In Situ Microstructure Characterization of Potassium Di-Phosphate (KDP) Densification during Cold Sintering

Abstract

:Featured Application

Abstract

1. Introduction

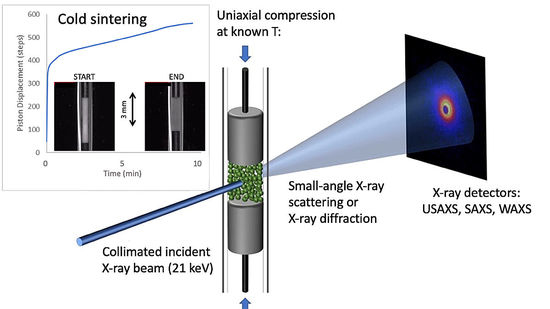

2. Materials and Methods

3. Results

3.1. Pore/Grain Morphology Evolution during CSP

3.1.1. Coarse (Macroscale) Pore Population and Densification

3.1.2. Fine (Nanoscale) Pore Population

3.1.3. Grain Morphology Changes during CSP

3.2. Core-Shell Features and High-Defect Low-Density KDP Component

3.2.1. Pore Shell Evolution during CSP

3.2.2. Ultrafine High-Defect Low-Density KDP Component during CSP

3.3. XRD Pattern Evolution during CSP

3.3.1. KDP XRD Pattern Evolution during CSP

3.3.2. XRD Peak Width

4. Discussion and Conclusions

4.1. Summary of In Situ CSP Results

4.2. Arrhenius Analysis of CSP for KDP

4.3. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Allen, A.J.; Levin, I.; Witt, S.E. Materials research and measurement needs for ceramics additive manufacturing. J. Am. Ceram. Soc. 2020, 103, 6055–6069. [Google Scholar] [CrossRef] [PubMed]

- Allen, A.J.; Levin, I.; Maier, R.A. Research, standards, and data needs for industrialization of ceramic direct ink writing. Int. J. Ceram. Eng. Sci. 2022, 4, 302–308. [Google Scholar] [CrossRef]

- Guo, J.; Guo, H.; Baker, A.L.; Lanagan, M.T.; Kupp, E.R.; Messing, G.L.; Randall, C.A. Cold sintering: A paradigm shift for processing and integration of ceramics. Angew. Chem. Int. Ed. 2016, 55, 11457–11461. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Baker, A.L.; Guo, J.; Randall, C.A. Cold sintering process: A novel technique for low-temperature ceramic processing of ferroelectrics. J. Am. Ceram. Soc. 2016, 99, 3489–3507. [Google Scholar] [CrossRef]

- Guo, J.; Floyd, R.; Lowum, S.; Maria, J.-P.; de Beauvoir, T.H.; Seo, J.-H.; Randall, C.A. Cold sintering: Progress, challenges, and future opportunities. Annu. Rev. Mater. Res. 2019, 49, 275–295. [Google Scholar] [CrossRef]

- Faouri, S.S.; Mostaed, A.; Dean, J.S.; Wang, D.; Sinclair, D.C.; Zhang, S.; Whittow, W.G.; Vardaxoglou, Y.; Reaney, I.M. High quality factor cold sintered Li2MoO4–BaFe12O19 composites for microwave applications. Acta Mater. 2019, 166, 202–207. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Sun, Q.; Wang, D.; Adair, K.; Liang, J.; Sun, X. Development of the cold sintering process and its application in solid-state lithium batteries. J. Power Sources 2018, 393, 193–203. [Google Scholar] [CrossRef]

- Hong, W.B.; Li, L.; Yan, H.; Chen, X.M. Cold sintering and microwave dielectric properties of dense HBO2-II ceramics. J. Am. Ceram. Soc. 2019, 102, 5934–5940. [Google Scholar] [CrossRef]

- Guo, H.; Bayer, T.J.M.; Guo, J.; Baker, A.; Randall, C.A. Current progress and perspectives of applying cold sintering process to ZrO2-based ceramics. Scr. Mater. 2017, 136, 141–148. [Google Scholar] [CrossRef]

- Grasso, S.; Biesuz, M.; Zoli, L.; Taveri, G.; Duff, A.I.; Ke, D.; Jiang, A.; Reece, M.J. A review of cold sintering processes. Adv. Appl. Ceram. 2020, 119, 115–143. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Julian, J.; Neuhaus, K.; Bernemann, M.; da Silva, J.P.; Laptev, A.; Bram, M.; Guillon, O. Unveiling the mechanisms of cold sintering of ZnO at 250 °C by varying applied stress and characterizing grain boundaries by Kelvin Probe Force Microscopy. Acta Mater. 2018, 144, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Galotta, A.; Sglavo, V.M. The cold sintering process: A review on processing features, densification mechanisms and perspectives. J. Eur. Ceram. Soc. 2021, 41, 1–17. [Google Scholar] [CrossRef]

- Frueh, T.; Ozer, I.O.; Poterala, S.F.; Lee, H.; Kupp, E.R.; Compson, C.; Atria, J.; Messing, G.L. A critique of master sintering curve analysis. J. Eur. Ceram. Soc. 2018, 38, 1030–1037. [Google Scholar] [CrossRef]

- Ilavsky, J.; Jemian, P.R.; Allen, A.J.; Zhang, F.; Levine, L.E.; Long, G.G. Ultra-small-angle X-ray scattering at the Advanced Photon Source. J. Appl. Crystallogr. 2009, 42, 469–479. [Google Scholar] [CrossRef]

- Ilavsky, J.; Zhang, F.; Andrews, R.N.; Kuzmenko, I.; Jemian, P.R.; Levine, L.E.; Allen, A.J. Development of combined microstructure and structure characterization facility for in situ and operando studies at the Advanced Photon Source. J. Appl. Crystallogr. 2018, 51, 867–882. [Google Scholar] [CrossRef]

- Allen, A.J.; Levin, I.; Maier, R.A.; Witt, S.E.; Zhang, F.; Kuzmenko, I. In situ characterization of ceramic cold sintering by small-angle scattering. J. Am. Ceram. Soc. 2020, 104, 2442–2448. [Google Scholar] [CrossRef]

- Orthaber, D.; Bergmann, A.; Glatter, O. SAXS experiments on absolute scale with Kratky systems using water as a secondary standard. J. Appl. Crystallogr. 2000, 33, 218–225. [Google Scholar] [CrossRef]

- Ilavsky, J.; Jemian, P.R. Irena: Tool suite for modeling and analysis of small-angle scattering. J. Appl. Crystallogr. 2009, 42, 347–353. [Google Scholar] [CrossRef]

- Ilavsky, J. Nika: Software for two-dimensional data reduction. J. Appl. Crystallogr. 2012, 45, 324–328. [Google Scholar] [CrossRef]

- Chantler, C.T.; Olsen, K.; Dragoset, R.A.; Chang, J.; Kishore, A.R.; Kotochigova, S.A.; Zucker, D.S. X-ray Form Factor, Attenuation, and Scattering Tables, Version 2.1; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2005. [CrossRef]

- Si, M.; Hao, J.; Zhao, E.; Zhao, X.; Guo, J.; Wang, H.; Randall, C.A. Preparation of zinc oxide/poly-ether-ether-ketone (PEEK) composites via the cold sintering process. Acta Mater. 2021, 215, 117036. [Google Scholar] [CrossRef]

- Pauw, B.R.; Kastner, C.; Thunemann, A.F. Nanoparticle size distribution quantification: Results of a small-angle X-ray scattering inter-laboratory comparison. J. Appl. Crystallogr. 2017, 50, 1280–1288. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ivakin, Y.D.; Smirnov, A.V.; Kormilitsin, M.N.; Kholodkova, A.A.; Vasin, A.A.; Kornyushin, M.V.; Tarasovskii, V.P.; Rybal’chenko, V.V. Effect of mechanical pressure on the recrystallization of zinc oxide in a water fluid medium under cold sintering. Russ. J. Phys. Chem. B 2021, 15, 1228–1250. [Google Scholar] [CrossRef]

- Maria, J.P.; Kang, X.; Floyd, R.D.; Dickey, E.C.; Guo, H.; Guo, J.; Baker, A.; Funihashi, S.; Randall, C.A. Cold sintering: Current status and prospects. J. Mater. Res. 2017, 32, 3205–3218. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Zhang, L.; Wu, Z. Effect of anisotropy of potassium dihydrogen phosphate crystals on its deformation mechanisms subjected to nanoindentation. ACS Appl. Mater. Interfaces 2021, 13, 41351–41360. [Google Scholar] [CrossRef]

- Shao, W.Q.; Chen, S.O.; Li, D.; Cao, H.S.; Zhang, Y.C.; Zhang, S.S. Apparent activation energy for densification of α-Al2O3 powder at constant heating-rate sintering. Bull. Mater. Sci. 2008, 31, 903–906. [Google Scholar] [CrossRef]

- Zuo, F.; Badev, A.; Saunier, S.; Goeuriot, D.; Heuguet, R.; Marinel, S. Microwave versus conventional sintering: Estimate of the apparent activation energy for densification of α-alumina and zinc oxide. J. Eur. Ceram. Soc. 2014, 34, 3103–3110. [Google Scholar] [CrossRef]

- Xie, D.; Wan, L.; Song, D.; Wang, S.; Lin, F.; Pan, X.; Xu, J. Pressureless sintering curve and sintering activation energy of Fe–Co–Cu pre-alloyed powders. Mater. Des. 2015, 87, 482–487. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Randall, C.A.; Mustapha, K.B.; Guo, J.; Walker, J.; Berbano, S.; Koh, S.C.L.; Wang, D.; Sinclair, D.C.; Reaney, I.M. Decarbonising ceramic manufacturing: A techno-economic analysis of energy efficient sintering technologies in the functional materials sector. J. Eur. Ceram. Soc. 2019, 39, 5213–5235. [Google Scholar] [CrossRef]

| Component | Form | X-ray SLD (1014 m−2) | Shell SLD (1014 m−2) |

|---|---|---|---|

| (i) Macropores (water-filled) | Core-shell globular | 9.42 | 14.63 |

| (ii) Nanoscale pores (water-filled) | Core-shell globular | 9.42 | 14.63 |

| (iii) Low-density KDP (solid) | Cylindrical needle or sheet | 9.92 | N/A |

| (iv) Fully dense KDP (solid) | Surrounding medium | 19.84 | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allen, A.J.; Maier, R.A.; Zhang, F.; Kuzmenko, I.; Ilavsky, J. In Situ Microstructure Characterization of Potassium Di-Phosphate (KDP) Densification during Cold Sintering. Appl. Sci. 2022, 12, 10493. https://doi.org/10.3390/app122010493

Allen AJ, Maier RA, Zhang F, Kuzmenko I, Ilavsky J. In Situ Microstructure Characterization of Potassium Di-Phosphate (KDP) Densification during Cold Sintering. Applied Sciences. 2022; 12(20):10493. https://doi.org/10.3390/app122010493

Chicago/Turabian StyleAllen, Andrew J., Russell A. Maier, Fan Zhang, Ivan Kuzmenko, and Jan Ilavsky. 2022. "In Situ Microstructure Characterization of Potassium Di-Phosphate (KDP) Densification during Cold Sintering" Applied Sciences 12, no. 20: 10493. https://doi.org/10.3390/app122010493

APA StyleAllen, A. J., Maier, R. A., Zhang, F., Kuzmenko, I., & Ilavsky, J. (2022). In Situ Microstructure Characterization of Potassium Di-Phosphate (KDP) Densification during Cold Sintering. Applied Sciences, 12(20), 10493. https://doi.org/10.3390/app122010493