A Method to Decompose the Streamed Acoustic Emission Signals for Detecting Embedded Fatigue Crack Signals

Abstract

:1. Introduction

2. Description of Experiments

2.1. Description of Gearbox Testing (NAVAIR Gearbox Test)

2.2. Laboratory Scale Fatigue Testing (UIC Fatigue Test)

2.3. Similarity and Differences of The NAVAIR Test Rig and The Laboratory Testing

3. Experimental Results

Waveform Characteristics

4. The Integration of the Streamed and Crack Growth Signals

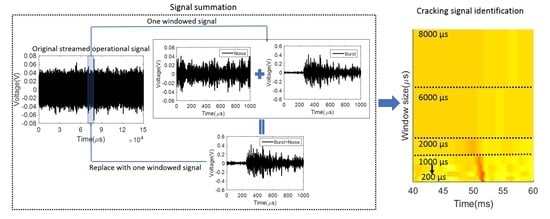

4.1. Signal Decomposition

4.2. Detectable Fatigue Crack Energy with Respect to Background Noise

4.3. The Application of Signal Decomposition to the NAVAIR Test Rig

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Eftekharnejad, B.; Addali, A.; Mba, D. Shaft crack diagnostics in a gearbox. Appl. Acoust. 2012, 73, 723–733. [Google Scholar] [CrossRef]

- Yesilyurt, I.; Gu, F.; Ball, A.D. Gear tooth stiffness reduction measurement using modal analysis and its use in wear fault severity assessment of spur gears. NDT E Int. 2003, 36, 357–372. [Google Scholar] [CrossRef]

- Eftekharnejad, B.; Mba, D. Monitoring natural pitting progress on helical gear mesh using acoustic emission and vibration. Strain 2011, 47, 299–310. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. A high sensitivity wear debris sensor using ferrite cores for online oil condition monitoring. Meas. Sci. Technol. 2017, 28, 75102. [Google Scholar] [CrossRef]

- Dempsey, P.J. Integrating Oil Debris and a High Sensitivity Wear Debris Sensor Using Ferrite Cores for Online Oil Condition Monitoring Vibration Measurements for Intelligent Machine Health Monitoring. Ph.D. Thesis, Toledo University, Toledo, OH, USA, 2003. [Google Scholar]

- Li, R.; He, D. Rotational machine health monitoring and fault detection using EMD-based acoustic emission feature quantification. IEEE Trans. Instrum. Meas. 2012, 61, 990–1001. [Google Scholar] [CrossRef]

- Ozevin, D.; Dong, J.; Godinez, V.; Carlos, M. Damage assessment of gearbox operating in high noisy environment using waveform streaming approach. J. Acoust. Emiss. 2007, 25, 355–363. [Google Scholar]

- Loutas, T.H.; Roulias, D.; Pauly, E.; Kostopoulos, V. The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Process. 2011, 25, 1339–1352. [Google Scholar] [CrossRef]

- Li, C.J.; Lee, H.; Choi, S.H. Estimating size of gear tooth root crack using embedded modelling. Mech. Syst. Signal Process. 2002, 16, 841–852. [Google Scholar]

- Samuel, P.D.; Pines, D.J. A review of vibration-based techniques for helicopter transmission diagnostics. J. Sound Vib. 2005, 282, 475–508. [Google Scholar] [CrossRef]

- Hase, A.; Mishina, H.; Wada, M. Correlation between features of acoustic emission signals and mechanical wear mechanisms. Wear 2012, 292, 144–150. [Google Scholar] [CrossRef]

- Li, R.; Seçkiner, S.U.; He, D.; Bechhoefer, E.; Menon, P. Gear fault location detection for split torque gearbox using AE sensors. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2012, 42, 1308–1317. [Google Scholar] [CrossRef]

- Gu, D.; kim, J.; An, Y.; Choi, B. Detection of faults in gearboxes using acoustic emission signal. J. Mech. Sci. Technol. 2011, 25, 1279–1286. [Google Scholar] [CrossRef]

- Wang, W. An enhanced diagnostic system for gear system monitoring. IEEE Trans. Syst. Man Cybern. Part B 2008, 38, 102–112. [Google Scholar] [CrossRef]

- Zhang, L.; Yalcinkaya, H.; Ozevin, D. Numerical Approach to Absolute Calibration of Piezoelectric Acoustic Emission Sensors using Multiphysics Simulations. Sens. Actuators A Phys. 2017, 256, 12–23. [Google Scholar] [CrossRef]

- Zhang, L.; Ozevin, D.; Hardman, W.; Timmons, A. Acoustic emission signatures of fatigue damage in idealized bevel gear spline for localized sensing. Metals 2017, 7, 242. [Google Scholar] [CrossRef]

- Oppenheim, A.V. Discrete-Time Signal Processing; Pearson Education India: Chennai, India, 1999; ISBN 8131704920. [Google Scholar]

| Test Type | Loading Condition | Sample Geometry | Sample Material | AE Sensor | Sensor Couplant | AE Sensor Position | Crack Direction |

|---|---|---|---|---|---|---|---|

| NAVAIR gearbox test | Hub moment | Cylinder spline gear | Structural steel | WD sensor | Vacuum grease | On the gearbox housing | Perpendicular to spline |

| UIC fatigue test | Tensile | Planar sample with splines | Structural steel | WD sensor | Super glue | On the planar sample | Perpendicular to spline |

| Signal Source | AE Signal Power (V*s2) | AE Peak Frequency (kHz) | AE Frequency Centroid (kHz) |

|---|---|---|---|

| Entire streamed signal | 0.000173 | 273 | 295 |

| Windowed streamed signal | 0.000174 | 277 | 300 |

| Crack growth | 0.0731 | 152 | 230 |

| Pencil lead break (PLB) source | 0.4335 | 228 | 255 |

| Noise of fatigue test | 0.0013 | 234 | 268 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Ozevin, D.; He, D.; Hardman, W.; Timmons, A. A Method to Decompose the Streamed Acoustic Emission Signals for Detecting Embedded Fatigue Crack Signals. Appl. Sci. 2018, 8, 7. https://doi.org/10.3390/app8010007

Zhang L, Ozevin D, He D, Hardman W, Timmons A. A Method to Decompose the Streamed Acoustic Emission Signals for Detecting Embedded Fatigue Crack Signals. Applied Sciences. 2018; 8(1):7. https://doi.org/10.3390/app8010007

Chicago/Turabian StyleZhang, Lu, Didem Ozevin, David He, William Hardman, and Alan Timmons. 2018. "A Method to Decompose the Streamed Acoustic Emission Signals for Detecting Embedded Fatigue Crack Signals" Applied Sciences 8, no. 1: 7. https://doi.org/10.3390/app8010007

APA StyleZhang, L., Ozevin, D., He, D., Hardman, W., & Timmons, A. (2018). A Method to Decompose the Streamed Acoustic Emission Signals for Detecting Embedded Fatigue Crack Signals. Applied Sciences, 8(1), 7. https://doi.org/10.3390/app8010007