Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper

Abstract

:1. Introduction

2. Materials and Experimental Procedure

2.1. Samples Preparation, Hardness Measurment, and the ECAP Process

2.2. Slurry Pot Tester

2.3. Erosion-Corrosion Test

2.4. Microstructural and Surface Roughness Evaluation

3. Results and Discussion

3.1. Microstructure Images

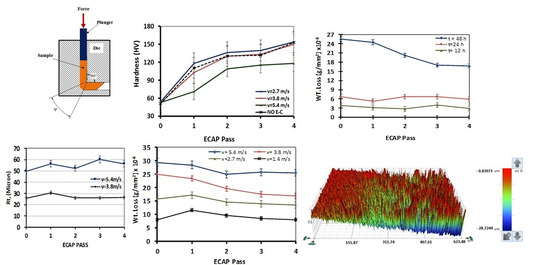

3.2. Hardness Results

3.3. Effect of ECAP on Erosion-Corrosion at Different Test Durations

3.4. Effect of ECAP on Erosion-Corrosion at Different Flow Velocities

3.5. Effect of ECAP on Erosion-Corrosion at Different Impacting Angles

3.6. Effect of ECAP on Erosion-Corrosion at Different Sand Concentrations

3.7. Metallography and Surface Roughness Observations

4. Conclusions

- The hardness magnitude of the ECAPed pure Cu is 200% higher than un-ECAP material.

- The impacting velocity has a significant effect on the E-C of copper. The results showed that the E-C rate increases with increasing the slurry velocity. In addition, the work hardening due to ECAP improved the E-C resistance. More damage is observed in the samples that were subjected to higher velocity compared to the lower velocities.

- The impacting angle plays a major role in the E-C behaviors of copper. The highest E-C rates were observed at an impacting angle of 45° in all ECAP passes.

- The ECAP process improved the surface roughness of the E-C copper samples.

- Generally, a 30% rise in resistance to E-C was achieved after four ECAP passes as compared to coarse-grain copper for the parameters studied in this work.

- Generally, severe plastic deformation processing is likely to improve the E-C resistance of all FCC metals and alloys.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Maoqiao, X.; Yingchun, Z.; Yun, Z.; Chaofu, W.; Wei, L.; Yonghong, Y. Effects of grain size and porosity on strength of Li2TiO3 tritium breeding pebbles and its grain growth behavior. J. Nucl. Mater. 2016, 482, 163–169. [Google Scholar]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Ravisankar, B. Handbook of Mechanical Nano Structuring; Wiley-VCH: Weinheim, Germany, 2015; ISBN 978-3-527-33506-0. [Google Scholar]

- Ebrahimi, M.; Djavanroodi, F.; Nazari Tiji, S.; Gholipour, H.; Gode, C. Experimental Investigation of the Equal Channel Forward Extrusion Process. Metals 2015, 5, 471–483. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.H.; Djavanroodi, F. Microstructure and texture evolution of Al-7075 alloy processed by equal channel angular pressing. Trans. Nonferrous Met. Soc. China 2015, 25, 1367–1375. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Zolfaghari, A.A.; Ebrahimi, M.; Nikbin, K. Route effect on equal channel angular pressing of copper tube. Acta Metall. Sin. Engl. Lett. 2014, 27, 95–100. [Google Scholar] [CrossRef]

- Li, J.H.; Yu, Z.J.; Zhang, L.P. Effect of Channel Inner Angle on Aluminum ECAP Plastic Deformation. Appl. Mech. Mater. 2014, 442, 27–31. [Google Scholar] [CrossRef]

- Djavanroodi, F.; Omranpour, B.; Sedighi, M. Artificial neural network modeling of ECAP process. Mater. Manuf. Process. 2011, 28, 276–281. [Google Scholar] [CrossRef]

- Valiev, R. Nano structuring of metals by severe plastic deformation for advanced properties. Nat. Mater. 2004, 3, 511–516. [Google Scholar] [CrossRef] [PubMed]

- Osama, M.I.; Saad, M.S.; Mukras, F.A.; Al-Mufadi, F.D. Surface Modelling of Nanostructured Copper Subjected to Erosion-Corrosion. Metals 2017, 7, 155. [Google Scholar] [CrossRef]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Wei, K.X.; Wei, W.; Wang, F.; Du, Q.B.; Alexandrov, I.V.; Hu, J. Microstructure, mechanical properties and electrical conductivity of industrial Cu-0.5% Cr alloy processed by severe plastic deformation. Mater. Sci. Eng. A 2011, 528, 1478–1484. [Google Scholar] [CrossRef]

- Ma, A.; Zhu, C.; Chen, J.; Jiang, J.; Song, D.; Ni, S.; He, Q. Grain Refinement and High-Performance of Equal-Channel Angular Pressed Cu-Mg Alloy for Electrical Contact Wire. Metals 2014, 4, 586–596. [Google Scholar] [CrossRef]

- Shokuhfar, A.; Nejadseyfi, O. A comparison of the effects of severe plastic deformation and heat treatment on the tensile properties and impact toughness of aluminum alloy 6061. Mater. Sci. Eng. A 2014, 594, 140–148. [Google Scholar] [CrossRef]

- Al-Mufadi, F.; Djavanroodi, F. Effect of Equal Channel Angular Pressing Process on Impact Property of Pure Copper. Int. J. Chem. Nucl. Mater. Metall. Eng. 2014, 8, 30–34. [Google Scholar]

- Al-Mufadi, F.; Djavanroodi, F. Equal-Channel Angular Pressing of Thin-Walled Copper Tube. Arab. J. Sci. Eng. 2015, 40, 2785–2794. [Google Scholar] [CrossRef]

- Wang, Y.; Lapovok, R.; Wang, J.T.; Estrin, Y. Effect of back pressure on the thermal stability of severely deformed copper. Mater. Sci. Eng. 2015, 628, 21–29. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, F.; Yao, J.; Dong, S.; Li, N. Erosion–corrosion behavior and corrosion resistance of AISI 316 stainless steel in flow jet impingement. Wear 2015, 328–329, 464–474. [Google Scholar] [CrossRef]

- Paulraj, P.; Garg, R. Effect of intermetallic phases on corrosion behavior and mechanical properties of duplex stainless steel and super-duplex stainless steel. Adv. Sci. Technol. Res. J. 2015, 9, 87–105. [Google Scholar] [CrossRef]

- Abouel-Kasem, A.; Abd-elrhman, Y.M.; Emara, K.M.; Ahmed, S.M. Design and performance of slurry erosion tester. J. Tribol. 2010, 132, 1–10. [Google Scholar] [CrossRef]

- Barik, R.C.; Wharton, J.A.; Wood, R.J.K.; Tan, K.S.; Stokes, K.R. Erosion and erosion-corrosion performance of cast and thermally sprayed nickel–aluminum bronze. Wear 2005, 259, 230–242. [Google Scholar] [CrossRef]

- ASTM G119-09. In Standard Guide for Determining Synergism Between Wear and Corrosion; ASTM International: West Conshohocken, PA, USA, 2009.

- Azarian, N.S.; Ghasemi, H.M.; Monshi, M.R. Synergistic Erosion and Corrosion Behavior of AA5052 Aluminum Alloy in 3.5 wt% NaCl Solution under Various Impingement Angles. J. Bio Tribo Corros. 2015, 1, 10. [Google Scholar] [CrossRef]

- Wang, S.-H.; Jiang, J.; Stack, M.M. Methodology Development for Investigation of Slurry Abrasion Corrosion by Integrating an Electrochemical Cell to a Miller Tester. J. Bio Tribo Corros. 2015, 1, 9. [Google Scholar] [CrossRef] [Green Version]

- Irfan, O.M. Erosion-corrosion behavior of nano-structured pure copper under different flowing velocities. Int. J. Mech. Mech. Eng. 2015, 15, 48–52. [Google Scholar]

- Hassani, S.; Roberts, K.P.; Shirazi, S.A.; Shadley, J.R.; Rybicki, E.F.; Joia, C. Characterization and prediction of chemical inhibition performance for erosion-corrosion conditions in sweet oil and gas production. Corrosion 2012, 68, 885–896. [Google Scholar] [CrossRef]

- Ranjbar, M.; Ghasemi, H.M.; Abedini, M. Effect of Impact Angle on the Erosion–Corrosion Behavior of AISI 420 Stainless Steel in 3.5 wt.% NaCl Solution. J. Tribol. 2015, 137, 3. [Google Scholar] [CrossRef]

- Tian, B.R.; Cheng, Y.F. Electrolytic deposition of Ni-Co-Al2O3 composite coating on pipe steel for corrosion/erosion resistance in oil sand slurry. Electrochim. Acta 2007, 53, 511–517. [Google Scholar] [CrossRef]

- Islam, M.A.; Farhat, Z.N. Mechanical and electrochemical synergism of API X42 pipeline steel during erosion-corrosion. J. Bio Tribo Corros. 2015, 1, 26. [Google Scholar] [CrossRef]

- Buszko, M.H.; Krella, A.K. Slurry Erosion—Design of Test Devices. Adv. Mater. Sci. 2017, 17, 5–17. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Bai, S.-L.; Liu, Z.-D. Study on Cavitation Erosion–Corrosion Behavior of Mild Steel under Synergistic Vibration Generated by Ultrasonic Excitation. Tribol. Lett. 2014, 57, 603–612. [Google Scholar] [CrossRef]

- Malik, J.; Toor, I.H.; Ahmed, W.H.; Gasem, Z.M.; Habib, M.A.; Ben-Mansour, R.; Badr, H.M. Investigations on the Corrosion-Enhanced Erosion Behavior of Carbon Steel AISI 1020. Int. J. Electrochem. Sci. 2014, 9, 6765–6780. [Google Scholar]

- Erfan, O.; Abo El-Nasr, A.-B.A.; Al-mufadi, F. Erosion-corrosion behavior of AA 6066 aluminum alloy. IJME 2014, 3, 15–24. [Google Scholar]

- Sakamoto, A.; Yamasaki, T.; Matsumura, M. Erosion-corrosion tests on copper alloys for water tap use. Wear 1995, 186–187, 548–554. [Google Scholar] [CrossRef]

- ASTM E92–04. In ASTM Hardness Standards Reference Guide; ASTM International: West Conshohocken, PA, USA, 2011.

- Al-Bukhaiti, M.A.; Ahmed, S.M.; Badran, F.M.F.; Emara, K.M. Effect of impingement angle on slurry erosion behaviour and mechanisms of 1017 steel and high-chromium white cast iron. Wear 2007, 262, 1187–1198. [Google Scholar] [CrossRef]

- McIClark, H. A comparison of particle impact in gas-solid and liquid-solid erosion. Wear 1995, 186–187, 465–472. [Google Scholar]

- Das, S.; Saraswathi, Y.L.; Mondal, D.P. Erosive-corrosive wear of aluminum alloy composites: Influence of slurry composition and speed. Wear 2006, 261, 180–190. [Google Scholar] [CrossRef]

- Shitole, P.P.; Gawande, S.H.; Desale, G.R.; Nandre, B.D. Effect of Impacting Particle Kinetic Energy on Slurry Erosion. Wear 2015, 1, 29. [Google Scholar] [CrossRef]

- Rajahram, S.S.; Harvey, T.J.; Wood, R.J.K. Evaluation of a semi-empirical model in predicting erosion–corrosion. Wear 2009, 267, 244–254. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, F.; Ma, A.; Song, D.; Chen, J.; Liu, H.; Qiang, M. Biodegradable Behaviors of Ultrafine-Grained ZE41A Magnesium Alloy in DMEM Solution. Metals 2016, 6, 3. [Google Scholar] [CrossRef]

- Divakar, M.; Agarwal, V.K.; Singh, S.N. Effect of the material surface hardness on the erosion of AISI316. Wear 2005, 259, 110–117. [Google Scholar] [CrossRef]

- Dular, M.; Osterman, A. Pit clustering in cavitation erosion. Wear 2008, 265, 811–820. [Google Scholar] [CrossRef]

- Sansui, K.O.; Oliver, G.J. Effects of grain size on mechanical properties of nanostructured copper alloy by severe plastic deformation (SPD) process. J. Eng. Des. Technol. 2009, 7, 335–341. [Google Scholar] [CrossRef]

| Channel Diameter, mm | Lubricant | Temperature °C | Channel Angle | Outer Corner Angle | Ram Speed, mm/s | Route |

|---|---|---|---|---|---|---|

| 20 | MoS2 | 28 ± 3 | 90° | 17° | 2 | BC |

| Experimental Time, h | Linear Velocity, m/s | Impacting Angle, Degree | Solid Particles Concentration, wt.% | |

|---|---|---|---|---|

| Time Effect | 12 | 3.8 | 45 | 20 |

| 24 | ||||

| 48 | ||||

| Velocity Effect | 48 | 1.4 | 45 | 20 |

| 2.7 | ||||

| 3.8 | ||||

| 5.4 | ||||

| Impacting Angle Effect | 48 | 3.8 | 30 | 20 |

| 45 | ||||

| 60 | ||||

| 90 | ||||

| Solid Particles Effect | 48 | 3.8 | 45 | 0 |

| 10 | ||||

| 20 | ||||

| 30 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, O.M.; Al-Mufadi, F.; Al-Shataif, Y.; Djavanroodi, F. Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper. Appl. Sci. 2017, 7, 1250. https://doi.org/10.3390/app7121250

Irfan OM, Al-Mufadi F, Al-Shataif Y, Djavanroodi F. Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper. Applied Sciences. 2017; 7(12):1250. https://doi.org/10.3390/app7121250

Chicago/Turabian StyleIrfan, Osama M., Fahad Al-Mufadi, Yaser Al-Shataif, and Faramarz Djavanroodi. 2017. "Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper" Applied Sciences 7, no. 12: 1250. https://doi.org/10.3390/app7121250

APA StyleIrfan, O. M., Al-Mufadi, F., Al-Shataif, Y., & Djavanroodi, F. (2017). Effect of Equal Channel Angular Pressing (ECAP) on Erosion-Corrosion of Pure Copper. Applied Sciences, 7(12), 1250. https://doi.org/10.3390/app7121250