1. Introduction

There is ample evidence that the quality and composition of children’s available food products contribute to the present and future health status of young children. Infant food, designed for children between 6 months and 2 years, is quite limited, so baby foods based on fruits and vegetables, which are commercially available, are an important source of energy, basic nutrients, vitamins, fiber and minerals [

1,

2].

In developing countries, micronutrient deficiency in the first two years of life is a general public health problem for infants and children [

3]. A good diet in childhood is essential for optimal growth and development [

4]. This is also the ideal time to introduce to the child’s diet a variety of foods and flavors to develop healthy eating habits and a variety of diets [

5].

Food based on fruits and vegetables provides the necessary vitamins, minerals, fiber and other nutrients essential for the proper functioning of the body, strengthens the immune system, provides protection and reduces the risk of cancer, cardiovascular disease and oxidative risk [

6].

Fruit and vegetable purees are a safe and fast option, suitable to provide the extra energy needed by babies [

7]. These products have appeared on the market as ready-to-consume products, which allows the consumer to save the time required for obtaining them at home. In recent years, the introduction of fruit and vegetable purees in children’s diets has been increasing [

8].

The rapid growth and normal and healthy development of children require a high intake of nutrients and energy [

9,

10]. Infants’ nutrient reserves are limited, so low nutrient intake can impair neuronal development [

11].

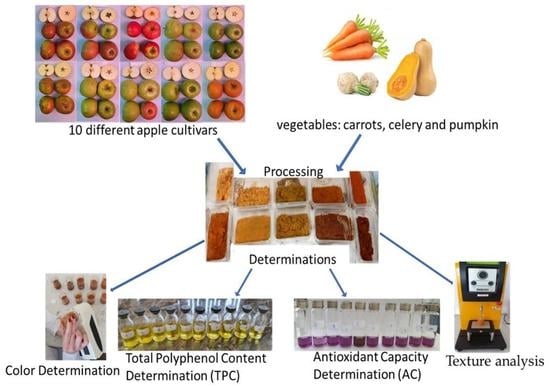

Therefore, due to all the above-mentioned advantages of infants consuming fruits and vegetables, and also because parents prefer to give children ready-to-eat products [

12], the aim of the present study was to develop purees from ten varieties of autumn apples and a mixture of vegetables (carrots, pumpkin and celery), which are ideal for the nutrition of children with ages between four months and two years, with four months being the earliest age when the fruits should be introduced in the diet, according to [

12]. The combination of these components, namely apples, which are rich in fiber, vitamin C and phenolic compounds, and the mixture of vegetables, which are rich in antioxidants, vitamins and minerals, led to a product that could ensure the harmonious development of children [

13].

2. Materials and Methods

2.1. Raw Materials

In order to obtain these baby food products, the following ingredients were used: apples (

Malus ×

domestica Borkh.), carrots (

Daucus carota subsp.

sativus), pumpkin (

Cucurbita subsp.

Cucurbita moschata Baby Pam) and celeriac (

Apium graveolens var.

rapaceum). Apples, which represent the main component, were obtained from the Horticulture Research and Development Institute, Mărăcineni, Pitești Mărului Street no. 402, Mărăcineni 117450, Romania (

Figure 1), and the carrots, pumpkin and celeriac were obtained from the Horticulture Research and Development Institute, Cluj-Napoca, 3-5 Manastur 119 Street, Cluj-Napoca, 400372, Romania.

2.2. Fresh Puree Manufacturing

As the current study determines the influence of apple variety in the composition of the baby food puree, it was included in the highest proportion in the formulation, as seen in

Table 1. From the harvest time to utilization, apples were placed in vacuum bags of 1 kg and kept in the refrigerator at a temperature of 4–6 °C Vegetables were washed and dried, except for the pumpkin, then stored at 10–12 °C at a relative humidity of about 50–60% in the institute’s storage facility.

All ingredients were washed, peeled, mashed, and subjected to evaporation-concentration operation in a vacuum chamber at 650–680 mmHg, which reduced the boiling temperature to 50 °C (

Figure 2). This operation can reduce the amount of product to be stored and can ensure the shelf life of the product because its water activity is decreased below 0.7. To prevent the development of spoilage microorganisms, the evaporation-concentration operation was realized in a vacuum chamber, which can also prevent the loss of volatile compounds (Dai et al., 2020) [

14].

The vegetables and apples were mashed in a Vegetable Masher Machine HL-617-1 (Zhengzhou Hongle Machinery Equipment Co., Ltd., Zhengzhou, China).

The purees obtained were dosed manually in glass containers of 125 g with the following dimensions: 5.1 cm diameter and 7.8 cm height. Twist-off lids were used to close the containers. Sterilization of the purees was performed in a vertical autoclave at 119 °C for 15 min [

15,

16,

17].

2.3. Determination Methods of Physico-Chemical Characteristics

2.3.1. Moisture Determination by Oven-Dry Method

Moisture determination (H) was conducted according to the AOAC Official Method 934.06 [

18]. The determination consists of drying a quantity of vegetal material at the temperature of 103 ± 2 °C until a constant mass is achieved.

Two parallel determinations were performed from the same sample preparation for analysis [

19].

2.3.2. Ash Content Determination

The ash content method was also conducted according to the AOAC Official Method 934.06 [

18]. The ash content was determined by calcination at 550–600 °C until a white, coal-free ash was obtained.

2.3.3. Titratable Acidity Determination

Titratable acidity was performed according to ISO 750:1998. The determination consists of the neutralization of acidity with 0.1 n sodium hydroxide in the presence of phenolphthalein as an indicator.

2.3.4. Vitamin C Dosing—Iodometric Method

This method was performed according to Zhao et al., 2020 [

20]. Chemical methods of dosing vitamin C are based on its reducing properties. Ascorbic acid is converted by oxidation to dehydroascorbic acid. After vitamin C has been completely oxidized, the iodine generated will form with the starch, presenting an intense blue-colored inclusion complex; the color must persist for 30 s.

2.3.5. Total Polyphenol Content Determination (TPC)

This determination was performed using the Folin–Ciocalteu method. and the absorbance of the samples was measured at 750 nm (UV-VIS Schimadzu, Kyoto, Japonia) [

21].

Extraction of total polyphenols was performed for all ten experimental puree variants. From each sample, 1 g was taken, homogenized with methanol and kept at refrigeration temperature for 24 h. The extracts obtained were filtered and concentrated at 35 °C under reduced pressure (Rotavapor Heidolph, Heidolph Instruments GmbH & Co., Schwabach, Germany). The concentrate was recovered in 9 mL of methanol. A quantity of 25 µL of the pre-prepared sample was mixed with 1.8 mL of distilled water and 120 µL of Folin–Ciocalteu reagent in a glass vial and homogenized. After 5 min, 340 μL of 7.5% Na2 CO3 solution in distilled water was added in order to create basic conditions (pH~10) for the redox reaction between the phenolic compounds and the Folin–Ciocalteu reagent. The samples were incubated at room temperature. The control sample was methanol.

The total polyphenol content of the raw materials used and the finished product was expressed in gallic acid equivalents, mg of GAE/100 g.

2.3.6. Antioxidant Capacity Determination (AC)

The antioxidant capacity was determined by evaluating the free radical scavenging effect on 1,1-diphenyl-2-picrylhydrazyl (DPPH) following Dibacto et al., 2021 [

22].

An amount of 150 μL of the methanolic extract of the analyzed samples was mixed with 2850 μL of DPPH solution. The mixture was properly homogenized and kept in the dark for 60 min. The absorbance of the samples was measured at 515 nm (UV-VIS Schimadzu) against a blank of methanol. The results were expressed as a percentage of the absorbance of the standard DPPH solution. Results are expressed in μm TE/g fresh mass (FM) [

23].

2.3.7. Color Determination

The color of the puree was determined using an NR200 portable colorimeter (3NH, Shenzhen, China). The puree color was scanned 4 times for each sample, and then their average was calculated. The color value was expressed as L*, a* and b*, where L* (brightness) represents how dark the sample is, ranging from 0 (black) to 100 (white), a* represents the color variation from green (−) to red (+), and b* represents the color variation from blue (−) to yellow (+), according to the International Commission on Lighting. Measurements were performed using a D65 illuminant with an opening of 8 mm. The colorimeter was subjected to an automatic black-and-white calibration [

24,

25].

2.3.8. Texture Determination

Texture is important for fruit purees because it evaluates the specific sensorial attributes appreciated by the consumers. The texture analysis was performed using a CT3 Brookfield Texture Analyzer (Brookfield, Middleboro, MA, USA) equipped with a TA39 probe (2 mm diameter rod, stainless steel 5 g, 20 mm length, flat end). A compression test with a 5 mm target value was selected, the probe test speed was set to 0.5 mm/s, the trigger load was 4 g, and 10 points/second were registered. The deformation curves were analyzed, and 4 parameters were studied: cohesiveness (n.a), firmness (N), deformation (mm), and adhesiveness (mJ), according to ISO 11036:2020 [

26]. The computed textural parameters are described in

Table 2.

2.3.9. Statistical Analyses

Registration data for the puree quality and index analysis elements were treated as the mean and standard deviation (SD) and coefficient of variation for the traits. An analysis of variance (ANOVA) was applied to the analyzed characteristics. The test yielded a significant F statistic. Tukey’s test (α < 0.05) was used as a post hoc test for the analysis of differences. Data were subjected to multivariate statistical analysis, namely principal component analysis (PCA), using Unscrambler X v.10.5.1 software.

3. Results and Discussion

3.1. Moisture Determination by Oven-Dry Method

The high moisture content is attributed to the high binding water capacity of the apple varieties’ starch, which is associated with weak molecular forces between the starch granules [

27]. On the other hand, the relatively low moisture content in purees can be due to the low binding capacity of starch in apples resulting in the excessive loss of moisture during ripening and storage [

28,

29,

30].

Following the determination, it was found that the highest moisture of the untreated puree was 87.27% for the Baujade apple variety, which decreased by 84.59%, and the lowest moisture value was 80.72% for the Juliana variety, which decreased by 78.14% (

Table 3).

After sterilization, the puree moisture decreased in all varieties, but the largest decrease was observed in the Parmen Clone apple variety, from 82.05% to 76.54%.

Other researchers obtained similar values for baby foods purees, where moisture decreased between 1–5% in different types of apple purees [

31,

32,

33].

3.2. Ash Content Determination

Total ash content determination in purees provides a measure of the total amount of minerals since minerals cannot be destroyed by heating. The mineral content varies and depends on many factors, such as the ripening grade of the apples and vegetables used, the variety of plant species, the soil where the plantation is located, as well as fertilization programs and the climate [

34].

Regarding the ash content of fresh purees, we obtained very different values depending on the variety of apples used. Thus, the varieties with the highest ash content are Elstar and Juliana (18.76% and 15.39%, respectively). The lowest values were registered for the Champion, Granny Smith, Pătul and Parmen Clone varieties (2.91–4.09%) (

Table 3).

Following the heat treatment applied, the ash content decreased in most of the varieties, except for the apple varieties Granny Smith and Parmen Clone, for which the ash content was higher after sterilization.

Other researchers reached similar values for some baby foods purees and also reported a 1–3% increase in the ash content after thermal processing [

2,

35,

36].

3.3. Titratable Acidity Determination

Titratable acidity is an important parameter in determining the puree quality, which also denotes the degree of ripening of the apples and vegetables used. Previous studies have shown that the trend in producing fruit purees is that organic acids increase during the heat treatment process and during storage [

37].

The acidity determined for the fresh puree was similar for all ten varieties of purees, with values ranging between 0.30% and 0.45%. Following the application of heat treatment, the acidity values decreased, reaching values of a maximum of 0.40% (

Table 3).

Our findings were consistent with those reported by Usal and Sahan in 2020 [

38], who studied 24 fruit-and-vegetable-based baby food purees, for which values between 0.23–0.54% were determined.

Table 3.

Moisture, ash content and titratable acidity determination.

Table 3.

Moisture, ash content and titratable acidity determination.

| | Moisture Determination% | Ash Content% | Acidity Determination (mg/100 g) |

|---|

| Puree Sample | Unsterilized Product | Sterilized Product | Unsterilized Product | Sterilized Product | Unsterilized Product | Sterilized Product |

|---|

| 1 | 84.0 ± 0.2 | 81.1 ± 0.1 | 2.9 ± 0.1 | 3.3 ± 0.1 | 0.34 ± 0.01 | 0.29 ± 0.01 |

| 2 | 84.4 ± 0.1 | 82.3 ± 0.1 | 1.8 ± 0.1 | 2.7 ± 0.2 | 0.30 ± 0.02 | 0.26 ± 0.01 |

| 3 | 87.2 ± 0.2 | 84.5 ± 0.2 | 1.9 ± 0.2 | 3.0 ± 0.1 | 0.42 ± 0.01 | 0.27 ± 0.02 |

| 4 | 83.4 ± 0.4 | 82.6 ± 0.3 | 1.6 ± 0.3 | 1.1 ± 0.1 | 0.26 ± 0.01 | 0.19 ± 0.01 |

| 5 | 86.7 ± 0.2 | 83.7 ± 0.2 | 2.4 ± 0.1 | 2.7 ± 0.3 | 0.45 ± 0.02 | 0.4 ± 0.02 |

| 6 | 82.6 ± 0.1 | 81.1 ± 0.1 | 2.6 ± 0.3 | 2.9 ± 0.2 | 0.38 ± 0.01 | 0.37 ± 0.01 |

| 7 | 86.2 ± 0.1 | 84.7 ± 0.1 | 3.7 ± 0.2 | 2.6 ± 0.3 | 0.4 ± 0.02 | 0.21 ± 0.02 |

| 8 | 80.7 ± 0.3 | 78.1 ± 0.1 | 2.3 ± 0.1 | 3.9 ± 0.1 | 0.48 ± 0.01 | 0.32 ± 0.01 |

| 9 | 84.5 ± 0.3 | 81.0 ± 0.2 | 1.6 ± 0.2 | 3.4 ± 0.2 | 0.29 ± 0.02 | 0.24 ± 0.02 |

| 10 | 82.0 ± 0.2 | 76.5 ± 0.2 | 4.7 ± 0.1 | 4.0 ± 0.3 | 0.41 ± 0.01 | 0.34 ± 0.01 |

3.4. Vitamin C Dosing—Iodometric Method

Regarding the vitamin C content of the fresh product, we obtained the highest values for the Domnesc and Granny Smith puree apple varieties, with 4.21 mg% and 3.5 mg%, respectively. The varieties of the baby food purees that had the lowest amounts of vitamin C were those containing Champion and Parmen Clone apple varieties (2.11 mg% and 2.57 mg%, respectively). Following sterilization, the vitamin C content suffered significant losses, between 50% and 70%, in all ten purees (

Table 4 and

Table 5) since vitamin C is a thermo-labile compound, which is very susceptible to thermal, chemical and enzymatic oxidation during processing. The vitamin C and oxidative enzymes might come into contact when the food matrix is disrupted by the thermal treatment. Therefore, the oxidative reactions of vitamin C in thermally treated puree could explain the lowest bioaccessibility and vitamin C content [

39].

Other researchers obtained similar values for baby foods purees developed from fruit and vegetables, while baby foods from apples demonstrated 3.5% mg/100 g vitamin C, and the highest 20% mg/100 g was determined in purees with other components besides apples, such as banana, oat, plum and broccoli [

40]. Additionally, another study showed similar values for vitamin C in baby puree with apple, apple juice, orange juice, banana, mango and pear, namely between 1.9–2.4 mg/100 g [

41].

3.5. Total Polyphenol Content Determination (TPC)

Regarding the content of total polyphenols in fresh puree, results range between 59.91 mg GAE/100 g for the puree with the Pătul apple variety to 86.31 mg GAE/100 g for the purre with the Domnesc apple variety (

Table 4 and

Table 5).

TPC almost doubled its values after thermal processing in some samples, such as the puree containing the Elstar apple variety, which increased its TPC concentration from 64.36 to 126.65 mg GAE/100 g. The range of TPC after the thermal treatment in other purees was between 76.87 and 139.67 mg GAE/100 g.

This increase is due to heat treatment, which breaks the cell walls and enhances the mobilization of polyphenols from the food matrix, which makes them more available [

42].

Similar results have been shown by multiple studies that presented a significant increase in TLC in food products after heat treatment was applied [

41,

43,

44] shows similar values for TPC in baby purees with apple, banana, apricot, orange juice, lemon and peach (values between 85 and 234.2 mg GAE/100 g).

3.6. Antioxidant Capacity Determination (AC)

The AC increased in line with the increase in the TCL based on the same consideration that many antioxidant compounds are mainly present as covalently bound forms with insoluble polymers [

42].

The values obtained from the determination of the antioxidant capacity of the untreated puree varied depending on the apple variety used. The Juliana puree apple variety had the highest antioxidant capacity of 0.91% inhibited DPPH, compared to the Reinette Harbert puree apple variety, which had a much lower value of only 0.51% inhibited DPPH.

Antioxidant capacity was almost doubled in some cases after thermal process application, with results after sterilization ranging between 0.83% (Elstar apple variety) and 0.93% (Juliana apple variety) (

Table 4 and

Table 5).

Heat treatment disrupts the cell wall and releases antioxidant compounds, leading to an increase in antioxidant capacity [

45,

46].

Researchers Carbonell-Capella [

41] determined higher values for AC in baby puree with apple, banana, apricot, orange juice, lemon and peach, with values between 3.6 and 41.6%. Researcher Čížková [

47] showed, for commercial fruit baby food, an AC between 1.87 and 4.75% in products based on apples, strawberries, bilberries, plums, pears and peaches. These increased values are due to the presence of berries and plums in the formulation, which have higher contents of natural antioxidants [

48].

Table 4.

Vit. C, TPC and AC determination in unsterilized product.

Table 4.

Vit. C, TPC and AC determination in unsterilized product.

| Puree Sample | Vitamin C (mg/100 g) | Polyphenols Content (mg GAE/100 g) | Antioxidant Capacity (μm TE/g FM) |

|---|

| 1 | 2.11 ± 0.1 | 73.67 ± 1.67 bc | 0.62 ± 0.47 f |

| 2 | 2.91 ± 0.3 | 64.36 ± 0.2 de | 0.64 ± 0.31 e |

| 3 | 3.27 ± 0.1 | 65.63 ± 0.1 de | 0.88 ± 0.70 b |

| 4 | 2.58 ± 0.1 | 61.9 ± 4.88 e | 0.67 ± 0.31 d |

| 5 | 3.5 ± 0.2 | 69.588 ± 0.59 cd | 0.67 ± 0.47 d |

| 6 | 2.8 ± 0.1 | 59.91 ± 0.1 e | 0.81 ± 0.39 c |

| 7 | 3.27 ± 0.2 | 70.492 ± 0.62 bcd | 0.51 ± 0.15 g |

| 8 | 3.28 ± 0.3 | 77.32 ± 1.95 b | 0.91 ± 0.31 a |

| 9 | 4.21 ± 0.3 | 86.31 ± 0.59 a | 0.81 ± 0.78 c |

| 10 | 2.57 ± 0.2 | 64.12 ± 1.03 de | 0.81 ± 0.78 c |

Table 5.

Vit. C, TPC and AC determination in sterilized product.

Table 5.

Vit. C, TPC and AC determination in sterilized product.

| Puree Sample | Vitamin C (mg/100 g) | Polyphenols Content (mg GAE/100 g) | Antioxidant Capacity (μm TE/g FM) |

|---|

| 1 | 1.18 ± 0.1 | 125.63 ± 1.24 b | 0.87 ± 0.15 b |

| 2 | 1.88 ± 0.1 | 126.65 ± 1.21 b | 0.83 ± 0.47 d |

| 3 | 0.94 ± 0.01 | 139.67 ± 3.22 a | 0.86 ± 0.78 bc |

| 4 | 0.93 ± 0.1 | 125.44 ± 1.28 b | 0.92 ± 0.62 a |

| 5 | 0.7 ± 0.02 | 76.87 ± 3.08 b | 0.92 ± 0.94 a |

| 6 | 1.41 ± 0.1 | 80.57 ± 1.28 d | 0.91 ± 0.78 a |

| 7 | 1.41 ± 0.2 | 80.07 ± 1.86 d | 0.87 ± 0.55 b |

| 8 | 1.17 ± 0.1 | 81.66 ± 0.61 d | 0.93 ± 0.78 a |

| 9 | 1.87 ± 0.2 | 102.19 ± 0.62 c | 0.85 ± 0.71 cd |

| 10 | 1.87 ± 0.1 | 129.6 ± 1.06 d | 0.83 ± 0.16 d |

3.7. Color Determination

Food color is a major factor that affects the quality and acceptance of food. It can also be used to predict the chemical and microbiological changes in food. In our case, the effect of sterilization on the color of the product was significant. In addition, the amount of yellow index and lightness decreased compared to the those of the unsterilized products. Enzymatic browning (catalyzed by PPO) and non-enzymatic browning (Maillard reactions) are also important factors regarding the color changing in the browning of the samples [

49].

According to Särkkä-Tirkkonen et al. [

50], sterilization, as a method used for baby puree thermal treatments, causes structural, taste and color defects. In the current study, we used a vertical autoclave for the sterilization process, and all values, L*, a* and b*, were decreased after the thermal treatment. Consumers prefer infant food with no artificial colors, revealing that over time, consumers became more aware of what they consume [

4,

51,

52,

53]. Therefore, the products with a lower color intensity did not affect the acceptability as long as the color did not represent a quality defect. For the fresh puree, which was not subjected to heat treatment, the highest brightness value was in the puree obtained from the Champion apple variety, 46.03, and the darkest in color was the Reinette Harbert variety, 32.72. The reddest variety of apples was the Elstar variety with a* value equal to 21.02, and the yellowest were the Granny Smith and Reinette Harbert varieties, with similar results of 5.18 (

Table 6).

After the sterilization was applied, the color parameters underwent changes, as follows: the brightness of the finished product decreased by 2–3 units for each variety, and the values of the parameter a* decreased significantly, from the range 20.15–15.18 to 14.07–11.51, so the shades of reddish decreased. At the same time, the values of the parameter b* were much lower, from the range 21.71–14.42 to 20.98–14.26, and the shades of yellow decreased.

The thermal treatment caused a decrease in the L* value for the processed samples when compared to the control samples. The purees were characterized by a darkened color determined by various factors such as processing temperature and time, type of cultivar, vitamin C content, and some pigments found in the raw material. Therefore, the brightest (L* = 43.04) and reddest (a* = 14.07) puree was obtained from the Grimmes Golden apple variety, and the yellowest was obtained from the Domnesc variety, with a b* value of 20.98.

According to a study conducted on 1200 subjects, age is one of the factors that influence color preference. Generally, people prefer red when they are 1 to 10 years old [

54].

For this reason, we tend to conclude that the purees from the Champion, and Elstar apple varieties could be more preferred by infants.

Table 6.

Effect of thermal treatment on color.

Table 6.

Effect of thermal treatment on color.

| Puree Sample | Unsterilized Product Color | Sterilized Product Color |

|---|

| L* | a* | b* | L* | a* | b* |

|---|

| 1 | 46.03 ± 0.74 a | 20.25 ± 1.9 a | 20.74 ± 1.81 a | 31.77 ± 1.19 b | 12.64 ± 0.29 cde | 16.15 ± 0.3 de |

| 2 | 43.56 ± 1.74 a | 21.2 ± 3.01 a | 19.72 ± 0.75 a | 38.31 ± 0.18 ab | 12.79 ± 0.09 cd | 15.64 ± 0.08 ef |

| 3 | 40.36 ± 0.38 ab | 15.21 ± 0.52 cd | 21.71 ± 1.44 a | 38.26 ± 0.33 ab | 12.4 ± 0.52 cde | 18.07 ± 0.34 b |

| 4 | 43.24 ± 0.56 a | 16.14 ± 0.71 bcd | 19.82 ± 0.52 a | 43.04 ± 3.88 a | 14.07 ± 0.15 b | 17.33 ± 0.29 c |

| 5 | 42.76 ± 0.61 a | 15.18 ± 0.59 cd | 20.16 ± 0.18 a | 40.97 ± 0.19 ab | 12.25 ± 0.11 de | 18.09 ± 0.3 b |

| 6 | 38.85 ± 0.59 ab | 15.33 ± 0.78 cd | 17.77 ± 0.75 a | 38.26 ± 2.11 ab | 11.51 ± 0.4 f | 14.26 ± 0.21 g |

| 7 | 32.72 ± 1.27 b | 15.18 ± 0.78 cd | 16.1 ± 0.83 a | 31.71 ± 0.16 ab | 12.99 ± 0.21 c | 16.47 ± 0.31 d |

| 8 | 36.88 ± 0.79 ab | 14.33 ± 0.73 d | 14.42 ± 0.42 a | 35.66 ± 0.12 ab | 12.01 ± 0.16 ef | 15.38 ± 0.26 f |

| 9 | 42.42 ± 2.13 b | 19.02 ± 1.27 ab | 21.41 ± 0.55 a | 42.35 ± 0.8 a | 14.9 ± 0.3 a | 20.98 ± 0.36 a |

| 10 | 36.58 ± 0.69 ab | 18.1 ± 1.73 abc | 17.3 ± 1.67 a | 38.06 ± 0.25 ab | 13.67 ± 0.09 b | 15.98 ± 0.41 def |

3.8. Texture Determination

After analyzing the textural parameters of the purees, we noticed a significant difference regarding the adhesiveness and firmness between unsterilized and sterilized products, while cohesiveness and deformation at hardness parameters suffered insignificant modifications.

Firmness was determined as the maximum penetration force registered for the first cycle. It was found that the firmness values of the purees obtained from the Champion and Juliana apple varieties before sterilization were the highest, having values of 2.46 N and 2.78 N, respectively. After sterilization, the puree containing the Champion apple variety registered a firmness of 3.5 N, while that containing the Juliana apple variety registered a value of 2.07 N. On the opposite side were the Domnesc varieties and Parmen Clone (

Table 7). These results are due to the content of pectin in apples, which creates firm gels. Since some apple varieties contain lower levels of pectin compared to others, it induces a weaker texture of the puree samples.

Adhesiveness represents the work required to pull the probe away from the sample. Before sterilization, the highest adhesiveness was observed in the purees obtained from the Champion and Parmen Clone apple varieties, with values of 1.85 mJ and 2.3 mJ, while the Elstar apple variety had a much lower value of 0.35 mJ. After the sterilization process, the highest value remained for the same purees obtained from the Champion and Parmen Clone apple varieties, with 8.1 mJ and 5 mJ. This variation in adhesiveness is due to the variation in the moisture of the samples.

Table 7.

Texture determination.

Table 7.

Texture determination.

| | Unsterilized Product Texture | Sterilized Product Texture |

|---|

| Puree Sample | Cohesiveness (n.a) | Firmness (N) | Deformation at Hardness (mm) | Adhesiveness (mJ) | Cohesiveness (n.a.) | Firmness (N) | Deformation at Hardness (mm) | Adhesiveness (mJ) |

|---|

| 1 | 0.615 ± 0.049 a | 2.46 ± 0.39 a | 7.79 ± 0.03 a | 0.55 ± 0.07 ab | 0.32 ± 0.06 a | 3.49 ± 0.12 a | 7.97 ± 0.03 a | 8.1 ± 0.7 a |

| 2 | 0.619 ± 0.084 a | 2.08 ± 0.09 a | 7.985 ± 0.007 a | 0.35 ± 0.35 b | 0.355 ± 0.205 a | 1.49 ± 0.31 bc | 7.97 ± 0.03 a | 4.1 ± 0.9 bc |

| 3 | 0.425 ± 0.163 a | 1.055 ± 0.007 a | 7.68 ± 0.27 a | 1.85 ± 0.92 ab | 0.455 ± 0.106 a | 2.455 ± 0.332 b | 7.4 ± 0.8 a | 3.4 ± 0.7 bc |

| 4 | 0.585 ± 0.049 a | 1.88 ± 0.08 a | 7.945 ± 0.007 a | 0.55 ± 0.64 ab | 0.53 ± 0.27 a | 1.44 ± 0.12 c | 7.97 ± 0.03 a | 2.8 ± 0.4 cd |

| 5 | 0.55 ± 0.01 a | 1.99 ± 0.41 a | 7.97 ± 0.02 a | 0.7 ± 0.1 ab | 0.32 ± 0.01 a | 2.09 ± 0.29 bc | 7.97 ± 0.03 a | 3.55 ± 0.49 bc |

| 6 | 0.38 ± 0.05 a | 1.49 ± 0.15 a | 7.645 ± 0.431 a | 1.35 ± 0.49 ab | 0.475 ± 0.106 a | 1.635 ± 0.091 bc | 7.99 ± 0.01 a | 3.8 ± 0.3 bc |

| 7 | 0.525 ± 0.007 a | 1.5 ± 0.2 a | 7.99 ± 0.01 a | 0.45 ± 0.21 ab | 0.42 ± 0.01 a | 1.7 ± 0.2 bc | 7.995 ± 0.007 a | 1.95 ± 0.63 cd |

| 8 | 0.59 ± 0.05 a | 2.795 ± 1.393 a | 7.92 ± 0.01 a | 1.2 ± 0.57 ab | 0.41 ± 0.07 a | 2.07 ± 0.23 bc | 7.975 ± 0.035 a | 0.9 ± 0.1 d |

| 9 | 0.355 ± 0.106 a | 1.17 ± 0.21 a | 7.87 ± 0.11 a | 1.15 ± 0.07 ab | 0.405 ± 0.148 a | 1.375 ± 0.233 c | 7.862 ± 0.049 a | 2.85 ± 0.35 bcd |

| 10 | 0.411 ± 0.099 a | 2.2 ± 0.2 a | 7.795 ± 0.028 a | 2.3 ± 0.6 a | 0.585 ± 0.049 a | 1.74 ± 0.41 bc | 7.97 ± 0.03 a | 5.1 ± 0.1 b |

Adhesiveness and firmness are the main parameters for baby foods [

55,

56]. Smooth baby foods and those with proper moisture have the highest acceptance rate by infants. This was also confirmed by researchers from Alberta Health Services and the Centre for Taste and Feeding Behavior, who conducted similar studies in 2017 and 2019, respectively [

57,

58]. The textural characteristics of the purees developed in the present study meet the textural properties required for baby food.

3.9. Chemometric Comparison and Classification

The PCA model was applied to vitamin C, TPC and AC data for unsterilized and sterilized purees to determine the most important variables that explain the relationships between the ten selected genotypes of apples used and to identify any group patterns (

Figure 3). The results from the current study showed that using the chemometric technique PCA, the physico-chemical quality attributes can be more comprehensively understood. The results showed that with a relative distance of 10, all the genotypes were grouped into four main clusters.

Principal component analysis (PCA) uses the maximum variance of the data in order to transform the original axes (parameters) into new axes named principal components (PCs) or factors. The PCs are orthogonal, and the intercorrelations are removed. The graph representation of the translation coordinates provides the scores plot and reveals the similarity/dissimilarity between cases (the grouping of the samples). On the other hand, the graph representation of the cosines of the rotational angles provides the loadings plot, which reveals the importance of the original parameters to the classification.

4. Conclusions

Following the studies and determinations performed in this paper, we can conclude that a range of products for children obtained from apples, carrots, pumpkins and celery has been developed. In order to develop the product, ten experimental puree variants were developed, corresponding to the ten varieties of apples used. Although there are a number of similar products on the market, the current study also aimed to choose the right apple varieties for making a puree, which would ensure the proper functioning of the young body.

The final products were analyzed from a physico-chemical point of view, using methods of determination according to the standards in force, and a comparison was made between the apple varieties used to obtain the puree. Following the results obtained, the puree can be introduced into the diet of infants and children, providing them with the necessary bioactive compounds and minerals for optimal development.

The analyses performed on both the fresh and the sterilized products highlighted the effects of the heat treatment on the components of the product.

TPC content is directly related to the AC of baby food analyzed. This relationship indicates that the contribution of TPC to the free radical scavenging potential of baby food is significantly related. Having the results that show the high content of puree in polyphenol compounds and a high antioxidant capacity confirms the hypothesis that baby food, which is considered a convenient food, is a source of nutritional value, so it can be recommended for use and added effectively to children’s diets.

Puree texture and color parameters were evaluated, these being two important factors in the perception of infants and children, being the ideal time to introduce the child to a variety of foods and flavors to develop healthy eating habits. Our product is very suitable in the parameters that correspond to baby food with the highest acceptance rate by infants, which proves the quality of the puree texture obtained in this research.

According to the present study, a suitable product for children based on Elstar apples, pumpkins, carrots and celery was produced. Baby puree obtained from the Elstar apple variety was, as the physico-chemical methods showed, the most suitable due to its high content of vitamin C, 3.27 mg/100 g, antioxidant capacity and polyphenol content in the sterilized product, 139.67 mg GAE/100 g, and 0.86 AC/100 g, respectively. Regarding the color and texture determinations, it has also been proved that the puree from this type of apple also fits in the parameters. We believe that this branch should be studied more, due to children’s nutrition being an important factor in their development and fruits and vegetables being a major source of nutrients that play a key role in achieving this goal.

Author Contributions

Conceptualization, A.M.M. and A.E.M.; methodology, A.M.M. and A.E.M.; software, A.M.M., A.P., R.E.S. and A.E.M.; validation, A.M.M. and A.E.M.; formal analysis, A.M.M., R.E.S., V.M. and A.E.M.; investigation, A.M.M., A.P. and A.E.M.; resources, A.M.M., S.M., R.E.S. and A.E.M.; data curation, V.M.; writing—original draft preparation, A.M.M.; writing—review and editing, A.M.M. and A.E.M.; visualization, A.M.M. and A.E.M.; supervision, A.E.M. and S.M.; project administration, S.M. and R.E.S.; funding acquisition, A.E.M., R.E.S. and S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from the Ministry of Research, Innovation and Digitization, CNCS/CCCDI—UEFISCDI, project number PN-III-P1-1.1-PD-2019-1108, within PNCDI III.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript, or in the decision to publish the results. The author A.M.M. (Alexandra Mădălina Mateescu) is an employee of MDPI; however, she is not working for the journal Applied Sciences at the time of submission and publication.

References

- Dhami, M.; Ogbo, F.; Diallo, T.; Olusanya, B.; Goson, P.; Agho, K.; on behalf of the Global Maternal and Child Health Research Collaboration (GloMACH). Infant and Young Child Feeding Practices among Adolescent Mothers and Associated Factors in India. Nutrients 2021, 13, 2376. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, M.D.; Lobo, M.O.; Sammán, N.C. Technological and Sensory Properties of Baby Purees Formulated with Andean Grains and Dried with Different Methods. Proceedings 2020, 53, 13. [Google Scholar] [CrossRef]

- Hondru, G.; Laillou, A.; Wieringa, F.T.; Poirot, E.; Berger, J.; Christensen, D.L.; Roos, N. Age-Appropriate Feeding Practices in Cambodia and the Possible Influence on the Growth of the Children: A Longitudinal Study. Nutrients 2019, 12, 12. [Google Scholar] [CrossRef] [Green Version]

- Elliott, C. Tracking Kids’ Food: Comparing the Nutritional Value and Marketing Appeals of Child-Targeted Supermarket Products Over Time. Nutrients 2019, 11, 1850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Padarath, S.; Gerritsen, S.; Mackay, S. Nutritional Aspects of Commercially Available Complementary Foods in New Zealand Supermarkets. Nutrients 2020, 12, 2980. [Google Scholar] [CrossRef] [PubMed]

- Mörkl, S.; Stell, L.; Buhai, D.; Schweinzer, M.; Wagner-Skacel, J.; Vajda, C.; Lackner, S.; Bengesser, S.; Lahousen, T.; Painold, A.; et al. ‘An Apple a Day’?: Psychiatrists, Psychologists and Psychotherapists Report Poor Literacy for Nutritional Medicine: International Survey Spanning 52 Countries. Nutrients 2021, 13, 822. [Google Scholar] [CrossRef]

- Johansson, U.; Öhlund, I.; Hernell, O.; Lönnerdal, B.; Lindberg, L.; Lind, T. Protein-Reduced Complementary Foods Based on Nordic Ingredients Combined with Systematic Introduction of Taste Portions Increase Intake of Fruits and Vegetables in 9 Month Old Infants: A Randomised Controlled Trial. Nutrients 2019, 11, 1255. [Google Scholar] [CrossRef] [Green Version]

- Bernal, M.; Roman, S.; Klerks, M.; Haro-Vicente, J.; Sanchez-Siles, L. Are Homemade and Commercial Infant Foods Different? A Nutritional Profile and Food Variety Analysis in Spain. Nutrients 2021, 13, 777. [Google Scholar] [CrossRef]

- Savarino, G.; Corsello, A.; Corsello, G. Macronutrient balance and micronutrient amounts through growth and development. Ital. J. Pediatr. 2021, 47, 1–14. [Google Scholar] [CrossRef]

- Patel, J.K.; Rouster, A.S. Infant Nutrition Requirements and Options. In StatPearls; StatPearls Publishing: Treasure Island, FL, USA, 2021. Available online: https://www.ncbi.nlm.nih.gov/books/NBK560758/ (accessed on 7 May 2022).

- Katiforis, I.; Fleming, E.; Haszard, J.; Hape-Cramond, T.; Taylor, R.; Heath, A.-L. Energy, Sugars, Iron, and Vitamin B12 Content of Commercial Infant Food Pouches and Other Commercial Infant Foods on the New Zealand Market. Nutrients 2021, 13, 657. [Google Scholar] [CrossRef]

- Westland, S.; Crawley, H. Fruit and Vegetable Based Purées in Pouches for Infants and Young Children. Available online: https://www.firststepsnutrition.org (accessed on 27 October 2021).

- Birch, L.; Savage, J.S.; Ventura, A. Influences on the Development of Children’s Eating Behaviours: From Infancy to Adolescence. Can. J. Diet. Pract. Res. 2007, 68, s1–s56. [Google Scholar]

- Dai, H.; Leung, C.E.; Corradini, M.; Xiao, H.; Kinchla, A.J. Increasing the nutritional value of strawberry puree by adding xylo-oligosaccharides. Heliyon 2020, 6, e03769. [Google Scholar] [CrossRef]

- Al-Ghamdi, S.; Sonar, C.R.; Patel, J.; Albahr, Z.; Sablani, S.S. High pressure-assisted thermal sterilization of low-acid fruit and vegetable purees: Microbial safety, nutrient, quality, and packaging evaluation. Food Control 2020, 114, 107233. [Google Scholar] [CrossRef]

- Gratz, M.; Sevenich, R.; Hoppe, T.; Schottroff, F.; Vlaskovic, N.; Belkova, B.; Chytilova, L.; Filatova, M.; Stupak, M.; Hajslova, J.; et al. Gentle Sterilization of Carrot-Based Purees by High-Pressure Thermal Sterilization and Ohmic Heating and Influence on Food Processing Contaminants and Quality Attributes. Front. Nutr. 2021, 8, 643837. [Google Scholar] [CrossRef]

- Sevenich, R.; Kleinstueck, E.; Crews, C.; Anderson, W.; Pye, C.; Riddellova, K.; Hradecký, J.; Moravcova, E.; Reineke, K.; Knorr, D. High-Pressure Thermal Sterilization: Food Safety and Food Quality of Baby Food Puree. J. Food Sci. 2014, 79, M230–M237. [Google Scholar] [CrossRef]

- AOAC Official Method 934.06 Moisture in Dried Fruits. Available online: https://dokumen.tips/documents/aoac-official-method-93406-moisture-in-dried-fruits.html (accessed on 27 October 2021).

- Nirmaan, A.M.C.; Prasantha, B.D.R.; Peiris, B.L. Comparison of microwave drying and oven-drying techniques for moisture determination of three paddy (Oryza sativa L.) varieties. Chem. Biol. Technol. Agric. 2020, 7, 1–7. [Google Scholar] [CrossRef]

- Zhao, W.-Z.; Cao, P.-P.; Zhu, Y.-Y.; Liu, S.; Gao, H.-W.; Huang, C.-Q. Rapid Detection of vitamin C content in fruits and vegetables using a digital camera and color reaction. Quim. Nova 2020, 43, 1421–1430. [Google Scholar] [CrossRef]

- Carmona-Hernandez, J.C.; Taborda-Ocampo, G.; González-Correa, C.H. Folin-Ciocalteu Reaction Alternatives for Higher Polyphenol Quantitation in Colombian Passion Fruits. Int. J. Food Sci. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Dibacto, R.E.K.; Tchuente, B.R.T.; Nguedjo, M.W.; Tientcheu, Y.M.T.; Nyobe, E.C.; Edoun, F.L.E.; Kamini, M.F.G.; Dibanda, R.F.; Medoua, G.N. Total Polyphenol and Flavonoid Content and Antioxidant Capacity of Some Varieties of Persea americana Peels Consumed in Cameroon. Sci. World J. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Thaipong, K.; Boonprakob, U.; Crosby, K.; Cisneros-Zevallos, L.; Hawkins Byrne, D. Comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. J. Food Compos. Anal. 2006, 19, 669–675. [Google Scholar] [CrossRef]

- Mureșan, A.E.; Sestras, A.F.; Militaru, M.; Păucean, A.; Tanislav, A.E.; Pușcaș, A.; Mateescu, M.; Mureșan, V.; Vlaic, R.A.M.; Sestras, R.E. Chemometric Comparison and Classification of 22 Apple Genotypes Based on Texture Analysis and Physico-Chemical Quality Attributes. Horticulturae 2022, 8, 64. [Google Scholar] [CrossRef]

- Markovic, I.; Ilic, J.; Markovic, D.; Simonovic, V.; Kosanic, N. Color Measurement of Food Products Using CIE L*a*b* and RGB Color Space. J. Hyg. Eng. Des. 2013, 4, 50–53. [Google Scholar]

- ISO 11036:2020(En), Sensory Analysis—Methodology—Texture Profile. Available online: https://www.iso.org/obp/ui/#iso:std:iso:11036:ed-2:v1:en (accessed on 27 October 2021).

- Malavi, D.; Mbogo, D.; Moyo, M.; Mwaura, L.; Low, J.; Muzhingi, T. Effect of Orange-Fleshed Sweet Potato Purée and Wheat Flour Blends on β-Carotene, Selected Physicochemical and Microbiological Properties of Bread. Foods 2022, 11, 1051. [Google Scholar] [CrossRef] [PubMed]

- Park, H.-S.; Chung, H.-S. Evaluation of the physicochemical properties of starch isolated from thinned young ‘Fuji’ apples compared to corn and potato starches. Korean J. Food Preserv. 2021, 28, 501–509. [Google Scholar] [CrossRef]

- Doerflinger, F.C.; Miller, W.B.; Nock, J.F.; Watkins, C.B. Variations in zonal fruit starch concentrations of apples—A developmental phenomenon or an indication of ripening? Hortic. Res. 2015, 2, 15047. [Google Scholar] [CrossRef] [Green Version]

- Carrín, M. Characterization of starch in apple juice and its degradation by amylases. Food Chem. 2004, 87, 173–178. [Google Scholar] [CrossRef]

- Seidel, K.; Kahl, J.; Paoletti, F.; Birlouez, I.; Busscher, N.; Kretzschmar, U.; Särkkä-Tirkkonen, M.; Seljåsen, R.; Sinesio, F.; Torp, T.; et al. Quality assessment of baby food made of different pre-processed organic raw materials under industrial processing conditions. J. Food Sci. Technol. 2013, 52, 803–812. [Google Scholar] [CrossRef] [Green Version]

- Asiimwe, A.; Kigozi, J.; Baidhe, E.; Muyonga, J. Optimization of refractance window drying conditions for passion fruit puree. LWT 2021, 154, 112742. [Google Scholar] [CrossRef]

- Alzamora, S.M.; Chirife, J. The Water Activity of Canned Foods. J. Food Sci. 1983, 48, 1385–1387. [Google Scholar] [CrossRef]

- Nor, N.Z.N.M.; Kormin, F.; Fuzi, S.F.Z.M.; Bin Abu Bakar, M.A.L. Comparison of Physicochemical, Antioxidant Properties and Sensory Acceptance of Puree from Tamarillo and Tomato. J. Sci. Technol. 2018, 10, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Summo, C.; De Angelis, D.; Rochette, I.; Mouquet-Rivier, C.; Pasqualone, A. Influence of the preparation process on the chemical composition and nutritional value of canned purée of kabuli and Apulian black chickpeas. Heliyon 2019, 5, e01361. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ettinger, L.; Keller, H.H.; Duizer, L.M. Characterizing Commercial Pureed Foods: Sensory, Nutritional, and Textural Analysis. J. Nutr. Gerontol. Geriatr. 2014, 33, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.-F.; Zhang, M.; Adhikari, B. Changes in Quality Attributes of Strawberry Purees Processed by Power Ultrasound or Thermal Treatments. Food Sci. Technol. Res. 2014, 20, 1033–1041. [Google Scholar] [CrossRef] [Green Version]

- Usal, M.; Sahan, Y. In vitro evaluation of the bioaccessibility of antioxidative properties in commercially baby foods. J. Food Sci. Technol. 2020, 57, 3493–3501. [Google Scholar] [CrossRef]

- Giannakourou, M.C.; Taoukis, P.S. Effect of Alternative Preservation Steps and Storage on Vitamin C Stability in Fruit and Vegetable Products: Critical Review and Kinetic Modelling Approaches. Foods 2021, 10, 2630. [Google Scholar] [CrossRef]

- de Sousa, T.L.; da Silva, J.P.; Lodete, A.R.; Lima, D.S.; Mesquita, A.A.; de Almeida, A.B.; Placido, G.R.; Egea, M.B. Vitamin C, phenolic compounds and antioxidant activity of Brazilian baby foods. Nutr. Food Sci. 2020, 51, 725–737. [Google Scholar] [CrossRef]

- Carbonell-Capella, J.M.; Barba, F.J.; Esteve, M.J.; Frígola, A. Quality parameters, bioactive compounds and their correlation with antioxidant capacity of commercial fruit-based baby foods. Food Sci. Technol. Int. 2013, 20, 479–487. [Google Scholar] [CrossRef]

- Arfaoui, L. Dietary Plant Polyphenols: Effects of Food Processing on Their Content and Bioavailability. Molecules 2021, 26, 2959. [Google Scholar] [CrossRef]

- Mongkontanawat, N.; Ueda, Y.; Yasuda, S. Increased total polyphenol content, antioxidant capacity and γ-aminobutyric acid content of roasted germinated native Thai black rice and its microstructure. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Wołosiak, R.; Drużyńska, B.; Piecyk, M.; Majewska, E.; Worobiej, E. Effect of Sterilization Process and Storage on the Antioxidative Properties of Runner Bean. Molecules 2018, 23, 1409. [Google Scholar] [CrossRef] [Green Version]

- Chumyam, A.; Whangchai, K.; Jungklang, J.; Faiyue, B.; Saengnil, K. Effects of heat treatments on antioxidant capacity and total phenolic content of four cultivars of purple skin eggplants. ScienceAsia 2013, 39, 246–251. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, S.M.; Chun, J.; Lee, H.B.; Lee, J. Influence of heat treatment on the antioxidant activities and polyphenolic compounds of shiitake (Lentinus edodes) mushroom. Food Chem. 2006, 99, 381–387. [Google Scholar] [CrossRef]

- Čížková, H.; Ševčík, R.; Rajchl, A.; Voldrich, M. Nutritional Quality of Commercial Fruit Baby Food. Czech J. Food Sci. 2009, 27, S134–S137. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.-Y.; Zhang, H.-C.; Liu, W.-X.; Li, C.-Y. Survey of antioxidant capacity and phenolic composition of blueberry, blackberry, and strawberry in Nanjing. J. Zhejiang Univ. Sci. 2012, 13, 94–102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Moura, S.C.S.R.; Tavares, P.E.D.R.; Germer, S.P.M.; Nisida, A.L.A.C.; Alves, A.B.; Kanaan, A.S. Degradation Kinetics of Anthocyanin of Traditional and Low-Sugar Blackberry Jam. Food Bioprocess Technol. 2011, 5, 2488–2496. [Google Scholar] [CrossRef]

- Särkkä-Tirkkonen, M.; Väisänen, H.-M.; Beck, A.; Kretzschmar, U.; Seidel, K. Overview on Different Sterilization Techniques for Baby Food; University of Helsinki: Helsinki, Finland, 2010. [Google Scholar]

- Ahmed, M.A.; Al-Khalifa, A.S.; Al-Nouri, D.M.; El-Din, M.F.S. Dietary intake of artificial food color additives containing food products by school-going children. Saudi J. Biol. Sci. 2020, 28, 27–34. [Google Scholar] [CrossRef]

- Stevens, L.J.; Burgess, J.R.; Stochelski, M.A.; Kuczek, T. Amounts of Artificial Food Dyes and Added Sugars in Foods and Sweets Commonly Consumed by Children. Clin. Pediatr. 2014, 54, 309–321. [Google Scholar] [CrossRef]

- Environmental Health Hazard Assessment, Office. Health Effects Assessment Potential Neurobehavioral Effects of Synthetic Food Dyes in Children. 2021. Available online: https://oehha.ca.gov/risk-assessment/report/health-effects-assessment-potential-neurobehavioral-effects-synthetic-food (accessed on 13 May 2022).

- Psicodinâmica Das Cores Em Comunicação—EDIÇÃO REVISTA E AMPLIADA|Nebraska, F.—Academia.Edu. Available online: https://www.academia.edu/40122222/Psicodinâmica_das_Cores_em_Comunicação_-_EDIÇÃO_REVISTA_E_AMPLIADA (accessed on 17 June 2022).

- Cappellotto, M.; Olsen, A. Food Texture Acceptance, Sensory Sensitivity, and Food Neophobia in Children and Their Parents. Foods 2021, 10, 2327. [Google Scholar] [CrossRef]

- Jasim, A.; Ramaswamy, H.S. Viscoelastic and thermal characteristics of vegetable puree-based baby foods. J. Food Process Eng. 2006, 29, 219–233. [Google Scholar] [CrossRef]

- Demonteil, L.; Tournier, C.; Marduel, A.; Dusoulier, M.; Weenen, H.; Nicklaus, S. Longitudinal study on acceptance of food textures between 6 and 18 months. Food Qual. Prefer. 2019, 71, 54–65. [Google Scholar] [CrossRef]

- Alberta, H.S. Food Textures for Children Developed by Registered Dietitians Nutrition Services 404107-NFS. Available online: https://peas.albertahealthservices.ca/Uploads/Food%20Textures%20for%20Children.pdf (accessed on 13 May 2022).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).