On the Visualization of Gas Metal Arc Welding Plasma and the Relationship Between Arc Length and Voltage

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

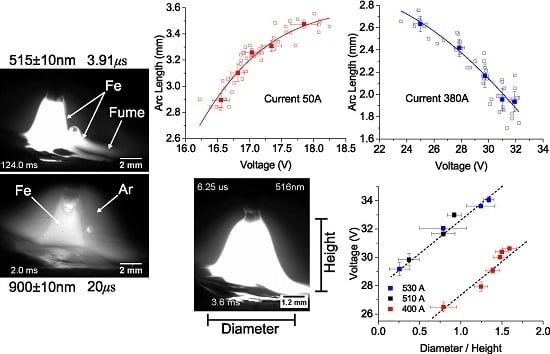

3.1. High-Speed Imaging

3.2. Arc Voltage and Arc Length

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Egerland, S. A Contribution to Arc Length Discussion. Soldagem Inspeção 2015, 20, 367–380. [Google Scholar] [CrossRef]

- BSI. British Standard BS 499-1:2009: Welding Terms and Symbols Part 1: Glossary for Welding, Brazing and Thermal Cutting; British Standards Institution: London, UK, 2009. [Google Scholar]

- American Welding Society (AWS). AWS Standard A3.0M/A3.0:2010: Welding Terms and Definitions: Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying; American Welding Society: Miami, FL, USA, 2010; p. 162. [Google Scholar]

- Lincoln Electric. Surface Tension Transfer (STT); Lincoln Electric: Cleveland, OH, USA, 2005; p. 4. [Google Scholar]

- Fronius. CMT: Cold Metal Transfer; Fronius: Wels, Austria, 2013; p. 8. [Google Scholar]

- Scotti, A. Mapping Transfer Modes for Stainless Steel Gas Metal Arc Welding. Sci. Technol. Weld. Join. 2000, 5, 227–234. [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V.; Lucas, W. A scientific application oriented classification for metal transfer modes in GMA welding. J. Mater. Process. Technol. 2012, 212, 1406–1413. [Google Scholar] [CrossRef]

- Hertel, M.; Spille-Kohoff, A.; Füssel, U.; Schnick, M. Numerical simulation of droplet detachment in pulsed gas–metal arc welding including the influence of metal vapour. J. Phys. D Appl. Phys. 2013, 46, 224003. [Google Scholar] [CrossRef]

- Hertel, M.; Rose, S.; Füssel, U. Numerical simulation of arc and droplet transfer in pulsed GMAW of mild steel in argon. Weld. World 2016, 60, 1055–1061. [Google Scholar] [CrossRef]

- Schnick, M.; Füssel, U.; Hertel, M.; Spille-Kohoff, A.; Murphy, A.B. Metal vapour causes a central minimum in arc temperature in gas–metal arc welding through increased radiative emission. J. Phys. D Appl. Phys. 2009, 43, 022001. [Google Scholar] [CrossRef]

- Murphy, A.B. The effects of metal vapour in arc welding. J. Phys. D Appl. Phys. 2010, 43, 165204. [Google Scholar] [CrossRef]

- Schnick, M.; Fuessel, U.; Hertel, M.; Spille-Kohoff, A.; Murphy, A.B. Numerical investigations of arc behaviour in gas metal arc welding using ANSYS CFX. Front. Mater. Sci. 2011, 5, 98–108. [Google Scholar] [CrossRef]

- Boselli, M.; Colombo, V.; Ghedini, E.; Gherardi, M.; Sanibondi, P. Dynamic analysis of droplet transfer in gas–metal arc welding: modelling and experiments. Plasma Sources Sci. Technol. 2012, 21, 055015. [Google Scholar] [CrossRef]

- Ogino, Y.; Hirata, Y.; Murphy, A.B. Numerical simulation of GMAW process using Ar and an Ar–CO2 gas mixture. Weld. World 2016, 60, 345–353. [Google Scholar] [CrossRef]

- Kim, Y.S.; Mceligot, D.M.; Eagar, T.W. Analyses of Electrode Heat Transfer in Gas Metal Arc Welding. Weld. J. 1991, 1, 20–31. [Google Scholar]

- Kim, Y.S.; Eagar, T.W. Analysis of metal transfer in gas metal arc welding. Weld. J. 1993, 72, 269s–278s. [Google Scholar]

- Jones, L.A.; Eagar, T.W.; Lang, J.H. Images of a Steel Electrode in Ar-2% O2 Shielding during Constant Current Gas Metal Arc Welding. Weld. J. 1998, 77, 135S–141S. [Google Scholar]

- Goecke, S.F. Auswirkungen von Aktivgaszumischungen im vpm-Bereich zu Argon auf das MIG- Impulsschweißen von Aluminium. Ph.D. Thesis, Technischen Universität Berlin, Berlin, Germany, 2005. [Google Scholar]

- Zielinska, S.; Musioł, K.; Dzierżȩga, K.; Pellerin, S.; Valensi, F.; de Izarra, C.; Briand, F. Investigations of GMAW plasma by optical emission spectroscopy. Plasma Sources Sci. Technol. 2007, 16, 832–838. [Google Scholar] [CrossRef]

- Zielinska, S.; Pellerin, S.; Valensi, F.; Dzierzega, K.; Musiol, K.; de Izarra, C.; Briand, F. Gas influence on the arc shape in MIG-MAG welding. Eur. Phys. J. Appl. Phys. 2008, 43, 111–122. [Google Scholar] [CrossRef]

- Gött, G.; Schöpp, H.; Hofmann, F.; Heinz, G. Improvement of the control of a gas metal arc welding process. Meas. Sci. Technol. 2010, 21, 25201. [Google Scholar] [CrossRef]

- Schnick, M.; Füssel, U.; Hertel, M.; Rose, S.; Haessler, M.; Spille-Kohoff, A.; Murphy, A.B. Numerical Investigations of the Influence of Metal Vapour in GMA Welding. Weld. World 2011, 55, 114–120. [Google Scholar] [CrossRef]

- Rouffet, M.E.; Wendt, M.; Goett, G.; Kozakov, R.; Schoepp, H.; Weltmann, K.D.; Uhrlandt, D. Spectroscopic investigation of the high-current phase of a pulsed GMAW process. J. Phys. D Appl. Phys. 2010, 43, 434003. [Google Scholar] [CrossRef]

- Schnick, M.; Hertel, M.; Fuessel, U.; Uhrlandt, D. Energy balance in MIG arcs. J. Phys. D Appl. Phys. 2013, 46, 224002. [Google Scholar] [CrossRef]

- Nomura, K.; Kataoka, K.; Mimura, K.; Hirata, Y.; Kishi, T. Tomographic spectroscopic observation of argon and metal vapor behavior in MIG arc welding. Weld. World 2016, 60, 117–125. [Google Scholar] [CrossRef]

- Kadoi, K.; Fujinaga, A.; Yamamoto, M.; Shinozaki, K. The effect of welding conditions on solidification cracking susceptibility of type 310S stainless steel during laser welding using an in-situ observation technique. Weld. World 2013, 57, 383–390. [Google Scholar] [CrossRef]

- Dos Santos, E.B.F.; Pistor, R.; Gerlich, A.P. Pulse profile and metal transfer in pulsed gas metal arc welding: Droplet formation, detachment and velocity. Sci. Technol. Weld. Join. 2017, 1–15. [Google Scholar] [CrossRef]

- Nave, G.; Johansson, S.; Learner, R.C.M.; Thorne, A.P.; Brault, J.W. A new multiplet table for Fe I. Astrophys. J. Suppl. Ser. 1994, 94, 221–459. [Google Scholar] [CrossRef]

- Yamashita, S.; Fujinaga, A.; Yamamoto, M.; Shinozaki, K.; Kadoi, K.; Mitsui, K.; Usui, H. In-situ Temperature Measurement using Monochrome High-speed Sensors during Laser Welding. Q. J. Jpn. Weld. Soc. 2013, 31, 78s–81s. [Google Scholar] [CrossRef]

- Kramida, A.; Ralchenko, Y.; Reader, J.; Team, N.A. NIST Atomic Spectra Database (ver. 5.3); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. Available online: http://physics.nist.gov/asd (accessed on 10 February 2017).

- Park, H.; Mudra, M.; Trautmann, M.; Murphy, A.B. A Coupled Chemical Kinetic and Nucleation Model of Fume Formation in Metal–Inert-Gas/Metal–Active-Gas Welding. Plasma Chem. Plasma Process. 2017, 37, 805–823. [Google Scholar] [CrossRef]

- Lancaster, J.F. The Physics of Welding, 2nd ed.; Pregamon Press: Oxford, UK, 1986; p. 360. [Google Scholar]

- Lancaster, J. The physics of fusion welding. Part 1: The electric arc in welding. IEE Proc. B Electr. Power Appl. 1987, 134, 233–254. [Google Scholar] [CrossRef]

- McIntosh, C.; Mendez, P.F. Experimental measurements of fall voltages in gas metal arc welding. Weld. J. 2017, 96, 121s–132s. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dos Santos, E.B.F.; Kuroiwa, L.H.; Ferreira, A.F.C.; Pistor, R.; Gerlich, A.P. On the Visualization of Gas Metal Arc Welding Plasma and the Relationship Between Arc Length and Voltage. Appl. Sci. 2017, 7, 503. https://doi.org/10.3390/app7050503

Dos Santos EBF, Kuroiwa LH, Ferreira AFC, Pistor R, Gerlich AP. On the Visualization of Gas Metal Arc Welding Plasma and the Relationship Between Arc Length and Voltage. Applied Sciences. 2017; 7(5):503. https://doi.org/10.3390/app7050503

Chicago/Turabian StyleDos Santos, Emanuel B. F., Letícia H. Kuroiwa, A. Felipe C. Ferreira, Rob Pistor, and Adrian P. Gerlich. 2017. "On the Visualization of Gas Metal Arc Welding Plasma and the Relationship Between Arc Length and Voltage" Applied Sciences 7, no. 5: 503. https://doi.org/10.3390/app7050503

APA StyleDos Santos, E. B. F., Kuroiwa, L. H., Ferreira, A. F. C., Pistor, R., & Gerlich, A. P. (2017). On the Visualization of Gas Metal Arc Welding Plasma and the Relationship Between Arc Length and Voltage. Applied Sciences, 7(5), 503. https://doi.org/10.3390/app7050503