Volatile Organic Compounds in Breads Prepared with Different Sourdoughs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Sourdough Preparation

2.3. Bread Preparation

2.4. Sourdough Microbiological Characterization

2.5. Physicochemical Analysis

2.6. Determination of Organic Acids in Sourdough and Bread

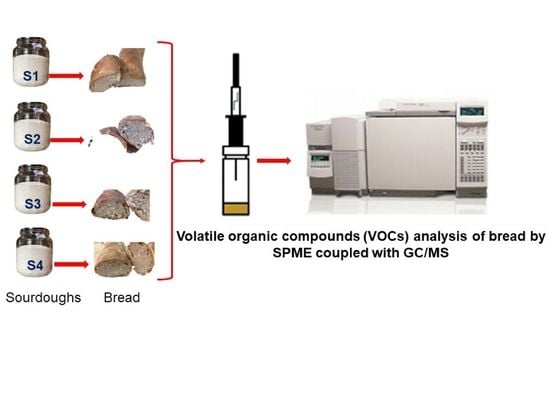

2.7. Volatile Organic Compounds of Bread

2.8. Statistical Analysis

3. Results

3.1. Microbiological and Physicochemical Analysis

3.2. Organic Acid in Sourdough and Bread

3.3. Volatile Organic Compounds of Bread

| Retention Index (min.) | Compound | S1 Bread | S2 Bread | S3 Bread | S4 Bread | Odor Descriptors |

|---|---|---|---|---|---|---|

| Alcohols | 367.33 a ± 25.10 | 140.88 c ± 3.98 | 401.20 a ± 1.70 | 276.49 b ± 15.45 | ||

| 1.57 | Ethanol | 202.73 a ± 26.34 | 58.45 c ± 0.86 | 185.52 b ±1.68 | 131.84 b ± 16.65 | Strong, alcoholic, ethereal, medicinal [3] |

| 3.25 | 3-Methyl-1-butanol | 84.45 b ± 2.06 | 30.24 d ± 1.68 | 97.46 a ± 0.21 | 52.25 c ± 1.93 | Banana, fruity, almonds [3] |

| 3.34 | 2-Methyl-1-butanol | 8.05 b ± 0.60 | 3.43 c ± 0.65 | 13.30 a ± 0.68 | 9.63 b ± 0.81 | Malty [56,57] |

| 3.81 | 1-Pentanol | 11.06 b ± 0.42 | 6.17 c ± 0.41 | 14.48 a ± 0.01 | 13.53 a ± 0.65 | Oil, sweet, balsamine, chemical mint, fusel like [3,49] |

| 5.90 | 1-Hexanol | 47.23 b,c ± 5.40 | 33.60 c ±4.06 | 65.72 a ± 1.40 | 57.98 a,b ± 1.13 | Ethereal, oil, alcohol, green, fruity, sweet, woody, floral compounds [3,48] |

| 12.12 | 2-Phenylethanol | 8.82 b ± 0.58 | 4.26 c ± 0.03 | 18.96 a ± 0.62 | 5.45 c ± 0.15 | Flowers, rose [45] |

| 9.94 | 2-Ethyl-1-hexanol | 5.32 a ± 0.53 | 4.73 a ± 0.29 | 5.76 a ± 0.36 | 5.81 a ± 0.38 | Green/vegetables [11,51] |

| Aldehydes | 231.63 b ± 1.86 | 185.01 c ± 3.98 | 253.51 b ± 4.98 | 454.95 a ± 5.15 | ||

| 1.83 | 2-Methylpropanal | 4.07 b ± 0.40 | 3.53 b ± 0.37 | 2.33 b ± 0.40 | 12.78 a ± 1.92 | Malty, fruity [3,49,52] |

| 2.39 | 3-Methylbutanal | 23.24 b ± 1.52 | 35.43 b ± 1.61 | 25.48 b ± 0.44 | 110.69 a ± 5.91 | Malty, fruity [3,49,52] |

| 2.47 | 2-Methyllbutanal | 13.57 a,b ± 1.94 | 9.13 b ± 1.11 | 12.64 a,b ± 0.68 | 29.37 a ± 8.30 | Malty, fruity [3,49,52] |

| 4.40 | Hexanal | 78.72 a,b ± 0.97 | 59.59 b ± 4.46 | 97.33 a ± 5.59 | 103.69 a ± 16.53 | Fresh, green, fatty, aldehydic, grass, leafy, fruity, sweaty, tallow [3,11,49] |

| 5.10 | Furfural | 54.37 a,b ± 1.28 | 16.73 b ± 4.00 | 31.98 b ± 0.60 | 94.66 a ± 21.16 | Burnt, sweet, woody, almond, bread, rancid [3] |

| 6.70 | Heptanal | 8.76 b ± 0.48 | 7.59 b ± 3.29 | 15.74 a,b ± 1.21 | 20.34 a ± 1.96 | Green, rancid, aldehydic, fatty, grass [3] |

| 8.17 | Benzaldehyde | 11.62 a,b ± 0.31 | 9.64 b ± 0.87 | 15.40 a ± 1.54 | 15.70 a ± 2.04 | Almond, sweet, cherry [3,51] |

| 9.27 | Octanal | <4.00 | <4.00 | <4.00 | 11.27 a ± 0.94 | Citrus-like, green [56] |

| 10.33 | Benzeneacetaldehyde | 23.92 a ± 0.54 | 12.20 b ± 1.19 | 26.75 a ± 2.41 | 29.10 a ± 2.53 | Honey-like [3] |

| 11.87 | Nonanal | 13.36 b ± 1.86 | 31.17 a ± 4.61 | 23.53 a,b ± 1.04 | 27.35 a,b ± 6.04 | Soapy, fruit, rose, citrus, orange [3,47] |

| Ketones | nf | 9.82 a ± 0.79 | nf | 8.43 a ± 0.62 | ||

| 2.77 | 2,3-Pentadione | <5.00 | <5.00 | <5.00 | 8.43 a ± 0.62 | |

| 8.88 | 6-Methyl-5-hepten-2one | <5.00 | 9.82 a ± 0.79 | <5.00 | <5.00 | |

| Organic acids | 171.57 a ± 17.17 | 91.40 b ± 6.38 | 173.81 a ± 1.18 | 143.04 a ± 13.34 | ||

| 1.94 | Acetic acid | 171.57 a ± 17.17 | 91.40 b ± 6.38 | 173.81 a ± 1.18 | 143.04 a ± 13.34 | Sharp, Acrid, Vinegar, Sour [11,47] |

| Heterocyclic compounds | 56.28 b ± 1.69 | 39.74 c ± 1.10 | 57.88 b ± 6.10 | 79.09 a ± 2.81 | ||

| 8.98 | 2-Pentylfuran | 53.30 b ± 1.65 | 31.95 c ± 1.09 | 52.90 b ± 8.39 | 72.49 a ± 3.01 | Fruity, green, earthy, bean, metallic [2,3] |

| 13.26 | 2,3-Dihydrofuran | 2.98 c ± 0.38 | 7.79 a ± 0.71 | 4.98 b ± 0.15 | 6.60 a,b ± 0.53 | |

| Alkanes | 43.35 b ± 3.10 | 31.68 d ± 2.10 | 67.03 a ± 2.14 | 38.88 c ± 1.44 | ||

| 2.00 | Hexane | <4.00 | 9.81 a ± 1.98 | 9.07 a ± 1.36 | <4.00 | |

| 3.57 | 2,3-Dimethylhexane | <5.00 | 9.21 a ± 0.02 | <5.00 | <5.00 | |

| 3.78 | Isoctane | 13.90 a ± 3.44 | 6.01 a ± 0.34 | 12.41 a ± 1.19 | 13.35 a ± 1.70 | |

| 4.04 | 2,2,5-Trimethylhexane | 9.02 b ± 0.93 | <4.00 | 16.42 a ± 2.09 | 18.83 a ± 0.16 | |

| 7.40 | 2-Nonane | 20.43 a ± 3.69 | 6.65 b ± 0.66 | 16.60 a ± 1.47 | <3.00 | |

| 9.53 | 2,5,5-Trimethylheptane | <3.00 | <3.00 | 12.53 a ± 0.89 | 6.70 b ± 0.04 | |

| Others | 112.99 a ± 3.38 | 57.23 c ± 1.44 | 121.37 a ± 3.44 | 72.55 b ± 3.32 | ||

| 5.26 | 2,4-Dimethylheptene | 75.34 a ± 4.82 | 27.96 b ± 6.02 | 61.37 a ± 0.85 | 42.10 b ± 4.20 | |

| 6.48 | p-Xylene | <5.00 | <5.00 | 12.92 ± 0.54 | <5.00 | |

| 10.70 | 4,4-Dimethyl-1-pentene | 3.84 b ± 0.22 | 4.76 a ± 0.17 | 2.68 c ± 0.25 | 3.46 b,c ± 0.15 | |

| 11.25 | 3-Ethyl-4-nonene | 11.16 a ± 1.78 | 4.79 b ± 0.43 | 7.89 a,b ± 0.57 | 6.68 b ± 0.18 | |

| 15.56 | m-Di-tert-butylbenzene | 22.65 b ± 3.31 | 19.72 b ± 2.89 | 36.51 a ± 3.71 | 20.31 b ± 1.16 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spicher, G.; Stephen, H.S. Handbuch Sauerteig: Biologie, Biochemie, Technologie; B. Behr’s Verlag GmbH: Hamburg, Germany, 1993. [Google Scholar]

- Chavan, R.S.; Chavan, S.R. Sourdough technology—A traditional way for wholesome foods: A review. Compr. Rev. Food Sci. Saf. 2011, 10, 169–182. [Google Scholar] [CrossRef]

- Pétel, C.; Onno, B.; Prost, C. Sourdough volatile compounds and their contribution to bread: A review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Gobbetti, M.; Rizzello, C.G.; Di Cagno, R.; De Angelis, M. How the sourdough may affect the functional features of leavened baked goods. Food Microbiol. 2014, 37, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Gänzle, M.G. Enzymatic and bacterial conversions during sourdough fermentation. Food Microbiol. 2014, 37, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Van Kerrebroeck, S.; Bastos, F.C.C.; Harth, H.; De Vuyst, L. A low pH does not determine the community dynamics of spontaneously developed backslopped liquid wheat sourdoughs but does influence their metabolite kinetics. Int. J. Food Microbiol. 2016, 239, 54–64. [Google Scholar] [CrossRef] [PubMed]

- De Vuyst, L.; Van Kerrebroeck, S.; Harth, H.; Huys, G.; Daniel, H.M.; Weckx, S. Microbial ecology of sourdough fermentations: Diverse or uniform? Food Microbiol. 2014, 37, 11–29. [Google Scholar] [CrossRef] [PubMed]

- Hansen, A.; Schieberle, P. Generation of aroma compounds during sourdough fermentation: Applied and fundamental aspects. Trends Food Sci. Technol. 2005, 16, 85–94. [Google Scholar] [CrossRef]

- Hansen, A.; Lund, B.; Lewis, M.J. Flavour of sourdough rye bread crumb. Lebensm. Wiss. Technol. 1989, 22, 141. [Google Scholar]

- Cho, I.H.; Peterson, D.G. Chemistry of bread aroma: A review. Food Sci. Biotechnol. 2010, 19, 575–582. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef]

- Damiani, P.; Gobbetti, M.; Cossignani, L.; Corsetti, A.; Simonetti, M.S.; Rossi, J. The sourdough microflora. Characterization of hetero-and homofermentative lactic acid bacteria, yeasts and their interactions on the basis of the volatile compounds produced. LWT Food Sci. Technol. 1996, 29, 63–70. [Google Scholar] [CrossRef]

- Seitz, L.M.; Chung, O.K.; Rengarajan, R. Volatiles in selected commercial breads. Cereal Chem. 1998, 75, 847–853. [Google Scholar] [CrossRef]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel insights on the functional/nutritional features of the sourdough fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Crowley, P.; Schober, T.J.; Clarke, C.I.; Arendt, E.K. The effect of storage time on textural and crumb grain characteristics of sourdough wheat bread. Eur. Food Res. Technol. 2002, 214, 489–496. [Google Scholar] [CrossRef]

- Park, Y.H.; Jung, L.H.; Jeon, E.R. Quality characteristics of bread using sour dough. J. Food Sci. Nutr. 2006, 11, 323–327. [Google Scholar] [CrossRef]

- G.U 189/1967. Disciplina per la Lavorazione e Commercio dei Cereali, degli Sfarinati, del Pane e Delle Paste Alimentari (Legge 4 luglio 1967, n. 580) Gazzetta Ufficiale Italiana n.189 del 29-07-1967 Serie Generale. Available online: https://www.gazzettaufficiale.it/eli/id/1967/07/29/067U0580/sg (accessed on 27 December 2020).

- Mueen-ud-Din, G.; Anjum, F.M.; Rehman, S.U.; Nawaz, H. Studies on organic acids and minerals content of sourdough naans made from different extraction rate wheat flours and starter cultures. Pak. J. Nutr. 2009, 8, 877–881. [Google Scholar] [CrossRef] [Green Version]

- Ua-Arak, T.; Jacob, F.; Vogel, R.F. Characterization of growth and exopolysaccharides production of selected acetic acid bacteria in buckweath sourdough. Int. J. Food Microbiol. 2016, 239, 103–112. [Google Scholar] [CrossRef]

- Aponte, M.; Boscaino, F.; Sorrentino, A.; Coppola, R.; Masi, P.; Romano, A. Volatile compounds and bacterial community dynamics of chestnut-flour-based sourdoughs. Food Chem. 2013, 141, 2394–2404. [Google Scholar] [CrossRef]

- Gobbetti, M.; Minervini, F.; Pontonio, E.; Di Cagno, R.; De Angelis, M. Drivers for the establishment and composition of the sourdough lactic acid bacteria biota. Int. J. Food Microbiol. 2016, 239, 3–18. [Google Scholar] [CrossRef]

- Torrieri, E.; Pepe, O.; Ventorino, V.; Masi, P.; Cavella, S. Effect of sourdoygh at different concentration on quality and shelf-life of bread. LWT Food Sci. Technol. 2014, 56, 508–516. [Google Scholar] [CrossRef]

- Scazzina, F.; Del Rio, D.; Pellegrini, N.; Brighenti, F. Sourdough bread: Starch digestibility and postprandial glycemic response. J. Cereal Sci. 2009, 49, 419–421. [Google Scholar] [CrossRef]

- Zolfaghari, M.S.; Asadi, G.; Ardebili, S.M.S.; Larijani, K. Evaluation and comparison of different dough leavening agents on quality of lavash bread. J. Food Meas. Charact. 2017, 11, 93–98. [Google Scholar] [CrossRef]

- Mohd Roby, B.H.; Muhialdin, B.J.; Abadl, M.M.T.; Mat Nor, N.A.; Marzlan, A.A.; Lim, S.A.H.; Mustapha, N.A.; Meor Hussin, A.S. Physical properties, storage stability, and consumer acceptability for sourdough bread produced using encapsulated kombucha sourdough starter culture. J. Food Sci. 2020, 85, 2286–2295. [Google Scholar] [CrossRef] [PubMed]

- Ho, L.H.; Abdul Aziz, N.A.; Bhat, R.; Azahari, B. Storage studies of bread prepared by incorporation of the banana pseudo-stem flour and the composite breads containing hydrocolloids. CyTA J. Food 2014, 12, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Markova, N.; Wadsö, L. A microcalorimetric method of studying mould activity as a function of water activity. Int. Biodeter Biodegr. 1998, 42, 25–28. [Google Scholar] [CrossRef]

- Gobbetti, M.; Simonetti, M.S.; Corsetti, A.; Santinelli, F.; Rossi, J.; Damiani, P. Volatile compound and organic acid productions by mixed wheat sour dough starters: Influence of fermentation parameters and dynamics during baking. Food Microbiol. 1995, 12, 497–507. [Google Scholar] [CrossRef]

- De Vuyst, L.; Neysens, P. The sourdough microflora: Biodiversity and metabolic interactions. Trends Food Sci. Technol. 2005, 16, 43–56. [Google Scholar] [CrossRef]

- Barber, B.; Ortolá, C.; Barber, S.; Fernandez, F. Storage of packaged white bread. Z. Lebensm. Unters. For. 1992, 194, 442–449. [Google Scholar] [CrossRef]

- Lim, S.B.; Tingirikari, J.M.R.; Seo, J.S.; Li, L.; Shim, S.; Seo, J.H.S. Isolation of lactic acid bacteria starters from Jeung-pyun for sourdough fermentation. Food Sci. Biotechnol. 2018, 27, 73–78. [Google Scholar] [CrossRef]

- Mamhoud, A.; Nionelli, L.; Bouzaine, T.; Hamdi, M.; Gobbetti, M.; Rizzello, C.G. Selection of lactic acid bacteria isolated from Tunisian cereals and exploitation of the use as starters for sourdough fermentation. Int. J. Food Microbiol. 2016, 225, 9–19. [Google Scholar] [CrossRef]

- Spicher, G.; Stephan, H. Handbuch Sauerteig, Biologie, Biochemie, Technologie, 5th ed.; Behr’s Verlag: Hamburg, Germany, 1999. [Google Scholar]

- Corsetti, A. Technology of sourdough fermentation and sourdough applications. In Handbook on Sourdough Biotechnology; Springer: Boston, MA, USA, 2013; pp. 85–103. [Google Scholar]

- Corsetti, A.; Gobbetti, M.; De Marco, B.; Balestrieri, F.; Paoletti, F.; Russi, L.; Rossi, J. Combined effect of sourdough lactic acid bacteria and additives on bread firmness and staling. J. Agric. Food Chem. 2000, 48, 3044–3051. [Google Scholar] [CrossRef] [PubMed]

- Casal, M.; Cardoso, H.; Leão, C. Effects of ethanol and other alkanols on transport of acetic acid in Saccharomyces cerevisiae. Appl. Environ. Microb. 1998, 64, 665–668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Casal, M.; Cardoso, H.; Leao, C. Mechanisms regulating the transport of acetic acid in Saccharomyces cerevisiae. Microbiology 1996, 142, 1385–1390. [Google Scholar] [CrossRef] [Green Version]

- Hadaegh, H.; Seyyedain Ardabili, S.M.; Tajabadi Ebrahimi, M.; Chamani, M.; Azizi Nezhad, R. The impact of different lactic acid bacteria sourdoughs on the quality characteristics of toast bread. J. Food Qual. 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Gobbetti, M. The sourdough microflora: Interactions of lactic acid bacteria and yeasts. Trends Food Sci. Technol. 1998, 9, 267–274. [Google Scholar] [CrossRef]

- Arendt, E.K.; Ryan, L.A.; Dal Bello, F. Impact of sourdough on the texture of bread. Food Microbiol. 2007, 24, 165–174. [Google Scholar] [CrossRef]

- Plessas, S.; Bekatorou, A.; Gallanagh, J.; Nigam, P.; Koutinas, A.A.; Psarianos, C. Evolution of aroma volatiles during storage of sourdough breads made by mixed cultures of Kluyveromyces marxianus and Lactobacillus delbrueckii ssp. bulgaricus or Lactobacillus helveticus. Food Chem. 2008, 107, 883–889. [Google Scholar]

- Kaseleht, K.; Paalme, T.; Mihhalevski, A.; Sarand, I. Analysis of volatile compounds produced by different species of lactobacilli in rye sourdough using multiple headspace extraction. Int. J. Food Sci. Technol. 2011, 46, 1940–1946. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Arneborg, N.; Hansen, Å.S. Influence of commercial baker’s yeasts on bread aroma profiles. Food Res. Int. 2013, 52, 160–166. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Hansen, Å.S. Aroma of wheat bread crumb. Cereal Chem. 2014, 91, 105–114. [Google Scholar] [CrossRef]

- Annan, N.T.; Poll, L.; Sefa-Dedeh, S.; Plahar, W.A.; Jakobsen, M. Volatile compounds produced by Lactobacillus fermentum, Saccharomyces cerevisiae and Candida krusei in single starter culture fermentations of Ghanaian maize dough. J. Appl. Microbiol. 2003, 94, 462–474. [Google Scholar] [CrossRef] [PubMed]

- Salin-ur-Rehman, P.A.; Piggott, J.R. Flavour in sourdough breads: A review. Food Sci. Technol. 2006, 17, 557–566. [Google Scholar] [CrossRef]

- Pozo-Bayon, M.A.; Guichard, E.; Cayot, N. Flavor control in baked cereal products. Food Rev. Int. 2006, 22, 335–379. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Hansen, Å.S. The aroma profile of wheat bread crumb influenced by yeast concentration and fermentation temperature. LWT-Food Sci. Technol. 2013, 50, 480–488. [Google Scholar] [CrossRef]

- Poinot, P.; Grua-Priol, J.; Arvisenet, G.; Rannou, C.; Semenou, M.; Le Bail, A.; Prost, C. Optimisation of HS-SPME to study representativeness of partially baked bread odorant extracts. Food Res. Int. 2007, 40, 1170–1184. [Google Scholar] [CrossRef]

- Bianchi, F.; Careri, M.; Chiavaro, E.; Musci, M.; Vittadini, E. Gas chromatographic–mass spectrometric characterisation of the Italian protected designation of origin “Altamura” bread volatile profile. Food Chem. 2008, 110, 787–793. [Google Scholar] [CrossRef]

- Paraskevopoulou, A.; Chrysanthou, A.; Koutidou, M. Characterisation of volatile compounds of lupin protein isolate-enriched wheat flour bread. Food Res. Int. 2012, 48, 568–577. [Google Scholar] [CrossRef]

- Jensen, S.; Oestdal, H.; Skibsted, L.H.; Larsen, E.; Thybo, A.K. Chemical changes in wheat pan bread during storage and how it affects the sensory perception of aroma, flavour, and taste. J. Cereal Sci. 2011, 53, 259–268. [Google Scholar] [CrossRef]

- Chiavaro, E.; Vittadini, E.; Musci, M.; Bianchi, F.; Curti, E. Shelf-life stability of artisanally and industrially produced durum wheat sourdough bread (“Altamura bread”). LWT Food Sci. Technol. 2008, 41, 58–70. [Google Scholar] [CrossRef]

- Hansen, Å.; Hansen, B. Flavour of sourdough wheat bread crumb. Z. Lebensm. Unters. For. 1996, 202, 244–249. [Google Scholar] [CrossRef]

- Adams, A.; Bouckaert, C.; Van Lancker, F.; De Meulenaer, B.; De Kimpe, N. Amino acid catalysis of 2-alkylfuran formation from lipid oxidation-derived α, β-unsaturated aldehyde. J. Agric. Food Chem. 2011, 59, 11058–11062. [Google Scholar] [CrossRef] [PubMed]

- Czerny, M.; Christlbauer, M.; Christlbauer, M.; Fischer, A.; Granvogl, M.; Hammer, M.; Hartl, C.; Hernandez, N.M.; Schieberle, P. Re-investigation on odour thresholds of key food aroma compounds and development of an aroma language based on odour qualities of defined aqueous odorant solutions. Eur. Food Res. Technol. 2008, 228, 265–273. [Google Scholar] [CrossRef]

- Park, H.J.; Lee, S.M.; Song, S.H.; Kim, Y.S. Characterization of volatile components in Makgeolli, a traditional Korean rice wine, with or without pasteurization, during storage. Molecules 2013, 18, 5317–5325. [Google Scholar] [CrossRef] [PubMed]

| Samples | Wheat Flour Used | Microbial Cultures |

|---|---|---|

| S1 sourdough | Wheat flour 00 and Manitoba flour (4:1) | Bacteria/Yeast in 1.5 ratio (selected cultures) |

| S2 sourdough | Wheat flour 00 and Manitoba flour (4:1) | Bacteria/Yeast in 3.3 ratio (selected cultures) |

| S3 sourdough | Wheat flour 00 and wheat flour 0 (4:1) | Bacteria/Yeast in 3.3 ratio (selected cultures) |

| S4 sourdough | Wheat flour 00 and Manitoba flour (4:1) | Yeast beer (natural cultures) |

| Samples | Bacteria/Yeasts Ratio | Bacteria (CFU/g) | Yeasts (CFU/g) | Predominant Yeast Species | Predominant Bacteria Species | pH | Titratable Acidity (mL NaOH/10 g Sample) |

|---|---|---|---|---|---|---|---|

| S1 sourdough | 12.75 | 3.25 × 108 c ± 0.77 | 2.55 × 107 b ± 1.1 | S. cerevisiae & K.unispora | L. sanfranciscensis | 4.02 c ± 0.01 | 6.33 c ± 0.01 |

| S2 sourdough | 47.05 | 4.00 × 108 b ± 1.27 | 8.50 × 106 c ± 1.27 | S. cerevisiae | L. sanfranciscensis | 4.07 b ± 0.01 | 6.50 b ± 0.01 |

| S3 sourdough | 159.15 | 5.65 × 108 a,b ± 0.35 | 3.55 × 106 c ± 0.07 | S. cerevisiae | L. sanfranciscensis | 4.22 a ± 0.01 | 6.32 c ± 0.03 |

| S4 sourdough | 11.59 | 6.55 × 108 a ± 0.21 | 5.65 × 107 a ± 0.35 | S. cerevisiae | L. sanfranciscensis | 3.87 d ± 0.01 | 7.32 a ± 0.03 |

| Sample | Moisture | aw |

|---|---|---|

| S1 bread | 28.20 a ± 0.22 | 0.90 a ± 0.01 |

| S2 bread | 25.26 b ± 0.43 | 0.89 a ± 0.01 |

| S3 bread | 22.99 c ± 0.84 | 0.81 b ± 0.01 |

| S4 bread | 27.33 a ± 0.78 | 0.90 a ± 0.01 |

| (a) | |||||

| Sample | Lactic Acid | Acetic Acid | Succinic Acid | Citric Acid | FQ |

| S1 sourdough | 1895.84 a ± 1.15 | 370.86 c ± 0.64 | 80.37 d ± 0.00 | <5.00 | 3.41 a ± 0.30 |

| S2 sourdough | 685.31 b ± 0.21 | 1164.61 a ± 3.25 | 641.62 b ± 2.05 | <5.00 | 0.39 c ± 0.04 |

| S3 sourdough | 1786.82 a ± 2.06 | 674.61 b ± 2.26 | 362.87 c ± 0.99 | <5.00 | 1.76 b ± 0.14 |

| S4 sourdough | 1888.32 a ± 6.22 | 808.36 b ± 0.49 | 1110.37 a ± 0.85 | <5.00 | 1.56 b ± 0.23 |

| (b) | |||||

| Sample | Lactic Acid | Acetic Acid | Succinic Acid | Citric Acid | FQ |

| S1 bread | 8722.24 a ± 4.45 | 774.23 b ± 2.12 | 5243.24 a ± 6.72 | <5.00 | 7.88 b ± 2.94 |

| S2 bread | 5607.30 b ± 8.27 | 254.21 c ± 0.42 | 1035.74 b ± 2.12 | 1402.40 a ± 2.83 | 14.70 a ± 2.77 |

| S3 bread | 5322.24 b ± 3.75 | 239.22 c ± 0.42 | 980.74 b ± 6.22 | 1417.43 a ± 2.69 | 14.80 a ± 3.48 |

| S4 bread | 4874.74 b ± 3.53 | 1234.20 a ± 0.71 | 1138.24 b ± 2.05 | <5.00 | 2.63 c ± 0.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Luca, L.; Aiello, A.; Pizzolongo, F.; Blaiotta, G.; Aponte, M.; Romano, R. Volatile Organic Compounds in Breads Prepared with Different Sourdoughs. Appl. Sci. 2021, 11, 1330. https://doi.org/10.3390/app11031330

De Luca L, Aiello A, Pizzolongo F, Blaiotta G, Aponte M, Romano R. Volatile Organic Compounds in Breads Prepared with Different Sourdoughs. Applied Sciences. 2021; 11(3):1330. https://doi.org/10.3390/app11031330

Chicago/Turabian StyleDe Luca, Lucia, Alessandra Aiello, Fabiana Pizzolongo, Giuseppe Blaiotta, Maria Aponte, and Raffaele Romano. 2021. "Volatile Organic Compounds in Breads Prepared with Different Sourdoughs" Applied Sciences 11, no. 3: 1330. https://doi.org/10.3390/app11031330

APA StyleDe Luca, L., Aiello, A., Pizzolongo, F., Blaiotta, G., Aponte, M., & Romano, R. (2021). Volatile Organic Compounds in Breads Prepared with Different Sourdoughs. Applied Sciences, 11(3), 1330. https://doi.org/10.3390/app11031330