Hard machining has been widely applied in mechanical processing due to the many advantages included. The advantages of hard machining were indicated to be geometric accuracy, improved quality of the finished surface, the reduction of the labor expenditures [

1] and also a reduction in burr formation, better chip disposal, higher stability, simplified tooling [

2] and flexible process design [

3,

4]. However, hard machining also has its disadvantages, such as high tool wear rate, reduction in tool life due to the effect of high hardness of workpiece material and cutting temperature [

2,

4]. The application of flood coolant in hard milling has not been satisfied, especially in the matter of environmental and health-related issues regarding workers. As a successful solution applied to hard machining, MQL is an effective, environmentally-friendly solution and has been widely used in the machining processes (

i.e., turning, drilling and milling). According to Phafat

et al. [

5], machining with MQL is a process in which a small amount lubricant utilized at a flow rate less than 250 mL/h is mixed with compressed air and sprayed onto the cutting zone. MQL helps to increase the quality of the surface finish [

6,

7,

8], improve tool life, reduce tool wear, decrease cutting temperature and reduce the cost of lubrication [

6,

7,

8,

9,

10,

11,

12]. The effectiveness of MQL has already been demonstrated in many studies and application of turning and milling processes. In machining with MQL, lubricant, air pressure and fluid flow are the main parameters. They will decide the effectiveness of MQL cutting. Applied lubricants in machining are ubiquitous, such as mineral oil, synthetic esters, fatty alcohols,

etc. [

8]. Even vegetable oil has been used and proven to be effective in machining [

7,

8]. Several authors optimized MQL parameters and achieved positive results. Thakur

et al. [

13] conducted optimization of MQL parameters to get minimum tool wear in the high-speed turning of super-alloy Inconel 718. Simultaneously, the cutting parameters, including cutting speed and feed rate, were also optimized. Nevertheless, the optimization of MQL parameters does not consist of a cutting fluid being an important factor of MQL. The result showed that the optimal cutting parameters for tool flank wear are lower cutting speed, lower feed rate, higher delivery pressure, higher quantity of lubrication, lower frequency of pulses and an inclined direction of the cutting fluid. In the study of Gandhe

et al. [

14], experiments were carried out to optimize the MQL parameters in the turning of EN-8 steel. It showed that the cutting fluid used is the most significant factor affecting tool wear. J. Barnabas

et al. [

15] have done a comparative analysis of particle swarm optimization and simulated annealing algorithm in the optimization of the MQL parameters for flank tool wear. The author presented a simulated annealing algorithm technique that is comparatively better than other techniques in use. However, the studies conducted on the effects and optimization of the parameters in MQL, such as flow rate, air pressure and type of lubricant used, still remain open.

Surface roughness is an important index used to estimate product quality in mechanical products. The parameters that influence surface roughness include cutting tool properties (

i.e., tool material, tool shape, run-out error, nose radius), workpiece properties (

i.e., workpiece diameter, workpiece hardness, workpiece length), cutting phenomena (

i.e., acceleration, vibrations, chip formation, friction in the cutting zone, cutting force variation) and machining parameters (

i.e., process kinematics, cooling fluid, step over, tool angle, depth-of-cut, feed rate, cutting speed) [

16]. In any machining process, the primary key point for insuring the quality of the manufacturing processes is the selection of suitable cutting parameters for the corresponding material of the workpieces. With a designed experiments approach, the Taguchi technique for the design of experimentation is a method extensively used in optimizing the cutting parameters and predicting surface roughness. There has been some notable research produced related to the effects of cutting parameters on surface roughness in which the Taguchi method was applied. Ahmet

et al. [

17], Ilhan

et al. [

18] applied the Taguchi method to optimizing the tuning parameters in hard turning. The authors concluded that feed rate contributes mostly to surface roughness. The Taguchi method and ANOVA were also employed in the study of Gopalsamy

et al. [

19]. The authors found optimum process parameters during hard machining of hardened steel. In the results of this research, the cutting speed is the most influential factor on surface roughness. The AISI H13 steel selected in this study constituted a workpiece material which has been widely used in manufacturing, especially in high pressure die-casting and extrusion molding, cutting blades, and hot dies due to good toughness levels and resistance to abrasion. AISI H13 steel has been studied in many types of research. Ding

et al. [

20] used the Taguchi method and ANOVA to establish and analyze an empirical model for establishing surface roughness. This model indicates a relationship between surface roughness and four factors of cutting parameters: cutting speed, feed, radial depth of cut, and the axial depth of cut. The results showed that axial depth of cut is the main influential factor on surface roughness. In the research of Outeiro [

21], the DOE method in Taguchi was used to design the experiment. The model of the residual stress and the optimization of cutting parameters was established by applying Artificial Neural Network (ANN) and a Genetic Algorithm (GA). The results indicated that the cutting parameters, which cause lower residual stress and contribute to better surface roughness. Ghani

et al. [

22] concluded that high cutting speed, low feed rate and lower depth of cut provided the best results for surface roughness in machining hardened steel AISI H13.

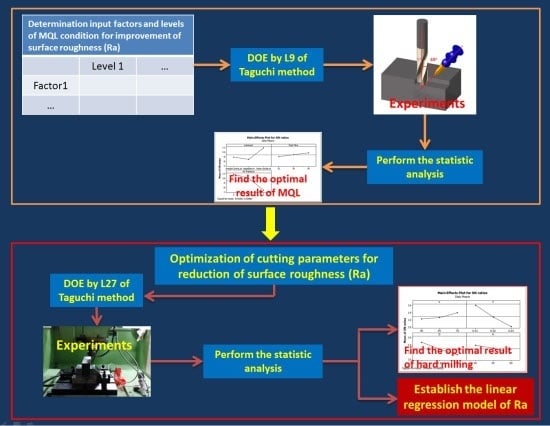

In the present study, the Taguchi method and ANOVA were applied to optimize MQL conditions for surface roughness. The best cutting parameters of hard milling of AISI H13, such as cutting speed, feed rate, depth-of-cut, and hardness of workpiece were found out in order to get the better surface roughness under MQL conditions optimized. A regression model for surface roughness was therefore established.