Feasibility Study of a Gripper with Thermally Controlled Stiffness of Compliant Jaws

Abstract

:1. Introduction

2. Theoretical Basis

3. Feasibility Study

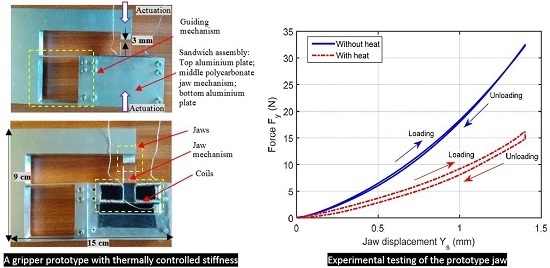

3.1. Prototype Fabrication and Testing

3.2. Further Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reddy, A.N.; Maheshwari, N.; Sahu, D.K.; Ananthasuresh, G.K. Miniature compliant grippers with vision-based force sensing. IEEE Trans. Robot. 2010, 26, 867–877. [Google Scholar] [CrossRef]

- Hao, G.; Hand, R. Design and static testing of a compact distributed-compliance gripper based on flexure motion. Arch. Civil Mech. Eng. 2016, 16, 708–716. [Google Scholar] [CrossRef]

- Hao, G.; Mullins, J.; Cronin, K. Simplified modelling and development of a bi-directionally adjustable constant-force compliant gripper. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016. [Google Scholar] [CrossRef]

- Chronis, N.; Lee, L.P. Electrothermally activated SU-8 microgripper for single cell manipulation in solution. J. Microelectromech. Syst. 2005, 14, 857–863. [Google Scholar] [CrossRef]

- Mackay, R.E.; Le, H.R.; Clark, S.; Williams, J.A. Polymer micro-grippers with an integrated force sensor for biological manipulation. J. Micromech. Microeng. 2012, 23, 015005. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Ho, S.S.; Low, C.L.N. A polymeric microgripper with integrated thermal actuators. J. Micromech. Microeng. 2004, 14, 969–974. [Google Scholar] [CrossRef]

- Choi, S.B.; Han, Y.M.; Kim, J.H.; Cheong, C.C. Force tracking control of a flexible gripper featuring shape memory alloy actuators. Mechatronics 2011, 11, 677–690. [Google Scholar] [CrossRef]

- Hao, G.; Li, H. Extended static modelling and analysis of compliant compound parallelogram mechanisms considering the initial internal axial force. J. Mech. Robot. 2016, 8. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, G.; Riza, M. Feasibility Study of a Gripper with Thermally Controlled Stiffness of Compliant Jaws. Appl. Sci. 2016, 6, 367. https://doi.org/10.3390/app6110367

Hao G, Riza M. Feasibility Study of a Gripper with Thermally Controlled Stiffness of Compliant Jaws. Applied Sciences. 2016; 6(11):367. https://doi.org/10.3390/app6110367

Chicago/Turabian StyleHao, Guangbo, and Mehdi Riza. 2016. "Feasibility Study of a Gripper with Thermally Controlled Stiffness of Compliant Jaws" Applied Sciences 6, no. 11: 367. https://doi.org/10.3390/app6110367

APA StyleHao, G., & Riza, M. (2016). Feasibility Study of a Gripper with Thermally Controlled Stiffness of Compliant Jaws. Applied Sciences, 6(11), 367. https://doi.org/10.3390/app6110367