Synthesis of Aligned TiO2 Nanofibers Using Electrospinning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Viscous Solution of PVP and (Ti(Oipr)4)

2.2. ES Procedure

2.3. Characterizations

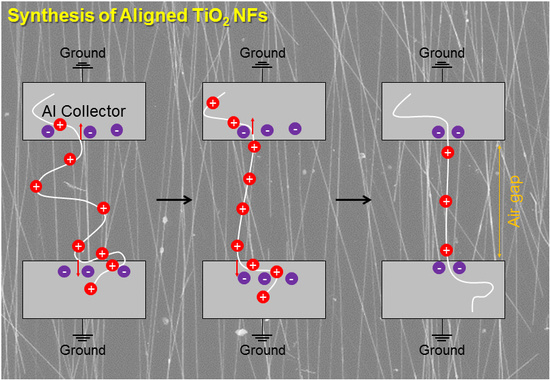

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kumar, S.G.; Devi, L.G. Review on Modified TiO2 Photocatalysis under UV/Visible Light: Selected Results and Related Mechanisms on Interfacial Charge Carrier Transfer Dynamics. J. Phys. Chem. A 2011, 115, 13211–13241. [Google Scholar] [CrossRef] [PubMed]

- Watthanaarun, J.; Pavarajarn, V.; Supaphol, P. Titanium (IV) Oxide Nanofibers by Combined Sol–Gel and Electrospinning Techniques: Preliminary Report on Effects of Preparation Conditions and Secondary Metal Dopant. Sci. Technol. Adv. Mater. 2005, 6, 240–245. [Google Scholar] [CrossRef]

- Park, J.Y.; Choi, S.-W.; Lee, J.-W.; Lee, C.; Kim, S.S. Synthesis and Gas Sensing Properties of TiO2–ZnO Core-Shell Nanofibers. J. Am. Ceram. Soc. 2009, 92, 2551–2554. [Google Scholar] [CrossRef]

- Drew, K.; Girishkumar, G.; Vinodgopal, K.; Kamat, P.V. Boosting Fuel Cell Performance with a Semiconductor Photocatalyst: TiO2/Pt−Ru Hybrid Catalyst for Methanol Oxidation. J. Phys. Chem. B 2005, 109, 11851–11857. [Google Scholar] [CrossRef] [PubMed]

- Ni, M.; Leung, M.K.H.; Leung, D.Y.C.; Sumathy, K. A Review and Recent Developments in Photocatalytic Water-Splitting Using TiO2 for Hydrogen Production. Renew. Sustain. Energ. Rev. 2007, 11, 401–425. [Google Scholar] [CrossRef]

- Daghrir, R.; Drogui, P.; Robert, D. Modified TiO2 for Environmental Photocatalytic Applications: A Review. Ind. Eng. Chem. Res. 2013, 52, 3581–3599. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Walker, J.; Samuelson, L.A.; Kumar, J. Efficient Light Harvesting Polymers for Nanocrystalline TiO2 Photovoltaic Cells. Nano Lett. 2003, 3, 523–525. [Google Scholar] [CrossRef]

- Koo, H.J.; Kim, Y.J.; Lee, Y.H.; Lee, W.I.; Kim, K.; Park, N.G. Nano-Embossed Hollow Spherical TiO2 as Bifunctional Material for High-Efficiency Dye-Sensitized Solar Cells. Adv. Mater. 2008, 20, 195–199. [Google Scholar] [CrossRef]

- Lu, Y.; Yu, H.; Chen, S.; Quan, X.; Zhao, H. Integrating Plasmonic Nanoparticles with TiO2 Photonic Crystal for Enhancement of Visible-Light-Driven Photocatalysis. Environ. Sci. Technol. 2012, 46, 1724–1730. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Aydil, E.S. Growth of Oriented Single-Crystalline Rutile TiO2 Nanorods on Transparent Conducting Substrates for Dye-Sensitized Solar Cells. J. Am. Chem. Soc. 2009, 131, 3985–3990. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, A.R.; Armstrong, G.; Canales, J.; García, R.; Bruce, P.G. Lithium-Ion Intercalation into TiO2-B Nanowires. Adv. Mater. 2005, 17, 862–865. [Google Scholar] [CrossRef]

- Zhu, K.; Neale, N.R.; Miedaner, A.; Frank, A.J. Enhanced Charge-Collection Efficiencies and Light Scattering in Dye-Sensitized Solar Cells Using Oriented TiO2 Nanotubes Arrays. Nano Lett. 2007, 7, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.-D.; Rothschild, A.; Lee, B.H.; Kim, D.Y.; Jo, S.M.; Tuller, H.L. Ultrasensitive Chemiresistors Based on Electrospun TiO2 Nanofibers. Nano Lett. 2006, 6, 2009–2013. [Google Scholar] [CrossRef] [PubMed]

- Formo, E.; Lee, E.; Campbell, D.; Xia, Y. Functionalization of Electrospun TiO2 Nanofibers with Pt Nanoparticles and Nanowires for Catalytic Applications. Nano Lett. 2008, 8, 668–672. [Google Scholar] [CrossRef] [PubMed]

- Park, J.Y.; Kim, S.S. Effects of Processing Parameters on the Synthesis of TiO2 Nanofibers by Electrospinning. Met. Mater. Int. 2009, 15, 95–99. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Xia, Y. Electrospinning of Polymeric and Ceramic Nanofibers as Uniaxially Aligned Arrays. Nano Lett. 2003, 3, 1167–1171. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of Nanofibers: Reinventing the Wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Jalili, R.; Morshed, M.; Ravandi, S.A.H. Fundamental Parameters Affecting Electrospinning of PAN Nanofibers as Uniaxially Aligned Fibers. J. Appl. Polym. Sci. 2006, 101, 4350–4357. [Google Scholar] [CrossRef]

- Choi, S.-H.; Ankonina, G.; Youn, D.Y.; Oh, S.G.; Hong, J.M.; Rothschild, A.; Kim, I.D. Hollow ZnO Nanofibers Fabricated Using Electrospun Polymer Templates and Their Electronic Transport Properties. ACS Nano 2009, 3, 2623–2631. [Google Scholar] [CrossRef] [PubMed]

- Kovtyukhova, N.I.; Mallouk, T.E. Nanowires as Building Blocks for Self-Assembling Logic and Memory Circuits. Chem. Eur. J. 2002, 8, 4354–4363. [Google Scholar] [CrossRef]

- Teo, K.; Chhowalla, M.; Amaratunga, G.; Milne, W.; Pirio, G.; Legagneux, P.; Wyczisk, F.; Pribat, D.; Hasko, D. Field Emission from Dense, Sparse, and Patterned Arrays of Carbon Nanofibers. Appl. Phys. Lett. 2002, 80, 2011–2013. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, L.; Howe, J.Y.; Liao, Y.; Speidel, J.T.; Smith, S.; Fong, H. Aligned Electrospun ZnO Nanofibers for Simple and Sensitive Ultraviolet Nanosensors. Chem. Commun. 2009, 0, 2568–2570. [Google Scholar] [CrossRef] [PubMed]

- Yin, K.; Zhang, L.; Lai, C.; Zhong, L.; Smith, S.; Fong, H.; Zhu, Z. Photoluminescence Anisotropy of Uni-Axially Aligned Electrospun Conjugated Polymer Nanofibers of MEH-PPV and P3HT. J. Mater. Chem. 2011, 21, 444–448. [Google Scholar] [CrossRef]

- Lin, V.S.; Lee, M.C.; O’Neal, S.; McKean, J.; Sung, K.P. Ligament Tissue Engineering Using Synthetic Biodegradable Fiber Scaffolds. Tissue Eng. 1999, 5, 443–451. [Google Scholar] [CrossRef] [PubMed]

- Bazbouz, M.B.; Stylios, G.K. Alignment and Optimization of Nylon 6 Nanofibers by Electrospinning. J. Appl. Polym. Sci. 2008, 107, 3023–3032. [Google Scholar] [CrossRef]

- Theron, A.; Zussman, E.; Yarin, A.L. Electrostatic Field-Assisted Alignment of Electrospun Nanofibres. Nanotechnology 2001, 12, 384. [Google Scholar] [CrossRef]

- Zhang, X.; Ge, X.; Wang, C. Synthesis of Titania in Ethanol/Acetic Acid Mixture Solvents: Phase and Morphology Variations. Cryst. Growth Des. 2009, 9, 4301–4307. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, W.; Zhang, Y.; Zhu, L.; Liu, Y.; Fan, X.; Cao, X. Preparation of TiO2 Hollow Nanofibers by Electrospining Combined with Sol-Gel Process. Cryst. Eng. Commun. 2010, 12, 2256–2260. [Google Scholar] [CrossRef]

- Arbiol, J.; Cerdà, J.; Dezanneau, G.; Cirera, A.; Peiró, F.; Cornet, A.; Morante, J.R. Effects of Nb Doping on the TiO2 Anatase-to-Rutile Phase Transition. J. Appl. Phys. 2002, 92, 853–861. [Google Scholar] [CrossRef] [Green Version]

- Vittadini, A.; Casarin, M.; Selloni, A. Chemistry of and on TiO2-Anatase Surfaces by DFT Calculations: A Partial Review. Theor. Chem. Acc. 2007, 117, 663–671. [Google Scholar] [CrossRef]

- Fujihara, K.; Kumar, A.; Jose, R.; Ramakrishna, S.; Uchida, S. Spray Deposition of Electrospun TiO2 Nanorods for Dye-Sensitized Solar Cell. Nanotechnology 2007, 18, 365709. [Google Scholar] [CrossRef]

- Park, J.Y.; Choi, S.W.; Asokan, K.; Kim, S.S. Growth of Nanograins in TiO2 Nanofibers Synthesized by Electrospinning. J. Nanosci. Nanotechnol. 2010, 10, 3604–3608. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Cobley, C.M.; Zeng, J.; Sun, Y.; Xia, Y. Synthesis of Anatase TiO2 Nanocrystals with Exposed {001} Facets. Nano Lett. 2009, 9, 2455–2459. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Coronado, D.; Rodríguez-Gattorno, G.; Espinosa-Pesqueira, M.E.; Cab, C.; Coss, R.D.; Oskam, G. Phase-Pure TiO2 Nanoparticles: Anatase, Brookite and Rutile. Nanotechnology 2008, 19, 145605. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Choi, D.; Yang, Z.; Viswanathan, V.V.; Nie, Z.; Wang, C.; Song, Y.; Zhang, J.-G.; Liu, J. Synthesis and Li-Ion Insertion Properties of Highly Crystalline Mesoporous Rutile TiO2. Chem. Mater. 2008, 20, 3435–3442. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Zheng, W.; Wang, W.; Huang, H.; Wang, C.; MacDiarmid, A.G.; Wei, Y. Highly Sensitive and Stable Humidity Nanosensors Based on LiCl Doped TiO2 Electrospun Nanofibers. J. Am. Chem. Soc. 2008, 130, 5036–5037. [Google Scholar] [CrossRef] [PubMed]

- Katsuhiro, O.; Bin, D.; Yosuke, T.; Takayuki, N.; Michiyo, Y.; Shinichiro, S.; Shingo, O.; Masato, Y.; Seimei, S. Electrospinning Processed Nanofibrous TiO2 Membranes for Photovoltaic Applications. Nanotechnology 2006, 17, 1026. [Google Scholar]

- Park, J.Y.; Choi, S.-W.; Asokan, K.; Kim, S.S. Controlling the Size of Nanograins in TiO2 nanofibers. Met. Mater. Int. 2010, 16, 785–788. [Google Scholar] [CrossRef]

- Katoch, A.; Choi, S.-W.; Kim, S.S. Nanograins in Electrospun Oxide Nanofibers. Met. Mater. Int. 2015, 21, 213–221. [Google Scholar] [CrossRef]

- Deitzel, J.M.; Kleinmeyer, J.; Harris, D.; Beck Tan, N.C. The Effect of Processing Variables on the Morphology of Electrospun Nanofibers and Textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Jarusuwannapoom, T.; Hongrojjanawiwat, W.; Jitjaicham, S.; Wannatong, L.; Nithitanakul, M.; Pattamaprom, C.; Koombhongse, P.; Rangkupan, R.; Supaphol, P. Effect of Solvents on Electro-Spinnability of Polystyrene Solutions and Morphological Appearance of Resulting Electrospun Polystyrene Fibers. Eur. Polym. J. 2005, 41, 409–421. [Google Scholar] [CrossRef]

- Sukigara, S.; Gandhi, M.; Ayutsede, J.; Micklus, M.; Ko, F. Regeneration of Bombyx Mori Silk by Electrospinning-Part 1: Processing Parameters and Geometric Properties. Polymer 2003, 44, 5721–5727. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Fabrication of Titania Nanofibers by Electrospinning. Nano Lett. 2003, 3, 555–560. [Google Scholar] [CrossRef]

- Wannatong, L.; Sirivat, A.; Supaphol, P. Effects of Solvents on Electrospun Polymeric Fibers: Preliminary Study on Polystyrene. Polym. Int. 2004, 53, 1851–1859. [Google Scholar] [CrossRef]

- Chowdhury, M.; Stylios, G. Effect of Experimental Parameters on the Morphology of Electrospun Nylon 6 Fibres. Int. J. Basic Appl. Sci. 2010, 10, 70–78. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Lee, J.-H.; Kim, J.-Y.; Kim, S.S. Synthesis of Aligned TiO2 Nanofibers Using Electrospinning. Appl. Sci. 2018, 8, 309. https://doi.org/10.3390/app8020309

Kim J-H, Lee J-H, Kim J-Y, Kim SS. Synthesis of Aligned TiO2 Nanofibers Using Electrospinning. Applied Sciences. 2018; 8(2):309. https://doi.org/10.3390/app8020309

Chicago/Turabian StyleKim, Jae-Hun, Jae-Hyoung Lee, Jin-Young Kim, and Sang Sub Kim. 2018. "Synthesis of Aligned TiO2 Nanofibers Using Electrospinning" Applied Sciences 8, no. 2: 309. https://doi.org/10.3390/app8020309

APA StyleKim, J. -H., Lee, J. -H., Kim, J. -Y., & Kim, S. S. (2018). Synthesis of Aligned TiO2 Nanofibers Using Electrospinning. Applied Sciences, 8(2), 309. https://doi.org/10.3390/app8020309