Google Scholar] [CrossRef]

- Kadota, M.; Kimura, T.; Ida, Y. Ultra wide band saw resonator composed of grooved Cu electrodes and its application to tunable filters. IEEJ Trans. Electron. Inf. Syst. 2011, 131, 1108–1114. [Google Scholar] [CrossRef]

- Zou, J.; Lin, C.M.; Lam, C.S.; Pisano, A.P. Transducer design for AlN Lamb wave resonators. J. Appl. Phys. 2017, 121. [Google Scholar] [CrossRef]

- Pashchenko, V.; Matloub, R.; Muralt, P.; Haffner, K. Hybrid BAW/SAW AlN and AlScN Thin Film Resonator. In Proceedings of the 2016 IEEE International Ultrasonics Symposium (IUS), Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Hadj-Larbi, F.; Serhane, R. Sezawa SAW devices: Review of numerical-experimental studies and recent applications. Sens. Actuators A Phys. 2019, 292, 169–197. [Google Scholar] [CrossRef]

- Martin, S.J.; Grate, J.W.; White, R.M. Acoustic Wave Microsensors. Anal. Chem. 1993, 65, 940–948. [Google Scholar]

- Hashimoto, K.Y.; Asano, H.; Omori, T.; Yamaguchi, M. Ultra-wideband surface acoustic wave devices using Cu-grating/rotated-YX- LiNbO3-substrate structure. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2004, 43, 3063–3066. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, J.; Xie, Y.; Tang, C.; Zou, Y.; Tovstopyat, A.; Yu, H.; Sun, C. Dual-Mode Hybrid Quasi-SAW/BAW Resonators with High Effective Coupling Coefficient. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 1916–1921. [Google Scholar] [CrossRef]

- Zou, J.; Lam, C.S. Electrode design of AlN Lamb wave resonators. In Proceedings of the 2016 IEEE International Frequency Control Symposium (IFCS), New Orleans, LA, USA, 9–12 May 2016. [Google Scholar] [CrossRef]

- Yantchev, V.; Turner, P.J.; McHugh, S.; Iliev, F.; Sato, T.; Lee, K.W.; Lee, C.H. Parametric study of resonant TC-SAW piston-mode configurations. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 17–20. [Google Scholar] [CrossRef]

- Su, R.; Shen, J.; Lu, Z.; Xu, H.; Niu, Q.; Xu, Z. Wideband and Low-Loss Surface Acoustic Wave Filter Based on 15°YX-LiNbO3/SiO2/Si Structure. IEEE Electron Device Lett. 2021, 42, 438–441. [Google Scholar] [CrossRef]

- Rughoobur, G.; Demiguel-Ramos, M.; Mirea, T.; Clement, M.; Olivares, J.; Díaz-Durán, B.; Sangrador, J.; Miele, I.; Milne, W.I.; Iborra, E.; et al. Room temperature sputtering of inclined c-axis ZnO for shear mode solidly mounted resonators. Appl. Phys. Lett. 2016, 108, 034103. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.Z.; Peng, B.; Shu, L.; Li, Y.R. AlN-based surface acoustic wave resonators on platinum bottom electrodes for high-temperature sensing applications. Rare Met. 2016, 35, 408–411. [Google Scholar] [CrossRef]

- Rughoobur, G.; Demiguel-Ramos, M.; Escolano, J.M.; Iborra, E.; Flewitt, A.J. Gravimetric sensors operating at 1.1 GHz based on inclined c-axis ZnO grown on textured Al electrodes. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Fu, S.; Su, R.; Shen, J.; Zeng, F.; Song, C.; Pan, F. Enhanced Coupling Coefficient in Dual-Mode ZnO/SiC Surface Acoustic Wave Devices with Partially Etched Piezoelectric Layer. Appl. Sci. 2021, 11, 6383. https://doi.org/10.3390/app11146383

Xu H, Fu S, Su R, Shen J, Zeng F, Song C, Pan F. Enhanced Coupling Coefficient in Dual-Mode ZnO/SiC Surface Acoustic Wave Devices with Partially Etched Piezoelectric Layer. Applied Sciences. 2021; 11(14):6383. https://doi.org/10.3390/app11146383

Chicago/Turabian StyleXu, Huiping, Sulei Fu, Rongxuan Su, Junyao Shen, Fei Zeng, Cheng Song, and Feng Pan. 2021. "Enhanced Coupling Coefficient in Dual-Mode ZnO/SiC Surface Acoustic Wave Devices with Partially Etched Piezoelectric Layer" Applied Sciences 11, no. 14: 6383. https://doi.org/10.3390/app11146383

APA StyleXu, H., Fu, S., Su, R., Shen, J., Zeng, F., Song, C., & Pan, F. (2021). Enhanced Coupling Coefficient in Dual-Mode ZnO/SiC Surface Acoustic Wave Devices with Partially Etched Piezoelectric Layer. Applied Sciences, 11(14), 6383. https://doi.org/10.3390/app11146383