Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

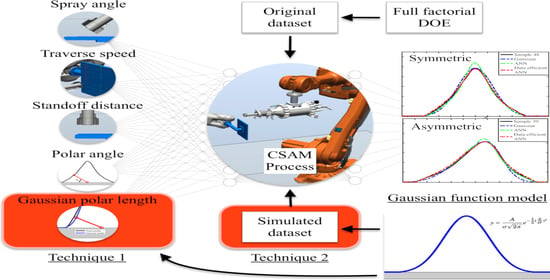

2.2. Data-Efficent Artificial Neural Network Model Design and Training

3. Results

3.1. Data-Efficient Artificial Neural Network Model Validation

3.2. Data-Efficient Artificial Neural Network Model Evaluation and Comparison

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Gärtner, F.; Stoltenhoff, T.; Schmidt, T.; Kreye, H. The cold spray process and its potential for industrial applications. J. Therm. Spray Technol. 2006, 15, 223–232. [Google Scholar] [CrossRef]

- Karthikeyan, J. The advantages and disadvantages of the cold spray coating process. In The Cold Spray Materials Deposition Process; Champagne, V.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 62–71. ISBN 978-1-84569-181-3. [Google Scholar]

- Villafuerte, J. Current and future applications of cold spray technology. Met. Finish. 2010, 108, 37–39. [Google Scholar] [CrossRef]

- Luo, X.-T.; Li, C.-X.; Shang, F.-L.; Yang, G.-J.; Wang, Y.-Y.; Li, C.-J. High velocity impact induced microstructure evolution during deposition of cold spray coatings: A review. Surf. Coat. Technol. 2014, 254, 11–20. [Google Scholar] [CrossRef]

- Sova, A.; Grigoriev, S.; Okunkova, A.; Smurov, I. Potential of cold gas dynamic spray as additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2013, 69, 2269–2278. [Google Scholar] [CrossRef]

- Pathak, S.; Saha, G. Development of sustainable cold spray coatings and 3D additive manufacturing components for repair/manufacturing applications: A critical review. Coatings 2017, 7, 122. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Yang, K.; Yin, S.; Yang, X.; Xu, Y.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Aggour, K.S.; Gupta, V.K.; Ruscitto, D.; Ajdelsztajn, L.; Bian, X.; Brosnan, K.H.; Kumar, N.C.; Dheeradhada, V.; Hanlon, T.; Iyer, N.; et al. Artificial intelligence/machine learning in manufacturing and inspection: A GE perspective. MRS Bull. 2019, 44, 545–558. [Google Scholar] [CrossRef]

- Mutombo, K. Research and development of Ti and Ti alloys: Past, present and future. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 0120071–0120076. [Google Scholar] [CrossRef]

- Titomic Titomic Kinetic FusionTM. Available online: https://www.titomic.com/titomic-kinetic-fusion.html (accessed on 22 March 2019).

- Barnett, B.; Trexler, M.; Champagne, V. Cold sprayed refractory metals for chrome reduction in gun barrel liners. Int. J. Refract. Met. Hard Mater. 2015, 53, 139–143. [Google Scholar] [CrossRef] [Green Version]

- Cormier, Y.; Dupuis, P.; Jodoin, B.; Corbeil, A. Pyramidal fin arrays performance using streamwise anisotropic materials by cold spray additive manufacturing. J. Therm. Spray Technol. 2016, 25, 170–182. [Google Scholar] [CrossRef] [Green Version]

- Lynch, M.E.; Gu, W.; El-Wardany, T.; Hsu, A.; Viens, D.; Nardi, A.; Klecka, M. Design and topology/shape structural optimisation for additively manufactured cold sprayed components. Virtual Phys. Prototyp. 2013, 8, 213–231. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, G.; Li, Z.; Yang, M.; Xiao, W. Optimization strategies for robotic additive and subtractive manufacturing of large and high thin-walled aluminum structures. Int. J. Adv. Manuf. Technol. 2019, 101, 1275–1292. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Zhang, G.; Horváth, I.; Han, Q. Interlayer closed-loop control of forming geometries for wire and arc additive manufacturing based on fuzzy-logic inference. J. Manuf. Process. 2020. [Google Scholar] [CrossRef]

- Liu, H.; Qin, X.; Huang, S.; Jin, L.; Wang, Y.; Lei, K. Geometry characteristics prediction of single track cladding deposited by high power diode laser based on genetic algorithm and neural network. Int. J. Precis. Eng. Manuf. 2018, 19, 1061–1070. [Google Scholar] [CrossRef]

- Gonçalves, D.A.; Stemmer, M.R.; Pereira, M. A convolutional neural network approach on bead geometry estimation for a laser cladding system. Int. J. Adv. Manuf. Technol. 2020, 106, 1811–1821. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Nenadl, O.; Kuipers, W.; Koelewijn, N.; Ocelík, V.; de Hosson, J.T.M. A versatile model for the prediction of complex geometry in 3D direct laser deposition. Surf. Coat. Technol. 2016, 307, 292–300. [Google Scholar] [CrossRef]

- Suryakumar, S.; Karunakaran, K.P.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in Hybrid Layered Manufacturing. Comput. Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Verdy, C.; Liao, H.; Deng, S. Modelling of coating thickness distribution and its application in offline programming software. Surf. Coat. Technol. 2017, 318, 315–325. [Google Scholar] [CrossRef]

- Wu, H.; Xie, X.; Liu, M.; Chen, C.; Liao, H.; Zhang, Y.; Deng, S. A new approach to simulate coating thickness in cold spray. Surf. Coat. Technol. 2020, 382, 125151. [Google Scholar] [CrossRef]

- Kotoban, D.; Grigoriev, S.; Okunkova, A.; Sova, A. Influence of a shape of single track on deposition efficiency of 316L stainless steel powder in cold spray. Surf. Coat. Technol. 2017, 309, 951–958. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Shikalov, V.S. Influence of nozzle velocity and powder feed rate on the coating mass and deposition efficiency in cold spraying. Surf. Coat. Technol. 2019, 367, 231–243. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, X.; Zhang, M.; Tian, X.; Li, D. Integral numerical modeling of the deposition profile of a cold spraying process as an additive manufacturing technology. Prog. Addit. Manuf. 2019, 4, 357–370. [Google Scholar] [CrossRef]

- Deng, J.; Xu, Y.; Zuo, Z.; Hou, Z.; Chen, S. Bead geometry prediction for multi-layer and multi-bead wire and arc additive manufacturing based on XGBoost. In Transactions on Intelligent Welding Manufacturing; Chen, S., Zhang, Y., Feng, Z., Eds.; Springer: Singapore, 2019; pp. 125–135. ISBN 978-981-13-8667-1. [Google Scholar]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Neural network modelling of track profile in cold spray additive manufacturing. Materials 2019, 12, 2827. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Zhang, Y.; Dong, W.; Yu, Z.; Liu, S.; Gomes, S.; Liao, H.; Deng, S. Grey modeling for thermal spray processing parameter analysis. Grey Syst. Theory Appl. 2020, 10, 265–279. [Google Scholar] [CrossRef]

- Olleak, A.; Xi, Z. Calibration and validation framework for selective laser melting process based on multi-fidelity models and limited experiment data. J. Mech. Des. 2020, 142, 1–13. [Google Scholar] [CrossRef]

- Shafi, I.; Ahmad, J.; Shah, S.I.; Kashif, F.M. Impact of varying neurons and hidden layers in neural network architecture for a time frequency application. In Proceedings of the 2006 IEEE International Multitopic Conference, Islamabad, Pakistan, 23–24 December 2006; pp. 188–193. [Google Scholar]

- May, R.; Dandy, G.; Maier, H. Review of input variable selection methods for artificial neural networks. In Artificial Neural Networks—Methodological Advances and Biomedical Applications; InTech: London, UK, 2011; pp. 19–44. ISBN 9789533072432. [Google Scholar]

- Cai, Z.; Deng, S.; Liao, H.; Zeng, C.; Montavon, G. The effect of spray distance and scanning step on the coating thickness uniformity in cold spray process. J. Therm. Spray Technol. 2014, 23, 354–362. [Google Scholar] [CrossRef]

- Evjemo, L.D.; Moe, S.; Gravdahl, J.T.; Roulet-Dubonnet, O.; Gellein, L.T.; Brøtan, V. Additive manufacturing by robot manipulator: An overview of the state-of-the-art and proof-of-concept results. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation ETFA, Limassol, Cyprus, 12–15 September 2017; Volume 99, pp. 1–8. [Google Scholar]

- Noriega, A.; Blanco, D.; Alvarez, B.J.; Garcia, A. Dimensional accuracy improvement of FDM square cross-section parts using artificial neural networks and an optimization algorithm. Int. J. Adv. Manuf. Technol. 2013, 69, 2301–2313. [Google Scholar] [CrossRef]

- Green, A. Cold Spray Heats Up. Available online: https://blog.csiro.au/cold-spray-heats-up/ (accessed on 4 February 2021).

- Krishaniah, K.; Shahabudeen, P. Fundamentals of experimental design. In Applied Design of Experiments and Taguchi Methods; PHI Learning Pvt. Ltd.: New Delhi, India, 2012; pp. 22–48. ISBN 978-81-203-4527-0. [Google Scholar]

- Karpatne, A.; Watkins, W.; Read, J.; Kumar, V. Physics-guided Neural Networks (PGNN): An application in lake temperature modeling. arXiv 2017, arXiv:1710.11431. [Google Scholar]

- Deist, T.M.; Patti, A.; Wang, Z.; Krane, D.; Sorenson, T.; Craft, D. Simulation-assisted machine learning. Bioinformatics 2019, 35, 4072–4080. [Google Scholar] [CrossRef]

- Burden, F.; Winkler, D. Bayesian regularization of neural networks. In Methods in Molecular Biology (Clifton, N.J.); Springer: Berlin, Germany, 2008; Volume 458, pp. 25–44. [Google Scholar]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson Education, Inc.: London, UK, 2009; ISBN 0131471392. [Google Scholar]

| Level | Spray Angle (°) | Traverse Speed (mm/s) | Standoff Distance (mm) |

|---|---|---|---|

| 1 | 45 | 25 | 30 |

| 2 | 60 | 100 | 40 |

| 3 | 75 | 200 | 50 |

| 4 | 90 | - | - |

| Absolute Error % | Data-efficient ANN | Curve-Fitted Gaussian | Purely Data-Driven ANN | ||

|---|---|---|---|---|---|

| Tech. 1 | Tech. 2 | Tech. 1 + 2 | |||

| Mean | 2.060 | 4.040 | 1.230 | 1.873 | 7.174 |

| Minimum | 0.003 | 0.003 | 0.006 | 0.001 | 0.060 |

| Lower Q | 0.8147 | 1.113 | 0.3724 | 0.2682 | 2.510 |

| Median | 1.719 | 2.795 | 0.9081 | 0.8204 | 5.306 |

| Upper Q | 3.004 | 5.173 | 1.753 | 2.619 | 9.831 |

| Maximum | 9.685 | 20.78 | 5.748 | 11.83 | 33.26 |

| R2 | 0.9984 | 0.9964 | 0.9988 | 0.9931 | 0.9925 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing. Appl. Sci. 2021, 11, 1654. https://doi.org/10.3390/app11041654

Ikeuchi D, Vargas-Uscategui A, Wu X, King PC. Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing. Applied Sciences. 2021; 11(4):1654. https://doi.org/10.3390/app11041654

Chicago/Turabian StyleIkeuchi, Daiki, Alejandro Vargas-Uscategui, Xiaofeng Wu, and Peter C. King. 2021. "Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing" Applied Sciences 11, no. 4: 1654. https://doi.org/10.3390/app11041654

APA StyleIkeuchi, D., Vargas-Uscategui, A., Wu, X., & King, P. C. (2021). Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing. Applied Sciences, 11(4), 1654. https://doi.org/10.3390/app11041654