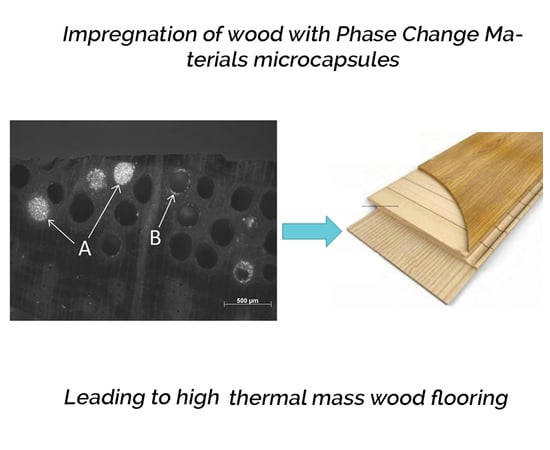

Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Phase Change Materials

2.1.2. EWF Surface Layer

2.2. Methodology

2.2.1. Wood and MPCM Morphology

2.2.2. Wood Impregnation

2.2.3. Heat Storage

2.2.4. Pull-Off Adhesion Tests

3. Results

3.1. Morphology of the Components

3.1.1. Wood Morphology

3.1.2. PCM Microcapsules

3.2. Impregnation of Small Samples

3.3. Impregnation of Wood Boards

3.3.1. Morphology

3.3.2. Heat Storage

3.3.3. Adhesion of a UV-Curable Coating Formulation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schultz, T.P.; Nicholas, D.D.; Preston, A.F. Perspective—A brief review of the past, present and future of wood preservation. Pest Manag. Sci. 2007, 63, 784–788. [Google Scholar] [CrossRef] [PubMed]

- Sweet, M.S. Fire Performance of Wood: Test Methods and Fire Retardant Treatments; Forest Products Laboratory: Madison, WI, USA, 1993.

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224. [Google Scholar] [CrossRef]

- Forest Products Society. Wood Handbook Wood as an Engineering Material; Forest Products Society: Madison, WI, USA, 2010. [Google Scholar]

- Shapiro, M.; Feldman, D.; Hawes, D.; Banu, D.J.P.S.J. Thermal storage in drywall using organic phase-change material. Passive Sol. J. 1987, 4, 419–438. [Google Scholar]

- Sharma, R.; Ganesan, P.; Tyagi, V.; Metselaar, H.; Sandaran, S.C. Developments in organic solid–liquid phase change materials and their applications in thermal energy storage. Energy Convers. Manag. 2015, 95, 193–228. [Google Scholar] [CrossRef]

- Kośny, J.; Yarbrough, D.W.; Riazzi, T.; Leuthold, D.; Smith, J.B.; Bianchi, M. Development and testing of ignition resistant microencapsulated phase change material. Proc. Effstock 2009. [Google Scholar]

- Kośny, J. PCM-Enhanced Building Components: An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer: Berlin, Germany, 2015. [Google Scholar]

- Noel, J.; Allred, P.; White, M. Life cycle assessment of two biologically produced phase change materials and their related products. Int. J. Life Cycle Assess. 2015, 20, 367–376. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Zhang, Z.; Zuo, J.; Huang, K.; Zhang, L. Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renew. Sustain. Energy Rev. 2015, 48, 692–703. [Google Scholar] [CrossRef]

- Zalba, B.; Marin, J.; Cabeza, L.; Mehling, H. Free-cooling of buildings with phase change materials. Int. J. Refrig.-Rev. Int. Froid 2004, 27, 839–849. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, R.; Wu, Y.; Zhao, C. Parametric analysis of using PCM walls for heating loads reduction. Energy Build. 2018, 172, 328–336. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Arcuri, N. Definition of a new set of parameters for the dynamic thermal characterization of PCM layers in the presence of one or more liquid-solid interfaces. Energy Build. 2017, 141, 379–396. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, L.; de Gracia, A.; Fernandez, A.I.; Cabeza, L.F. In situ thermal and acoustic performance and environmental impact of the introduction of a shape-stabilized PCM layer for building applications. Renew. Energy 2016, 85, 281–286. [Google Scholar] [CrossRef] [Green Version]

- Athienitis, A.; Liu, C.; Hawes, D.; Banu, D.; Feldman, D. Investigation of the thermal performance of a passive solar test-room with wall latent heat storage. Build. Environ. 1997, 32, 405–410. [Google Scholar] [CrossRef]

- Li, M.; Guo, Q.G.; Nutt, S. Carbon nanotube/paraffin/montmorillonite composite phase change material for thermal energy storage. Sol. Energy 2017, 146, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, J.-S.; Kwon, A.; Cho, C.-G. Microencapsulation of octadecane as a phase-change material by interfacial polymerization in an emulsion system. Colloid Polym. Sci. 2002, 280, 260–266. [Google Scholar] [CrossRef]

- Hawlader, M.; Uddin, M.; Khin, M.M. Microencapsulated PCM thermal-energy storage system. Appl. Energy 2003, 74, 195–202. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Martinez, M.; Cabeza, L.F.; Fernandez, A.I. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef]

- Alkan, C.; Sari, A.; Karaipekli, A.; Uzun, O. Preparation, characterization, and thermal properties of microencapsulated phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2009, 93, 143–147. [Google Scholar] [CrossRef]

- Jeong, S.; Jeon, J.; Seo, J.; Lee, J.; Kim, S. Performance evaluation of the microencapsulated PCM for wood-based flooring application. Energy Convers. Manag. 2012, 64, 516–521. [Google Scholar] [CrossRef]

- Guo, X.; Cao, J.; Peng, Y.; Liu, R. Incorporation of microencapsulated dodecanol into wood flour/high-density polyethylene composite as a phase change material for thermal energy storage. Mater. Des. 2016, 89, 1325–1334. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Thermal characterization of bio-based phase changing materials in decorative wood-based panels for thermal energy storage. Green Energy Environ. 2018, in press. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Liu, D.; Cheng, X.; He, X.; Wu, Y.; Li, X.; Huang, Q. Fabrication and Properties of Polyethylene Glycol-Modified Wood Composite for Energy Storage and Conversion. BioResources 2016, 11, 7790–7802. [Google Scholar] [CrossRef]

- Barreneche, C.; Vecstaudza, J.; Bajare, D.; Fernandez, A. PCM/wood composite to store thermal energy in passive building envelopes. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012111. [Google Scholar] [CrossRef] [Green Version]

- Vasco, D.A.; Salinas-Lira, C.; Barra-Reyes, I.; Elustondo, D.M. Kinematic characterization of the pressure-dependent PCM impregnation process for radiata pine wood samples. Eur. J. Wood Wood Prod. 2018, 76, 1461–1469. [Google Scholar] [CrossRef]

- Blanchet, P. Caractérisation du comportement des lames de plancher d’ingénierie. Résumé 2004, 2, 2–3. [Google Scholar]

- Panshin, A.J.; Zeeuw, C.D. Textbook of Wood Technology. Volume I. Structure, Identification, Uses, and Properties of the Commercial Woods of the United States and Canada; McGraw-Hill Book Company Inc.: New York, NY, USA, 1970. [Google Scholar]

- Navi, P.; Heger, F. Comportement Thermo-Hydromécanique du bois: Applications Technologiques et dans les Structures; PPUR Presses Polytechniques: Lausanne, Switzerland, 2005. [Google Scholar]

- Jiang, X.; Hou, Q.; Liu, W.; Zhang, H.; Cui, Y.; Wang, X.J.H. Improved permeability of autohydrolyzed poplar sapwood against sodium hydroxide for CMP production. Holzforschung 2018, 72, 347–355. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring. Appl. Sci. 2018, 8, 2696. https://doi.org/10.3390/app8122696

Mathis D, Blanchet P, Landry V, Lagière P. Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring. Applied Sciences. 2018; 8(12):2696. https://doi.org/10.3390/app8122696

Chicago/Turabian StyleMathis, Damien, Pierre Blanchet, Véronic Landry, and Philippe Lagière. 2018. "Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring" Applied Sciences 8, no. 12: 2696. https://doi.org/10.3390/app8122696

APA StyleMathis, D., Blanchet, P., Landry, V., & Lagière, P. (2018). Impregnation of Wood with Microencapsulated Bio-Based Phase Change Materials for High Thermal Mass Engineered Wood Flooring. Applied Sciences, 8(12), 2696. https://doi.org/10.3390/app8122696